Look around right now. See your phone case? The car keys on your table? Almost every solid object in factories starts as soft stuff pushed into a shape. This shaping process is called molding. Workers load materials like hot metal or plastic pellets into hard frame molds. Cooling or chemistry makes them hard. Open the mold. You get a finished thing – a casting. Simple? But molding runs the world. Let’s compare them properly.

What Is Molding?

Do you know how you can use a cookie cutter to shape dough? Molding is like that but for factories. Workers take soft or liquid materials—plastic, glass, metal, even some powders—and push or pour them into a hollow metal or plastic frame called a mold. This mold is a hard container shaped exactly like the object you want to make—a toy car, a bottle, a phone case. Leave the material inside until it hardens (by cooling down or chemical reaction), then open the mold. Out comes a solid piece called a “casting” or “part.” This is molding. Simple idea, right? But it makes almost everything around us.

Why factories love molding:

Factories have a strong preference for injection molding, mainly because it is truly efficient and cost-effective. First of all, it is incredibly fast – once a mold is in operation, it can “spit out” a formed part every few seconds. Secondly, the processing cost of each product has been kept extremely low: Although making the mold itself requires an initial investment, once this mold is completed, the cost of each part produced later is only a few cents when calculated.

Coupled with the extraordinary ability to precisely replicate molds, the shape and size of each item produced by injection molding are as precise and consistent as copying and pasting, without the slightest deviation.

Different Types

Casting

- Pour molten material (metal/plastic) into a mold; cool to solidify.

- Examples: Statues, jewelry.

Blow Molding

- Inflate heated plastic tubing inside a mold (like a balloon).

- Examples: Bottles, jugs.

Compression Molding

- Press hot material (e.g., rubber) between two molds under high pressure.

- Examples: Tires, electrical plugs.

Extrusion Molding

- Push softened plastic through a die to create continuous shapes.

- Examples: PVC pipes, window frames.

Injection Molding

- Inject molten plastic into a mold at high pressure; cool and eject.

- Examples: Lego bricks, toothbrushes.

Rotational Molding (Rotomolding)

- Rotate a mold with plastic powder in an oven; coat the interior for hollow parts.

- Examples: Kayaks, storage tanks.

Transfer Molding

- Pre-heat material, then force it into a mold via a plunger.

- Examples: Silicone spatulas, insulators.

Thermoforming/Vacuum Forming

- Heat plastic sheet, stretch over mold, and vacuum seal to shape.

- Examples: Packaging trays, yogurt cups.

Powder Metallurgy & Sintering

- Compress metal powder in a mold; bake to fuse particles.

- Examples: Gears, bearings.

Reaction Injection Molding (RIM)

- Mix reactive chemicals; inject into mold where they foam/harden.

- Examples: Car bumpers, shoe soles.

Insert Molding

- Place pre-made part (e.g., metal insert) in a mold; inject plastic around it.

- Examples: Screwdriver handles.

What Is Casting?

Casting is a foundry process where liquid material (typically metal) is poured into a hollow mold, solidifies, and takes the mold’s shape upon cooling. This ancient technique, dating back thousands of years, transforms molten alloys into solid objects—from engine blocks to jewelry. Its core value lies in:

- Complex shape capability: Creates intricate geometries impossible with machining.

- Material versatility: Works with metals (iron, aluminum, titanium), plastics, and concrete.

- Cost efficiency: Low equipment costs and recyclable scrap reduce expenses.

Example: Bronze statues are produced by pouring molten bronze into clay molds, cooled, and broken open to reveal the artwork.

Primary Casting Types

Die casting is merely one subtype of casting. Below are key methods documented in industrial sources:

Sand Casting

Workers pack special sand tight around a copy of the part (called a pattern). They pull out the pattern. Then they pour hot liquid metal into the hollow space left behind. The metal stays until solid. Finally, they break the sand mold to pull out the finished part. Good things: It’s the cheapest metal casting method for making molds. You can cast huge heavy pieces with it. Bad thing: Parts come out with rough surfaces needing extra grinding or smoothing.

Investment Casting

The first step is making a model of the part from wax. Next comes dipping that wax model into thin ceramic goo multiple times to build a shell coating. Workers melt away the wax inside that shell. Then they pour hot metal into the hollow ceramic mold. Finally, they crack off the ceramic. This gives very accurate shapes, perfect for things like jet engine blades. The smooth finish means less cleanup later. The downside: Doing all these small steps takes lots of hands-on labor, making this a pricey method.

Hot melted metal gets shot fast into strong steel molds using really high force. People reuse the molds thousands of times. It’s super fast—you can make a new part in just seconds. You get close and exact measurements perfect for electronic cases. But there’s trouble too. Sometimes little air bubbles get stuck inside the metal parts, making them weaker inside. Also, paying for making the tough steel molds costs a big pile of money upfront. So it works best for huge orders where you can spread that mold cost thin across many parts.

Low-Pressure Casting

A tank of melted metal sits below the mold. Gas pressure pushes that liquid metal upward gently into the mold shape. This method wastes very little metal because the feeder channels recycle well. It also keeps air off aluminum surfaces, stopping rusting problems. The catch? The metal stays soft longer before becoming solid. That longer hardening time makes making each part a slow game.

Die Casting vs Injection Molding: Key Manufacturing Differences

While both die casting and injection molding force liquid material into molds to make solid parts, they solve different industrial problems. Die casting shapes molten metals (like aluminum or zinc) into strong components for cars or airplanes. Injection molding works only with plastics or polymers to create lighter items like phone cases or medical tools. Let’s see the difference between molding and casting.

- Casting and Molding Process

Die Casting: How It Works

Die casting forces hot liquid metal (like aluminum, zinc, or magnesium) into a steel mold called a “die” using high pressure (15-100 MPa). The metal cools fast to make solid parts. This method is good for strong metal parts with smooth surfaces, such as car engine parts or gear housings. But it has limits: only metals with low melting points work, and large parts are hard to make.

Injection Molding: How It Works

Injection molding melts plastic pellets (like ABS or nylon) and pushes them into a mold. After cooling, the plastic hardens into shapes like phone cases or toys. It is better for making many plastic items quickly with thin walls. However, starting costs are high because molds are expensive.

- Molding and Casting Materials

Die casting works with melted metals. Common metals are aluminum (melts at 660°C), zinc (melts at 300°C), and magnesium. These metals are poured hot into the mold. Injection molding uses solid plastic pellets, like polyethylene, nylon, or ABS. The pellets soften between 150–350°F. Plastic then goes into the mold as a thick liquid.

- Process Conditions: Casting and Molding Difference

In die casting, the metal mold gets very hot—over 700°F for aluminum work. High pressure (15–100 MPa) forces the metal into the mold quickly. Injection molding needs careful temperature control. Plastic melts at 300–800°F inside the machine barrel, but molds stay cooler (150–350°F). This stops problems like warping.

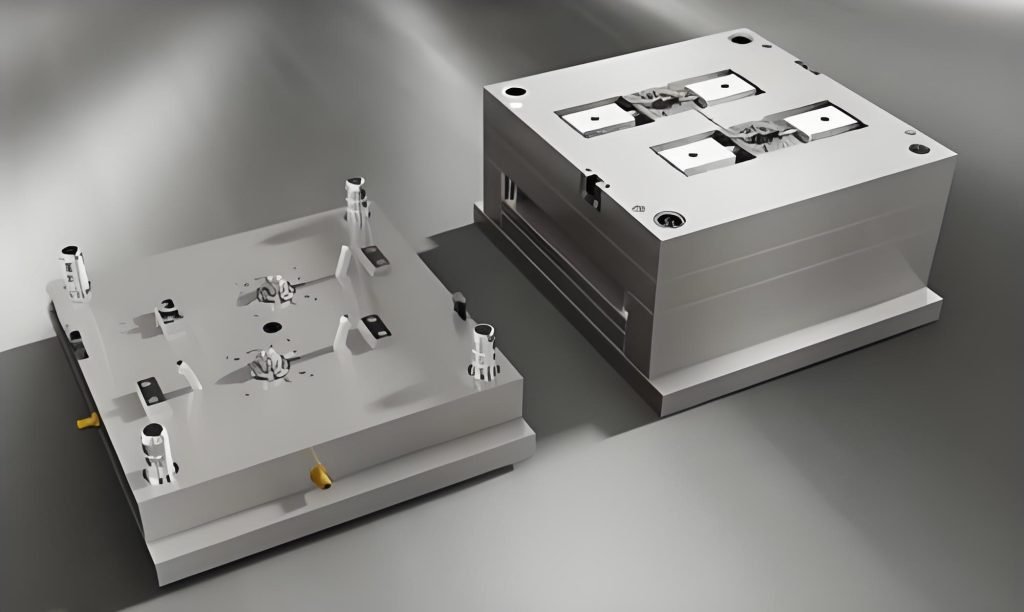

- Mold Design

Die-casting molds use thick steel. The steel handles heavy pressure and heat. Air needs to escape the mold, so special slots are added. Injection molds use steel or aluminum. These molds work for many cycles—from 100,000 to 1 million times. But they must have exact cooling channels for temperature.

- Product Quality

Die cast parts fit very tight tolerances (±0.1mm) with smooth surfaces. A little extra work like sanding is needed. Injection molded plastic parts often have extra bits called flash or gates. Workers trim these after molding. Painting usually adds color since the plastic is plain.

- Cost and Production

Die-casting molds cost a lot of money. But they are good for big orders of metal parts—making 5,000 to 100,000 pieces per mold. Small orders become too expensive. Injection molding cuts part costs for huge plastic runs. Starting costs are high due to heavy equipment prices.

- Common Problems

Die casting sometimes traps air in the metal. This makes tiny holes called porosity. It weakens the metal part. Injection molding causes warping if the plastic walls are not even. Thick and thin spots cool at different speeds and bend the part.

Difference Between Die Casting and Injection Molding: Quick Comparison

| Aspect | Die Casting | Injection Molding |

| Material Type | Metals (Al, Zn, Mg) | Plastics (ABS, Nylon, etc.) |

| Mold Temperature | Up to 700°F | 150-350°F |

| Injection Pressure | 15-100 MPa | Varies by plastic type |

| Part Precision | ±0.1mm tolerance | Lower precision for large parts |

| Mold Cost | High (thick steel molds) | Lower (aluminum/steel) |

| Best For | Auto parts, metal housings | Toys, electronics, thin-wall items |

Where Each Process Is Used

Die casting: Car parts (engine blocks, gears), metal tools, bathroom fixtures.

Injection molding: Plastic consumer goods (phone cases, medical devices), packaging.

Fecision: Precision Manufacturing for Die Casting & Injection Molding

Fecision delivers industrial-grade metal and plastic components through die casting and injection molding services. With ISO 9001:2015 and IATF 16949:2016 certifications, Fecision ensures reliability for the automotive, medical, and electronics sectors.

Fecision’s Die Casting Services

Fecision provides die casting services that make strong metal parts for important uses. They use non-ferrous alloys only. The main metals are aluminum for light parts, zinc for low-cost complex shapes, and magnesium for strong structures. Their machines use 100 to 3500 tons of force. These machines make parts very fast—in seconds or minutes each—with few air holes (porosity). The work is very exact, holding tolerances to ±0.001 inches. This precision is good for parts like electric vehicle (EV) charging ports.

After casting, they add finishes: anodizing stops rust, electroplating makes surfaces hard, and sandblasting changes texture. For example, they make EV housings that block electromagnetic interference (EMI) using precise die casting.

Fecision’s Injection Molding Services

Fecision is excellent at making many plastic parts in high numbers. They offer over 200 types of thermoplastics. These include ABS, PP, PC, and Nylon, which can be strong against impact or clear. Their machines clamp with 50 to 3200 tons of force. These handle jobs from test samples to huge orders—they can make 4.5 million parts per month. Tolerance control is tight, with ±0.005mm accuracy needed for things like medical syringe bodies or car interior trims. For surfaces, they offer spray coating, laser engraving, and metal plating like chrome or nickel.

Why Fecision Stands Out

- Zero Minimum Orders

Prototype batches to 100k+ units accepted—ideal for startups testing EV components or medical devices.

- Integrated Workflow

Combines mold design, material selection, and assembly in-house. CMM inspection catches errors early, reducing waste.

- Speed-to-Market

Injection molding samples in 3 days; Die casting prototypes in 5 days

- Industry-Specific Compliance

Medical: ISO 13485:2016 for surgical tools

Automotive: IATF 16949:2016 for engine mounts

Fecision’s certified processes turn concepts into market-ready parts—fast.