In the world of manufacturing, there’s a hidden hero: metal extrusion. It can turn a plain metal block into all sorts of useful shapes. Ever thought about how your phone’s frame or a building’s structure gets its form? Let’s explore this amazing process together.

What’s Metal Extrusion?

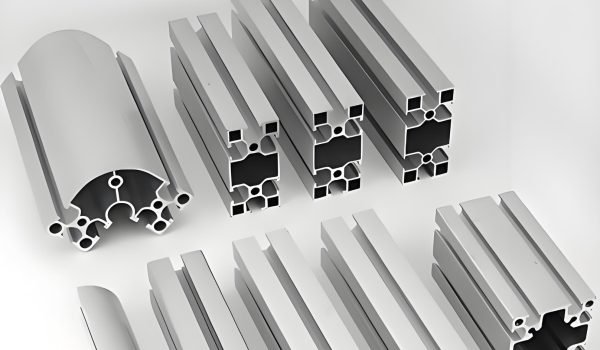

Metal extrusion is a versatile manufacturing process used to produce long, straight metal products with consistent cross-sections, such as rods, tubes, and structural components. The process begins by heating a metal billet until it becomes malleable, then placing it into a container. A piston applies high pressure, forcing the billet through a die to achieve the desired shape.

This method allows for precise, complex designs and is widely used in industries like construction, automotive, and aerospace for its efficiency and ability to work with various metals, including aluminum, steel, and copper.

Main Characteristics of Metal Extrusion

To understand the efficiency and versatility of metal extrusion, it’s essential to explore its main characteristics. These features highlight the process’s requirements, steps, and quality control measures, ensuring optimal results for various industrial applications.

Raw Materials:

- Use solid, large billets (e.g., aluminum, steel) as starting materials.

- Materials must become malleable when heated (aluminum: 370–500°C, steel: over 1000°C).

Containers and Shaping:

- Requires a variety of containers (dies) to shape the metal billet into desired cross-sections.

Cooling Process:

- After extrusion, the product is placed in cold water to cool and solidify.

Quality Control:

- Monitor and control parameters (e.g., temperature, pressure, speed) to ensure the final product’s quality and consistency.

Materials of Metal Extrusion

| Material | Features |

| Aluminum | It is always lightweight. |

| Steel | It has the ability to withstand high pressure and stress. |

| Copper | It can transmit current and is often used in electrical machines. |

| Brass | It has a golden appearance and it can not be eroded easily. |

| Titanium | It is not only strong but also lightweight, even corrosion-resistant. It’s bio-compatible that it can be used in medical implants. |

6 Common Types of Metal Extrusion

Direct Extrusion

Direct extrusion is a metal extruder process where a metal billet is forced through a stationary die by a moving ram, creating a shaped product in the same direction as the ram’s movement.

Advantages:

- Simple & easy setup is accessible.

- It’s like a shape-making magician. You can create a huge variety of shapes and sizes, from skinny rods to wide sheets.

- It’s a production powerhouse. Great for churning out tons of metal products in no time.

Disadvantages:

- The metal billet rubs against the container like a kid dragging their feet on the floor. This friction can cause some ugly surface defects.

- The container is like a small cage. It limits how long your extruded metal can be.

Indirect Extrusion

Indirect extrusion is a process where the metal billet remains stationary while the die is pushed against it by the ram, causing the material to flow in the opposite direction, resulting in a shaped product.

Advantages:

- Witless rubbing and tugging, it’s like giving the metal a smooth, friction-free ride. This results in a super shiny surface finish.

- It can produce more small and unique shapes.

- It needs less muscle power

Disadvantages:

- It is complex and expensive to set up.

- It has requirements for the size and can not change the size flexibly.

Hydrostatic Extrusion

Hydrostatic extrusion is also a kind of metal extrusions. It is a process where a metal billet is forced through a die using high-pressure fluid, reducing friction and allowing for the extrusion of complex shapes and harder materials.

Advantages:

- It is capable of processing tough materials with precision and delivers products with exact specified sizes with excellent surface finish.

- It can stretch the metal to amazing lengths. It’s like a superhero with super-stretching powers.

Disadvantages:

- It is a little expensive and it needs a huge pay for its protection.

- It’s a bit of a slowpoke when it comes to production speed. It’s like a snail compared to some of the other extrusion methods.

Lateral or Vertical Extrusion

Lateral or vertical extrusion is a process where the metal billet is extruded horizontally (lateral) or vertically, allowing for specialized shapes and orientations based on the design requirements.

Advantages:

- It excels in unique shape creation, producing extraordinary, one-of-a-kind designs that go beyond conventional methods, transforming imaginative concepts into reality and pushing the boundaries of metal shaping.

- They’re suitable for products that have certain orientation requirements.

- You can get better control of the flow of metal.

Disadvantages:

- You need special equipment for these methods since it can not change flexibly.

- Limited shapes & lack of innovation ability.

Impact Extrusion

Impact extrusion is like a metal-shaping action movie. A high-speed impact force hits the metal slug, and it’s like a superhero punching through a wall. The metal is forced through the die in an instant, creating all sorts of cool parts.

Advantages:

- It’s a speed demon.

- For a large-scale production, it’s a real money-saver. It’s like getting a big discount at the store.

Disadvantages:

- It’s unsuitable for making big parts.

- The high-speed impact can cause some internal damage to the metal. It’s like hitting a glass with a hammer and causing cracks inside.

So, which of these metal-extrusion “super-methods” do you think is the coolest?

Best Metal Extrusion Service Provider – Fecision

Hey there, metal-enthusiasts! After taking a wild ride through the diverse universe of metal extrusion types, you’re probably itching to find the ultimate service provider that can turn your metal-related dreams into reality.

Well, hold onto your hats because I’m about to introduce you to Fecision , the cosmic champion of metal extrusion!

- Innovative Technology Meets Craftsmanship: Combines advanced technology for smooth metal extrusion process with traditional craftsmanship to create perfectly extruding metal masterpieces.

- Shape-Bending Magic: A team of experts capable of producing incredibly complex shapes, as if designed in a parallel dimension.

- Customizable Solutions: Delivers any shape you envision, turning ideas into reality with precision.

- High-Quality Standards: Utilizes cutting-edge technology to ensure products meet the highest industry standards.

- Sustainability Focus: Incorporates eco-friendly practices to minimize energy loss and promote environmental protection.

- Customer-Centric Approach: A dedicated team that listens, understands, and collaborates with customers at every step, ensuring tailored solutions.

Whether you’re a startup with a crazy new invention or large corporation looking to upgrade your metal extrusion products, Fecision treats you like a VIP. They offer personalized solutions that are tailored to your specific requirements, making the whole metal extrusion experience a breeze. Contact Fecision for professional & free ideas NOW>>