The global plastic injection molding market was $187.7 billion in 2022 and is expected to grow to $240.9 billion by 2027. This is driven by the increasing demand for durable and cost effective plastic products. Simple components take just two seconds to manufacture, while complex parts need up to two minutes. This manufacturing process works quickly and efficiently.

The process has two basic stages: getting the mold and using it to create parts. Medical products and other industries need medium—to high—volume production, and injection molding provides an affordable manufacturing solution. Unlike other methods, injection molding allows manufacturers to create similar, perfectly molded products and minimize waste material.

This complete guide shows how injection molding works by explaining its core components, process steps, material options, and real-world applications in modern manufacturing.

What is Injection Molding?

Injection molding is a simple manufacturing method that forces molten materials into carefully designed molds to create precisely shaped products. This versatile process helps manufacturers produce complex-shaped components with exceptional accuracy and consistency.

The main principle involves melting plastic materials under controlled heat conditions and injecting them into specifically designed mold cavities. The material cools and solidifies inside the mold, taking the shape of the cavity. The process needs proper mold preparation by mapping the final shape of the finished product.

The manufacturing cycle starts when plastic pellets enter a heated barrel and melt under precise temperature control. A screw-type plunger forces this molten material into the mold cavity under high pressure. The finished part emerges with the exact specifications from the mold’s design after the material solidifies.

Why is it important in manufacturing?

Injection molding has proven to be the most common method in the plastics processing industry. The process offers several advantages that make it essential in modern manufacturing:

- High precision and consistency in producing similar parts

- Minimal material waste during production

- Budget-friendly for high-volume manufacturing runs

The technology’s versatility let’s manufacturers work with materials of all types, including thermoplastics, thermosetting polymers, metals, glasses, and elastomers. The process also supports mass production capabilities that help create thousands of similar items with consistent quality.

Injection molding has improved by a lot over time, with advanced molding techniques that boost efficiency and precision. The technology now serves industries of all types, from automotive components to medical devices, showing its vital role in modern manufacturing. The process continues to adapt as manufacturing needs become more complex, offering solutions for sophisticated product designs.

Core Components of Injection Molding

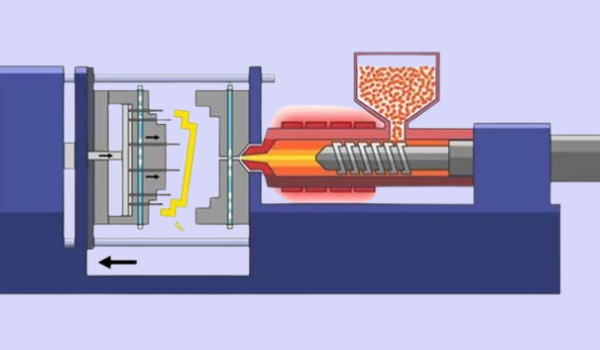

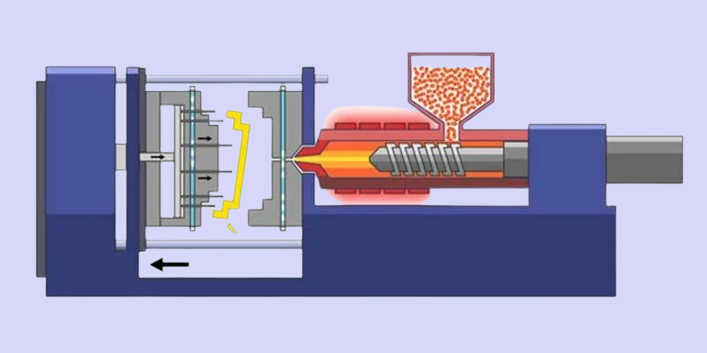

Modern injection molding machines need three parts that work together to make precise plastic components. These parts play unique roles in manufacturing.

The injection unit

The injection unit acts as the machine’s heart that melts plastic materials and pushes them into the mold. Inside, you’ll find a reciprocating screw that spins within a heated barrel to melt and blend the plastic material evenly. The screw’s design includes three zones: a feed zone that preheats, a compression zone that melts, and a metering zone that mixes.

Band heaters wrap around the barrel to create a smart heating system that keeps temperatures just right throughout the process. The unit also has a check valve system that stops melted plastic from flowing backward when the screw moves forward.

The mold system

The mold system shapes the final product and controls its quality. This complex system has several key parts:

- A sprue bushing guides material from the nozzle

- Runners channels direct the melted plastic

- Cooling channels control temperature

- Ejector pins remove parts

- Venting systems push out trapped air

The clamping unit

The clamping unit holds the mold halves together with intense pressure and forms the machine’s foundation. It creates strong forces using hydraulic systems, mechanical devices, or both working together. This is a big deal as it means that the clamping force must be higher than the injection pressure to keep mold halves from separating.

Two main parts make up this unit: a stationary platen and a moving platen. These platens connect to tie bars that line up the mold halves perfectly. Smart toggle systems convert straight-line motion into the opening and closing movements of the mold.

How Does Injection Molding Work? Step-by-Step Process

The injection molding manufacturing cycle creates high-quality plastic parts through several precise steps.

1) Material preparation

Raw plastic pellets need proper drying before the molding process starts. This step is vital since excess moisture can create silver-colored marks on the finished product’s surface. The dried plastic needs storage in sealed containers to prevent it from absorbing air moisture.

2) Melting and Mixing of Plastic

The dried plastic pellets move into a heated barrel with an internal auger. The screw’s rotation melts the thermoplastic material through mechanical energy and the barrel’s heat. Temperature control remains exact to maintain the material’s optimal flow properties.

3) Injection of Plastic into the Mold

The screw acts like a plunger and moves forward under high pressure to inject molten plastic into the mold cavity. This phase needs a careful balance of injection and clamp pressure to keep plastic inside the tool. The machine controls the screw’s speed to manage material flow.

4) Cooling and Solidification

The cooling phase takes up 70-80% of the total molding cycle. Cooling channels inside the mold circulate water or other coolants to remove heat. The material cools below its heat distortion temperature to prevent warping. The cooling system’s design is significant because uneven cooling leads to part defects.

5) Ejection and Finishing of the Part

Ejector pins push the solidified part out of the mold cavity after sufficient cooling. The system uses different ejection mechanisms based on part requirements:

- Ejector blades for thin-walled components

- Sleeves for parts with bosses

- Stripper plates for perimeter ejection

The ejection system applies even force to protect parts from damage. To meet final specifications, parts might need finishing processes like polishing or excess material removal.

Common Materials and Their Properties

Material selection is a key factor in successful injection molding operations. Manufacturers can choose from many plastics that are accessible to more people, and each one has its own unique properties.

Plastic types

- ABS (Acrylonitrile Butadiene Styrene) is a popular choice because it resists impact and maintains dimensional stability. This versatile material stays strong at different temperatures and works great for electronic housings and automotive parts.

- PP (polypropylene) is the second most used plastic in the world, and it offers excellent chemical resistance while retaining its shape. The material’s resistance to moisture degradation makes it perfect for food storage.

- Nylon, also known as polyamide, is known for its wear resistance and toughness. Engineers use it to make mechanical parts like bushings and gears. However, the material absorbs water which limits its use in marine applications.

- PC (Polycarbonate) combines great impact resistance with crystal clear optical properties. Parts made from this material keep their shape due to uniform mold shrinkage patterns. Manufacturers need highly polished mold tools to create optically clear parts.

Material selection criteria

Several factors come into play when selecting a material. You need to consider the part’s function and environmental exposure. Temperature changes, moisture levels, chemical contact are the foundation of this assessment.

A material’s strength, durability and flexibility determine if it’s suitable for a particular application. For example, parts that carry weight need materials with high strength that resist impact well.

Chemical resistance becomes critical when parts are exposed to solvents or reactive substances. The material’s thermal properties, including melting point and heat deflection temperature, also affect the final choice.

Budget plays a big role in material selection. High performance materials may have better properties but cost more which affects project feasibility. Most manufacturers balance performance needs with budget limits to find the best solution.

Conclusion

Injection molding is the lifeblood of modern manufacturing. It offers precision in many industries. This process combines high tech machines with precise temperature control and carefully selected material to produce consistent high quality parts.

Manufacturing professionals like injection molding because it creates complex parts with minimal waste. The process works through three main components: the injection unit, mold system, and clamping unit. These components turn raw materials into finished products.

Material selection is key to successful injection molding. Each plastic type – ABS, polypropylene, nylon or polycarbonate – has its own properties that suit specific applications. This versatility makes injection molding important in automotive, medical, consumer electronics and aerospace industries.

The technology is continuously improving to produce better efficiency and precision. It’s economical for medium to high volume production runs. Manufacturing’s demands drive injection molding to adapt and provide a solution for complex product designs.