When it comes to shaping metal with precision, speed, and efficiency, metal stamping stands out as one of the most cost-effective manufacturing processes. However, not all stamping methods are equal, and using the wrong one could lead to wasted material, poor tolerances, and costly redesigns.

To avoid these pitfalls, it’s essential to understand the four core types of metal stamping services and how each one works. Let’s explore them: Type 1: Progressive Die Stamping

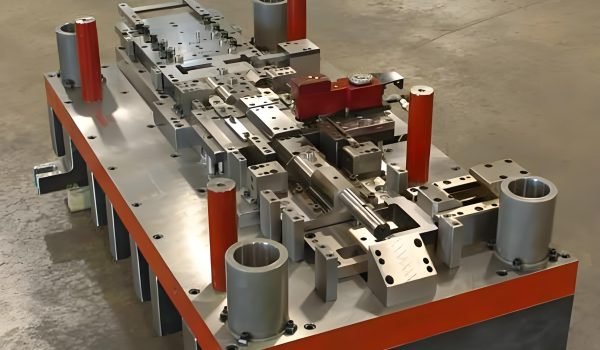

Progressive die stamping is one of the most successful and widely used stamping techniques in high-volume production. It combines multiple operations, such as cutting, bending, coining, and punching, into a single continuous process.

How Does It Work?

A progressive die is made up of a series of individual stations, each performing a specific function on the metal strip as it moves through the press. The metal strip is fed into the machine and automatically advanced after each press stroke.

With each movement, the material is precisely positioned so that each section reaches the next die station in sequence. By the time the strip reaches the final station, a completely formed part is separated from the rest of the strip, ready for use.

Advantages

- High Efficiency: Multiple operations are performed in a single press cycle, drastically reducing production time.

- Consistency and Accuracy: Because the entire operation is automated, parts are produced with high precision and repeatability.

- Minimal Waste: Optimized tooling and layout reduce scrap, which lowers material costs.

- Low Labor Costs: Once set up, the process requires minimal manual intervention.

Applications

Progressive die stamping is a go-to solution for manufacturing automotive components, electrical contacts and connectors, appliance parts, and consumer electronics frames.

Type 2: Transfer Die Stamping

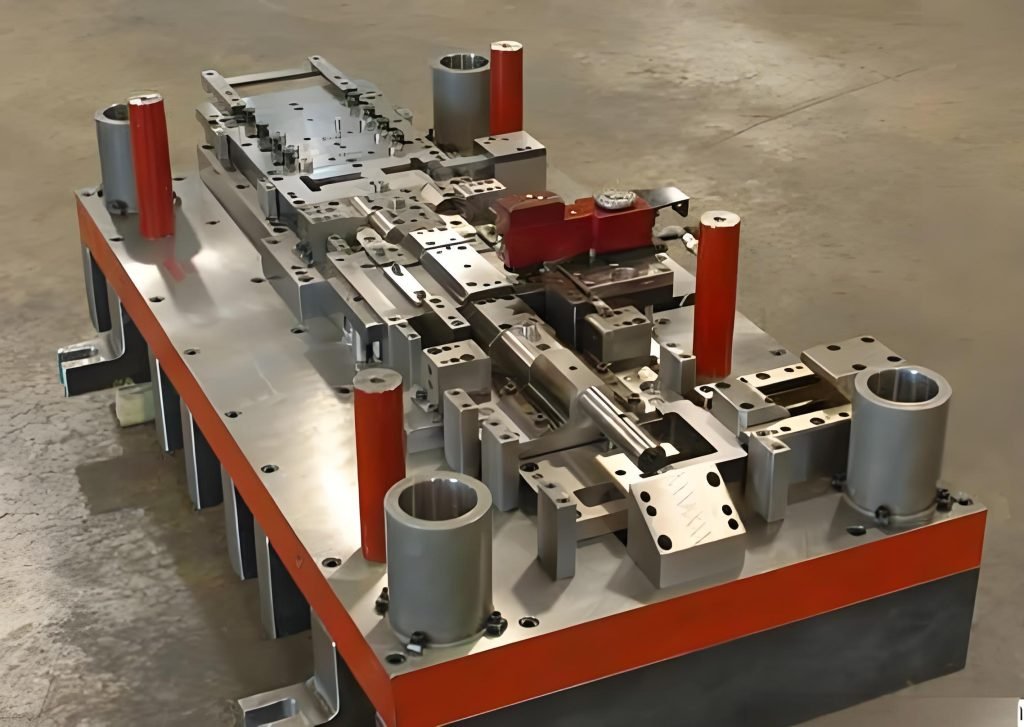

Transfer stamping die is a highly versatile metal forming method used when parts require complex, multidirectional shaping or are too large or delicate for progressive dies. Unlike progressive stamping, the entire part is transferred from one die station to the next rather than connected by a metal strip.

How Does It Work?

In transfer die stamping, a blank (a pre-cut piece of metal) is separated at the very beginning of the process. From there, robotic or mechanical transfer mechanisms move that individual blank from station to station inside the press.

Each die station performs a distinct operation, such as drawing, punching, forming, trimming, or piercing. Since the part is not connected to a metal strip, it can be formed from all sides, allowing for deeper draws or more intricate shapes.

Advantages

- Greater Part Design Flexibility: Ideal for forming deep-drawn or complex shapes that aren’t possible in a progressive setup.

- Handles Larger or Odd-Shaped Parts: Since each part moves independently, it doesn’t need to be attached to a strip.

- Efficient for Medium to High Volumes: Once set up, the system is highly repeatable and efficient across longer runs.

- Customizable Operations: Stations can be added or changed based on evolving part requirements.

Applications

This type of custom metal stamping is widely used in industries where structural integrity, deeper forms, and tight tolerances matter. Typical applications include automotive components, heavy-duty appliance parts, HVAC system housings, and more.

Type 3: Deep Draw Stamping

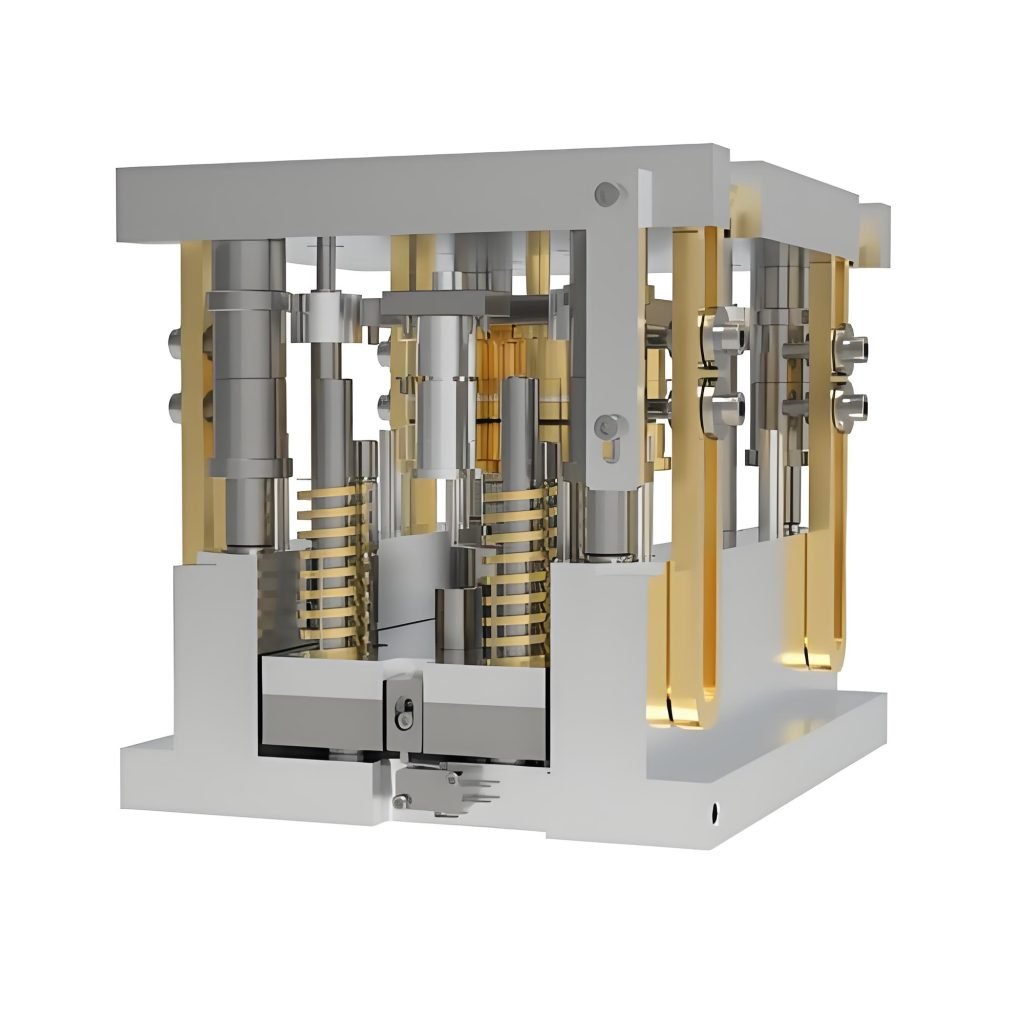

Deep draw stamping is a specialized metal forming process used to create hollow or cup-like shapes by stretching the metal beyond its original flat form without breaking or thinning it excessively. It’s perfect for making strong, seamless, and lightweight parts with depth.

How Does It Work?

In deep draw stamping, a metal blank is placed over a die and pushed (or “drawn”) into the die cavity by a punch. As the punch moves downward, the metal stretches into the desired shape.

Unlike other stamping methods that bend or cut, deep drawing involves material flow in the vertical direction. It allows greater part depth without adding extra seams or joints.

Advantages

- Produces Seamless, Strong Parts: No need for welding or assembly, which improves structural integrity and reduces failure points.

- Material Efficiency: Uses a single blank with minimal waste.

- Great for High-Volume Runs: Once tooling is in place, the process is fast, repeatable, and cost-effective.

- Ideal for Lightweight Designs: Helps reduce material use while maintaining strength. This makes it perfect for weight-sensitive industries.

Applications

Deep draw stamping is used to manufacture parts that are deep, tubular, or need to hold fluids such as automotive components (fuel tanks, oil filters, transmission components), consumer products (kitchen sinks, aerosol cans, cookware), and medical (syringe barrels, implant housings, surgical containers).

Type 4: Multi-Slide Metal Stamping

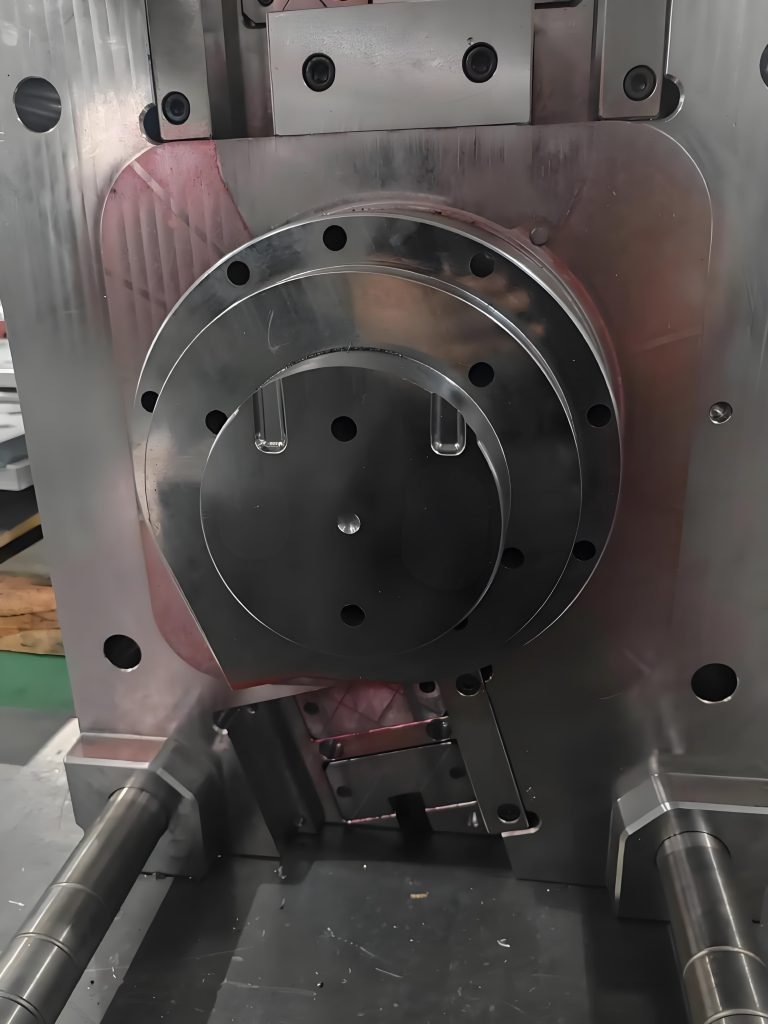

Multi-slide metal stamping (also called four-slide stamping) is a unique, highly flexible process designed to produce complex parts with multiple bends or intricate forms—all in one seamless operation.

These multi-direction machines use multiple moving slides to shape the metal from different angles at once.

How Does It Work?

In a multi-slide machine, the metal strip is fed horizontally into the machine. Instead of a top-down press, the machine uses four or more tool slides that move in from different directions. These slides operate simultaneously, bending and forming the metal into shape with high precision.

This setup allows for detailed, multi-axis bending and forming, all done rapidly in a single cycle without transferring the part between stations.

Advantages

- High Precision for Complex Parts: Ideal for components requiring multiple bends, angles, or intricate shapes.

- Lower Tooling Costs: Compared to traditional progressive dies, multi-slide tools are often faster and cheaper to produce and maintain.

- Fast Cycle Times: With all operations happening simultaneously, production speeds are incredibly efficient.

- Flexible Design Changes: Easier to adjust tooling for design tweaks or small production runs without major retooling.

Applications

Four-sided metal stamping is used across industries where complex geometry and small part size are common.

For instance, electronics include connectors, terminals, and spring contacts; automotive components such as brake clips, retaining springs, and small brackets; and aerospace components such as lightweight fasteners and wire forms.

How to Choose the Right Metal Stamping Method

Choosing the right metal stamping method depends on your part’s shape, size, complexity, and production volume.

- Use progressive die stamping for high-volume runs of small to medium parts with simple or moderate complexity.

- Choose transfer die stamping when the part is large or needs deep draws and multiple complex steps.

- Go with deep draw stamping if your part is cup-shaped, cylindrical, or needs to hold liquids.

- Pick multi-slide stamping for small, intricate parts with multiple bends from different angles.

Partner with Fecision for Smarter Metal Stamping Solutions

Choosing the right metal stamping method can streamline your production, reduce costs, and ensure part reliability—but only when matched with expert tooling and execution.

That’s where Fecision comes in.

We provide expert mold tooling, CNC machining, and stamping services customized to your exact requirements.

Contact Fecision today to get started.