Foam molding is transforming the way we create modern products. Regardless of a bouncy sneaker sole or a protective case, it is everywhere for its lightweight and flexible properties. Among the different forms on the market, EVA injection molding process is often the favorite, due to its lightness, incredible elasticity, and cost-efficiency benefits.

This article is your complete guide to EVA injection molding. We will discuss what EVA plastic is, explain the molding process, and highlight its main advantages. You will also discover common applications, the conditions to have a successful project, and how to determine whether this process is right for you.

What Is EVA Plastic?

Basic Chemistry & Grades

So, what is EVA plastic? EVA refers to Ethylene Vinyl Acetate Copolymer, a special type of plastic produced by polymerizing ethylene and vinyl acetate molecules under high pressure. The amount of vinyl acetate (VA) is the factor in changing the material state.

If there is low VA content in the EVA plastic (under 20%), it behaves more like a rigid plastic. As you increase the VA content to above 20%, it begins to behave more like a flexible rubber-like material. This makes EVA very versatile.

Physical & Mechanical Properties

EVA is well known for being lightweight yet strong. With a low density of roughly 0.95 g/cm³, it can float on water. This is a very desirable property for use in products such as buoys or certain types of footwear.

In addition to being lightweight, injection molded EVA is actually incredibly tough. It possesses flexibility and strength in low temperatures. Its low temperature resistance is a considerable asset for products like outdoor gear, where being flexible and strong is a necessity in cold weather.

Environmental & Safety Profile

One of the great things about EVA is its safety and environmental friendliness. It is chemically safe, free of odor, and antibacterial, which makes it a wonderful option for any sort of product that is in contact with people, such as toys and medical devices.

EVA is also resistant to many things you can encounter in nature and industrial settings – seawater, acids, alkalis, oils, etc. This resistance, along with its recycling properties, makes injection molded EVA a prime sustainable manufacturing material.

Comparison With PE, TPU, EPP

EVA has some unique qualities compared to other common plastics like PE, TPU, and EPP. PE has a more crystalline structure, making it less clear and less elastic. In contrast, EVA is less crystalline and can provide better clarity and more flexibility.

Although TPU is also flexible, it is dramatically more expensive than EVA. EPP is also a wonderful injection molding foam, but tends to be very stiff. Thus, EVA is the perfect middle ground, giving users an outstanding balance of cost-effectiveness, softness, and durability for your injection molded foam projects.

The EVA Injection Molding Process: How It Works

With a solid grasp of EVA’s characteristics, we can now delve into the specific manufacturing steps and requirements that bring out its best qualities: injection molding.

Step-by-Step Workflow

1. Drying

Before molding, the EVA pellets are dried for 2-4 hours at a low temperature of approximately 40-50 °C. This step is very important, as any moisture will create defects in the final part, like bubbles or silver streaks.

2. Plasticizing

After this, the dry pellets are placed in the barrel of the machine, where they are heated to 150–180 °C. This will change the solid pellets into a molten liquid, which prepares the material for its next step.

3. Injection

The molten EVA is injected into a cooled mold at high pressure (600-800 kg/cm²). This forces the material to completely fill every part of the mold cavity and ensures the exact final product shape as designed.

4. Cooling & Demolding

The temperature of the mold is controlled at 30–40 °C to reduce the cooling time for the part. Once cooled, the part is removed from the mold. You should expect a dimensional shrinkage of approximately 0.7-2%.

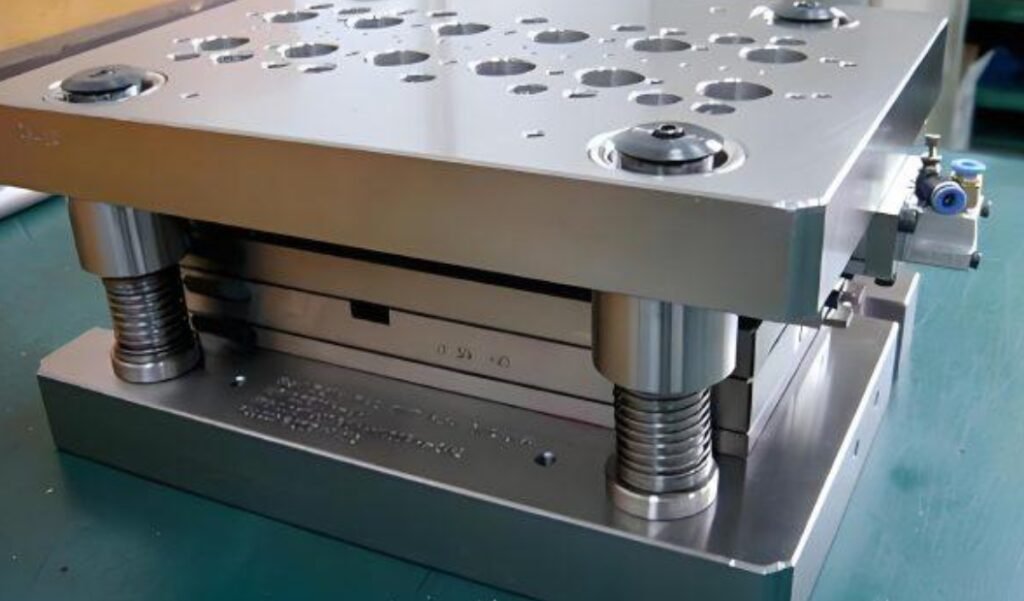

Machine Requirements

To achieve optimal results with EVA, a specific type of machine is required. The screw needs to have a high ratio of length to diameter (L/D) and be capable of low-temperature applications. It is also critical to have a special shut-off nozzle, which prevents any material from dripping out and making a mess prior to the injection, thereby creating a clean process.

Foaming vs Solid Molding

EVA can be molded in two major forms — solid or foamed. Solid EVA forms a dense product with a glossy, smooth surface. It is a tough and perfect material for parts that require rigidity and strength in application, such as hard cases or structural components.

Common Defects & Quick Fixes

As with any molding process, there can be issues. A common problem is the presence of bubbles in the finished part. The main cause is often too much moisture in the material. And a quick solution is to lower the melt temperature and remove excess air with a vacuum hopper.

Key Advantages of EVA Foam Injection Molding

The unique combination of material and method results in a powerful set of benefits. What makes this process so advantageous? Let’s have a look!

Lightweight & Buoyant

EVA foam injection molding is beneficial due to its incredible light weight. The tiny cellular structure provides significant weight savings over the solid EVA due to the foaming process used to create the final product. This is a game-changer for many applications.

The considerable weight savings are ideal for flotation devices, water sports gear, and automotive parts when every gram saving is critical. This also brings about lower shipping costs and is a great benefit to your business.

Superior Cushioning & Shock Absorption

EVA foam is well known for its superior cushioning capabilities. Not only does it absorb shock, but it is capable of returning a great deal of energy. This is the reason why it is a go-to material for sports padding, protective gear, and the midsoles of running shoes.

It is soft and springy – able to protect you from shock, while allowing your joints to work less hard. This significant energy return also makes it suitable for high-quality products that need to be both comfortable and protective for the consumer.

Fast Cycle & Low Energy

The EVA molding process is incredibly efficient. The mold itself is at a very low temperature, usually between 30–40 °C, meaning that you save a lot of time on cooling (the longest portion of the injection molding cycle).

Since it is efficient, you are able to create a fair amount of parts in a very short time. With the temperatures being lower, it will also save energy and money, in more cost-effective and sustainable way.

Design Freedom & Colorability

EVA injection molding gives you an incredible amount of freedom in terms of design. You can create different parts with both thick and thin walls, undercuts, and even multi-color streaks in one shot. This enables complex and unique designs.

EVA is easy to color; you can easily infuse bright, vibrant, and consistent colors in your product. It makes a perfect choice for products where appearance and branding are important, including consumer goods, toys, and other items.

Cost-Effective Tooling

The cost of tooling for EVA injection molding process is generally less expensive than that for other processes. For many applications, a good aluminum mold is entirely suitable and will last for tens of thousands of shots while keep the quality.

This results in much lower upfront costs compared to steel molds, which must be used for tougher plastics. This shorter payback period makes custom foam injection molding a terrific option for a wide range of applications.

Common Applications of Injection Molded EVA

The proof of EVA’s value is evident in the wide array of everyday and specialized products it helps create. Let’s examine some of its most common applications.

Footwear & Insoles

There’s no overstating how much EVA has changed the footwear industry. A significant majority of the world’s EVA plastic goes into making shoes. It’s the key material for athletic shoe midsoles, giving you that soft, springy feeling.

Consumer Electronics Cases

The next time you see a protective case for a laptop or tablet, it is probably made of injection molded foam. The case is designed to absorb impacts and keep your electronics safe. They are also very light.

Toys & Educational Mats

EVA is a great material for children’s products since it is not toxic and is often used for long-lasting uses. It is a safe and strong material for children to interact with for marvelous things, such as bite-proof foam puzzles and soft play mats.

Automotive & Aerospace Interior Padding

EVA foam injection molding is often used in vehicles and aircraft. It is found in soft, comfortable, lightweight interior parts like headliners and armrests as an important choice for a lot of companies needing a balance of performance, comfort, and safety.

Sports & Protective Gear

With its great shock absorption, EVA foam injection molding is also found in a wide range of sports and protective gear. Think about the padding on a helmet, knee pads for skateboarding, and your yoga blocks for that daily stretch. It’s a key material for athlete safety.

Conditions for Successful EVA Injection Molding

To consistently replicate the advantages and applications we’ve discussed, manufacturers must optimize several key conditions. What does it take to ensure a successful EVA injection molding operation?

Material Preparation

Adequate material preparation is essential to the success of an EVA molding project. Before you even start, the pellets must be perfectly dry. You should dry them for at least 2 hours at around 45 °C.

It is important to achieve a very low moisture content. If there is too much moisture, it will convert to steam in the mold, and it will create ugly surface defects like silver streaks on the finished part. This step will guarantee a very smooth finish if performed correctly.

Optimal Parameter Window

To achieve the best results, you must work within a specific set of parameters. The melt temperature should be between 160–180 °C, and the mold should be kept low at 30–40 °C.

You will need a holding pressure of 600–700 kg/cm², so the part completely fills. Getting your numbers correct is the secret to making strong, defect-free parts that meet your specifications every time.

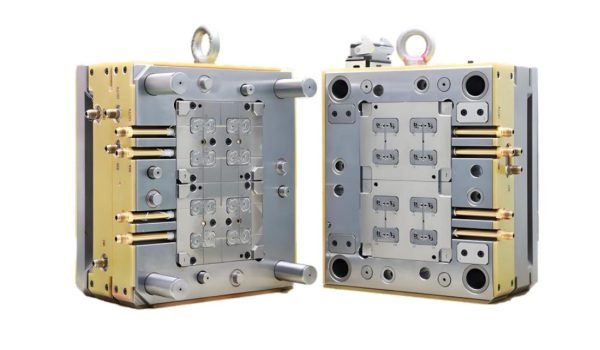

Mold Design Guidelines

The mold itself is very important to the project’s success. It should have at least a one-degree draft angle so when the part cools, it can slide out easily. This slight taper allows for easy sliding out for the part from the mold without damage.

Proper venting is also needed to allow air to escape while the material fills the cavity. The vent depths should be extremely thin and deep enough so that air can pass through while keeping the material in the mold. This guarantees a complete and perfect part.

Post-Processing & Finishing

After a part is formed, finishes can be added to the look and feel. In-mold texturing is a method whereby you add a pattern to the surface of a part during the molding process that works well in terms of results and cost.

Another alternative is that water transfer printing can be used for more detailed designs, or CNC engraving can be used for defined logos or text. These post-processing options can help create a more luxurious level of product and add additional customization.

Quality Control Checks

It’s essential to do several quality control checks on your finished products prior to sending them out. You should examine the density gradient of the injection molding foam to confirm that it is consistent throughout the part.

You must also check the compression set, which tells you how well the material returns to its original shape after being compressed – you want a very low compression rate. These checks ensure that every part meets your high quality standards.

Custom Foam Injection Molding: Is It Right for You?

When to Choose EVA Foam

It can be difficult to decide on a material for your project, but custom foam injection molding is a great selection when you’re looking for a product that has a soft touch, is lightweight, and comes in a range of vibrant colors. It is also perfect if you have tight deadlines.

In terms of production and cost, EVA foam is a great economical option for projects with an annual output ranging from thousands to half a million pieces. The molds are also affordable, with prototype aluminum molds starting at just a couple of thousand dollars.

Why Partner With Fecision

When you partner with Fecision, you are getting more than a manufacturer; you will have access to a full team of specialists. Our ISO-certified facilities and precision machinery guarantee that every EVA foam part manufactured is consistent and of the utmost quality. Our skilled engineers have extensive experience in foam molding, from material selection to end production.

In addition to molding, we have advanced manufacturing capabilities that allow us to accommodate both rapid prototyping and high-volume production with flexible delivery schedules to ensure your project is completed on time. We offer value-added operations, such as assembly and packaging, to make your entire supply chain smooth and efficient.

Are you ready for your next EVA injection molding project? Contact Fecision today for a consultation!