Polystyrene (PS) is a thermoplastic that serves versatile purposes and is desired for its low cost and outstanding manufacturability. With PS injection molding, it can be formed into low-cost, precise parts in a relatively short amount of time. It is a commonplace material in modern manufacturing — from transparent yogurt cups to the durable housings of TV remotes.

This guide covers the entire polystyrene injection molding process, from selecting a material to mold making, its benefits and limitations, and numerous examples of applications, so you can determine if PS injection molding is a suitable process for your next project.

What Is PS in Injection Molding?

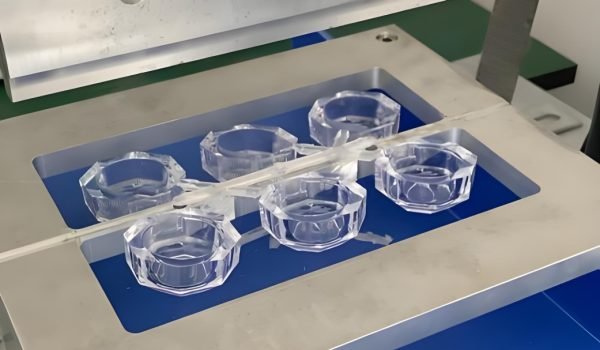

Polystyrene (PS) is a rigid thermoplastic that melts quickly when heated and solidifies fast upon cooling. In polystyrene injection molding, the molten PS pellets are forced into a cooled mold. The low viscosity of PS allows it to easily fill thin, complicated shapes. As an amorphous material, it provides excellent dimensional stability with minimal warpage. Additionally, PS is odorless, food-safe, and often found in products such as disposable cutlery and laboratory ware.

Different Types of PS Plastic Materials

Not all polystyrene is created equal. Selecting the right grade of PS is the first important decision you will make in any polystyrene injection molding process. You will find each type to have different strengths and uses. By selecting the ideal option, you can be sure your end product meets the requirements.

General Purpose Polystyrene (GPPS)

GPPS is known for its crystal-clear transparency similar to glass, and will typically transmit great light — almost 90%. The beautiful glossy surface makes it an ideal choice for print graphics. This property, combined with its clarity, creates a great opportunity for see-through products, such as clear lids or cosmetic packaging. While GPPS is generally quite brittle with impact, it is easily processed in a lower temperature range, making it a very user-friendly molding material.

High-Impact Polystyrene (HIPS)

HIPS is a rubber-modified grade with a nature of increased toughness and less brittleness compared with GPPS. It has an opaque matte to semi-gloss finish for painting, gluing, and stamping. This feature allows HIPS to work particularly well for products that require drop resistance, for example, toys, appliance housings, and TV bezels, and will have a slightly higher shrinkage for consideration in the mold design.

Expandable Polystyrene (EPS)

EPS is a specialized type of polystyrene that is typically not injection molded. Rather, it is a bead foam that is combined by steam, so it is a low-density material. Because of this, EPS makes excellent use of cushioning and thermal properties, suitable for protective packaging applications like fish boxes and bike helmets. When you need a strong yet lightweight foam part, EPS would be a great choice.

Plastic Polystyrene Properties

Polystyrene is a material that has good electrical properties with ultra-low moisture absorption, making it an excellent electrical insulator. It is also very lightweight, helping with part weight to reduce shipping costs. However, its weaknesses are poor UV resistance and sensitivity to chemicals, creating the potential for stress-cracking and degrading performance.

The following table shows the properties of polystyrene (PS). They are important when choosing the right material for your project. You should always check these properties every time you design a new product.

| Property | Value / Description |

| Density | 1.04–1.09 g/cm³ |

| Transparency | 88% – 92% |

| Refractive Index | 1.59 – 1.60 |

| Tensile Strength | 40 – 50 MPa |

| Flexural Strength | 200% – 350% |

| Impact Strength | Low to Moderate |

| Melting Range | 180°C – 270°C |

| Thermal Decomposition Temperature | ~300°C |

| Moisture Absorption | Very Low |

| Chemical Resistance | Poor to Moderate (Dissolves in solvents like acetone and gasoline. Holds up well against most acids, alcohols, and oils.) |

| UV Resistance | Poor |

| Volume Resistivity | Excellent (High, stable under varying humidity/temperature) |

| Flammability | Flammable (Produces black smoke and a distinct odor) |

The Key Points of PS Mold Making

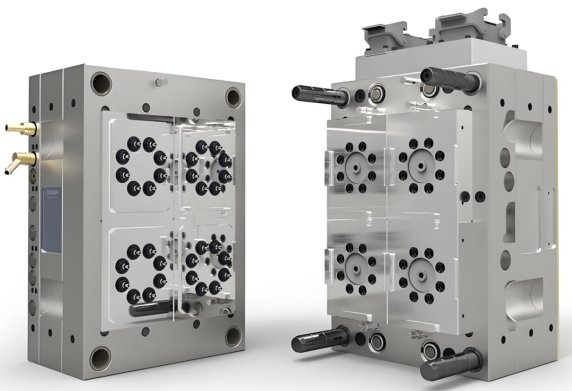

The success of a polystyrene injection molding process is highly dependent upon the quality, as well as the design of the mold tool itself. If you have a well-designed mold, you will more likely guarantee high-quality parts every time. Here’s what you need to know about making a good mold for PS.

Mold Design & Manufacturing

Precision is everything. Your mold must be designed with very tight tolerances. Since PS duplicates even the smallest textures, high-precision EDM and CNC finishing are a must. For glossy parts, mirror-polished cavities are essential. You also need venting grooves to prevent burns on thin, transparent parts.

Material Selection

Choosing the proper material for your mold is also very important. P20 pre-hardened steel is a cost-effective material for medium runs, generally lasting somewhere between 100k and 300k shots. For higher volume jobs, a durable, corrosion-resistant stainless steel, such as H13, is more recommended, especially if the water channels are going to be operating at low temperatures. The use of beryllium-copper inserts allows for quicker cooling.

Accounting for Shrinkage

The PS material shrinks from 0.2 to 0.8% as it cools, so you need to design the mold with this in mind and add an allowance for the correct size of final parts. If you do not, you will likely end up with a part that is too small. Always use the shrinkage rate specific to your grade of PS.

Gate Design

The gate design affects the final part’s look. Edge gates are used for clear parts, leaving a small vestige that’s easy to trim. A wide fan gate reduces shear on large panels and hides flow lines. A diaphragm gate ensures concentric filling, while a hot-tip valve gate is great for high-volume projects to eliminate runner waste.

Conditions of PS Injection Molding

To get great results, you need to set your machine correctly. Getting the optimal settings right is key to creating crystal-clear parts with low warpage and short cycle times. Here’s a look at the most important conditions you need to control.

Melt Temperature

PS meets a flexible processing temperature for injection molding applications, typically between 185–220°C. The melting point is 166°C; however, the decomposition temperature must be kept strictly below 280°C. Within this recommended range, PS can be processed without affecting the integrity of the material, and any variation might degrade the material and affect the product.

Mold Temperature

The mold temperature ranges from 20 °C to 70 °C. For optical parts made from GPPS, a mold temperature of 50 °C is best. It gives you the highest gloss. For thick HIPS housings, a polystyrene injection molding temperature of 30 °C is often used. This helps to cool the part faster and shorten the cycle time.

Injection Pressure & Speed

You’ll need a plastic pressure of 70–150 MPa. For instance, if you mold thin-wall GPPS cups with a thickness of 0.4 mm, you will likely need an injection pressure of over 120 MPa. Also, it is important to have a high enough injection speed to ensure the mold fills fully before a solid skin begins to form. Make sure your design has good venting built in to avoid burn marks caused by the high shear.

Screw & Nozzle

A standard single-flight, three-zone screw is a good choice for PS. A check valve or non-return ring is essential to prevent drooling from the nozzle. Also, using decompression after plastication can prevent splay marks on clear injection molded polystyrene, ensuring your parts look perfect.

Drying and Material Handling

Injection molding polystyrene absorbs very little moisture. This is a big advantage since injection molding using PS pellets typically does not require drying. But if the pellets have been exposed to high humidity, drying at 80 °C for around 2 hours is a simple step to prevent defects such as splay marks on your final parts.

Pros and Cons of PS Injection Molding

As with any material, PS has its strengths and weaknesses. It’s important to know both before you choose it for your application and use the material in the most efficient way. Understanding the advantages and disadvantages of the material will help assure the right selection for your product and application.

Advantages

First, PS injection molding is an effortless process. PS melts and flows almost like water. This means you can create parts with long flow paths using minimal injection pressure. Another major benefit is its glass-like clarity. GPPS is as clear as acrylic, but often less than half the cost, making it a cost-effective solution for see-through parts.

The polystyrene pellets for injection molding are among the least expensive of all commodity thermoplastics, helping to keep your production costs low. PS is an amorphous structure that has consistently low and predictable shrinkage, allowing for multi-cavity tools to produce identical parts shot after shot. Plus, its surface is easy to decorate with various printing methods.

Limitations

A significant disadvantage of PS is its poor UV resistance. It will yellow and become brittle with prolonged sunlight exposure. While some additives will help a little, the problem will still exist. PS is sensitive to solvents like hydrocarbons and is likely to experience stress-cracking.

GPPS has low impact strength and will shatter if dropped. Only high-impact polystyrene injection molding grades can survive moderate abuse. The impact strength of PS drops sharply below 0 °C, so it’s not a good choice for freezer applications. You should consider other resins if your part will be used in a cold environment.

Applications of PS Injection Molding

Injection molded polystyrene is used in a wide variety of products. Its different grades and properties allow it to be suitable for many different product uses and industries. Here are some of the most common applications you’ll find.

Rigid Packaging

Polystyrene is the top choice for rigid packaging. Think about yogurt cups, deli lids, bakery trays, and even single-serve coffee pods, all utilizing clear GPPS grade due to its transparency and food safety specifications. It’s a reliable and affordable way to package food products.

Consumer Electronics

HIPS is the default material for many consumer electronics. It’s used for TV bezels, router housings, and printer trays. HIPS is a great choice here because it’s easy to paint and flame-retardant grades are available. This makes it ideal for durable and safe electronic enclosures.

Medical & Labware

The medical field depends on injection molding polystyrene for many disposable goods. Petri dishes, culture trays, and test-tube racks are all made from PS that is sterilizable. The clarity and cost-effectiveness of PS make it ideal for one-time use lab equipment.

Toys & Stationery

Toys and stationery items often use GPPS. Items like LEGO-compatible bricks, CD cases, and transparent rulers benefit from its sparkle and dimensional accuracy. The ability to hold tight tolerances is critical for toys that need to snap together perfectly.

Appliance Interiors

HIPS is used for the interior parts of appliances. Refrigerator air ducts and blender jars are products that combine the toughness of HIPS, along with good cost savings. Both of these parts need to hold up to heavy-duty use, which HIPS can provide, without sacrificing cost.

Point-of-Purchase Displays

Clear GPPS lenses are often used with HIPS bases for back-lit signage in stores. The GPPS provides a clear, sharp lens, while HIPS base offers a durable frame, which allows for easy painting or decorating. This combination creates an attractive and long-lasting display.

Conclusion

Polystyrene Injection molding is a process necessary for making parts that are clear, rigid, and economically produced. Knowing material properties, mold design requirements, and processing conditions is important to maximizing the use of PS. After understanding all these elements, manufacturers can create a multitude of products.

At Fecision, we focus on polystyrene injection molding by combining advanced machinery with a strong engineering team to deliver quality parts. With strict quality assurance, each injection molded polystyrene part — whether prototype or mass production — is produced to precise specifications. We manage key parameters like the polystyrene injection molding temperature appropriately, as we always have done in the past, to provide you with the optimized quality at a fair price.

We offer comprehensive solutions for every project stage. Our process, certified with ISO standards, ensures you get exceptional consistency whether you need rapid prototyping or high-volume runs. We work with the best grade polystyrene pellets for injection molding, ensuring top-quality results of both standard and high-impact polystyrene injection molding projects.

Do not compromise on quality or productivity! Contact Fecision for a professional polystyrene injection molding process built to your specifications and budgets.