Among the most important choices one can make in the field of manufacturing and product development is which kind of tooling in manufacturing to use: soft or hard. Your decision can shape the entire success of a project. Every method has unique advantages and restrictions that make it appropriate for various production volumes and phases of manufacture.

Optimizing your production process, controlling costs, and guaranteeing on-time delivery of premium products depend on knowing the distinctions between these two manufacturing techniques. This guide explores what soft and hard tooling are, their pros and cons, their comparison on critical factors, and when to use each.

What is Soft Tooling?

Soft tooling is the process of making molds and prototypes utilizing comparatively soft, readily changed materials like silicone, urethane, aluminum, or some composites. The use of soft tooling is limited to prototyping, design validation, and low to medium-batch production.

Before deciding on expensive mass production, engineers and designers can use this method to test and modify parts effectively. Urethane casting and additive manufacturing, like 3D printing, are two commonly used methods for rapidly altering your design. Therefore, soft tooling becomes a crucial middle stage in product development as it enables teams to assess form, fit, and functional performance without a major initial investment.

Advantages of Soft Tooling

- Quick production: Due to the employment of easy-to-machine materials and processes such as 3D printing or CNC machining, molds can be created rapidly, usually within hours or days.

- Cost-effective for low volumes: It’s ideal for prototyping and small batch manufacturing since it lowers initial costs and lowers financial risk during early development.

- Design flexibility: Create soft materials that facilitate creative and iterative design by enabling delicate shapes and complex geometries difficult to produce with rigid tooling.

- Easy modifications: Simple adjustments allow for fast design changes and less time spent on reworking by means of quick and inexpensive changes.

- Supports early validation: By assisting in checking the market viability, function, and design of a product before making a costly commitment to hard tooling.

Disadvantages of Soft Tooling

- Limited durability: Since softer materials wear out more quickly, the molds are inappropriate for long production runs.

- Lower material resistance: Less qualified than hard tooling materials to withstand high temperatures, strong chemicals, or mechanical stress.

- Dimensional instability: Under continuous usage, particularly over time, prone to warping, deformation, and loss of accuracy.

- Not appropriate for large volumes: Designed for small to medium-sized batches. Large-scale production requires hard tooling for economic efficiency.

- Higher cost per unit at scale: Although starting costs are cheap, in bigger volumes, the cost per part can go up as mold replacement and upkeep are needed.

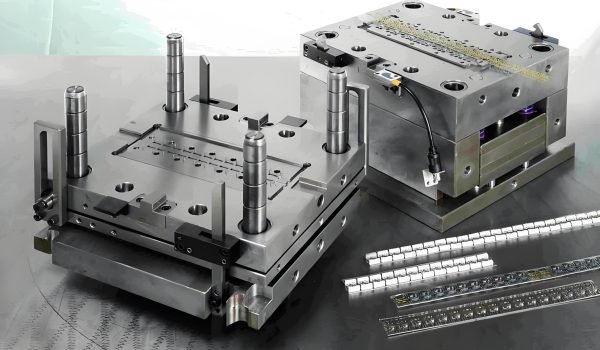

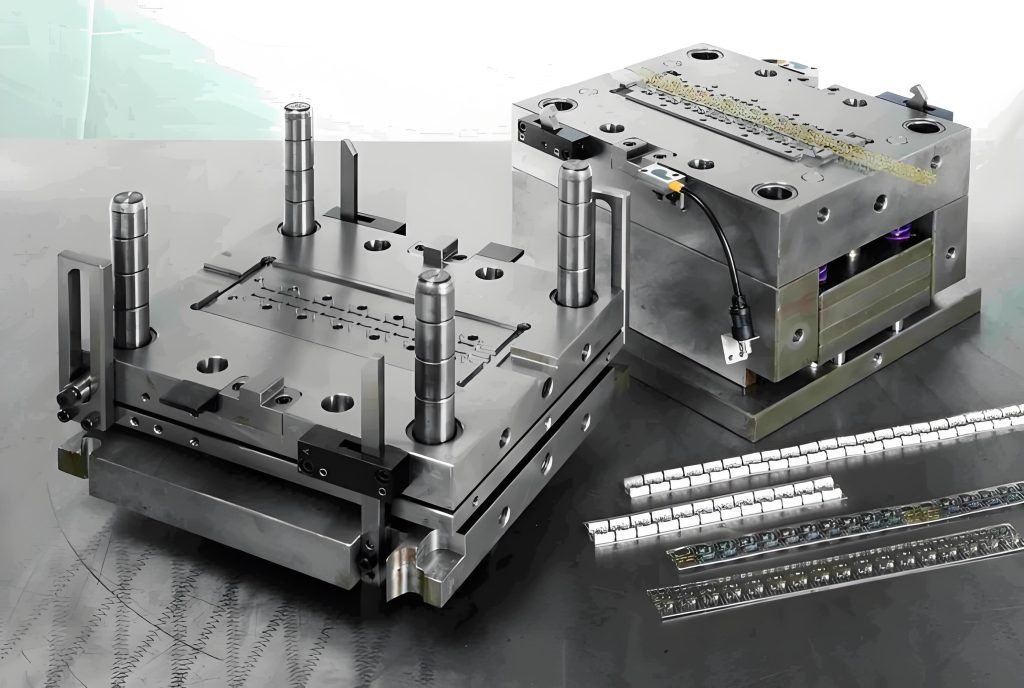

What is Hard Tooling?

Hard tooling is the making of strong, long-lasting molds usually made of hardened metals like steel, carbide, or nickel. Hard tooling is intended for high-volume production runs. Unlike soft tooling, it is mostly utilized for low-volume production and prototyping.

Hard tooling is defined by its capacity to keep structural integrity under extreme pressure and frequent usage and includes processes like injection molding, stamping, casting, and machining. Hard tooling requires a longer lead time and higher initial investment because of the tough materials employed and extra processes, including heat treatment and precision machining. It is the go-to method for mass production across industries such as automotive, aerospace, and medical devices.

Advantages of Hard Tooling

- Superior durability: Made of robust metal alloys, hard tooling can withstand heat, pressure, and wear. They have a long lifespan (usually millions of cycles) and reduced long-term maintenance needs in contrast to soft tooling.

- High precision and repeatability: It achieves tight tolerances to guarantee almost identical parts with each manufacturing cycle, which is essential for putting together complicated components that need dependability.

- High production capacity: During large runs, several cavities in hard tooling molds enable the simultaneous manufacture of multiple parts, therefore increasing efficiency and reducing material waste.

- Long-term cost efficiency: Although first expenditures are considerable, the per-unit cost is drastically reduced with high-volume manufacturing. Therefore, it is more cost-effective than soft tooling for large quantities.

Disadvantages of Hard Tooling

- Expensive to start: Hard tooling involves a large capital investment upfront in time and money, because materials are expensive and methods of manufacturing are complex.

- Limited flexibility: Deviations in the design are less easy or more expensive once created from the mold. The creation of a new tool is often required for changes, leading to reduced adaptability in production. However, there are exceptions.

- Long lead time: A prolonged delay in production start-up is caused by the time-consuming process of designing, machining, and treating hard tools through CNC and heat treatment.

- Design constraints: The limitations of traditional manufacturing methods create constraints on the use of hard tooling. It is not suitable for new processes like 3D printing and may not support all materials or complex design iterations.

Soft Tooling vs Hard Tooling

Choosing between soft tooling vs hard tooling is an essential decision, as the manufacturing method used directly affects cost, production time, and product quality. To help guide your selection, here is a comparison across key factors.

Material

Soft Tooling: It usually comprises silicone, urethane, aluminum, or some composites. Prototype or short-run applications benefit from these materials, which are also simpler to machine. They lack long-term durability yet allow for quick adjustment.

Hard Tooling: Created from hardened steel, carbide, or nickel. These have excellent strength and wear resistance when put to the additional testing that high-volume or very precise manufacturing calls for.

Production Volumes

Soft Tooling: It is most appropriate for low to medium production volumes, including market testing and prototypes. It provides an economical solution when full-scale manufacturing is not justified yet.

Hard Tooling: Designed for high-volume production where high volumes would justify the increased first cost, hard tooling is suited. It guarantees uniform production across long manufacturing runs.

Lead Time

Soft Tooling: Owing to simpler design and machining methods, it features lower lead times. This is perfect for projects with quick turnaround times or often changing designs.

Hard Tooling: Because of complex machining and demanding quality controls, hard tooling needs longer lead times. Long run, though, it provides greater durability and performance.

Cost

Soft Tooling: Lower initial costs translate into less financial risk during product development. Small production volumes are economical but can add up to more per-part costs over time.

Hard Tooling: Requires a bigger initial investment, but with high volumes, the cost per part drops dramatically. Mass manufacturing then becomes more cost-effective.

Flexibility

Soft Tooling: Because of their softer materials and basic architecture, soft tooling is quite flexible to accommodate design changes. Changes can be made fast and affordably.

Hard Tooling: Less flexible once produced; design modifications typically necessitate tool replacement. It is best used for finalized designs with stable requirements.

Durability

Soft tooling: Only appropriate for small production cycles, as it is less robust and more prone to wear. To prolong its lifespan, routine maintenance may be required.

Hard Tooling: It’s really strong and can handle high-pressure production settings. It guarantees long-term dependability and demands little maintenance.

Summary Table:

| Factor | Soft Tooling | Hard Tooling |

| Material | Silicone, urethane, aluminum, or some composites | Hardened steel, carbide, nickel |

| Production Volumes | Low-to-medium | High |

| Lead Time | Short | Long |

| Cost | Lower initial investment | Higher initial, lower per unit at volume |

| Flexibility | Easy and inexpensive to modify | Difficult and costly to change |

| Durability | Less durable, suited for short runs | Highly durable, made for long-term use |

Applications: When to Use Which Tooling?

Choosing the right tooling approach is a critical decision in production since it balances aspects such as cost, timeline, and volume. Understanding the best use for these two types of tooling ensures the best product quality and efficiency. Here are the key scenarios for employing soft and hard tooling.

When to Use Soft Tooling

Made from silicone, urethane, or low-grade metals, soft tooling prioritizes flexibility and cost-efficiency for early-stage or small-scale projects.

Prototyping and Product Development

It works well for testing designs that may change. Modified or rebuilt quickly, it keeps development agile without repeated tool investments.

Low-Volume Production

For small batches of parts like custom machinery components, it avoids the high upfront costs of hard tooling with minimal setup expenses.

Fast Turnaround Times

Made quickly, ideal for short lead time, such as urgent changing parts or trade show prototypes.

Budget-Conscious Projects

When strict surface finishes or tight tolerances aren’t critical, it reduces costs significantly while meeting basic functionality needs.

When to Use Hard Tooling

Hard tooling crafted of materials such as hardened steel, carbide, or nickel is the choice for customized precision cutting solutions and long-term production runs.

Mass Production

For large batches of identical parts like phone or car components, it maintains consistent precision across many production cycles, handling high-pressure processes that soft tooling can’t.

Long-Term Use

A well-maintained steel hard tool lasts for far more production cycles than soft tools, making it cost-effective for ongoing production over extended periods.

High Precision and Quality

For tight tolerance components, such as medical devices or aerospace parts, advanced machining is so important to produce ultra-smooth finishes and other accuracy results.

Durable Materials

It withstands abrasive materials (glass-filled plastics, carbon fiber) and high-heat processes, preventing wear that would damage soft tooling.

Special Consideration: Sheet Metal Soft Tooling vs Hard Tooling

When selecting tooling for sheet metal projects, understanding sheet metal soft tooling vs hard tooling options is critical—each serves distinct needs, with cost, lead time, and durability differences shaping project success. Below is a breakdown of special considerations for both.

Special Consideration for Sheet Metal Soft Tooling

Sheet metal soft tooling utilizes either soft, less durable materials (such as aluminum) or cutting-edge methods like laser cutting that do not require dedicated tooling equipment. It is ideal for market testing, prototyping, and low-volume runs of a few thousand components or fewer.

Its key pros include faster production—simpler setup lets production start sooner, cutting turnaround—and lower upfront costs, thanks to minimal initial investment. It also offers flexibility for design changes.

However, soft tooling has downsides: labor intensity drives higher per-part costs, and faster tool wear limits use for extended or high-volume runs.

Special Consideration for Sheet Metal Hard Tooling

Sheet metal hard tooling is made from strong, hardened materials such as steel and nickel for long-term, high-demand use. It is perfect for large runs—thousands to millions of pieces—where accuracy and consistent quality are essential.

The major benefits include lower per-part costs, where the high initial investment is offset by volume production; high precision and durability for repeatably tight specifications; and a strong long-term ROI, as a single tool can produce a vast number of parts.

Drawbacks include high upfront tooling costs, longer lead times from complex manufacturing, and low flexibility—design changes post-tool creation are costly and difficult.

Key Selection Considerations (Comparison Table)

| Consideration | Sheet Metal Soft Tooling | Sheet Metal Hard Tooling |

| Production Volume | Low volume (≤ a few thousand parts) | High volume (thousands to millions of parts) |

| Budget | Budget-friendly for initial project phases | Worthwhile investment for large-scale production |

| Lead Time | Enables quick turnaround | Requires longer preparation time |

| Part Complexity | More manageable for adjustments | Harder to create intricate parts, but precision suits high-volume needs |

| Design Stability | Ideal for expected design changes | Best for stable, unchanging designs |

Conclusion

More than only a technological one, the selection between hard tooling vs soft tooling is a tactical one, influencing your manufacturing costs, time to market, product quality, and overall business success. Your early-stage ally is soft tools, which are quick, inexpensive, and flexible for prototyping and limited runs. For high-volume, long-term manufacturing, hard tooling—which is sturdy, accurate, and economical—is your key partner for scaling.

Once you have identified your tool needs, you need a partner that provides reliability, competence, and quality. That’s where Fecision excels. At Fecision, our capabilities in mold tooling are designed to support your product journey from concept to mass production. Whether your project requires the rapid flexibility of soft tooling or the durable precision of hard tooling, we provide:

- Full-Cycle Service Integration: Covers design, prototyping, and mass production stages to meet various mold tooling needs.

- Precision Specifications: Features tolerance control of ±0.01 mm, mold cavity number ranging 1-128, and cooling channel diameter of 6-12 mm.

- Advanced Machining Capabilities: Ensures CNC accuracy of ±0.005 mm, surface roughness (Ra) between 0.4-1.6 μm, and electrode wear ratio (EDM) of 0.01-0.03 mm/min.

- Quality Materials: Applies common steel grades like P20, H13, S136 with hardness ranging 28-52 HRC for mold tooling.

- Rigorous Testing: Includes injection pressure of 50-150 MPa, 15-30% cycle time optimization, and dimensional verification via 3D scanning (≤±0.02 mm).

- Standards Compliance: Ensures mold base compatibility with HASCO, DME, and LKM, and offers surface treatment of nitriding (0.1-0.3 mm depth).

Ready to choose the right tooling path? Reach out to Fecision today to discuss your special requirements and get a tailored solution for your project’s success.