The healthcare sector uses diverse medical devices — from single-use disposables to complicated diagnostic devices — as these devices help to diagnose, treat, and track patients and improve and save lives. With the rapid advancement of medical technology, the demand for precision, reliability, and efficiency in the manufacturing of these devices has never been higher.

Among the various manufacturing processes available, medical plastic injection molding has become unique in producing complicated medical parts in high volume. Today, we will explore how medical plastic injection molding technology is vital in the application of one such important part – chemistry reagent discs.

Overview of Plastic Injection Molding for Medical Parts

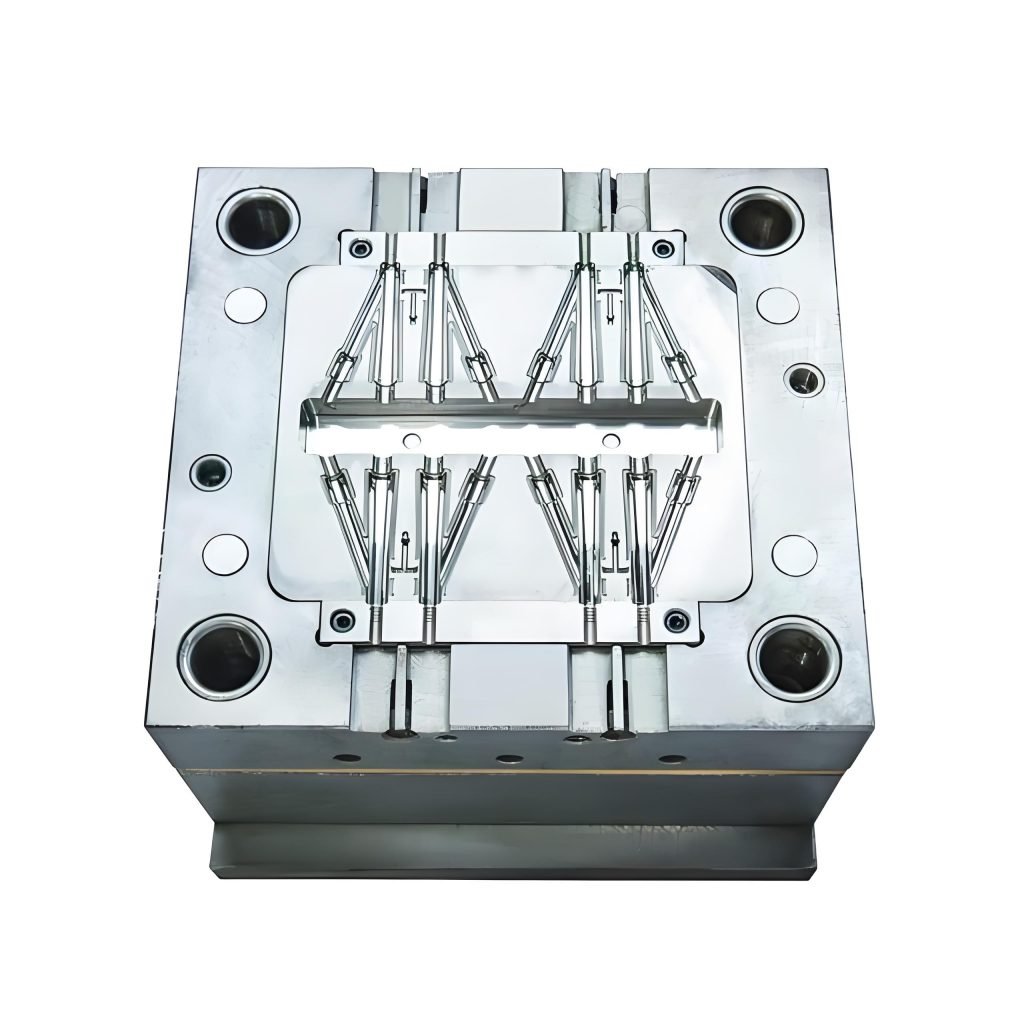

So, what is medical plastic injection molding? It is an orderly, accurate manufacturing method that uses a superior-shaped mold into which hot molten plastic materials, in liquid form, are placed under high pressure in the mold cavity. After the cooled and solidified plastic material is removed from the molded part, the molded part is ejected by opening the mold. The process has clear benefits in producing high-volume, precision medical parts.

Consistency and Precision in Production

Injection molding is usually said to be an ideal manufacturing process for producing identical parts, time and time again, while maintaining very tight tolerances. For medical devices, having uniformity, fidelity, and getting the part completed accurately is paramount since various components and parts that can differ by millimeters can affect performance or safety.

Imagine a diagnostic test; the accuracy of that test can depend on the precise volume of a well or the exact shape of a channel in a chemistry reagent disc. Medical plastic injection molding techniques ensure these features are replicated flawlessly across millions of units.

Design Flexibility and Customization

Do you have a complex part design in your head? You can use injection molding medical plastics to achieve complexity in geometry and features in a way that is likely not possible to achieve with any other manufacturing process. This opens new doors for you as designers and engineers to be creative, thereby designing and developing medical devices that are more effective, easier to use, and compact. From microfluidic channels to specific surface textures that interact with biological samples, the design possibilities are vast.

Cost Efficiency for Mass Production

While the initial investment for making a high-quality mold may be high, the cost per part becomes extremely low once you are producing in potentially high quantities. This is why leading medical plastic injection molding companies like Fecision specialize in high-volume production of disposable medical components. In the case of disposable medical items or components made in high quantities for medical devices, like chemistry reagent discs, plastic injection molding medical devices become a viable economic solution. This cost-effectiveness helps make advanced medical technologies more accessible.

Now, let’s narrow our focus and see how these benefits translate to a specific, vital application: the production of chemistry reagent discs.

What Are Chemistry Reagent Discs?

You might be asking, “What are chemistry reagent discs?” They are sophisticated, and often, compact, circular devices designed to hold a multitude of chemical reagents, usually in individual wells or chambers. Their primary role is to make automatic diagnostic testing possible. You could think of them as miniature laboratories on a disc. Many automated chemistry analyzers and point-of-care testing (POCT) devices use chemistry reagent discs as one of their fundamental working parts.

Key Features That Make Reagent Discs Essential

- Compact and Circular Design: The small form makes it very easy to be integrated into various analytical instruments.

- Multiple Reagent Wells: Multiple analytes can be tested simultaneously from a single sample, which can streamline the diagnostic process

- Ready-to-Use Format: No preparation of filling reagents, which reduces the chance of error and saves time.

The Benefits You Gain from Using Reagent Discs

All-in-One Testing Capability

Many chemistry reagent discs are designed as test panels, allowing multiple tests to be run simultaneously from a single, small patient sample. This is incredibly efficient and patient-friendly. For example, a liver function panel or an electrolyte panel can be performed using one disc.

Quick and Simple Operation

For healthcare professionals, especially in fast-paced and resource-constrained locations, chemistry reagent discs represent a large simplification of the testing process. Many times, the steps involve taking the sample and putting it into the disc, and placing it in the analyzer. The automated procedures of today often eliminate the hands-on time and potential for human error.

Versatile Applications

You’ll find chemistry reagent discs being used extensively in veterinary clinics for rapid animal diagnostics and in human POCT devices in doctors’ offices, emergency rooms, and remote clinics. They enable quick decision-making by providing results within minutes rather than hours or days.

Key Applications of Plastic Injection Molding in Chemistry Reagent Discs

The precise manufacturing capabilities of injection molding medical plastics are essential in realizing the full potential of chemistry reagent discs in multiple application settings. Let’s briefly discuss some specific markets where we are seeing this harmony play out in the healthcare sector.

1. Precision Requirements Dictate Manufacturing Solutions

Chemistry reagent discs require extremely tight dimensional tolerances, particularly for microfluidic channels, which often need ±0.01 mm accuracy. Advanced injection molding achieves this precision through controlled melt temperature, pressure profiles, and optimized cavity filling, ensuring material stability and complete replication of fine features.

Modern optical measurement systems are integrated into in-line quality control, automatically verifying critical microstructures during high-volume production. This combination of process control and precision mold design guarantees consistent part quality across batches, ensuring reliable diagnostic results.

2. Structural Complexity Enabled by Injection Molding

Today’s reagent discs feature multilayer constructions, intricate microfluidic networks, and integrated venting systems—designs that would be impractical to mass-produce using traditional methods. Injection molding allows these complex geometries to be manufactured as single, integrated components.

Multi-cavity molds enable the simultaneous production of dozens of discs with identical channel designs. Gas-assisted molding further enhances structural integrity while achieving ultra-thin walls. The ability to cost-effectively produce intricate 3D fluidic pathways has revolutionized point-of-care diagnostic devices.

3. Material Innovation for Diagnostic Accuracy

Medical-grade polymers with specialized surface properties are critical for reagent disc performance. Injection molding processes have been adapted to handle low-protein-adhesion materials while maintaining diagnostic efficacy. For optical detection applications, molding fluorescence-compatible transparent polymers requires precise thermal control to prevent distortion.

Advanced tooling techniques can create controlled surface energy variations within a single part, producing distinct hydrophilic and hydrophobic zones that guide fluid flow without additional post-processing.

4. Compliance with Medical Standards

Manufacturing diagnostic components demands adherence to strict cleanliness and regulatory standards. Closed-loop injection molding systems prevent contamination, while automated cleanroom handling ensures aseptic transfer from mold to packaging.

Process validation protocols document all critical parameters, ensuring compliance with medical device regulations (ISO 13485, FDA 21 CFR Part 820).

5. Economic Viability for Disposable Devices

Injection molding offers significant economies of scale for high-volume, disposable reagent disc production. Quick-change mold systems minimize downtime when switching between product variants.

Scientific molding techniques optimize cycle times while maintaining quality, allowing high-throughput production with tight tolerances. This makes injection molding highly cost-effective for large-scale diagnostic applications.

6. Emerging Technologies in Diagnostic Molding

Recent advancements in microcellular foaming injection molding enable the production of lighter-weight reagent discs without compromising structural performance. The integration of in-mold electronics creates opportunities for smart diagnostic devices with embedded sensors. Advances in the processing of biodegradable polymers are developing to meet increasing sustainability requirements in medical diagnostics. All of these advances reaffirm that injection molding is still evolving to meet the demands of diagnostic devices.

In these applications, what remains consistent is the demand for high accuracy and reproducibility, along with the factor of mass production – all hallmarks of medical plastic injection molding. The capability to craft intricate geometries, guarantee biocompatibility when necessary, and adhere to stringent quality control measures renders this manufacturing process essential for the production of contemporary chemistry reagent discs and comparable diagnostic consumables, including reagent panel and reagent tray.

Conclusion: Partner With Fecision in Reliable Medical Device Manufacturing

To summarize, plastic injection molding is a great foundation for the efficient and accurate production of chemistry reagent discs, which are critical tools in modern healthcare and beyond. As diagnostic testing, microfluidics, and environmental analysis increase, the importance of these devices becomes more critical.

Selecting medical plastic injection molding companies for your diagnostic components is an important step to work with partners who have experience in medical-grade production. Fecision specializes in making high-performance medical components with Plastic Injection Molding for Medical Parts services At Fecision, we specialize in manufacturing high-performance medical components for Plastic Injection Molding for Medical Parts services with:

✔ ISO 13485 Certification – Meeting strict medical industry standards.

✔ Biocompatible Materials – Ensuring safety.

✔ End-to-End Solutions – All the way from prototyping to mass production.

Whether you need reagent discs, microfluidic chips, or any other plastic injection molding for medical devices, we provide high-quality, efficient, and cost-effective solutions. Contact us today!