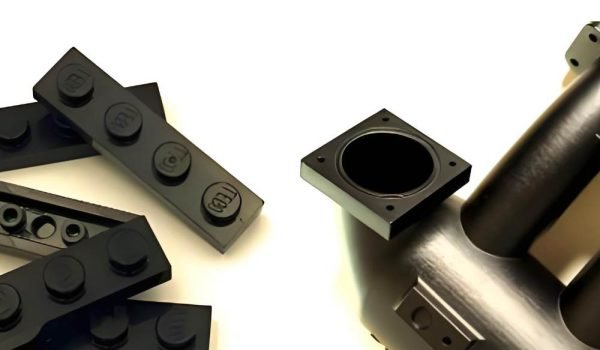

Manufacturers use different methods to create plastic parts, but two of the most common are 3D printing and plastic injection molding. 3D printing builds objects layer by layer from digital designs, making it ideal for custom parts and small production runs. Plastic injection molding, on the other hand, involves injecting melted plastic into a mold to create large quantities of identical parts.

Both methods have unique advantages and limitations. This article will compare them to help you choose the best option for your needs.

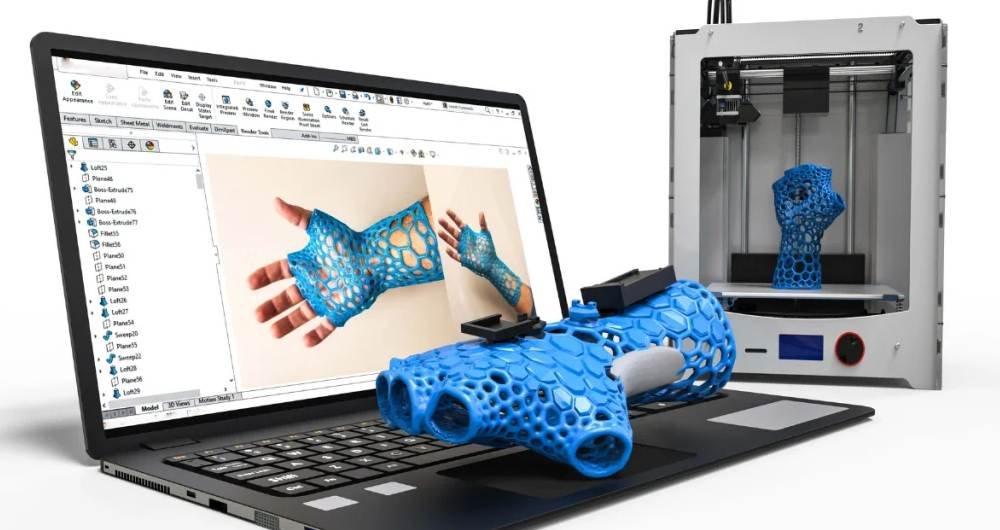

What Is 3D Printing?

Through 3D printing machines, producers construct objects, which they create by sequentially adding material from digital design specifications. The printing process adds materials of plastic or metal through a nozzle or laser installation. The process provides quick product development alongside customizable designs and cost-effective start-up expenses yet restricts performance strength, features few materials, and produces at a slow pace.

Advantages of 3D Printing

Low Initial Cost: 3D printing is an affordable option for small-scale production and prototyping because it does not require expensive molds or tooling. Traditional manufacturing methods, like injection molding, need costly equipment, which can be a barrier for startups and small businesses. Since 3D printing builds objects layer by layer, manufacturers can avoid large upfront investments. This makes it a cost-effective solution, especially for businesses that need custom or limited-run products without spending a fortune on production tools.

Rapid Prototyping: One of the biggest advantages of 3D printing is its ability to create prototypes quickly. Since it uses digital files, manufacturers can make design changes and print new versions without delay. Unlike injection molding, which requires new molds for every design change, 3D printing allows for fast testing and improvement. This speeds up the development process, helping businesses bring their products to market faster. It is especially useful in industries where innovation and continuous design updates are important.

Customization: Through 3D printing, manufacturers obtain both personalized solutions at affordable rates. Montoring design modifications becomes simple and cheap for manufacturers because they steer clear of fixed molds. Manufacturers benefit from this capability most in healthcare since prosthetics and dental implants need to be tailored to specific patients. Businesses with small operations can create one-of-a-kind customized items for their customers. 3D printing provides flexible production capabilities together with economic benefits rather than increasing costs through customization like standard manufacturing does.

Reduced Material Wastage: Excessive excess material results in significant waste throughout production using conventional manufacturing procedures. The process of 3D printing requires only exactly what is needed for object creation. Products produced through sequential layer addition result in virtually no waste. The approach of 3D printing reduces material expenditure and simultaneously establishes itself as an eco-friendly manufacturing method. The successful application of resources by 3D printing offers sustainable production advantages to companies.

Disadvantages of 3D Printing

Limited Material Selection: Although 3D printing materials are expanding, they still do not match the variety available for injection molding. Industrial-grade plastics, composites, and metals used in traditional manufacturing are often unavailable for 3D printing. This limits its applications, especially in industries that require durable or heat-resistant materials. While advancements continue, the current selection restricts its use in large-scale industrial production where specialized materials are essential.

Lower Strength and Durability: 3D-printed parts are generally weaker than those made with injection molding. Since 3D printing builds objects layer by layer, weak points can form between layers. This reduces the overall strength and durability of the product. In contrast, injection molding creates solid, uniform structures that can handle more stress. For industries that require strong, long-lasting components, 3D printing may not be the best choice unless additional reinforcements are applied.

Slower Production Speed: 3D printing is much slower compared to plastic injection molding. A single 3D-printed object can take hours to produce, while injection molding can create thousands of identical parts at the same time. This makes 3D printing impractical for large-scale production. While it is useful for prototyping and small batches, businesses needing mass production may find it too slow to meet their demands efficiently.

Higher Per-Part Cost for Large Production Runs: For low-volume production, 3D printing is cost-effective. However, when producing large quantities, it becomes expensive compared to injection molding. Since 3D printing is slow and uses costly raw materials, the per-unit cost remains high. Injection molding, on the other hand, spreads costs over thousands of parts, making each unit cheaper. For businesses needing high production volumes, injection molding is a more economical choice.

Surface Finish and Post-Processing Requirements: 3D-printed parts often have rough surfaces with visible layer lines. Unlike injection molding, which produces smooth, finished parts, 3D-printed objects require additional work to improve their appearance. Sanding, polishing, or chemical treatments are needed to achieve a high-quality finish, increasing both time and costs. This extra processing can make 3D printing less attractive for industries that require flawless, professional-looking products.

What Is Plastic Injection Molding?

Molten plastic receives injection into molded shapes to generate finished products through the plastic injection molding process. Mass manufacturers rely on injection molding because of its capability to produce products efficiently at high precision. Large-scale manufacturing benefits from this method because it guarantees both high durability and affordable pricing along with standard product quality. The initial cost for equipment, together with setup requirements, remains high.

Advantages of Injection Molding

Highly Efficient for Mass Production: Injection molding serves as a highly efficient and speedy technology that enables large-scale manufacturing operations. The finished mold enables production output of multiple thousands to millions of parts with identical specifications in fast manufacturing periods. The manufacturing speed of injection molding exceeds 3D printing since it produces high volumes of items much faster. Industrial facilities choose injection molding because it enables them to achieve high-volume production together with uniform quality assurance.

High Precision and Consistency: Each developed product benefits from injection molding because it requires exact measurements to achieve precise results. A repeatable mold usage guarantees uniformity for part dimensions alongside shape along with quality attributes. The automotive and medical sectors require high accuracy because this aspect is fundamental. 3D printing creates possible differences in manufactured parts, but injection molding ensures absolute consistency throughout large production quantities.

Broad Material Selection: Manufacturers can choose suitable plastics from the many available options because injection molding provides diverse material selections. The requirements for flexibility or heat- or impact-resistance determine the selection of appropriate plastic materials that will meet these needs. The production process of injection molding adapts well to multiple industry sectors, including consumer electronics and medical devices. 3D printing systems provide a more restricted set of industrial-grade materials when compared to injection molding frameworks.

Stronger Parts: Materials produced by injection molding demonstrate superior strength attributes than the components manufactured using 3D printing methods. Through the molding procedure, manufacturers create a strong and compact material structure, which differs from 3D printing techniques because they work by stacking layers. The manufacturing process leads to products that maintain better resistance against pressure and stress while enduring higher amounts of wear throughout their operational lifespan. The production of durable components with high strength constitutes a better fit for injection molding processes.

Disadvantages of Injection Molding

High Initial Cost: The creation of custom molds for injection molding requires high initial costs as the main disadvantage. A mold requires expensive manufacturing tools together with machinery that restricts low-scale production or minimal unit requirements. The reduction in part expenses occurs with extensive production volumes; however, the manufacturing setup expenses block entry for micro manufacturers.

Longer Lead Time for Molds: Mastering custom mold production demands multiple weeks since production initiation will not commence until manufacturing time expires. The production timeline stretches too long, which prevents its use in industries seeking fast design alterations or prototype development. Instant manufacturing is possible through 3D printing since mold-making delays become obsolete.

Limited Design Flexibility: Mold production creates difficulties and expenses for changing the designed product. Manufacturing a new mold to modify products enlarges both cost and manufacturing period for a company. Injection molding becomes inadequate for design-evolved products and custom products because it maintains restricted design flexibility.

Plastic Injection Molding vs. 3D Printing: Key Considerations

Below is a comparison chart highlighting the key differences between 3D printing and plastic injection molding:

| Factor | 3D Printing | Plastic Injection Molding |

| Production | Best for low-volume production and prototypes. | Ideal for high-volume manufacturing. |

| Cost Effectiveness | Lower setup costs, but higher per-unit cost for large production. | Higher tooling costs but lower per-unit cost for mass production. |

| Materials | Limited materials; best for prototypes and custom parts. | Wide range of materials; ideal for functional and industrial parts. |

| Part Features | Lower strength; suitable for complex geometries. | Stronger parts with tight tolerances. |

| Design | Quick and easy modifications. | It requires extensive validation before production. |

| Surface Finish | May require post-processing for a smooth finish. | Produces smooth, polished parts. |

| Applications | Prototyping, medical models, aerospace components. | Consumer products, automotive parts, industrial equipment. |

Production: Low-volume manufacturing together with rapid prototyping represents the best application of 3D printing systems. The absence of mold requirements allows you to make multiple parts in a fast and resourceful manner.The production of large numbers of products requires plastic injection molding as its optimal solution. When production molds exist, thousands up to millions of parts can be consistently made because it works well for mass production.

Cost Effectiveness: Because mold expenses are eliminated, 3D printing operation costs start off at a low value. The unit price becomes expensive during widespread production since this technique works poorly for mass manufacturing operations.A high initial expense exists in plastic injection molding since production requires the development of molds first. When a mold becomes ready for production, its unit pricing becomes highly competitive, thus becoming the ideal solution for quantity manufacturing.

Materials: 3D printing is more competitive with material selections than production, injection molding is. The method demonstrates success when working with plastics and metals along with resins, yet the possible materials have poor durability, making them unfit for industrial settings.Injection molding of plastic allows producers to select their materials from an extensive range of engineering plastic types. The production of functional alongside industrial-grade components requires this process as the preferred manufacturing solution.

Part Features: The complex designs possible through 3D printing produce parts that reduce strength along with durability levels. The process is perfect for complex shapes, yet it lacks durability features required for functional strength applications.Plastic injection molding utilizes its method to create durable objects with exacting dimensions, which makes it necessary for situations demanding robustness and high precision.

Design: 3D printing enables fast design changes through which manufacturers can easily evaluate multiple design concepts. Superior for both experimentation and prototype creation as well as single-use custom manufacturing.The design procedure for plastic injection molding requires thorough validation due to high expenses to change a mold after its creation because production modifications take significant time.

Surface Finish: End products from 3D printing require finishing treatments like sanding or polishing for attaining professional-grade polish. The surface includes visible marks that result from layer formation.Plastic injection molding enables manufacturers to create parts with built-in smooth polished surfaces within the mold-forming process, which provides optimum results for consumer-oriented products.

Applications: Manufacturers use 3D printing primarily for making prototypes along with medical models, aerospace components, and customized designs that need production in small batches. Plastic injection molding serves the production of consumer products, automotive parts, industrial apparatus, and mass manufacturing of durable materials.

Comparative Table of 3D Printing vs. Plastic Injection Molding

| Feature | 3D Printing | Plastic Injection Molding |

| Production Volume | Low-volume & prototyping | High-volume manufacturing |

| Setup Cost | Low | High (mold costs) |

| Per-Part Cost | High | Low for mass production |

| Material Selection | Limited | Wide variety |

| Part Strength | Lower | Higher |

| Design Flexibility | High | Low (due to mold constraints) |

| Surface Finish | Rough (requires post-processing) | Smooth |

| Production Speed | Slow | Fast for large quantities |

3D printing works best for low-volume production and prototyping because of its flexibility and minimal setup costs, yet plastic injection molding produces high-volume manufacturing due to lower per-part costs with stronger materials. Manufacturers base their decisions on manufacturing requirements along with financial constraints and dimensional intricacies.

Make the Right Choice for Your Project With a Plastic Injection Molding Expert

3D printing and plastic injection molding offer distinct advantages and are suited for different applications. If you need quick prototyping or small batch production, 3D printing is the best choice. If you require high-volume production with durable and cost-effective parts, injection molding is the way to go. However, mold design and material selection require expertise. A molding expert helps optimize production, reduce costs, and improve efficiency.

Choosing the right manufacturing method is essential for cost savings and quality. Understanding your project requirements will help you select the right method. Get expert guidance to avoid errors and achieve high-quality results.

FAQs

Does 3D printing prove better or worse than injection molding concerning long-term spending?

The setup costs for 3D printing stay low and make this production method cheaper for short production runs. A large-scale production requires the use of injection molding since it delivers better cost efficiency for each manufactured unit.

Can 3D printing replace injection molding?

Not entirely. Production on a large scale demands injection molding over 3D printing since it delivers better performance for high-volume manufacturing.

Do 3D-printed components show equivalent durability levels as injection-molded products?

The material density coupled with stable production parameters in injection molding leads to parts that normally exhibit stronger durability.

What businesses implement both 3D printing technology and injection molding methods?

3D printing dominates the prototyping and aerospace and healthcare sectors, but injection molding leads the market for consumer goods, automotive and industrial uses.

How much time does each manufacturing method require for producing finished parts?

Parts made through 3D printing systems emerge from design within hours, even though injection molding setup takes multiple days to weeks before creating its parts at high speed.