Welcome to the field of heat treatment! In metal casting, heat treatment is an incredibly important process that truly transforms the overall capacities of cast metals. It generally improves features of cast metal, such as ductility, hardness, and resistance, to prepare cast metal for further functional processes. Without proper heat treatment, many cast parts would no longer meet the expectations of performance standards that are looked for in industries today.

Let us look at how this heat treatment process has been around for centuries as a revolutionary modern manufacturing process for producing metal parts today.

What Is Heat Treating?

Definition of Heat Treatment

Heat treatment is simply defined as a controlled process of heating and cooling metals to change the microstructure of the metals, and hence the physical and mechanical properties. Think of it as a highly controlled alteration to the internal structure of metals that allows you to achieve specific properties. Heat treatment is much more than just heating metal and letting it cool down; it is a predetermined sequence of induced temperature changes that are designed into the process.

Why Heat Treatment Matters

There is a profound difference with heat treatment. It is how we improve mechanical properties such as strength, ductility, and wear resistance. Heat treatment also directly impacts the life and performance of metal parts. Think of a component that can take an extreme force or take massive wear from operational activities for years. In these examples, it is likely that a key part of the improvement is heat treatment. It can ensure your metal parts don’t just exist but thrive in their intended roles.

To sum up, only heat treatment can:

- Improve properties throughout the entire part (not just surface layers)

- Reverse undesirable characteristics from previous processing

- Fine-tune properties without changing the part’s dimensions

- Achieve property combinations (like hardness and toughness) that other ways can not in combination

How Does Heat Treatment of Metals Work?

The Basic Process

The core of heat treatment involves three main steps: heating the metal to a specific temperature, holding it at that temperature for a set “soak time,” and then cooling it. The magic happens during these stages. The soak time is crucial because it allows the metal’s internal structure to rearrange itself. The cooling method is just as vital – rapid cooling (like quenching) can make a metal hard, while slow cooling might make it softer or more ductile. Each step is precisely controlled to achieve a particular outcome.

Microstructural Changes

During heat treatment of metals, there is a change in the ordering or structuring of the atoms inside the material. When, for example, a metal is hardened, the atomic structure of the metal is locked into a very densely arranged and strong structure. When a metal is softened, the ordering of its atoms is allowed to relax into a flexible, reasonable structure. The reorganizing of atoms is a microscale change that has large implications for how a metal behaves, allowing it to achieve multiple uses.

Benefits of Heat Treatment of Metals

Heat treatment offers a host of advantages that significantly improve the performance and utility of metal castings.

Enhanced Strength and Durability

One of the most attractive benefits is a significant improvement in a metal’s durability and strength. Heat treatment has the power to change a somewhat weak casting into a strong part that can carry extremely heavy loads in extremely challenging operational conditions; in other words, the parts have a longer lifespan and better assurance of reliability.

Improved Machinability

Some heat treatment processes, such as annealing, soften metals to be more ductile types of materials. Therefore, when a metal is more machinable, it will be less likely to wear down tools or waste the material, and it cuts more easily and shapes with little tear and wear; this makes it quicker and cheaper to manufacture.

Reduced Brittleness

Hardening a metal will make that metal strong, but often brittle. Tempering is a heat treatment meant to decrease brittle factors of the metal and greatly increase toughness factors, which will contribute to making metals less prone to cracking or unexpectedly failing when under stress.

Increased Wear and Corrosion Resistance

Some heat treatments would help a metal increase its resistance to wear due to friction and absorption, and help the metal be more resistant to the effects of the environment, which does increase how long components may last especially when used in severe or corrosive environments.

Stress Relief

Certain manufacturing procedures, like casting and machining, will create internal stresses in a metal part. These residual stresses will lead to bending or cracking, or even cause unintentional initial failure. A heat treatment can relieve internal stresses and you can produce a more robust and reliable part.

Common Types of Heat Treatment for Metal Castings

Understanding heat treatment processes is necessary to assess the correct process required for your metal castings. Each type of heat treatment has a specific purpose and employs specific heat and cooling cycles.

Annealing

Purpose: The general purpose of annealing is to soften the metal and improve ductility (its ability to deform without breakage), and reduce maximum internal stresses that may be building. It is often performed prior to machining or on components that must remain highly formable.

Process: To anneal a metal, the metal is raised to an elevated temperature, usually above the recrystallization temperature, and then cooled very slowly, frequently without any external force applied (it’s common practice to leave the metal in the furnace until it has cooled down with the furnace). Cooling the metal slowly allows the microstructure of the metal to rearrange into a less stressed and more stable structure.

Hardening

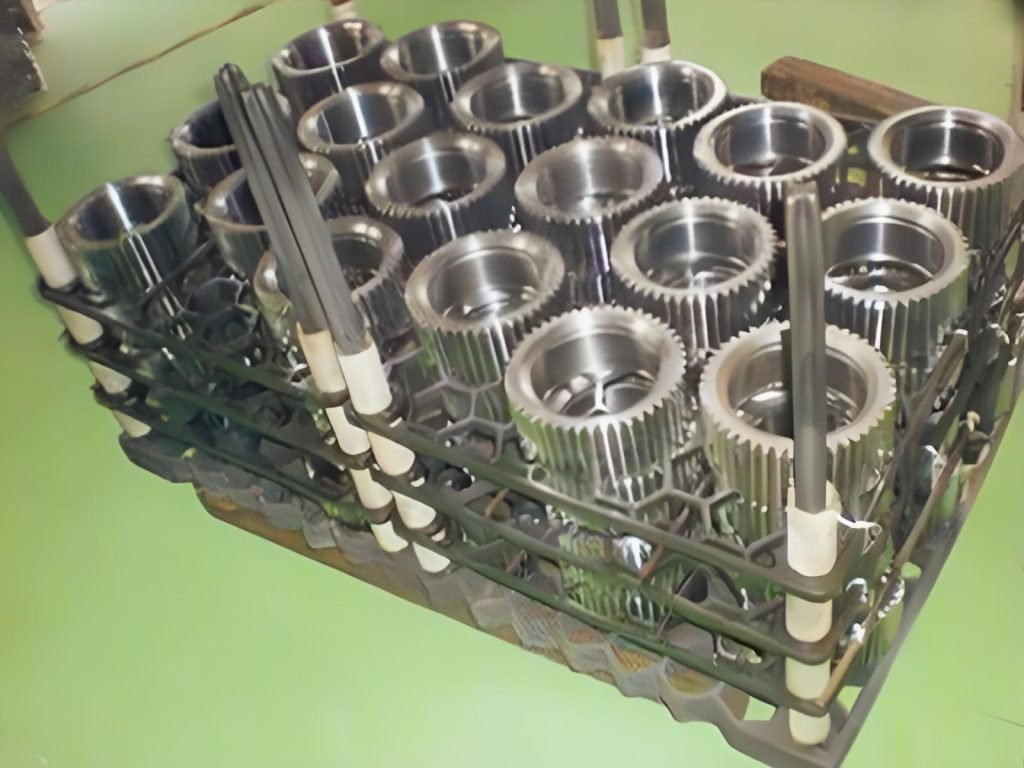

Purpose: Hardening is used to improve the surface hardness and overall strength of metals. This is an important process for parts, e.g., gears, cutting tools, and bearing surfaces that have to resist wear and deformation.

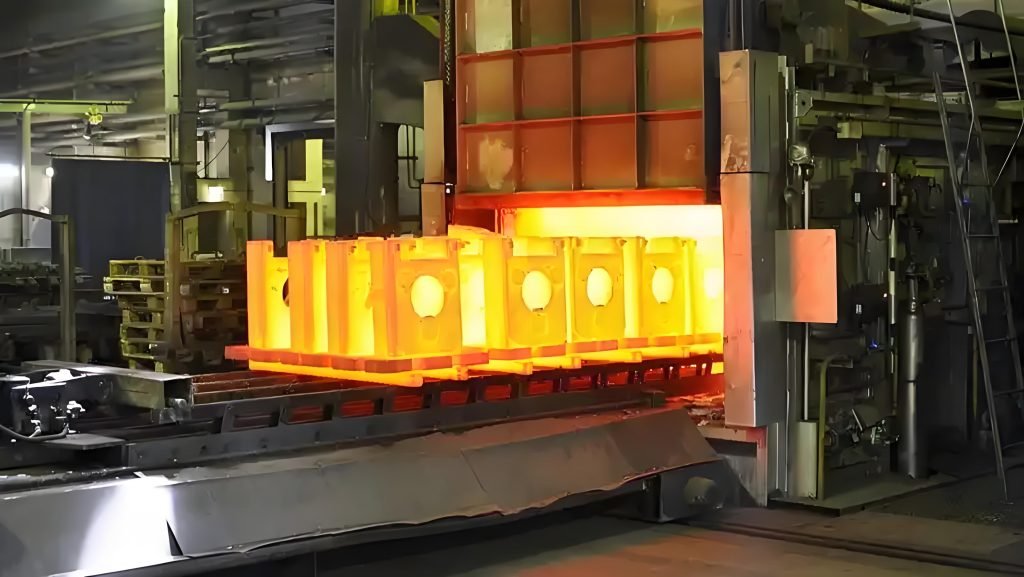

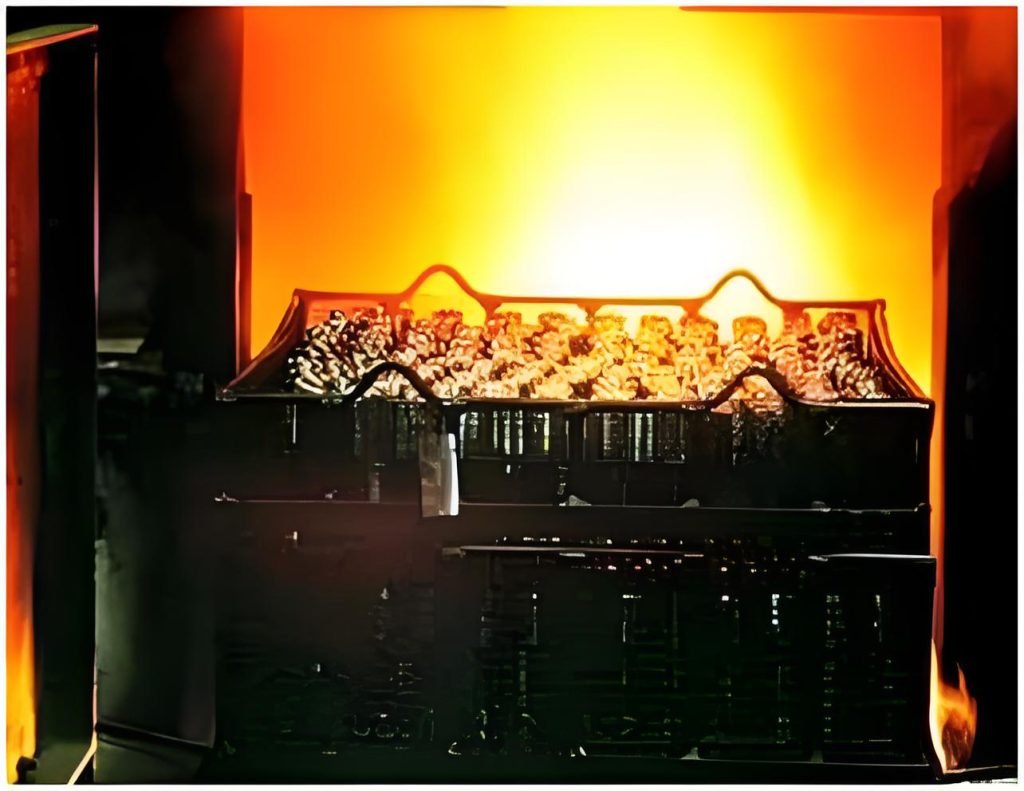

Process: This process is essentially heating metal to a high temperature (generally above its critical temperature), then quenching through a rapid cooling stage. Quenching can be done with water, oil, or polymers where the quickly cooled microstructure will be frozen in a hard, strained state.

Tempering

Purpose: In almost every case, tempering occurs immediately after hardening so that it can reduce the degree of brittleness that is a result of the hardening process while creating a high degree of hardness. Furthermore, the entire process improves the toughness and ductility of the final product, thereby making it less prone to fracture.

Process: After the hardening is complete, the metal is reheated to a lower temperature (below its critical temperature for hardening) and held at that temperature to relax stress internally, and then cooled again. Reheating to a lower temperature relaxes a portion of the internal stresses and does not alter the level of hardness achieved.

Normalizing

Purpose: The purpose of normalizing is to refine a metal so that there is more uniformity in the crystal structure, overall strength, and toughness. It’s often used to prepare metal for further heat treatments, machining, or to reduce the mechanical properties across a casting.

Process: First, the metal is heated to a temperature, elevating it above its critical temperature (just like hardening), but is allowed to air cool at room temperature. This method provides a slower and more uniform cooling rate than that of furnace cooling (annealing), producing a finer, more homogeneous grain structure.

Stress Relieving

Purpose: To reduce or eliminate residual internal stress that may have been put in the part when it was created (cast, welded, or heavily machined). Parts may become distorted in service or crack, or fail before the end of service life because of residual internal stresses.

Process: The metal is heated to a specific relatively high temperature but below the critical temperature, held for a defined period of time, and then cooled either in still air or in the furnace. The heating of the part is important to relieve internal stresses and have the part relax without significantly changing the microstructure of the metal or overall hardness.

Solution Heat Treatment and Aging

Purpose: This two-part process is mainly performed on select non-ferrous alloys such as aluminum, magnesium, and some types of stainless steel in order to provide increased corrosion resistance and strength. It makes it an effective process for alloys that need platform re-precipitation hardening.

Process: First, in solution heat treatment, the alloy is heated to a high temperature where certain elements (precipitates) dissolve into a uniform solid solution. It’s then rapidly quenched to “trap” these elements in solution. Second, in aging, the quenched alloy is reheated to a moderate temperature. This allows the dissolved elements to precipitate out in a controlled manner, forming tiny, uniformly dispersed particles that strengthen the alloy and improve its properties over time.

Heat Treatment Processes: A Quick Guide

| Heat Treatment | Key Benefits | Typical Applications |

| Annealing | – Softens metal | – Pre-machining preparation |

| – Improves ductility | – Electrical components | |

| – Relieves internal stresses | – Cold-worked part recovery | |

| Hardening | – Maximizes hardness | – Cutting tools |

| – Increases wear resistance | – Bearing surfaces | |

| – Boosts strength | – Gears | |

| – Knife blades | ||

| Tempering | – Reduces brittleness | – Hardened tools |

| – Improves toughness | – Automotive components | |

| – Maintains adequate hardness | – Industrial machinery parts | |

| Normalizing | – Refines grain structure | – Steel castings before hardening |

| – Improves mechanical uniformity | – Forgings | |

| – Large structural components | ||

| Stress Relieving | – Eliminates residual stresses | – Welded structures |

| – Prevents distortion | – Precision machined parts | |

| – Large castings | ||

| Solution Treatment & Aging | – Enhances strength in alloys | – Aerospace aluminum parts |

| – Improves corrosion resistance | – Marine hardware | |

| – High-performance engine components |

Tips on Choosing the Right Heat Treatment for Your Metal Casting

Selecting the heat treatment process that is right for your metal casting is a momentous decision; the correct heat treatment can greatly affect the part’s performance and usable life. You can consider the following factors:

Consider the Metal Alloy

Different metal alloys respond differently to heat treatment. And the exact chemistry of your metal dictates which heat treatment processes may be available to you, and how much each one may improve your part. For instance, plain carbon steels will respond well to hardening and tempering, but some aluminum alloys won’t respond to the same process in the same way – rather, they will require solution heat treatment and aging. The metallurgy of your material is the first consideration. This is particularly important when considering heat treating steel or other specialized alloys.

Evaluate the Application Requirements

What will the finished part be used for? This is perhaps the most important question. Do you need maximum strength and hardness for a wear-resistant component? Or is ductility and toughness more critical for a part that might experience impact loads? Perhaps corrosion resistance is paramount. Defining the mechanical and environmental demands of the application will guide you toward the appropriate heat treatment that optimizes the part’s properties for its intended use. This is where you can truly thermally strengthen metal for specific functions.

Size and Shape of the Casting

The physical characteristics of your casting play a significant role. Complex geometries can make achieving more uniform heating and cooling challenging; therefore, they are paramount to consistent results for the heat treatment process. The size and shape also influence the cooling rates during quenching or air cooling, which can cause distortion and impact uniformity of material properties if not well considered during the heat treatment process. Sometimes, the use of special fixtures or quenching techniques may be necessary for effective casting metalworking.

Consult with Experts

One of the best ways to make sure you pick the right process is to take advantage of the experience of experts. An experienced expert can look at your metal alloy, application needs, and casting practices, and make recommendations, or even develop a heat treatment process that perfectly suits your application. Tapping into their experience could save you valuable time and money, as well as result in the most effective product for your metal parts. For complex applications, an expert in heat treating steel can be invaluable.

Fecision – Expert Heat Treating Services

For an expert partner in producing heat-treated cast metal, you can trust the experience and knowledge of Fecision.

Why Choose Fecision?

You have seen that heat treating is an extremely important step for achieving optimal properties in your cast metal parts. It is the key to better strength, improved durability, and reliable performance in many applications. When you need precision and quality in your metal components, Fecision is your reliable partner. You can truly thermally strengthen metal with our processes.

At Fecision, we provide customized metal parts with heat treatment services that enhance your cold- and hot-worked components, ensuring that you receive the precision-engineered metal parts you need. Our heat treatment service covers the cold working process (stamping and forging) and the hot working process (extruding and forging), to help your parts optimize hardness, yield strength, wear resistance, and service stability, no matter the type of metal (aluminum to high-strength alloys).

Getting Started With Us, Whether You Need:

- Prototype development with optimized thermal processing

- High-volume production featuring strict metallurgical control

- Problem-solving expertise for heat treatment challenges

Need durable, precision metal parts? Contact Fecision today. Let us help you take your metal castings to the next level with our expert casting metalworking capabilities.