Vacuum casting gives you parts with the quality of injection molding, but without needing costly steel tools. Imagine transforming your 3D file into production-ready polyurethane parts in a matter of days. That’s the power of this incredibly fast and effective manufacturing method.

You are now ready to learn all you need to know about vacuum casting. This guide will show you how to manufacture high-quality pieces quickly – we’ll discuss the process and how it works, what materials suit your task best, the important design rules, and its practical uses.

What Is Vacuum Casting?

So what is vacuum casting? Simply put, it is a soft tooling process that draws liquid polyurethane resin into a flexible silicone mold in a full vacuum chamber. This process is best for prototypes or small series plastic parts when you need a production-grade look and mechanical properties without expensive hard tooling. It is the perfect route for pre-series validation or low-volume end-use vacuum casting products.

| Advantages | Limitations |

| Injection-like surface finish straight out of the mold. | Silicone mold life is short, typically ≤25 shots before degradation. |

| Wide material choice: rigid, clear, elastomeric, or metal-filled. | Silicone molds have size constraints (500 mm – 900 mm). |

| Color matching with RAL or Pantone pigments added to the mix. | Not suitable for high-pressure vacuum casting metal applications; use vacuum die casting instead. |

| Undercuts and inserts are possible without side actions or slides. | Manual steps raise unit cost compared to injection molding. |

Materials Used in Vacuum Casting

It is vital to select the correct resin in order to dictate your part’s resulting properties, ranging from stiffness to transparency. Let’s take a look at the wide variety of polyurethane resins available to accurately replicate the performance of common engineering plastics.

ABS-Like Resins

Resins like UP4280, PX100, and PX250 are formulated to mimic the properties of ABS plastic. They offer good heat resistance and high impact strength. These materials are perfect for creating things like electronic housings and strong snap-fit components.

Glass-Filled Nylon-Like

Adding short glass fibers dramatically boosts stiffness, sometimes by as much as three times. This makes these materials perfect for manufacturing functional brackets and specific automotive clips that need extra structural integrity. They provide a strong, dependable solution.

Clear Resins (PMMA & Acrylic)

Materials such as X522HT let a high percentage of light pass through them. You can polish these resins to an optical grade finish, which is important for clarity. They are mainly used to produce high-quality lenses and various light pipes for displays.

Elastomeric TPE-Like

The UP8400 resin has a soft, flexible feel and can stretch significantly before breaking. This excellent flexibility makes it an ideal choice for creating seals, comfortable grips, and parts like dampening wheels on a cast cutter with a vacuum.

High-Impact Resins

Resins, such as PU8098 (PC-like) and UP5690 (PP-like), have been developed and tested for their ability to withstand tough impact tests, like the IK08 standard. Given their extreme durability, these resins are ideal for robust products like drone bodies and protective power-tool guards.

Specialty Fillers

You can add aluminum powder to the resin mix to give the final part a metallic feel and weight. This addition also improves thermal conductivity. This technique is often used to simulate a die-cast heatsink for testing without having to actually vacuum cast the metal.

How Does Vacuum Casting Work?

Understanding the question – how does vacuum casting work – reveals why vacuum casting process delivers such high-quality results. The whole process is carefully controlled, moving from a digital file to a physical part through several precise stages.

Step 1 – Build the Master Pattern

The foundation of a great vacuum cast part is a perfectly accurate master pattern. This initial component is typically created with a highly precise CNC machine or an SLA 3D printer to ensure geometric accuracy.

Once the master is fully formed, the surface is crucial. It is carefully sand-blasted and primed to remove any layer lines or imperfections. This preparation step ensures the master has a flawless Class-A surface finish before it moves to the next stage.

Step 2 – Create the Silicone Mold

The master pattern is precisely positioned and securely suspended inside a casting box. Next, a liquid, two-part silicone compound is poured around it, filling the entire box volume.

This silicone mold is then allowed to cure for about 8 to 16 hours in an oven set to 40 ℃. Once cured and solid, the mold is surgically cut open along a planned parting line to create the cavity and to form the necessary resin gates and air vents.

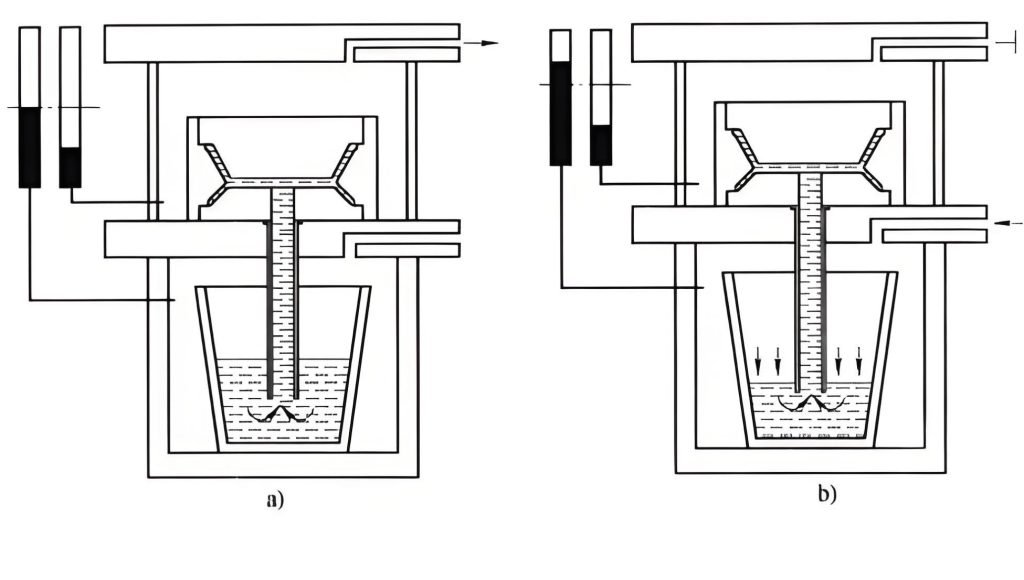

Step 3 – Cast the Parts Under Vacuum

Before casting, the polyurethane resin is briefly degassed for 60 seconds to eliminate any trapped air bubbles. The mixed resin is then poured into the silicone cavity while under a powerful 5 mbar vacuum to ensure it captures all fine details.

The resin is then allowed to cure in a dedicated oven for one to four hours. The finished part can then be removed from the mold, and the excess material that was left behind by the gating can be trimmed off, resulting in a part that is ready for use.

Optional Post-Processing

When you want your vacuum cast parts to resemble a final consumer-product appearance, there are a number of optional finishing steps you can take, such as professional painting if a custom-color option is desired, silk-screening for logos, or metallizing for a reflective finish.

If you assemble the final product, you can incorporate threaded inserts by over-molding them directly into the part with the casting process. This allows you to securely attach the vacuum cast parts to other elements of your overall product design.

Design Considerations for Vacuum Casting

Silicone has incredible flexibility; however, using specific design rules will ensure the highest quality part and long-lasting molds. Paying attention to these geometric details ensures easy part removal and superior final aesthetics.

Draft Angle

It’s highly recommended to add a 1 to 2 degree draft angle per side to your design. This makes it much easier to eject the part from the mold. Although the silicone is flexible and can handle near-zero draft, 1∘ prevents the surface from scuffing or tearing during removal.

Tolerance Strategy

Your goal should be to meet the ISO 2768-C standard for general tolerances. You should anticipate a base tolerance of ±0.1 mm for every 30 mm of dimension. Also, be aware of an additional 0.15% material shrinkage as the plastic cures.

Wall Thickness

Strive for a uniform wall thickness of between 1.5 mm and 2.5 mm. This thickness results in a good tradeoff between your final part’s strength and the cure time required. Localized thick zones up to 5 mm are acceptable without the risk of sink marks, thanks to the material’s low heat generation (exotherm).

Ribs & Bosses

To prevent sink marks on the opposite side of the wall, ensure that the thickness of any ribs is less than 60% of the main wall thickness. Design bosses to have a minimum diameter of 1 mm and a 0.5 mm radius. This is perfect for securely inserting screw brass inserts.

Embossed Details

For embossed (raised) and debossed (recessed) text and logos, maintain a minimum height or depth of 1 mm, and a minimum width of 1 mm – this allows the details to be crisp and still show well in the final part. Additionally, individual characters should maintain a gap of 1 mm between each other to aid readability.

Undercuts & Overhangs

Silicone is highly elastic and can stretch by up to 20%. This allows you to design features like snap hooks and side holes without the need for complex slides or side actions. Simply plan a split line so you can easily peel the mold off the finished part.

Applications of Vacuum Casting in Various Industries

Every major industry benefits from rapid prototyping and low-volume production to advance any project. Because of vacuum casting’s versatility, it is used across sectors, from cars to advanced medical gear.

Automotive

In the automotive industry, vacuum casting process is used to produce dashboard prototypes, durable lens covers, and precise air vents. Using polyurethane vacuum casting allows you to fully validate the fit and form of the component prior to investing in cutting the expensive steel mold.

Consumer Electronics

In consumer electronic goods, this process is great for ensuring precise smartphone enclosures and robust battery trays. It is also frequently used to create clear vacuum casting plastic windows for displaying LED indicators on devices.

Medical Devices

Vacuum casting service is an important process used to produce high-quality shells for hand-held ultrasound devices and ergonomic TPE grips. You can also find bio-compatible resins that are ISO 10993-5 certified for safe use in medical applications.

Aerospace

The aerospace industry utilizes this process for its interior cabin panels and ducting components. There are also specialized flame-retardant UL94-V0 vacuum casting materials available that have met the strict FAR 25.853 fire safety regulations.

Food & Beverage

You can create transparent PMMA-like prototypes for items like coffee machine housings. You will also find BPA-free resins, which are suitable for food-contact applications and additionally provide assurance that your parts are compliant with industry safety standards.

Vacuum Casting vs. Other Manufacturing Processes

It may be beneficial to evaluate vacuum casting versus other manufacturing methods when looking at manufacturing methods. Let’s compare it to some of the most recognized methods to help clarify where vacuum casting would fit most.

1. Vacuum Casting vs Injection Molding

The biggest difference is in tooling cost and lifespan. The silicone mold for vacuum casting is incredibly affordable, typically less than 5% of the cost of a full, high-volume steel injection molding mold. This makes silicone vacuum casting the perfect low-budget solution for early-stage testing.

But with vacuum casting, this process is not scalable for mass production. You should only switch to injection molding when your production volume reaches higher quantities. That is when the significantly lower piece price eventually offsets the initial, high investment cost of the steel tool.

2. Vacuum Casting vs 3D Printing

Vacuum Casting is ideal when you need to manufacture a number of identical copies of a part. It offers a consistent high-quality surface finish and material properties for all parts. Once the mold has been made, you can replicate a number of parts quickly.

3D Printing is great for single prototypes and parts with extremely complicated geometries, and for fast and rapid design iterations. It does not require tooling, but it can slow down rapid production if manufacturing many identical parts, and it often takes some post-processing to achieve a smooth surface for a finished part.

3. Vacuum Casting vs Centrifugal Casting

The processes serve entirely different functions. Centrifugal casting is a spinning technique of molten metal and is primarily used for symmetrical items, such as pipes, tubing, and some jewelry components.

Standard vacuum casting is for plastics, not metal vacuum casting. It relates to using a static silicone mold and pouring the liquid resin into the mold to get a complex plastic part with intricate details, and it is not intended for molten metal or large-scale situations.

4. Vacuum Casting vs Vacuum Forming

Vacuum forming is a process of heating a plastic material until it reaches a pliable state, and then draping it over a male mold while pulling it down with a vacuum. It is better for thin-wall, lower detail items, such as food trays or simple consumer packaging.

In comparison, silicone vacuum casting introduces liquid resin into an entirely sealed cavity. This allows for thicker, stronger, and very detailed parts with improved mechanical properties and solid internal structure.

Quick Comparison

| Process | Vacuum Casting | Injection Molding | 3D Printing | Centrifugal Casting | Vacuum Forming |

| Key Differences | Low-cost silicone molds; high-quality, identical parts. | High-cost steel molds; very low per-part cost at scale. | No tooling; builds parts layer-by-layer from a digital file. | Spins molten metal in a mold for symmetrical shapes. | Heats and stretches a plastic sheet over a mold. |

| Best Suited For | Low-volume batches of functional prototypes or end-use parts. | Mass production (1,000s to millions of units) requires high repeatability. | Single prototypes, highly complex geometries, and rapid iteration. | Creating symmetrical metal parts like pipes, tubes, and rings. | Large, thin-walled, hollow parts like packaging and trays. |

Source Your Vacuum Cast Parts at Fecision

Vacuum casting is a proven and reliable manufacturing solution for you, allowing you to create high-fidelity prototypes as well as functional small batch production parts more quickly and cost-effectively. By understanding the entire process, the material options, and the proper design rules, you can fully leverage the process.

When you need an expert partner for your vacuum casting service, Fecision is the right choice. We excel at delivering high-quality, low-volume plastic parts fast. We achieve dimensional precision for your complex geometries, maintaining tolerances around ±0.5mm. With over 200 different plastic materials available, we quickly meet your needs with surface finishes up to Ra 0.4μm.

Choosing Fecision for your vacuum cast parts means you benefit from our comprehensive manufacturing expertise, which includes decades of experience. We provide full engineering support from concept to part. Our certified processes (like ISO 9001) fully guarantee that you have the reliable, high-performance solution you need for your prototyping or small-batch production.

Contact Fecision today to discuss your project and discover the ideal manufacturing solution for your needs!