Nylon is a strong and flexible plastic used in many fields. It’s known for its durability and resistance to wear and chemicals. The injection molding method is key for making complex plastic parts.

This method involves melting plastic and shaping it in a mold. It’s a common way to create parts with precise details. Knowing nylon’s properties is important for this process.

The injection molding process works well with nylon. Its melting point and flow rate affect how the molding turns out. By understanding these, makers can create high-quality nylon parts with exact shapes and sizes.

Nylon is a top pick for injection molding because of its many benefits. It’s strong, light, and doesn’t corrode easily. These qualities make nylon perfect for parts that need to be tough, bendable, and resistant to chemicals.

Understanding Injection Molding

Injection molding is key in making lots of the same plastic parts. It works by pouring molten plastic into a mold. The plastic then cools and hardens, taking the mold’s shape. This method can make everything from simple items to complex parts, thanks to material science.

First, a mold is made for a specific part. Then, molten plastic, like nylon, is pushed into the mold under pressure. After cooling, the mold opens, and the part pops out. This can happen thousands of times, making it great for making lots of parts.

Some common materials used in injection molding include:

- Polypropylene

- Polyethylene

- Nylon

- Polyvinyl Chloride (PVC)

These materials are picked for their strength, flexibility, and how well they handle heat and chemicals. The right material depends on what the part will be used for, making sure it meets the needed standards.

Knowing how injection molding works and the qualities of different materials is vital. It helps make the production process better and ensures the quality of the final product. This is important in plastic manufacturing and material science.

Nylon: An Overview

Nylon is a versatile synthetic polymer used in many industrial applications. Its unique properties make it perfect for a wide range of products. To understand nylon’s value in injection molding, we need to look at the different nylon types and their characteristics.

There are several nylon types, each with its own properties and uses. The most common types include nylon 6, nylon 6,6, and nylon 12. These types are used in industries like automotive, aerospace, and consumer goods.

Types of Nylon

- Nylon 6: known for its high strength and resistance to abrasion

- Nylon 6,6: offers excellent heat resistance and chemical stability

- Nylon 12: provides low moisture absorption and high dimensional stability

Properties of Nylon

Nylon has many properties that make it great for various uses. It’s strong, elastic, and resistant to chemicals. It can also handle extreme temperatures and conditions, making it perfect for harsh environments.

Applications of Nylon in Industry

Nylon is a popular choice for many industrial applications. Its high strength, chemical resistance, and ability to withstand extreme temperatures make it ideal. It’s used in the automotive, aerospace, and consumer goods industries.

In conclusion, nylon is a versatile material with many industrial applications. Its unique properties make it perfect for various products, from automotive parts to consumer goods. Knowing the different nylon types and their properties is key to choosing the right material for specific applications.

| Nylon Type | Properties | Industrial Applications |

|---|---|---|

| Nylon 6 | High strength, resistance to abrasion | Automotive, aerospace |

| Nylon 6,6 | Heat resistance, chemical stability | Consumer goods, industrial equipment |

| Nylon 12 | Low moisture absorption, high dimensional stability | Aerospace, automotive |

Advantages of Using Nylon in Injection Molding

Nylon is a favorite for injection molding because of its special mix of traits. It’s durability makes it perfect for parts that face a lot of use and tough conditions. Plus, its lightweight materials are great for when you need to cut down on weight.

Some of the main pluses of nylon in injection molding are:

- High strength-to-weight ratio

- Excellent chemical resistance

- Good abrasion resistance

- Low friction coefficient

Nylon is a top pick for many fields, like cars, industry, and even medical tools. It’s also great for making complex shapes and designs.

So, nylon’s benefits in injection molding make it a go-to for many industries. Its durability, lightweight materials, and other good points make it perfect for making top-notch parts and products.

| Property | Description |

|---|---|

| Durability | High resistance to wear and tear |

| Lightweight | Low density material |

| Chemical Resistance | Ability to withstand harsh chemicals |

Challenges of Injection Molding Nylon

Injection molding nylon is a complex process because of its unique properties. One big concern is temperature sensitivity. If nylon is not processed at the right temperature, it can degrade. This can make the material weaker and affect the product’s quality.

Nylon also absorbs moisture easily. This can cause it to change shape and weaken its mechanical properties. This is a big problem in applications where keeping the shape and strength is important.

Common Challenges

- Temperature sensitivity: affects mechanical properties and quality

- Moisture absorption: causes dimensional changes and affects mechanical properties

- Shrinkage issues: can lead to warping or distortion of the final product

To overcome these challenges, it’s key to control the process and choose the right material. Knowing nylon’s properties and its challenges helps manufacturers make better products.

Best Practices

Following best practices can help. This includes controlling temperature and humidity, handling materials right, and designing molds well. These steps help reduce risks and make high-quality products.

| Challenge | Solution |

|---|---|

| Temperature sensitivity | Control processing temperature and use thermal stabilizers |

| Moisture absorption | Use dryers and control humidity levels |

| Shrinkage issues | Optimize mold design and use shrinkage-reducing additives |

The Role of Additives in Nylon Injection Molding

Nylon injection molding is a complex process. It involves choosing the right nylon and adding special materials. These additives boost the product’s strength, durability, and resistance to heat and chemicals.

Using additives in nylon molding can greatly improve the product’s performance. For example, glass or carbon fibers make the material stronger and stiffer. Silicone or Teflon, on the other hand, help it resist heat and chemicals better.

Common Additives Used

- Glass fibers: improve strength and stiffness

- Carbon fibers: increase strength and reduce weight

- Silicone: enhances heat resistance

- Teflon: improves chemical resistance

Benefits of Additives in Performance

Adding special materials to nylon molding has many advantages. It can make the material last longer, need less maintenance, and look better. This makes the product more appealing to buyers.

| Additive | Benefit |

|---|---|

| Glass fibers | Improved strength and stiffness |

| Carbon fibers | Increased strength and reduced weight |

| Silicone | Enhanced heat resistance |

| Teflon | Improved chemical resistance |

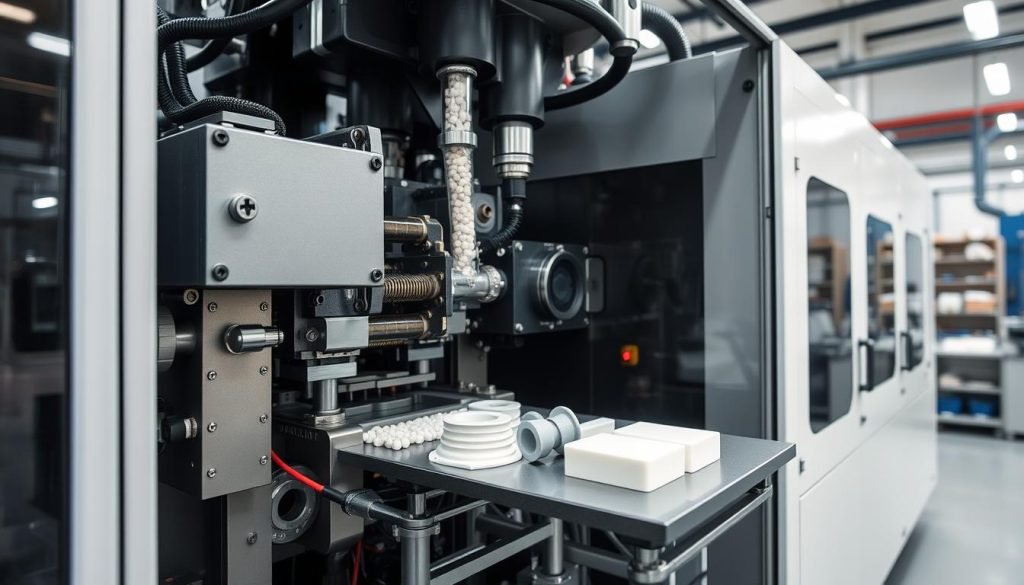

Equipment Required for Nylon Injection Molding

To make high-quality nylon products, you need the right tools. This includes injection molding machines that work well with nylon. The type of machine you choose depends on the product’s size, complexity, and how many you want to make.

Molds and tooling are also key. They are made to fit the product’s design exactly. The quality of these molds greatly affects the product’s look and feel.

Key Equipment Components

- Injection molding machines: These machines melt and inject nylon into molds.

- Molds and tooling: Made to shape nylon into the exact product form.

- Auxiliary equipment: Helps with preparing nylon, recycling, and managing workflow.

Keeping injection molding machines and molds and tooling in good shape is important. It helps keep production going and prevents mistakes. Regular care can make the equipment last longer, reduce downtime, and keep product quality high.

| Equipment | Description |

|---|---|

| Injection Molding Machines | Core equipment for melting and injecting nylon into molds. |

| Molds and Tooling | Custom-designed for shaping nylon into the desired product form. |

| Auxiliary Equipment | Supports the injection molding process with material preparation and workflow management. |

Best Practices for Injection Molding Nylon

To make high-quality nylon products, following best practices is key. This means thinking about the product’s design and choosing the right materials. It also involves checking the mold and watching the production closely to avoid mistakes.

Some important design tips for nylon injection molding include:

- Wall thickness: Keeping walls the same thickness to avoid warping or cracking

- Gate location: Placing gates wisely to reduce flow problems and material damage

- Material selection: Picking the best nylon for the job, based on strength, flexibility, and chemical resistance

Quality control is also vital for a good product. This means having a system to check and test regularly. By following these steps, makers can create nylon products that are top-notch.

By focusing on design and quality, makers can make nylon products that last. This makes customers happier and reduces the chance of product failures.

| Design Considerations | Quality Control Measures |

|---|---|

| Product geometry | Regular inspections |

| Material selection | Testing and analysis |

| Gate location | Process monitoring |

Case Studies of Nylon Injection Molding

Nylon injection molding has been a hit in many industries. Its strength, durability, and chemical resistance make it perfect for many uses. This includes automotive applications and consumer goods.

In the car world, nylon is used for fuel tanks and air intake manifolds. These parts need to be strong and not react to chemicals. For everyday items, nylon is great for outdoor gear, sports equipment, and home goods.

Nylon has also led to new, better products in consumer goods. For example, it makes backpacks and camping gear that are both tough and light. This is thanks to nylon’s unique qualities.

- Automotive parts, such as fuel tanks and air intake manifolds

- Consumer goods, such as outdoor gear and household items

- Medical devices, such as surgical instruments and implantable devices

These examples show how nylon injection molding makes top-notch products. Its special qualities make it great for many uses. As technology advances, we can expect to see even more uses for nylon.

Conclusion: The Future of Nylon in Injection Molding

The future of nylon in injection molding is looking bright. New advancements in materials science are leading to better nylon materials. These materials are more durable and sustainable. The industry is also focusing more on environmentally-conscious practices.

There’s a big push towards sustainability in nylon molding. Companies are using recycled nylon to cut down waste and carbon emissions. They’re also exploring bio-based nylon made from renewable sources, which is better for the planet.

At the same time, technological innovations are changing the game. New machines and processes are making nylon production more efficient and cost-effective. This means better quality and lower costs for everyone.

Looking ahead, nylon’s role in injection molding will only grow. It will help make manufacturing more sustainable and innovative. The future is looking very promising for nylon in this field.