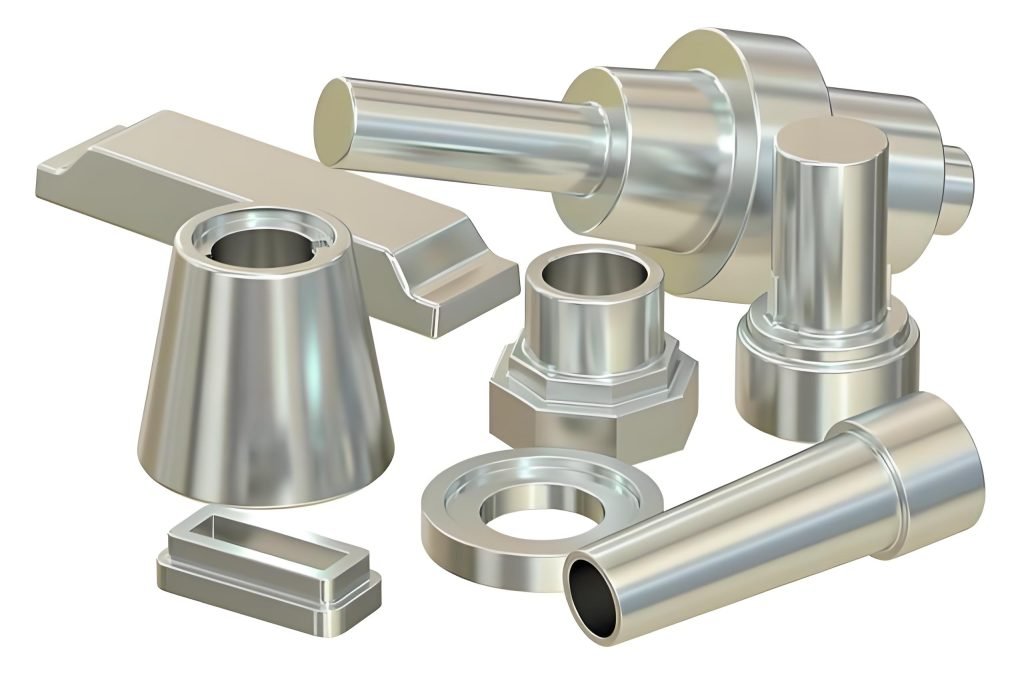

Die cast metal manufacturing creates precision parts under extreme pressures reaching 25,000 psi. These parts have become essential to modern industries. The printing industry’s solution from 1838 has transformed into the lifeblood of production for many sectors.

Die casting leads all casting processes in productivity and delivers parts with better surface finish. The process maintains consistent dimensions. Production efficiency is 67% material yield and finished parts have 415 megapascals tensile strength.

This article will cover everything you need to know about die-casting, including the process, benefits, applications and common materials used. Whether you’re a manufacturing professional or just curious about how everyday metal products are made, this article will give you useful information on metal die casting.

What is Die Cast Metal and How Does it Work?

Die casting is a precise metal forming process that forces molten metal into specially designed molds under controlled pressure. This manufacturing method creates complex metal parts through reusable molds, called dies.

The process forces molten metal into 3D molds at specific pressures between 1,500 to 25,000 PSI. Most die castings use non-ferrous metals like zinc, copper, aluminum, magnesium, lead, pewter and tin-based alloys. It produces parts with consistent quality and economical solutions by reducing per-unit cost.

How Does Die Casting Work?

The metal die-casting process involves the following steps:

- Mold Preparation: Manufacturers apply a specific lubricant to the inside of the mold. This lubricant regulates mold temperature, creates a film between molten metal and mold and makes it easier to remove the finished casting.

- Metal Injection: The mold is sealed tight after preparation. Molten metal enters at pressures ranging from 1,500 to 25,000 PSI depending on the application. The pressure remains constant until the metal solidifies.

- Cavity Ejection: Ejector pins, a standard feature in most molds, release the cavity once the metal hardens. The ejection process requires the molten metal to fully solidify.

- Shakeout: The last step removes excess scrap metal from the newly made cavity. Manufacturers remove any waste metal formed during the process to get the mold ready for reuse.

Die casting machines

Die casting machines come in two main categories:

Hot Chamber Machines: These machines, also called gooseneck machines, have an internal furnace inside the casting equipment. The furnace links to the die cavity through a feeding system called the ‘gooseneck’ and delivers faster cycle times of about 20 minutes. These machines are best for low melting point metals like lead alloys, zinc alloys and magnesium alloys.

Cold Chamber Machines: Cold chamber machines differ from hot chamber ones by melting metal in an external furnace. A ladle moves the molten metal from the furnace to the cold chamber die casting machine. This setup is best for metals with higher melting points like aluminum, copper and their alloys.

Common Die Cast Metals and Their Properties

Die casting uses three main metals and each has its own benefits for specific applications. Knowing their properties helps manufacturers choose the right material for their projects.

1) Aluminum die castings

Aluminum is the most popular non-ferrous metal in die casting due to its strength-to-weight ratio. These castings resist corrosion well and maintain their shape consistently. Aluminum die cast parts conduct electricity well and can handle higher operating temperatures better than other non-ferrous materials.

2) Zinc alloys in die casting

Zinc alloys pack the strongest punch among non-ferrous metals and can match or beat most cast irons. These alloys flow well during casting which allows manufacturers to create thin walls and complex designs. The metal’s lower melting point means tools last longer and a single mold can produce over 1 million parts.

3) Magnesium die cast parts

Magnesium parts are very light – they weigh 75% less than steel and 33% less than aluminum. These components hold their shape well and are easy to machine. Magnesium die castings are good at blocking EMI and RFI signals making them perfect for housing electronic components.

Choosing the right metal

Several factors determine which die casting metal to use:

- Temperature Requirements: Aluminum maintains its structural properties across a wider temperature range than other alloys.

- Strength Considerations: ZA alloys have the highest ultimate and yield strength which is perfect for high stress applications.

- Weight Restrictions: Magnesium alloys are the clear winners when weight matters most.

- Surface Finish: Zinc and ZA-8 alloys work well with die steel for consistent finishes over long production runs.

- Cost: Aluminum alloys are the least expensive per cubic inch, which is why they are so popular.

Die Casting Benefits

Die casting combines manufacturing expertise with engineering precision. Molten metal becomes complex parts in a controlled environment. This process stands out from traditional manufacturing methods in several ways.

1) High Precision – Complex Shapes

One of the biggest advantages of die-casting is the ability to produce complex shapes with high precision. The dies are custom made to produce parts with intricate details that would be difficult to achieve with other metal forming methods.

2) Fast Production

Since the process is highly automated, die casting is fast production. A single die can produce thousands or even millions of identical parts.

3) Strength – Durability

Die cast metal parts are strong – durable. The high pressure process results in a dense, defect-free structure that can withstand heavy loads and harsh environments.

4) Smooth Surface Finish

Unlike other casting methods, die casting produces parts with a smooth surface finish, reducing the need for additional machining and finishing processes.

5) Minimal Material Waste

Die casting is an efficient process with minimal material waste. Scrap metal can often be recycled and reused, making it a cost effective and environmentally friendly process.

Die Casting Drawbacks

Despite the many benefits, die casting has some challenges and limitations:

- Initial Cost: The dies used in die casting are expensive to make. This makes it cost effective for large runs but not for small runs.

- Setup Time – Testing: Setting up a die casting machine takes time because the die must be installed and the molten metal tested. If adjustments are needed, the process is delayed.

- Material Restrictions: Die casting only works with non-ferrous metals like aluminum, zinc and magnesium. If you need parts made from steel or iron, other methods like sand casting or investment casting may be required.

- Defects: If not done right, die casting can produce defects such as air pockets (porosity), cracks or rough edges. Temperature, pressure and mold design control is necessary to avoid these.

Die Cast Metal Applications

Die casting is used in many industries because manufacturers can create strong, precise and lightweight metal parts fast. Here are some common applications:

- Automotive: Many car parts are die cast, engine components, transmission cases and wheel parts. Aluminum die casting is popular because it makes cars lighter and more fuel efficient.

- Aerospace: Aerospace industry uses die cast metal for aircraft parts that need to be lightweight and strong. This is used for brackets, housings and structural parts.

- Electronics and Telecommunications: Die cast metal is used in electronic devices, mobile phone casings, laptop parts and heat sinks. It’s durable and allows for complex designs.

- Medical: Medical tools, equipment casings and imaging devices often need die cast parts because they are precise and durable. The smooth finish also makes them easy to sterilize.

- Industrial Machinery: Many machines and tools use die cast components, pump housings, gear casings and motor parts. These parts need to be strong enough to withstand heavy use.

- Household and Consumer Goods: Common household items, cookware, power tools and decorative fixtures are often die cast. It ensures long lasting, high quality products with smooth finish.

Conclusion

Die casting is a manufacturing process that helps industries create precise and high quality metal parts fast. It combines engineering expertise with practical benefits, allowing manufacturers to produce complex shapes with high accuracy and smooth finish.

One of the biggest benefits of die casting is that it can work with different materials, from lightweight magnesium to strong aluminum alloys. This flexibility helps manufacturers meet their specific needs, whether in automotive, electronics or industrial sectors.

Industries use die casting because it’s cost effective, reliable and produces durable parts. Over time, this process has evolved and improved, offering more capabilities. As technology advances, die casting will continue to be part of modern manufacturing, making it essential for the future.