Welcome to the dynamic world of electric vehicle (EV) manufacturing, where technological advancements and efficiency are paramount. If you are a very interested reader curious to learn about the role of automotive metal stamping in a rapidly evolving industry, you are in the right place.

In this guide, we’ll outline every detail about EV metal part stamping, including the benefits of automotive metal stamping applications, the challenges, the materials used, and the automotive stamping processes, as well as many design tips to incorporate stamping effectively.

What Is EV Metal Part Stamping?

Definition

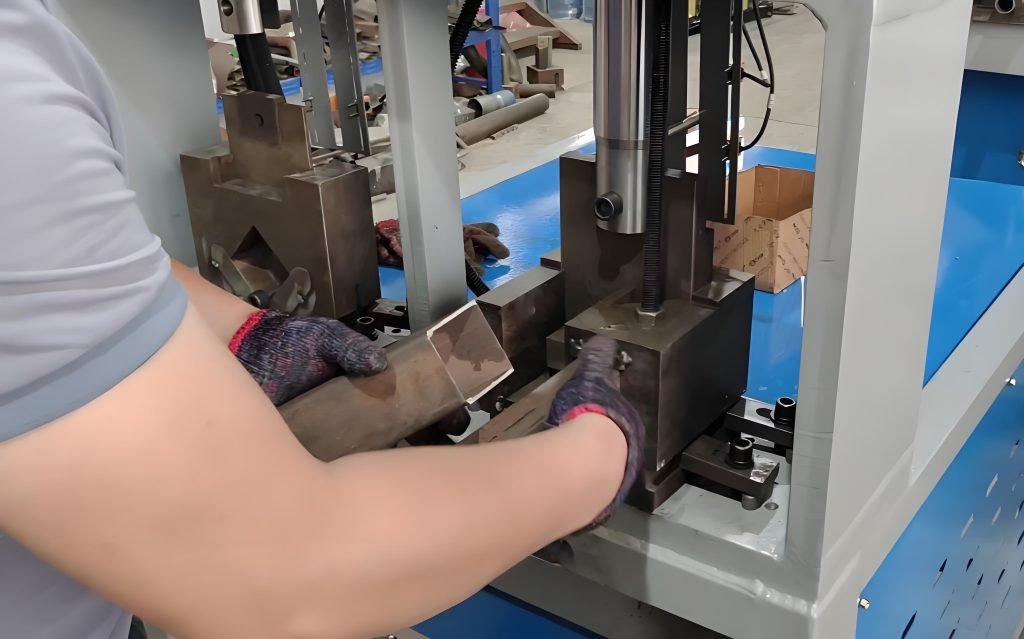

Fundamentally speaking, EV metal part stamping is a sophisticated manufacturing process. EV metal part stamping is accomplished with force presses and custom-built forming dies that take flat sheets of metal and imprint them into detailed parts to be used in EVs. This is critical for the parts that have the challenging requirements for EVs, like lightweight, durability, and performance.

Benefits & Challenges

There are numerous benefits to EV metal part stamping that make it an essential step in any EV production. These include cost-effectiveness, great material efficiency, automation, and advanced process control. Nonetheless, as with any advanced manufacturing process, it comes with its own liabilities, like perhaps the substantial upfront tooling costs and the continuing need for highly skilled labor.

| Aspect | Benefits | Challenges |

| Weight & Strength | Lightweight yet strong, improving EV range & performance. | Material selection must balance conductivity, strength, and corrosion resistance. |

| Cost Efficiency | High-volume production lowers per-unit costs. | High initial tooling costs for custom dies. |

| Precision & Consistency | Tight tolerances ensure safety and reliability. | Complex part designs require advanced die expertise. |

| Automation & Speed | Fast, automated production for mass-scale output. | Demands skilled labor for die design and press operation |

| Material Versatility | Works with aluminum, copper, high-strength steel, etc. | Limited to ductile metals; brittle materials may crack. |

Common Materials

The metals used in EV metal part stamping are meticulously chosen for a variety of material properties that are needed to satisfy the demanding performance requirements for electric vehicles.

Aluminum

Aluminum has exceptional lightweight characteristics along with excellent corrosion resistance, which is the best in terms of overall vehicle weight reduction and helps with energy efficiency.

Copper & Brass

The copper and brass materials are irreplaceable in any electric vehicle when it comes to electrical components. Copper’s and brass’s high electrical conductivity allows for battery contacts, busbars, and many different types of electrical interfaces in an EV.

High-Strength Steel

For structural crash safety parts and components that must withstand significant forces, high-strength steel is better. It is more durable and has more crashworthiness, thus making it safe for the electric vehicle.

Stainless Steel

Corrosion-resistant and strong stainless steel is used to manufacture many EV parts, especially where the manufacturing components may be facing harsh environments or high temperatures.

Advanced High-Strength Steels (AHSS)

These next-generation steels have an even better strength-to-weight ratio than high-strength steels and, in turn, can provide even greater weight loss with no loss in safety or structural capacity.

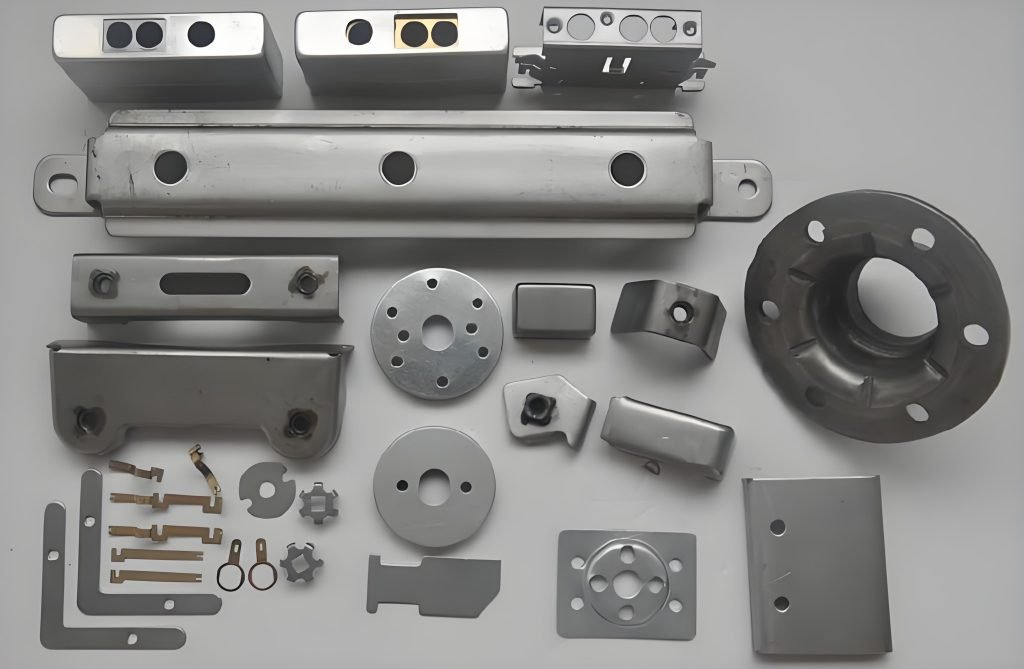

Applications

EV metal part stamping is a flexible process used to create multiple parts throughout an electric vehicle; they are generally the base of those electric vehicle components that facilitate the purpose of the EV, such as physical carrying capacity, safety, and efficiency.

In Vehicle Body Construction

From a practical standpoint, stamped metal parts make up some of the EV’s total structure. They include housing chassis components, frame components, and the outer body panels. On top of being lighter parts, they also must be incredibly durable. These stamped metal parts support vehicle performance and often help protect your passengers from crashing.

In Manufacturing Motor Housings

The electric motor is the engine of an EV, and its housing can often be produced in automotive metal stamping. Internal to the housing, the motor is comprised of several components that must remain unexposed while also being resistant to heat and the elements. Automotive stamping ensures the complex geometries required for optimal motor performance.

In Producing Battery Trays

In addition to the electric motor housing, one of the important applications of automotive stamping is battery trays. This tray acts as a secure housing for the EV’s current heavy battery pack with characteristics of solid strength, weight reduction while maintaining strength, and various protective qualities towards heat, temperature, and vertical displacement.

In Electrical and Electronic Components

Automotive stamping advantages exist in the production of many smaller critical electrical and electronic elements too, such as busbars that convey high currents, connectors that attach to numerous different high-voltage electrical systems, and heat sinks that reduce the thermal load of today’s electrical and electronic systems. The accuracy of stamped metal parts ensures reliable electrical conductivity and efficient operation.

In Suspension and Braking Systems

There are many components of the EV’s suspension system that are also produced from metal stamping, such as brackets, mounting plates, and many of the components in the braking mechanism. Due to the level of precision, consistency, and strength that is available for many of the applications, it can help you to guarantee that due to the weight of other systems required.

Key Processes in EV Metal Stamping

Overview of Stamping Processes

At the heart of EV metal part stamping are several fundamental processes that transform flat metal sheets into complex three-dimensional components.

- Blanking: Blanking is typically the first operation. It is the process of cutting a larger piece of metal into a smaller, precise shape referred to as a “blank.” The blank is sized and shaped for the final part and creates less wasted material.

- Forming: Forming is the action of bending, stretching, or changing the shape of the metal blank into a three-dimensional shape. This includes simple bends or a more complex draw where the metal is stretched over a die.

- Piercing: The process of piercing is essentially punching holes or cutouts into the blank. Piercing is important on parts that will need fasteners like screws or bolts or an opening for another part to pass through.

- Coining: Coining is the process of applying very high pressure to a metal surface to create very fine, shallow indentations or raised features that are very accurate. Coining is frequently used for fine details, thickening certain areas, or creating a surface texture.

- Trimming: The next step is to trim the leftover material outside of the part’s shape. The trimming process is a critical finishing operation. It allows the finalized part to have crisp and accurate edges and dimensions.

- Flanging: Flanging is bending the edge of a metal sheet or part to create a flange – a rim or an edge. Flanging can provide stiffness and mounting capabilities or create a jointing area.

Advanced Die Techniques

To handle the intricate designs and high production volumes required for EVs, automotive metal stamping utilizes several advanced die techniques.

Progressive Die Stamping

Progressive die stamping is a highly efficient, high-speed process that uses one linear strip of metal and then moves this strip of metal through a series of stamping operations that are all enclosed within one press. As the strip of metal continues through the automotive metal stamping process, each specific stamping station will cut, bend, punch, or form the strip in a specific order of operations.

When the metal strip completes the die, you will typically have a separated or “blanked” part at the end of the process. This method is perfect for high-volume production runs, as you can perform multiple tasks at once. It is tremendously efficient for high-volume automotive stamping applications, such as stamping EV battery contacts or similar detailed connectors. It significantly reduces handling time and boosts productivity.

Compound Die Stamping

Compound die stamping offers a different approach to efficiency. Unlike progressive dies that perform operations in sequence, compound dies perform multiple cutting and forming actions simultaneously in a single stroke of the press. This means that a finished part, often a flat part with some internal features, will be produced with each press cycle. This process type is extremely economical for most parts, especially if the company is stamping simpler high-precision parts where all cuts and forms occur in one step. It’s known for its accuracy and consistency in producing flat components.

Transfer Die Stamping

Transfer die stamping is a more flexible process often used for larger or more complex parts where the formed piece needs to be physically moved between different stamping stations. In this type of process, the metal sheet is cut into a blank first. At the first operation, the formed part is cut free from the sheet and is then mechanically moved, either by robotic arms or a type of transfer bar system, to the next station for additional operations.

There can be more complex and diverse designs than seen in progressive stamping, so the designers can design each station independently. Transfer die stamping is particularly ideal for large components like EV motor housings, chassis parts, or other intricate structural elements where multiple deep draws or significant forming operations are required.

Design Tips for EV Metal Stamping

When developing parts for EV metal stamping, there are several specifics to ensure manufacturability, cost, and performance of the part.

Optimize for Lightweighting

Always consider using materials like aluminum and Advanced High Strength Steels (AHSS). An important design consideration is to design the part as thin as the material allows, but not if you compromise the structural integrity. In automotive applications, your EV’s weight is a factor affecting range and efficiency.

Minimize Sharp Corners

Design plans should include rounding out sharp internal and external corners whenever possible. Sharp corners create stress concentrations on the metal stampings for EV manufacturers, potentially leading to a shorter part life because of cracks or material fatigue. A radius corner allows for a smoother flow of the material during the metal stampings for EV manufacturers and can also lead to a longer part life of the component.

Consider Tolerances

Be careful with the tolerances needed for your parts. While metal stampings for EV manufacturers are highly precise, overly tight tolerances can be costly in tooling and reduce manufacturability. Be aware of the functional properties of the part (i.e., the needed sealing for battery seals) and note tolerances that are critical.

Design for Manufacturability (DFM)

Simplify shapes and features where possible to lower production costs and reduce manufacturing challenges. Consider how the stamped metal parts will be blanked, formed, and pierced in the dies. Designing with DFM in mind can prevent costly reworks and optimize production efficiency.

Ensure Sufficient Flanges and Bends

If your part is designed with bends or flanges, you must consider how much material is available for bends or flanges without tearing or thinning too much. It is also critical that you think about bend radius and flange width to help ensure that the metal stampings for EV manufacture are successful.

Account for Springback

Metal will spring back slightly when bent or formed. It is important to account for this “spring back” in die development so that the part reaches the desired angle or shape. Collaborate closely with your stamping partner to manage springback effectively.

Standardize Features

If possible, try to standardize features like hole sizes, bend radii, and material thicknesses across parts. This might allow for better tooling efficiencies and lower costs.

Precision Stamping Services for EV Manufacturers

High-quality EV metal part stamping includes more than a manufacturing process; it is vital to the successful production of electric vehicles. Stamped metal parts have precision, durability, and lightweight characteristics that all have a direct effect on the performance, safety, and cost-effectiveness of every single EV.

This is where Fecision comes in. We understand the unique demands of the EV industry and offer specialized precision stamping services designed to meet those needs head-on. Our capabilities include:

- High-speed presses: Our high-speed presses are designed for mass production, which allows for our turnaround times to be fast and efficient without compromising on quality.

- Custom dies: We build custom dies that will produce even the most complex geometries of your EV components, producing precision stamping with high quality through the entire production run.

- Strict quality assurance: Quality is everything to us. We follow strict quality assurance policies and ISO-certified processes with robust precision testing to ensure every part we make meets quality assurance requirements.

Looking for reliable automotive stamping solutions for your electric vehicle components? Reach out to Fecision today! We would love to chat about how we can leverage our precision EV metal part stamping to streamline your electric vehicle production and drive innovation.