Injection molding is the most dominant method for mass-producing plastic parts. Cooling is undeniably one of the most critical stages of the entire process. Achieving the optimal cooling time has many benefits, such as dimensional accuracy, material strength, and, ultimately, high-quality products.

But how do we attain this optimal cooling window? Keep reading this article to learn more about the importance of cooling time in injection molding, key influencing factors, and different techniques to reduce cooling time in injection molding.

What is Cooling Time in Injection Molding?

Cooling time in injection molding is the period when the molten plastic remains within the mold cavity after injection to solidify properly for a safe ejection. It is a crucial phase of the molding process as it directly impacts the final part’s quality, dimensional accuracy, and overall production efficiency.

It’s like a phase change, in which the heated plastic transforms from molten to solid. Proper cooling time is necessary for the plastic to solidify properly and avoid issues like internal stresses, warping, shrinkage, and part deformation.

Why Does Cooling Time Matter?

Cooling time in injection molding has a direct influence on several key factors. From the overall cycle timing to dimensional stability and mechanical strength, it significantly affects the overall productivity and cost of the manufacturing process.

Let’s see how cooling time affects different aspects of injection molding:

1. Dimensional Stability

Proper cooling time is essential for dimensional stability in injection molding. It allows the molten plastic to solidify and shrink uniformly within the mold cavity. This controlled solidification maintains the dimensional stability of the part and prevents issues such as warping, distortion, or other forms of deformation.

2. Material Properties

Adequate cooling allows the polymer chains to arrange themselves in an optimal manner. It helps them achieve the desired crystalline structure and enhances their mechanical properties such as strength, rigidity, and impact resistance. On the other hand, insufficient cooling can result in a rigid, less rigid structure. This can negatively impact the overall performance of the molded component.

3. Surface Finish

Optimal cooling duration helps you achieve a high-quality surface finish in injection molded parts. An even solidification gives you a smooth and defect-free surface. Premature or prolonged cooling can cause visible surface faults like flow lines, sink marks, or a generally rough texture. These defects not only negatively impact the aesthetic appeal of the product but can also affect its functionality.

Factors That Influence Cooling Time

There are numerous factors that can impact the cooling time in injection molding. These factors range from the part’s design and material to the mold’s construction method. We will take a look at them one by one:

1. Material Type

The thermal properties of your chosen material directly impact the cooling time. Polymers with low melt temperatures require less energy, which leads to faster cooling cycles.

Common thermoplastics such as polyethylene (PE), polypropylene (PP), and Acrylonitrile Butadiene Styrene (ABS) have lower melting points than engineering-grade resins. These characteristics can improve production output and enable shorter cooling cycles.

2. Wall Thickness and Geometry

Certain applications, such as automotive bumpers, protective casings, or particular plastic gears, often require thicker walls for better structural strength. These thicker sections inherently require a longer duration to dissipate heat and solidify.

Beyond thickness, consider the overall shape and features of the part. Complex geometries with varying wall thicknesses or intricate details can lead to uneven cooling and longer cycle time.

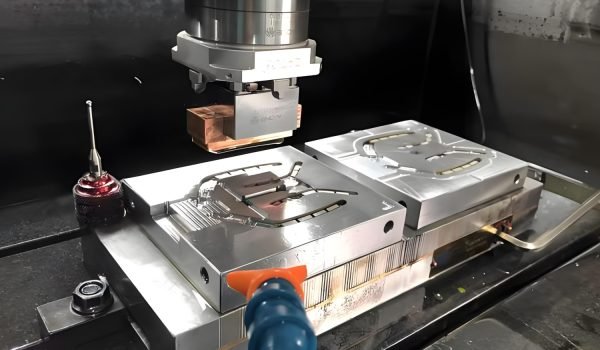

3. Mold Temperature and Cooling Channel Design

A lower mold temperature creates a major temperature differential between the molten plastic and the mold surface. This facilitates faster heat transfer, which reduces cooling times. Conversely, a higher mold temperature can slow down the cooling process.

The design and efficiency of cooling channels are equally critical. While many conventional methods exist, conformal cooling channels can be the best option. These advanced channels are often created using 3D printing and integrated during the mold cavity formation. Conformal cooling optimizes heat removal by closely following the contours of the part. This leads to a substantial reduction in the overall cycle time.

4. Processing Parameters

Different processing parameters, such as melt temperature, injection speed, packing pressure, and cycle time, can also influence cooling time. Higher melt temperatures require more time for the plastic to cool. Faster injection speeds can introduce more heat, potentially needing longer cooling. Similarly, a high packing pressure can increase material density and affect heat transfer.

Calculating Cooling Time Formulas

Calculating the cooling time in injection molding accurately can be complex, as it depends on numerous factors. Here are some of the most commonly used formulas:

1. Cooling Time Equation

It is a simple formula you can use as a starting point:

Cooling Time (Tc) = (K * V * ΔT) / Q

The terms represent:

- Tc = Cooling time in seconds

- K = Constant related to material and mold properties

- V = Volume of the molded part (in cubic inches or centimeters)

- ΔT = Temperature difference (in °F or °C) between the melt temperature and the ejection temperature

- Q= Cooling rate (in °F or °C per unit time)

2. Empirical Method

Experienced molders often use rules of thumb based on material and wall thickness. For example, a common quick estimate is:

Tc≈1.5 to 2.5×(s)2

The terms represent:

- Tc is the cooling time in seconds.

- S is the maximum wall thickness of the part in millimeters.

- The factor 1.5 to 2.5 is a rough estimate that varies depending on the type of plastic material and processing conditions.

3. Material-Specific Cooling Time

It is another simplified theoretical equation used to estimate the material-specific cooling time (tc) in injection molding:

Tc=(0.8∗(part thickness)2)/α

The terms represent:

- Tc is the cooling time (in seconds).

- Part thickness is the maximum wall thickness of the molded part (in mm).

- Α is the thermal diffusivity of the plastic material (in mm²/s). It is a measure of how quickly temperature changes within a material. It is calculated as: α= k/ρ.Cp

- K is the thermal conductivity

- p is the density

- Cp is the specific heat capacity

Techniques to Reduce Cooling Time

Here are some useful strategies and best practices to reduce cooling time in injection molding and improve your production process:

1. Choose the Right Material

Selecting the right material can make a huge difference. Different polymers possess unique melting points, cooling rates, shrinkage behavior, and viscosity. Opt for a material with a lower melting point, faster cooling rate, minimal shrinkage, and lower viscosity. These factors can significantly shorten the injection cooling, and ejection phases of the molding cycle.

2. Rapid Cooling Processes

Using rapid cooling techniques can accelerate the heat extraction in injection molding. High-pressure systems using water or air blasts remove heat from the mold surface. An advanced method employs liquified CO2, directly sprayed or injected into the mold. The liquid expands into a snow-gas mixture (-79°C), absorbing heat from the challenging areas.

3. Use of Thermal Simulations

Thermal simulations are computer models in injection molding. They predict and analyze heat transfer dynamics within the mold, the molten plastic, and the environment throughout the molding cycle. They can accurately simulate the cooling phase, help optimize cooling channel design, identify hot spots, and determine the most efficient cooling parameter.

It helps engineers minimize cooling time, maintain uniform solidification, reduce potential defects like warpage, and enhance part quality and production standards.

Conclusion

Achieving the right cooling time in injection molding can make a huge difference in achieving dimensional stability, robust material strength, and superior final part quality. While there are numerous factors that influence this critical stage, employing strategic design considerations and advanced cooling techniques offers significant optimization potential.

Manufacturers can produce high-quality parts in less time by managing material selection, mold design, and processing parameters. For optimal results, trust a credible partner like Fecision.

As an industry leader in mold tooling, CNC machining, and molding services, we are committed to delivering precision, efficiency, and top-tier quality for your manufacturing needs. Contact us today and see how our expertise can optimize your production process.