Additive and subtractive manufacturing are two critical ways of making things, each with its particular process. Additive manufacturing, which constructs objects by adding one layer of material at a time, is frequently done with 3D printers. This is perfect for intricate shapes and unique designs. Subtractive manufacturing, on the other hand, begins with a solid block of material and takes away from it using drills, or lasers, to create the final product.

This technique is common for generating strong, accurate parts speedily, particularly at a large scale. Understanding the distinctions between the two approaches can help businesses determine what is best for them, whether that’s creating custom, one-of-a-kind pieces or churning out pieces reliably on a large scale.

This guide will explain both of those process simple and easy.

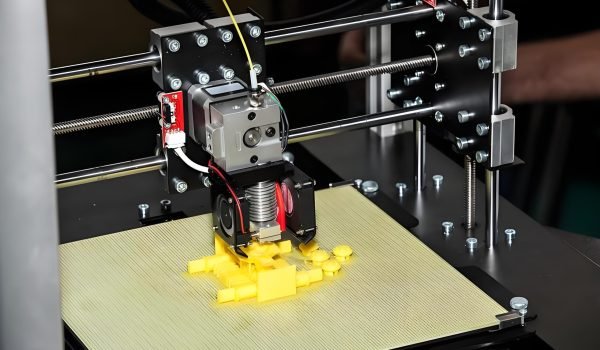

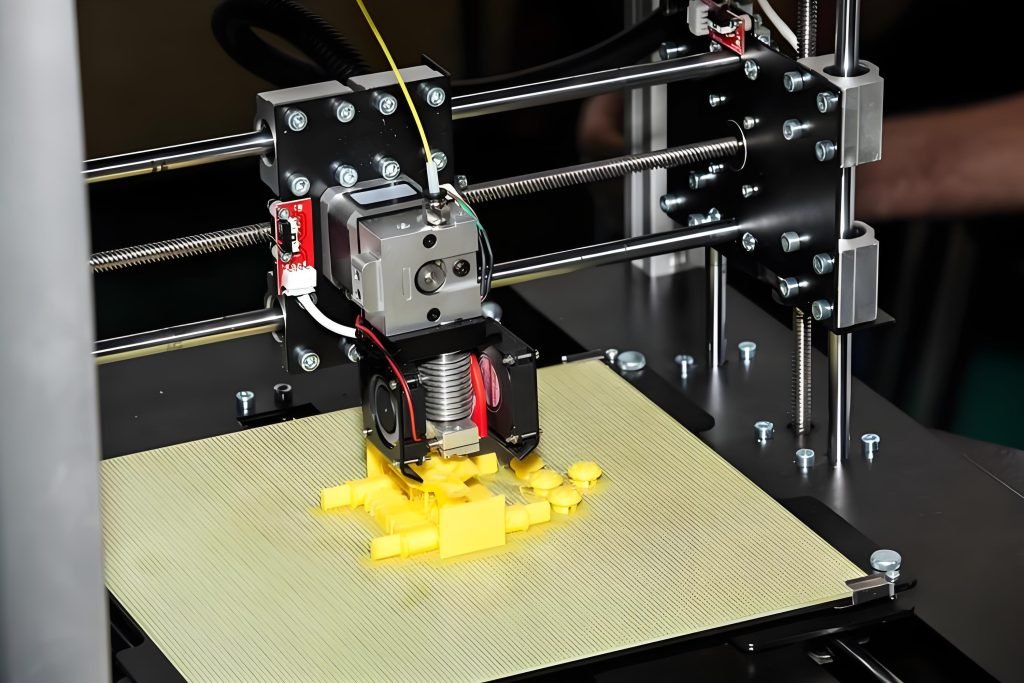

What is Additive Manufacturing?

Additive manufacturing is a great new way to make things. It manufactures things by adding minuscule layers of material, the way you pile on thin slices of dough to make a cake. You begin with a design on a computer, and you use special programs to draw the things you want. A machine, typically a 3D printer, then follows that plan to build the object in layers. It feels like you’re watching an image fill in, one flimsy bit at a time.

This type of process is beneficial for a complex part design that would be difficult to manufacture with other types of processes. For instance, you can create a toy with twisty, turning tunnels that all open up at once. It’s used in settings such as hospitals to fashion custom body parts or in airplane factories to manufacture lightweight, sturdy, and experimental methods of creating one-of-a-kind items in a hurry. It is transforming how we make everything, from devices to machines.

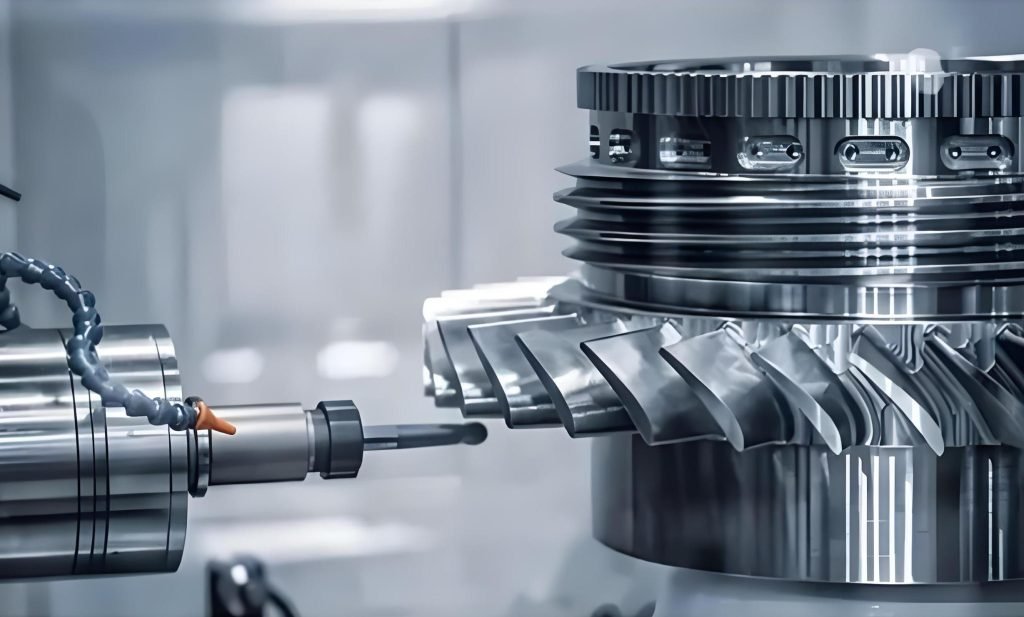

What is Subtractive Manufacturing?

Subtractive manufacturing is a well-established method for shaping an object. It’s where a chunk of material, such as wood or metal, starts as a solid block, and then parts are chipped away to transform it into the final object. Consider whittling a piece of wood to fashion a whistle – machines , such as saws, drills, or lasers, remove the unnecessary material based on a programmed plan. Computers often run those machines to ensure everything goes just right.

This technique has long been employed. It’s used in a variety of places, from car plants to construction sites. It’s great for making strong, reliable parts, like screws or engine parts. When you want to produce a large quantity of the same item quickly and efficiently, subtractive manufacturing is the way to go. It’s a reliable path to strong, sturdy items that last.

How Are They Different?

Additive and subtractive manufacturing are like opposites. Here’s how they differ:

- How They Work: Additive builds objects by adding material – think of building a structure with Legos. It’s the old Michelangelo thing – chipping away at the figure, just the opposite of shaving soap.

- Waste: The additive requires only the material the product needs, so almost no residual mess is generated. Scrap can be produced when subtractive processes are applied, such as shredder flakes, wood chips, or bits of steel block.

- Shapes They Make: Additives leave complex, wavy patterns, like a spider’s web. Subtraction processes struggle more with complex shapes because tools have trouble reaching the tricky bits.

These distinctions impact the time, money, and effort that is invested. It is best suited for special items and one-time use or test models, as the additive can become expensive. It is most efficient to use subtractive processes to produce many simple parts that are strong. Your decision will depend on what you’re making, how much you need, and your budget.

Common Ways to Do Additive Manufacturing

Additive manufacturing has a few different tricks to build things:

- Fused Deposition Modeling (FDM): This technology melts plastic and extrudes it, much like icing, to create layers. It’s inexpensive and ideal for trying out new ideas, such as creating a model of a toy car.

- Stereolithography (SLA): This process uses a laser to solidify liquid resin into complex parts. It’s ideal for small, detailed items, such as dental molds used by dentists.

- Selective Laser Sintering (SLS): This process utilizes a laser to sinter powdered materials, such as metal or plastic, into a solid form. It’s used for tough parts, such as machine components.

These methods use 3D printers that follow computer plans. Each one works best with specific materials, such as plastic for FDM or metal for SLS. FDM is popular with people at home because it’s affordable. SLS is used in factories for stronger stuff. New 3D printers continue to make this method faster and more enjoyable.

Common Ways to Do Subtractive Manufacturing

Subtractive manufacturing uses tools to cut and shape things:

- CNC Mill: This machine features a harp tool for slicing and etching metal or plastic. It’s great for flat or boxy shapes, like parts for a computer case.

- Laser Cutting: A laser burns through thin materials, such as metal or wood sheets, to make clean cuts. It’s used for things like signs or car parts.

- Turning: This process spins the material while a tool cuts it, creating sound objects such as pipes.

These methods often idealize machines controlled by CNC machines for exact cuts. They work with various materials, including steel, wood, and plastic. Subtractive manufacturing is an excellent and reliable method for producing smooth, strong parts quickly and efficiently. It’s a favorite in factories because it’s quick, reliable, and consistently produces high-quality results.

Good and Bad Stuff About Additive Manufacturing

Additive manufacturing has some great points but also a few downsides:

- Good Stuff:

- It creates crazy shapes, such as a hollow ball or one with patterns inside, extremely easily.

- It doesn’t waste much material, so it’s kinder to your budget and the earth.

- It’s perfect for custom items, such as a ring made just for you or a specialized tool for a doctor.

- Not-So-Good Stuff:

- It’s slow when you’re making big things, like a whole chair.

- You can’t use every kind of material, so your choices are limited.

- High-quality 3D printers can be expensive, making them a challenge for small businesses.

This method is excellent for trying out new ideas, testing, and creating unique items. It lets people dream up wild designs and bring them to life. However, if you need thousands of parts quickly, it’s not the best option. Small shop businesses love it for its freedom, but big factories might find it too slow for their needs.

Good and Bad Stuff About Subtractive Manufacturing

Additive manufacturing is solid but has some limits:

- Advantages:

- It produces powerful, precise parts, such as those for a car engine.

- It works with a wide range of materials, from metal to plastic, providing you with numerous choices.

- It’s excellent for scale: It’s fast when you need a large quantity of the same item, such as nails or bolts.

- Disadvantages:

- It wastes material: It generates waste, including a large amount of metal scraps, which can incur additional costs for cleanup and disposal.

- Fancy shapes can be complex to create, requiring additional steps if not taken into account.

This method is excellent for large jobs that require tough, strong, and fast parts. It’s ideal for applications such as bridges or car parts. However, it’s not ideal for custom or super-fancy, detailed work because it’s not the best waste material-extra effort is required.

Where They’re Used in Industries

Both methods are used in tons all of the kinds places of places:

- Additive Manufacturing:

- Healthcare: Creates custom items such as prosthetic hips or arm braces that fit a person ideally.

- Airplanes: Develop lightweight parts, such as oddly shaped brackets, that reduce fuel consumption in plane manufacturing.

- Consumer Goods: Create fun items, such as custom phone cases or earrings, that you design yourself.

- Subtractive Manufacturing:

- Cars: Build parts, such as strong materials for engines or gears, that keep cars running.

- Buildings: Makes big stuff like steel beams or support molds for concrete that holds up houses.

- Electronics: Creates tiny, exact parts like circuit boards or metal cases for phones.

Additive manufacturing is excellent for small, special custom jobs where you want something unique. Subtractive manufacturing is well-suited for large, demanding, and complex tasks that require numerous robust components. Together, they make all the stuff we use every day.

A Final Word

In the end, additive manufacturing and subtractive manufacturing are both super key to building stuff things today. Additive manufacturing is unique, great for testing fancy models, and with custom, less-part waste, perfect for test models or one-off custom items. Subtractive manufacturing processes are fast, strong, steady, and reliable for producing parts, making them ideal for the production of various items, such as car parts. Subtractive Each has its tools, advantages, benefits, and challenges. They’re used in numerous places, such as hospitals and factories, for various purposes to solve different problems.

Picking one depends on what you’re making, how much money you have, and what you need it for. As machines continue to improve, both will further enhance our ability to create innovative products for the world of tomorrow.