Acrylic injection molding has become more popular in recent years. It’s known for making high-quality products with special thermoplastic properties. Acrylic is a type of thermoplastic that can be molded into many shapes and forms.

The process involves injecting molten plastic into a mold. It then cools and solidifies, taking the mold’s shape.

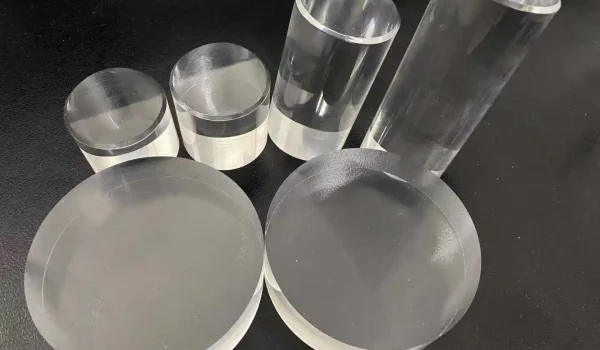

Knowing acrylic’s properties is key to understanding if it’s good for injection molding. This method can create products with great clarity and beauty. Acrylic’s thermoplastic nature makes it a top choice for making high-quality, complex products.

Acrylic’s unique properties combined with the injection molding process are very exciting. We’ll look into the challenges and opportunities of working with this material. This includes its sensitivity to temperature and its uses in different industries.

Overview of Acrylic as a Thermoplastic

Acrylic is a versatile thermoplastic material used in many manufacturing processes. It’s great for molding complex shapes. This makes it perfect for a wide range of applications.

Acrylic’s chemical makeup and physical traits are key. It can be made to be tough, clear, and flexible. These qualities are important for its use in injection molding.

What is Acrylic?

Acrylic comes from acrylic acid and is a synthetic material. It’s a thermoplastic that can be melted and reshaped many times. This makes it great for molding and reshaping.

Properties of Acrylic

Acrylic is known for being clear, tough, and easy to color. These traits make it popular for signs, displays, and lights. It can be molded in several ways, like injection molding and extrusion.

Comparison with Other Thermoplastics

Acrylic is compared to other thermoplastics like polycarbonate and polyethylene. While similar, they differ in impact resistance and flexibility. Knowing these differences helps choose the right material for a project.

In summary, acrylic is a versatile thermoplastic with many benefits. It’s perfect for molding complex shapes and forms. Understanding its properties and comparisons helps manufacturers pick the best material for their needs.

The Injection Molding Process

The injection molding process is complex and needs a good grasp of material science. It uses thermoplastics like acrylic, which are melted and shaped as needed. First, the mold is designed, often from metal or aluminum.

Then, the mold is filled with hot plastic under high pressure. This process is key in many fields, like cars, medicine, and everyday items. It’s precise, cost-effective, and can make complex shapes. But, picking the right material is critical, as each has its own needs.

Steps Involved in Injection Molding

- Design of the mold

- Selection of the material

- Melting of the material

- Injection of the material into the mold

- Cooling and solidification of the material

Materials Suitable for Injection Molding

Many materials work for injection molding, like acrylic, polypropylene, and polyethylene. The right material depends on the product’s needs. For example, acrylic is great for clear items, like medical tools and household goods.

The injection molding process is vital in material science. It’s used more and more in different areas. Knowing the process and the right materials helps make high-quality, detailed products.

| Material | Properties | Applications |

|---|---|---|

| Acrylic | Transparent, impact resistant | Medical devices, consumer goods |

| Polypropylene | Chemical resistant, flexible | Automotive, packaging |

| Polyethylene | Chemical resistant, durable | Packaging, industrial |

Challenges of Injection Molding Acrylic

Acrylic is a versatile thermoplastic used in many ways. But, it also has some big challenges in injection molding. One major issue is its temperature sensitivity. If the temperature isn’t just right, it can cause warpage or discoloration in the final product.

Another big problem is acrylic’s brittleness. This can lead to stress issues and cracking. This is a big issue when the product is under mechanical stress or impact. To tackle these problems, manufacturers need to think about acrylic’s material limitations and find ways to get past them.

- Temperature sensitivity, which can affect the material’s flow and solidification

- Material limitations, such as brittleness and susceptibility to stress cracking

- Difficulty in achieving consistent color and texture

By understanding these challenges and finding ways to solve them, manufacturers can make high-quality products. These products will meet their needs and overcome the hurdles of injection molding acrylic.

Advantages of Using Acrylic in Injection Molding

Acrylic is a favorite for injection molding because of its clear look, beauty, and toughness. It’s great for many uses, from everyday items to medical tools. Its shiny finish is perfect for products that look sleek and modern.

Acrylic has many benefits for molding, like being light and strong. This makes it perfect for items that are both useful and look good. Some main advantages of using acrylic include:

- It’s clear and transparent, great for where you need to see things clearly

- It has a shiny finish that can be changed to fit design needs

- It’s light and strong, ideal for items that are easy to carry and last long

- It can handle impacts and stress well, so it’s good for items that get used a lot

Overall, acrylic is a top choice for many uses because of its clear look, beauty, and toughness. It’s a great material for injection molding.

| Material | Clarity | Aesthetic Appeal | Lightweight | Durable |

|---|---|---|---|---|

| Acrylic | High | High | Yes | Yes |

| Polycarbonate | High | Medium | Yes | Yes |

| Polypropylene | Low | Low | Yes | No |

Applications of Injection Molded Acrylic

Acrylic is used in many ways across different industries. It’s perfect for making new and useful items. This is because of its special qualities, which make it great for electronics, medical devices, and more.

Some common industries that use acrylic include:

- Electronics: acrylic is used in the production of screens, displays, and other components

- Medical devices: acrylic is used in medical equipment, such as diagnostic instruments and implantable devices

- Consumer goods: acrylic is used in a variety of everyday products, including kitchen utensils, cosmetic containers, and lighting fixtures

Acrylic is found in lighting fixtures, cosmetic containers, and kitchen utensils. Its clear look and feel make it a favorite. It’s also light and strong, making it perfect for daily use.

New uses for acrylic are always being found. As technology gets better and more people need molded plastic, we’ll see even more cool uses for acrylic.

| Industry | Acrylic Application |

|---|---|

| Electronics | Screens and displays |

| Medical devices | Diagnostic instruments and implantable devices |

| Consumer goods | Kitchen utensils, cosmetic containers, and lighting fixtures |

Alternatives to Injection Molding Acrylic

Injection molding isn’t always the best choice for working with acrylic. Other methods like alternative manufacturing methods are available. These include CNC machining and 3D printing, each with its own benefits.

These alternatives offer more flexibility and faster production times. CNC machining is great for detailed designs. 3D printing, on the other hand, can create complex shapes that traditional methods can’t.

Here are some plastic production techniques that can replace injection molding:

- CNC machining: Uses computer-controlled machines to shape acrylic.

- 3D printing: Builds complex structures by layering plastic.

In summary, CNC machining and 3D printing are great for making high-quality acrylic products. They offer flexibility, speed, and the ability to create complex shapes. These methods are perfect for projects that go beyond traditional injection molding.

| Manufacturing Method | Benefits | Applications |

|---|---|---|

| CNC Machining | Precise cutting and shaping, increased flexibility | Intricate designs, complex geometries |

| 3D Printing | Complex geometries and structures, reduced production time | Prototyping, production of complex parts |

Best Practices for Injection Molding Acrylic

Injection molding acrylic needs careful thought about many factors for success. By sticking to best practices and guidelines, makers can avoid problems and make the process better.

Recommended Temperatures and Pressures

Getting the right temperatures and pressures is key to avoid defects and keep quality high. The best temperature is between 180°C to 220°C. Pressures should be between 80 MPa to 120 MPa.

Tooling Design Considerations

Designing the tool well is also vital for molding acrylic. Think about these important points:

- Gate size and location

- Cooling system design

- Ejection system design

A good tool design can cut costs and boost product quality. By following these tips and thinking about the production needs, makers can make acrylic molding a success.

| Factor | Recommended Value |

|---|---|

| Temperature | 180°C to 220°C |

| Pressure | 80 MPa to 120 MPa |

Environmental Considerations and Recycling

As we worry more about the environment, it’s key to think about acrylic’s sustainability and recycling. Making and throwing away acrylic can harm our planet. So, we need to find green alternatives and recycling ways.

Recycling plastics, including acrylic, saves resources and cuts down landfill waste. We can recycle and reuse acrylic, saving the planet from more harm.

Sustainability of Acrylic Materials

Acrylic is made from recyclable plastic. Its greenness depends on how it’s made, the plastic type, and recycling choices. Some businesses use recycled acrylic, making their products better for the earth.

Recycling Options for Acrylic Products

There are many ways to recycle acrylic, like curbside programs and special facilities. Some companies let you return used items for recycling. Recycling acrylic helps lessen plastic waste and saves resources.

We all must work together to lessen acrylic’s environmental harm. Manufacturers, consumers, and recyclers can make a difference. Using recycled acrylic in making products also helps reduce plastic waste.

Future Trends in Acrylic Injection Molding

The future of acrylic injection molding is exciting. New technologies will bring big changes. We can expect better efficiency, precision, and care for the environment.

Innovations in Technology

Companies are always looking for new ways to improve injection molding. They’re using better computer design and simulation tools. This means they can make molds and parts more accurately.

They’re also adding smart sensors and data analytics. This lets them watch the process in real time. It helps them catch problems quickly and make better products.

Potential Market Growth and Demand

The future of injection molding is looking good. Experts think there will be steady market trends for acrylic products. People want materials that are light, strong, and look good.

This means more uses for injection-molded acrylic. It will be used in cars, electronics, and everyday items.

FAQ

Can acrylic be injection molded?

Yes, acrylic can be injection molded. It’s a thermoplastic material that works well with this technique.

What are the properties of acrylic that make it suitable for injection molding?

Acrylic is great for injection molding because it’s clear, rigid, and resistant to impact. It’s also easy to color and has low density. These qualities make it popular for many uses.

How does the injection molding process work?

The process starts by melting the plastic. Then, it’s pushed into a mold under pressure. Once it cools, it takes the mold’s shape. This method is fast and cost-effective for making complex parts.

What are the challenges of injection molding acrylic?

One big challenge is its sensitivity to temperature. Acrylic needs careful temperature control to avoid problems like warping. It can also crack or craze under stress, which must be managed during molding.

What are the advantages of using acrylic in injection molding?

Acrylic offers high clarity and a smooth surface. It’s also light but strong. Plus, it can be tinted or colored easily. These traits make it a favorite for many applications, from gadgets to medical tools.

In what industries is injection molded acrylic commonly used?

It’s used in many fields, like electronics, lighting, cars, healthcare, and consumer goods. Common uses include lenses, signs, displays, packaging, and household items.

Are there alternatives to injection molding for working with acrylic?

Yes, methods like CNC machining and 3D printing are alternatives. They’re better for complex shapes or small batches.

What are the environmental considerations and recycling options for acrylic?

Acrylic is recyclable and can be reused. But, consider the environmental impact of molding it. Recycling options exist, and efforts to make the material and process more sustainable are ongoing.