You hardly ever consider the manufacturing process when you pick up a clear food container or water bottle. PET injection molding, which turns raw resin into robust, sanitary, and lightweight components, is responsible for the high quality of these products. PET needs to be handled carefully when being molded, unlike many other plastics. Its heating, cooling, and drying processes need to be meticulously regulated.

PET offers safe packaging options, strength, and clarity when handled properly. This article guides you through the PET injection molding procedure, outlines the required temperatures, and highlights the various industries that utilize PET. You will understand why PET remains the material of choice in contemporary manufacturing if you grasp this concept.

What Is PET Injection Molding?

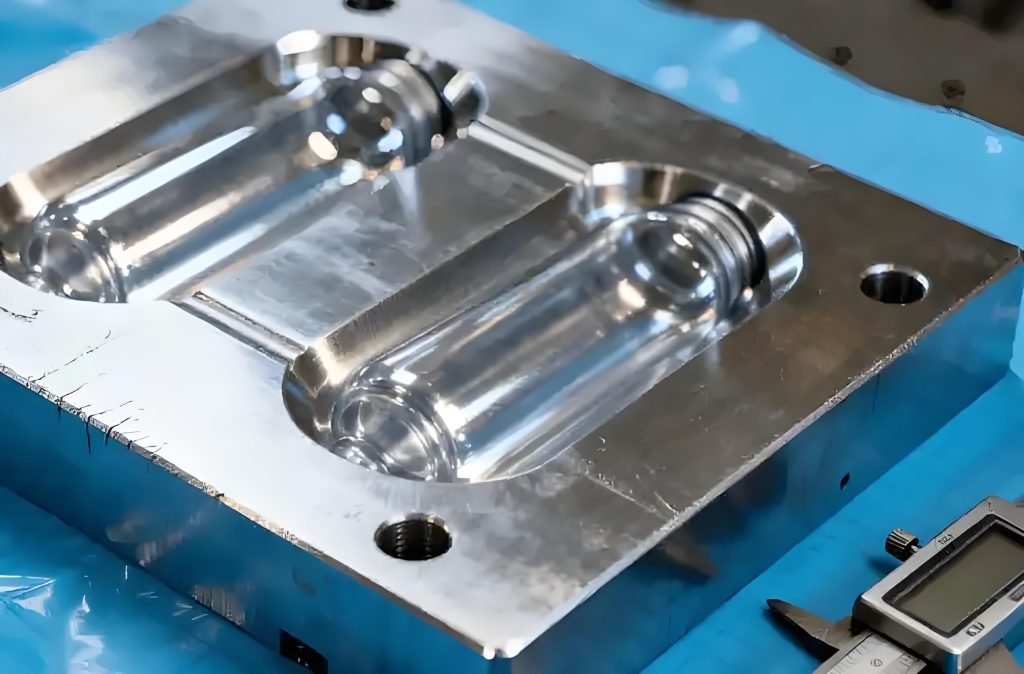

PET is a thermoplastic polymer that is widely used in consumer goods and packaging. It is perfect for applications that require reliability and security, as it combines strength with light weight. Melted resin pellets are injected under pressure into a mold cavity using the PET (Polyethene Terephthalate) injection molding technique. The end product is a sturdy component that precisely duplicates the mold design.

How PET Differs From General Injection Molding

- Compared to many other plastics, PET is less forgiving and needs stricter processing control.

- Its chemical structure causes it to react differently to pressure and heat.

- PET creates parts that are stiffer and more dimensionally stable than softer resins.

Why PET Injection Molding Matters

- produces large quantities of precise shapes.

- Supports sectors that require hygienic practices and a high-quality appearance.

- Ensures strength without adding extra weight.

Can PET Be Injection Molded?

Injection molding is feasible for PET, offering benefits over many other plastics. You acquire the capacity to create components that are robust, transparent, and safe for direct contact with consumables. For industries where appearance and performance must coexist, this combination makes it one of the most reliable options.

Benefits Of Injection-Molded PET

- Maintains transparency in finished products.

- Provides high stiffness for long-lasting use.

- Supports recycling for sustainable production.

- Allows design flexibility for both thin and thick walls.

Common Products Made With PET

- Food jars and drink bottles.

- Laboratory containers and medical trays.

- Precise parts for consumer products.

PET Injection Molding Process Explained

The PET injection molding process adheres to a rigorous protocol to produce high-quality results. Because even minor mistakes can result in flaws, each step needs to be handled carefully.

To achieve high-quality results, the PET injection molding process follows a precise sequence. Each stage must be handled carefully, as even small errors can lead to defects.

Main Steps In The Process

- Drying: Before heating, PET pellets must be dried to remove moisture.

- Melting: Heat is applied to the dried resin until it melts.

- Injection: Under pressure, the melted PET is pushed into a mold cavity.

- Cooling: Inside the mold, the part cools and solidifies.

- Ejection: After completion, the part is released and examined. Stress the importance of precision at each step.

Why The Process Requires Precision

- Small errors result in bubbles, cracks, or haze.

- Repeatable outcomes across lengthy production runs are guaranteed by consistency.

- Automation lowers waste and enhances control.

PET Injection Molding Temperature Guide

The most important element in PET molding is temperature. You must carefully handle both heat and moisture because the material reacts strongly to both.

Temperature Stages

- To prevent moisture damage, the drying temperature should be maintained between 160 °C and 180°C.

- For optimal flow, the melting temperature should be between 250 and 290°C.

- To balance strength and clarity, the mold temperature should be between 80°C and 120°C.

Why Temperature Control Matters

- Weak parts are the result of improper drying.

- Poor flow is caused by a melting temperature that is too low.

- Resin deterioration and discolouration can occur due to excessive heat.

- An incorrect mold temperature can cause surface flaws or brittleness.

Applications Of Injection Molded PET

In sectors where safety, clarity, and hygienic conditions are critical, injection-molded PET is trusted. It is adaptable due to its capacity to satisfy both design and performance requirements.

Important Sectors Employing PET

- Packaging: Jars for cosmetics, food containers, and water bottles.

- Medical: protective casings, sterile trays, and diagnostic equipment.

- Electronics: Lightweight Device housings.

- Automotive: Interior components that must be lightweight and strong.

Why Industries Prefer PET

- It combines aesthetic appeal with safety.

- Keeps durability while lowering the weight of the packaging.

- Provides reliable performance in demanding settings.

Challenges In PET Plastic Injection Molding

There are challenges when working with PET. Compared to other plastics, the material requires more maintenance, and failure frequently occurs when steps are omitted.

Common Challenges

- Moisture Sensitivity: The material is weakened by improper drying.

- Clarity Problems: Haze is caused by slight temperature variations.

- High Mold Costs: Precise machining is essential for PET molds.

- Thin-Wall Complexity: It is challenging to produce lightweight components without warping.

How To Overcome Challenges

- To eliminate concealed moisture, use drying equipment.

- Use precise controls at every stage.

- Invest in high-quality PET molds design.

- For complicated projects, collaborate with skilled manufacturers.

How To Optimize PET Injection Molding For Your Project

Prioritise preparation and process stability if you want injection molding PET to meet your needs. You can reduce expenses, increase productivity, and guarantee product consistency with the correct strategy.

Practical Optimization Steps

- Resin should always be dry before processing.

- Maintain constant melt and mold temperatures.

- For producing highly accurate molds, utilize CNC machining.

- Use automation to guarantee reliable outcomes.

Why Partnering With Experts Helps

- Teams with experience lower the chance of errors.

- Long-term cost savings are achieved through the proper design of molds.

- Every stage of production is supported by mold manufacturing and CNC machining from a trustworthy partner like Fengchi.

Conclusion:

There is more to the PET injection molding process than merely melting and cooling plastic. To produce goods that meet stringent safety and performance standards, a precise process is employed that balances drying, temperature, and tooling.

Injection-molded PET is used in a variety of industries, including packaging and medicine, due to its durability and recyclability. The challenges are real, but they can be easily overcome with the right companion. Fecision helps you create reliable, superior PET parts that meet your project objectives by combining CNC machining and state-of-the-art mold manufacturing.