You’ve probably handled countless silicone products without giving them a second thought—from heat-resistant baking molds in your kitchen to sweatproof fitness bands on your wrist. These seemingly similar rubbery materials hide a critical safety divide.

The line between standard silicone and medical-grade silicone runs far deeper than most realize, tracing back to molecular-level precision and extending into life-or-death scenarios. When a baby bottle nipple withstands boiling water, an artificial joint integrates with living tissue, or surgical tools endure hundreds of sterilization cycles, even trace contaminants (measured in parts per million) can rewrite health outcomes.

This divergence starts with manufacturing rigor. While standard silicone prioritizes cost-efficiency on factory floors, medical-grade variants undergo pharmaceutical-grade refinement in dust-free labs. Consider the difference between hiking boots and mountaineering gear—the stakes define the standards.

What Is Silicone?

Silicone is like a rubbery plastic, but softer. Do you know how sand has silicon in it? Scientists mix that with oxygen and other stuff to make silicone. It’s super flexible and doesn’t melt easily—imagine using a silicone spatula in a hot pan or a phone case that survives summer heat.

Why It’s Widely Used

- Heat Resistance:

Ordinary silicone can handle extreme temperatures, making it ideal for oven mitts and industrial seals. For example, silicone baking mats endure repeated oven cycles without degrading.

- Chemical Stability:

It resists water, oils, and UV radiation, which is why waterproof bathroom seals and outdoor electronic coatings rely on it.

- Skin Safety:

Food-grade silicone passes basic safety tests, so baby bottle nipples and kitchen utensils often use it. However, low-quality variants may still release traces of siloxanes (volatile compounds) during prolonged use.

Limitations to Consider

- Cost vs. Performance:

High-purity silicone production requires expensive platinum catalysts, driving up costs compared to plastics. A silicone phone case might cost 3x more than a plastic one, despite similar durability.

- Environmental Impact:

While reusable, silicone isn’t biodegradable. Discarded silicone products linger in landfills for centuries unless sent to specialized recycling facilities.

- Strength Constraints:

Silicone lacks the tensile strength of metals. For instance, silicone straps on smartwatches may snap under heavy tension, unlike steel bands.

- Medical Risks:

Non-medical grades might contain unreacted monomers or fillers. A study found that some cheap silicone bracelets caused skin irritation due to residual chemicals.

What Is Medical Grade Silicone?

Medical grade silicone for molding is the “hospital-safe” version of regular silicone. It’s designed to meet super strict rules (like ISO 10993 and USP Class VI tests) so doctors can use it in surgeries, implants, or devices that touch your body for years. For example, it’s used in drip tubes, artificial heart valves, or even the soft tips of hearing aids.

Good things about it:

- No nasty stuff inside: Regular silicone might have tiny chemicals from production, but medical-grade versions are cleaned so well that even sensitive skin or organs won’t react to it. Think of baby bottle nipples—safe for boiling and daily use.

- Survive hospital cleaning: It doesn’t melt or crack when sterilized with steam, strong chemicals, or radiation. Surgical tools made from this material can be reused safely hundreds of times.

- Built to last: Unlike cheaper silicone, medical silicone injection molding types stay flexible and strong for decades. Pacemaker parts or joint implants made from it won’t break down inside your body.

But it’s not perfect:

- Costs a fortune: Making it requires expensive materials and labs to check purity. A simple medical-grade silicone seal can cost 5x more than a regular one.

- Hard to produce: Factories need super-clean rooms (like for computer chips) to stop dust from ruining the silicone. Even tiny flaws can make a batch fail safety checks.

- Design headaches: Engineers have to plan carefully—if a mold is slightly wrong, the final product might have bubbles or weak spots. Most companies need experts (like Fecision’s team) to avoid these problems.

Key Differences in Properties

| Property | Medical Grade Silicone | Industrial Grade Silicone |

| Purity | Highly purified; no harmful additives or contaminants. | May contain fillers, dyes, or chemicals to enhance performance. |

| Biocompatibility | Tested and certified safe for prolonged contact with human tissue (e.g., implants). | Not tested for biocompatibility; may cause skin irritation or allergies. |

| Regulatory Standards | Must meet strict FDA/ISO standards for safety and quality control. | Follows general industrial standards; no medical safety certifications required. |

| Temperature Resistance | Stable across a wide range (-60°C to 250°C) but optimized for body-safe applications. | Often modified for extreme temperatures (e.g., -70°C to 300°C) in harsh environments |

| Chemical Additives | Free from toxins, heavy metals, or volatile compounds. | May include additives (e.g., flame retardants) for specific industrial uses. |

| Applications | Medical devices (implants, catheters), baby products, wound care. | Automotive parts, machinery seals, electrical insulation, and construction materials. |

| Cost | Higher cost due to strict production controls and certifications. | Lower cost; optimized for bulk production and industrial demands. |

Medical silicone is designed with biocompatibility to prevent immune reactions, whereas industrial grades focus on durability rather than safety. Despite visual similarities, regulatory differences make industrial silicone unsuitable for medical use. Industrial formulations often contain performance-enhancing additives like heat-resistant compounds, which improve functionality but reduce safety for healthcare applications. These critical distinctions prevent interchangeable use between the two grades.

Choosing Between Regular Silicone and Medical-Grade Silicone

Selecting the right silicone type depends on how the material will be used and what safety standards it must meet. Below is a detailed guide to help you decide without technical jargon.

Part 1: Regular Silicone – Best for Non-Medical Uses

- Household Items

Kitchen Tools: Spatulas, baking molds, and oven gloves work well with regular silicone. It handles temperatures up to 230°C (common in home ovens) and is easy to clean.

Seals & Gaskets: Bathroom sealants or window insulation strips don’t need medical grade silicone injection molding purity. Regular silicone resists water and lasts 2-5 years in these applications.

- Industrial Prototyping

When making experimental molds or trial products (like rubber parts for machinery), regular silicone saves costs. It’s suitable for testing shapes and functions before investing in higher-grade materials.

- Short-Term Wearables

Watch bands or fitness tracker straps that touch skin briefly (under 8 hours/day) can use regular silicone. Avoid it if users have sensitive skin or allergies.

Limitations:

• Breaks down faster when exposed to oils or strong chemicals.

• Not approved for situations requiring sterilization.

Part 2: Medical Grade Silicone – Essential for Healthcare

- Implantable Devices

Pacemaker components, artificial joints, and cosmetic implants require medical grade silicone molding. It’s tested to be safe inside the body for years without causing reactions.

- Long-Term Skin Contact

Products worn continuously (like diabetic wound dressings or prosthetic liners) need this grade. Regular silicone might irritate the skin after weeks of use.

- Sterilizable Equipment

Surgical tools, breathing tubes, or lab equipment that undergo steam/chemical cleaning must use medical-grade silicone. Regular types crack under repeated sterilization.

Part 3: Decision Checklist

Ask these questions to choose correctly:

| Question | Regular | Medical |

| Will it touch internal body parts? | × | √ |

| Does it need daily sterilization? | × | √ |

| Is the user a child/elderly? | × | √ |

| Is cost more important than safety? | √ | × |

Examples:

- Home Kitchen: Regular (cost-effective, no sterilization)

- Hospital IV Line: Medical (body contact, frequent cleaning)

- Car Engine Gasket: Regular (high heat but no safety risk)

Part 4: Common Mistakes to Avoid

- Using “Food-Grade” for Medical Needs

Food-safe silicone meets standards different from medical silicone molding. Don’t assume they’re interchangeable.

- Ignoring Cleaning Requirements

Regular silicone degrades if cleaned with alcohol or bleach regularly.

- Overpaying for Simple Tasks

Medical-grade costs 4-8x more. Use it only when necessary.

Conclusion

Getting silicone parts right in healthcare isn’t just about picking materials—it’s about choosing partners who know what “medical-grade” truly means. While generic silicone works for everyday items, products touching patients’ lives need more: precision molds, contamination controls, and proven compliance.

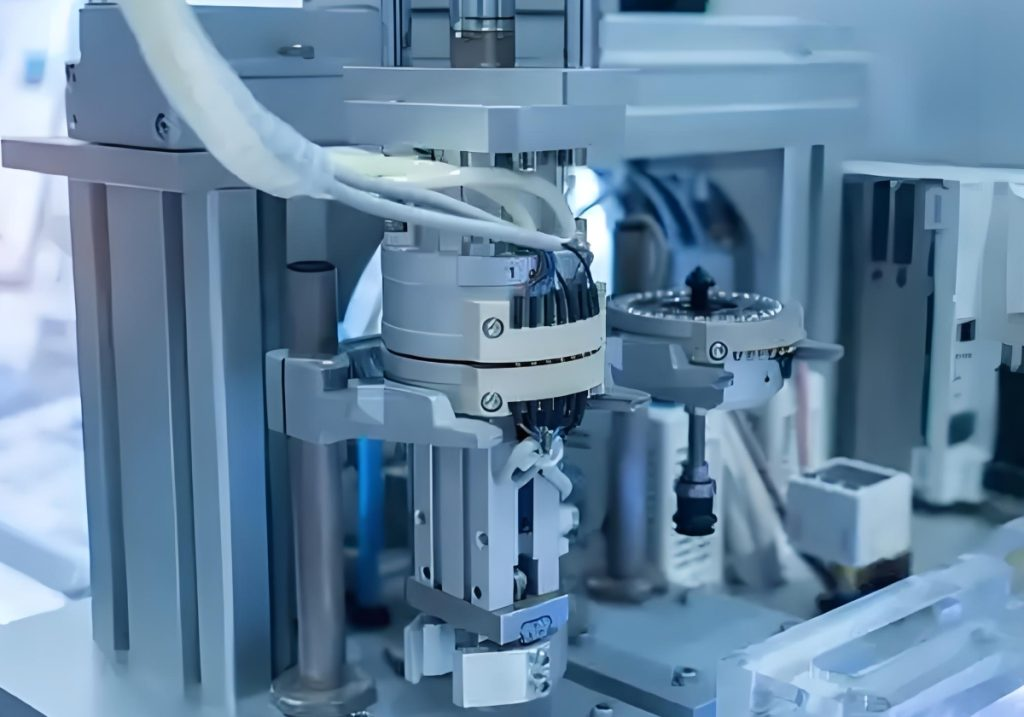

At Fecision, we’ve spent years earning trust from medical device makers. Our certified processes ensure biocompatibility, durability, and patient safety for critical healthcare applications. How? By treating every project like it’s destined for an operating room. Our workshops look different from typical factories—here’s why:

- Ultra-Precision Molding: Best tolerances for microfluidic devices, implants, and seals

- Medical-Grade Materials: USP Class VI & FDA-compliant silicones for long-term bodily contact

- End-to-End Validation: Full traceability, cleanroom production, and sterilization compatibility

- Rapid Prototyping to Mass Production: Accelerated development cycles without compromising quality

- Custom Formulations: Tailored hardness, transparency, and drug-eluting properties

If you’re tired of suppliers who treat medical orders like regular plastic work, explore our mold tooling rigor. With Fecision, you’re not just buying parts—you’re securing a partnership that treats safety as non-negotiable.