Casting is one of the first and the most popular manufacturing processes used to design metal parts. It is cast by heating the metal and pouring it into a mold in a molten state so that it becomes the shape the mold. This allows complex geometries and large parts to be made in a way not otherwise possible. This process is indispensable when applied to the automotive, aerospace, and construction sectors. Knowledge of the casting process and its many variations is essential to choosing the right method for the job.

This article is aimed at presenting the overall casting concept and its various methods, which play a vital role in the present-day growth of technology.

The Casting Manufacturing Process

Casting starts with the event of making a mold in the form of the part-to-be cast. The mould is filled with molten metal and will cool and set. When the part has solidified, the mold is pulled away to release the cast part. It is a multi-step process that begins with mold preparation and metal melting, pouring, cooling, and finishing.

The type of material used for the mold also depends on the type of casting, as in the case of the sand or the metal used for die casting. The metal — aluminium, steel, brass — depends on the part’s needs. The advantages are that casting allows for the creation of more intricate shapes with a higher degree of consistency than other processes. Accurate control at every stage is essential to prevent defects and maintain quality.

Main Types of Casting: Sand Casting, Die Casting, and Investment Casting

Casting is a flexible manufacturing process with a wide range of methods to suit a range of application, material, and quantity requirements. The most commonly used cast types are sand casting, die casting and investment casting. Both have their unique Pros and Cons, which makes them the right fit for certain types of parts and industries.

Sand Casting

Sand casting is one of the oldest forms of casting and has been used primarily over the centuries. The process includes introducing a sand mixture around a pattern forming the cavity. The mold is subsequently extracted, and this space is filled with melted metal to produce the part. The sand mould is then cooled, broken away, and the casting removed.

The process is also very flexible and can produce a high quantity of large and complex parts with internal cavities and complex details. Low-to-moderate production volumes are inexpensive to achieve (due to low-cost tooling), with the final products being a cost-effective manual assembly. But, the accuracy and the surface finish of sand molds are less than other methods. It will likely need to be machined after this second process to the final dimensions.

Typical products produced via sand casting are engine blocks, pump housings, and various parts of machinery. Due to its compatibility with a variety of metals, including cast iron, steel, and aluminium, this type of saw is popular across industries.

Die Casting

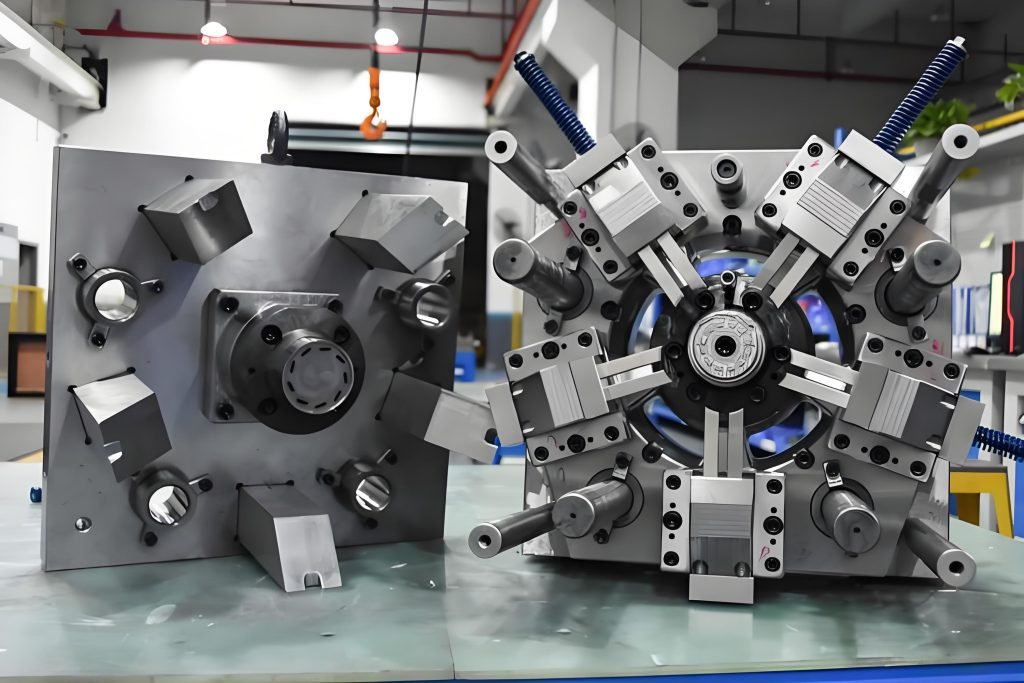

Die casting is a high-pressure casting process that forces molten metal into a reusable metal mould or dies. The method has been used to produce smooth, thin-walled and accurately dimensioned articles. Die cast molds are normally produced from hardened steel that provides each part being produced a high volume of accuracy.

A die-cast component can be a complex, accurate shape that can be produced quickly and requires little or no machining. It is suited to produce small to medium-sized parts, and it is widely used in the automotive, electrical, consumer goods and other industrial domains. Aluminium, zinc, and magnesium are the most common metals used in die casting.

However, the cost of the tooling is significantly higher with die casting, just because of the intricacy and the longevity that they have to be made. It’s great for high volume because, in high volume, these initial costs can be distributed across thousands of parts. Furthermore, die-casting is restricted to low melting point metals due to the mold material.

Investment Casting

Investment or lost wax casting is a precision casting process used to create complex and detailed industrial parts with great accuracy and a smooth surface. It involves making a wax pattern of the part that is to be cast, coating it with a ceramic molding material to create a shell, and then melting the wax out of the shell with steam or water to leave a cavity in which the part can be cast. After the ceramic is set, the wax is melted out, leaving a mold with a cavity to pour the hot metal.

Investment casting makes complex geometries, thin walls & fine details economically, which are hard to see in any other process. It is widely used in aerospace, medical devices and jewellery production. The technique can be applied to a wide range of metals, including stainless steel, titanium and superalloys.

Although it provides a premium quality, investment casting is a costlier and lengthier process than sand or die casting. The process is multistep and requires labour, so it is better adapted for high-resolution, low-volume parts or more intricate prototypes.

Selecting the right casting technique; You would need to choose the casting method that suits you best. It would generally depend on the part complexity, material, volume, budget and precision that you would require. The knowledge of these processes helps the manufacturers to maximize the production efficiency and quality of the product.

Casting Applications in Metalworking

Casting is a crucial process in metal forming, which has been used from very ancient times to produce products of complex geometry and strength and is used for the mass production of components. It is universal, which means designers can produce parts that would be challenging or even impossible to produce with other manufacturing methods.

In the automotive sector, casting is used to make engine blocks, cylinder heads and transmission cases, among other vital parts. Such parts demand strength, heat resistance and accurate dimensions, which are possible to obtain by casting techniques. The aerospace industry uses casting to produce turbine blades, structures, and casings made of high-performance alloys that must be lightweight and strong.

Foundry is used to make parts such as Pumps, valves, Gearboxes and structural frame members in heavy machinery and construction industry. Casting makes possible the production of large and heavy components with intricate shapes which can be used under severe operating conditions.

It is also vital in the production of consumer goods, including cookware, hardware, tools and appliances. Its capacity to repeatedly produce parts at different sizes makes it just as fit for mass production as it does for tailor-made batches.

The combination of material flexibility, design complexity, and cost-effectiveness makes casting indispensable in a myriad of metalworking applications, aiding in driving innovation and performance in manufacturing today.

Casting Material Selection

Choosing the proper material is the first step to building a good casting, as it has an impact on the mechanical properties, durability and suitability of the product. Metals and alloys are assayed for a wide variety of divergent characteristics, including strength, corrosion resistance, heat resistance, and machinability.

The following are some of the materials commonly used in casting:

- Aluminium: Aluminium is used in an array of applications, though it is lightweight and will not rust, making it ideal for automotive parts, aerospace projects, and consumer goods. It is used for engine components and heat exchangers due to its high thermal conductivity.

- Steel and Iron: Both of these materials are strong and resistant to wear and are found in heavy machinery, construction and automotive equipment. Fit for high wear resistance and vibration, a good fit for cast iron.

- Copper Alloys (brass and bronze): The brass and bronze ones give good corrosion resistance and electrical conductivity. They are commonly employed in plumbing fixtures, electrical connections, and ornamental objects.

The material choice comes down to the operating environment, mechanical stresses, cost, and the required finish. For instance, higher temperature applications may mandate stronger, more heat-resistant alloys and decorative parts may focus on surface finish.

A comprehensive understanding of the characteristics of casting materials can support manufacturers in selecting the best possible casting material for functional and economic needs, leading to the faithful performance of the final product throughout its service life.

Challenges in Casting

Casting is a flexible process, having however many issues that influence the quality as well as the performance of the end product. One common defect is porosity, in which gas bubbles are trapped in the metal as it solidifies. This can weaken the component and possibly lead to leakage or failure in important applications.

Another common issue is shrinkage. Cooling for metals means contracting, which in turn can cause voids or gaps and result in imprecise or incorrect dimensional properties. Designers can consider shrinkage by making molds a little bit bigger, using risers (additional blobs of material that supply molten metal as materials cool) or by being aware of how their part will shrink and adjusting the size to compensate for that effect.

Surface finish quality can also be inconsistent due to casting techniques and mold materials. The rough surfaces may need to be machined or polished further, which may be expensive and time-consuming to do so.

Other challenges include:

- Wear and tear on the mold, leading to shortened mold life and reducing the accuracy of dimensions.

- Partial fill or cold folds, where the liquid metal does not fill the mold completely and leaves weak spots.

- Cracks or distortions during cooling due to thermal stresses.

Final Thoughts

Casting is still one of the most important manufacturing processes for the manufacture of high-value and high-quality metal products in many industrial sectors. Knowing the differences between sand casting, die casting and investment casting can help you select the best method for manufacturing your products. Every method presents unique advantages in terms of price, accuracy, and throughput. Appropriate material selection and the consideration of porosity and shrinkage become important in obtaining high-quality casting.

Mold design and simulation have also come a long way, resulting in better casting reliability and throughput. As a tool for producing many metallic part types with specific performance and design requirements, the casting process is a valuable one when properly managed.