If you are reading this with any larger interest in injection molding or are working on an injection-molded part, then it is good for you to have a basic understanding of parting lines. Let’s explore what parting line injection molding is, how they are created, some types of parting lines, and how to design with a parting line in mind.

What Is the Parting Line in Injection Molding?

What is parting line in injection molding? The parting line, or injection molding parting line, is the definitive physical attribute that separates the two halves of your injection mold. All injection-molded parts come with parting lines, since in a way, it’s a continuous line that references the overall contour of your part.

While it may appear to be a simple straight division between two mold halves in less complicated geometries, the path of a part line will become considerably more complex and varied for complicated three-dimensional parts. Think of it like the equator in your molded world, separating the two territories of a part by the two halves of the mold.

Though this line seems a subtle detail, it is significant to both the function and look of your part. The location of the parting line first determines the aesthetics — or at which place that faint seam can be seen — but it also directly influences where you can place other design features. You must think carefully about the placement of important features when they cross the parting line; those features may become misaligned and inaccurate. If the parting line is poorly located, there could be complications in what the mold design looks like, increased potential for flash, and adverse effects on proper venting that could lead to defects like voids.

So, placing direct attention on the placement of parting lines can aid in preventing issues related to final accuracy, structural integrity, and quality of your final injection-molded part, all of which are paramount when it comes to efficiency and expense.

How Are Parting Lines Formed?

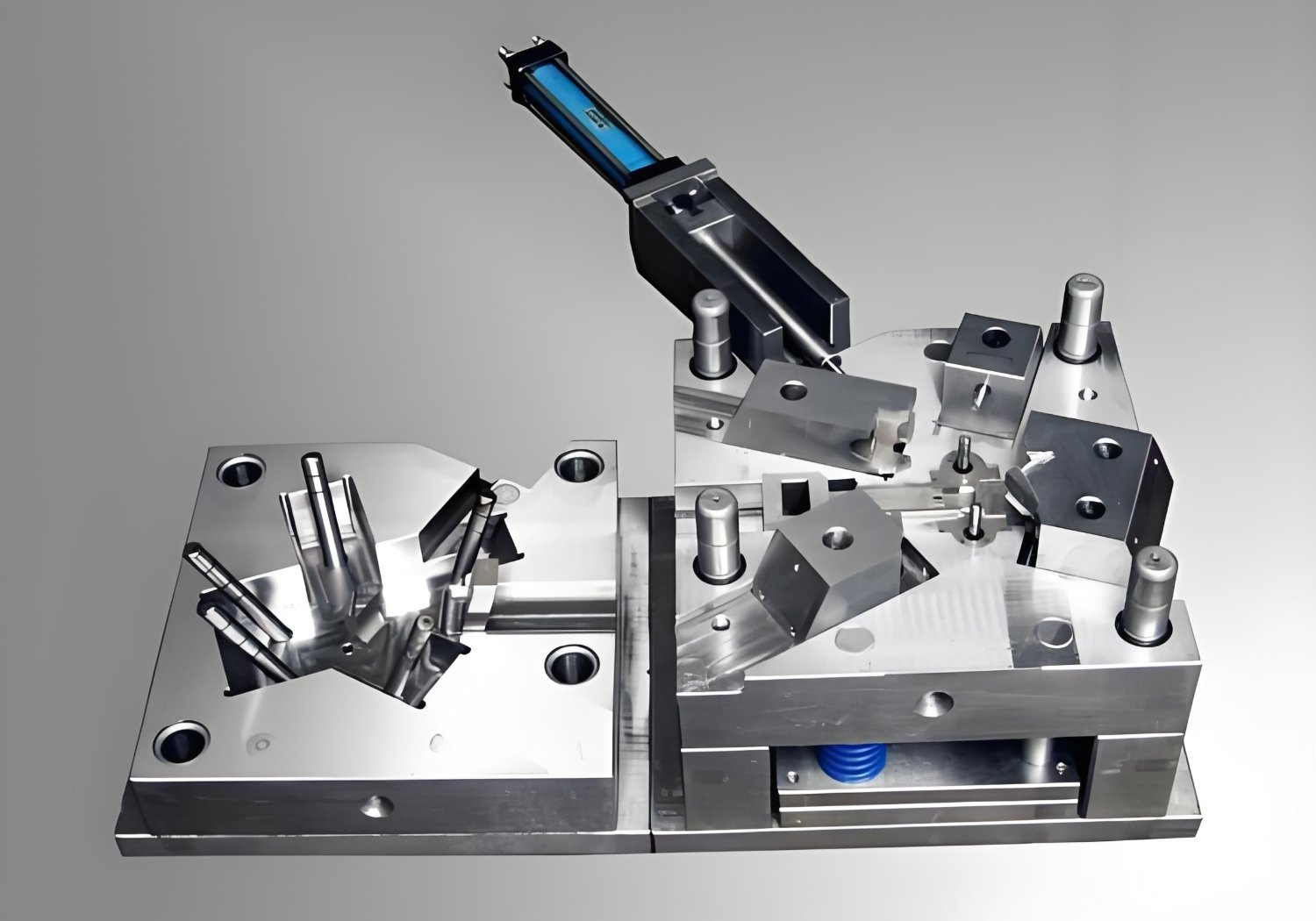

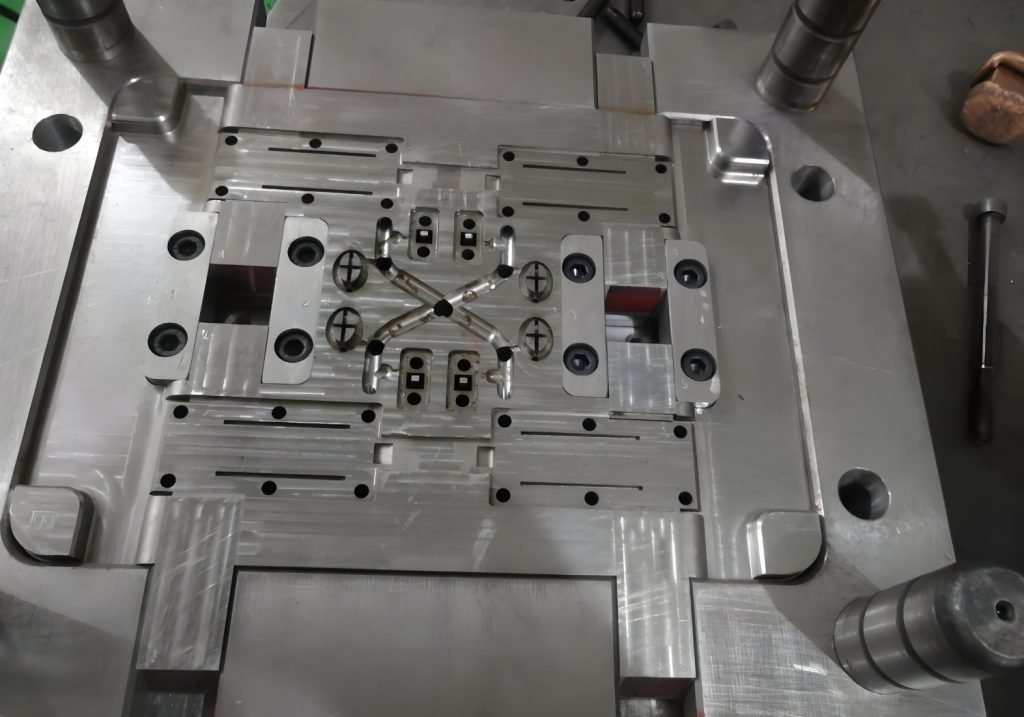

Injection-molded parts are typically produced using a mold that is comprised of two halves: a fixed half and a moving half. When the mold is closed, the two halves meet each other, and a line of separation exists at this joint, which is referred to as a parting line.

During the mold cycle, the two halves will be secured in position, and there will be considerable force holding the two halves together. The mold will be filled with molten material injected under pressure to form the cavity with heated plastic. The material solidifies in the shape of the mold, and then the material cools while in the mold. When cooling is complete, the mold will be opened on the parting line, and the finished part will be removed.

A void or misalignment, no matter how small, between the two halves of the mold will create a finish line in the molded part—or parting line. Generally, the parting line is perpendicular to the mold’s opening direction—on occasion, the mold will separate in multiple stages and from different directions—this is seen as multi-parting.

Types of Parting Line in Injection Molding

The orientation and complexity of the parting line vary drastically with the part geometry. Here are some common types you might see after knowing what is parting line injection molding:

Vertical Parting Line

This is perhaps the simplest type. A vertical parting line occurs when the mold halves part along a straight vertical plane. For example, think of a simple block or a cylinder molded in two halves, parting in a vertical direction. The resulting line that runs along the side will be a vertical parting.

Beveled Parting Line

A beveled parting line may be needed for parts that have some slightly angled or tapered sides. A beveled parting line is defined as a parting line that follows an angled plane to acknowledge the change in the draft angles for the easy removal of the part. The bevel itself will contribute to the parting from the mold without sticking.

Curved Parting Lines

For parts with curved or complex surfaces, a straight parting line cannot be used, and the parting line will follow some contour of the part itself—most often curved or irregular. The geometry must allow both mold halves to effectively create their portion of the complex geometry.

Stepped Part Lines

For parts that have features at different heights or planes, a stepped parting line may be used. A stepped parting line involves changes in the parting plane along the part’s surface, creating some “steps” or transitions needed to accommodate the differing geometry.

Comprehensive Parting Lines

Some very complex parts will require a combination of the above types; this is referred to as a comprehensive or complex parting line plastic injection molding. Comprehensive or complex part lines can be mixtures of straight, curved, and stepped, and all are designed carefully in order to allow a form to function (mold) and eject properly.

Injection mold parting lines vary in their geometry for the part, as parting lines are classified as vertical, beveled, curved, stepped, and quality, permitting mold separation and part ejection. The selection of parting lines will directly impact mold design, manufacturing cost, aesthetics, and function of the part.

If you want to set a parting line, you first will want to establish the basic shape of your part. In most cases, simple designs often suit a vertical parting line. A beveled parting line that matches the draft angles of a taper will allow for the proper ejection of a tapered part. Curved parts will have a curved parting line to follow the curvature of the part. Stepped parting lines are accomplished where the design has features that deviate in height.

However, complex parts will generally produce a comprehensive parting line that covers features from all these types of lines. Always remember to use the simplest line that allows for proper part ejection and the best function of the intended mold, which provides the least visible seams or lines in important or visible places of your part or object.

Factors to Consider When Designing Parting Lines

Paying attention to the parting line in the design phase is a vital step in improving the chances of a successful injection molding project, so here are a few things to consider.

| Factor | Description |

| Mold Design | The chosen parting line heavily influences the complexity and construction of the mold. Simpler parting lines generally lead to easier and more cost-effective mold creation. Consider how the parting line will affect mold alignment, venting channels, and the overall mold structure. |

| Component Placement | The placement of the parting line will differ when working with multiple design features, or inserts, in your part design. The placement may even impact how you will mold these inserts in the molded part to eventually be assembled. The placement of the parting line before or after adding would improve how the device is assembled and the integrity of the finished part design. |

| Drafting | Proper draft angles are essential for easy part ejection. The parting line must be designed in conjunction with these angles to prevent the part from getting stuck in the mold. Incorrect parting line placement can complicate the application and effectiveness of draft angles. |

| Design for Manufacturability (DfM) | Picking the right parting line is an important part of DfM. Think about how the parting line impacts manufacturability, namely cycle times, material flow, and whether secondary operations will be needed. An optimized parting line means a more cost-effective and efficient way to produce parts. |

| Flash and Ejection | An ill-advised parting line increases the chance of flash (leakage of excess material) and creates unnecessary problems with part ejection. Careful consideration of where the parting line will be placed and how it will fit will help to improve flash and part ejection, as the part will eject more easily and more efficiently without damage. |

| Costs | The selection of the parting line will impact the overall cost of injection molding your part. Complex parting lines typically necessitate a more complex mold and mold process, which will increase the cost of your mold or injection molding. Thinking of ways to create the parts parting line to be simple in geometry can save you overall costs |

- Strategic Parting Line Planning for Efficient Injection Molding

Early consideration of these design variables prevents costly complications by optimizing the parting line’s position. A well-planned parting line:

- Reduces mold complexity by simplifying alignment/venting and preventing flash/ejection issues

- Streamlines production through faster cycle times and fewer secondary operations

- Ensures manufacturability via proper draft angles, insert molding compatibility, and assembly-friendly geometry

- Directly lowers tooling and per-part costs while minimizing scrap from defects

Good thoughts on these interrelated items are critical, making your injection molding successful, efficient, and hopefully cost-effective.

Conclusion

While a parting line is often not a readily identifiable feature on a plastic part, it is an important principle concerning the injection molding process. Understanding how a parting line occurs, the types of parting lines, and considerations to be aware of while you are designing is an important part of developing a quality, functioning, and attractive part. Thoughtful parting line implementation leads to smoother production, fewer defects, and optimal results – making it a critical factor in successful plastic part development.

- Precision in Every Detail: Your Trusted Injection Molding Partner

At Fecision, we know that success in injection molding hinges on getting every detail right—especially critical elements like the parting line. Our team of experts guides you through each step, ensuring your part is optimized for performance, quality, and manufacturability.

With a full range of materials—including ABS, PE, and PP—we tailor solutions to meet your exact needs, whether you require impact resistance, chemical durability, or specialized finishes.

We’re committed to making your designs work:

- Free DfM feedback to refine manufacturability

- IP protection with encrypted data and strict NDAs

- End-to-end support—from design to production

Want to take your injection molding project to the next level? Contact Fecision today – we look forward to working with you to create batches of high-quality parts to your specifications. Whether you are new to injection molding or have worked with other firms, we would love to assist you every step of the way.

Partner with Fecision for confidence at every stage.