When selecting materials for manufacturing parts, understanding their mechanical behavior is crucial. You might wonder, “What happens when a material is subjected to stress, and how can we predict its performance?”

The answers lie in two critical material properties: the point at which a material deforms permanently under stress, and the maximum stress it can withstand before breaking.

These properties are essential in characterizing a material’s response to external forces and its overall strength under various conditions. Understanding these concepts is vital for engineers and designers to ensure the reliability and safety of finished products.

By grasping these fundamental concepts, you’ll be able to make informed decisions about material selection based on strength requirements for specific applications, ultimately impacting the performance and longevity of machined or molded parts.

Understanding Material Strength Properties

Material strength properties serve as the foundation for engineering design decisions, particularly in structural applications where safety and reliability are paramount. You need to understand these properties to ensure that the components you design can withstand various forces without failing or deforming permanently.

The Importance of Material Properties in Engineering

Material properties, including tensile strength and yield strength, offer valuable insights into a material’s durability and suitability for specific applications. These properties are critical in determining the overall structural integrity and reliability of various products and structures. By understanding material properties, engineers can make informed decisions about material selection and design.

How Material Strength Affects Part Performance

The strength of a material directly impacts its performance in real-world applications. For instance, in automotive and aerospace industries, material strength is crucial for ensuring the safety and reliability of components. If a material’s strength is inadequate, it can lead to premature failure, safety hazards, and increased maintenance costs. By selecting materials with appropriate strength properties, you can optimize part performance and ensure the overall reliability of the final product.

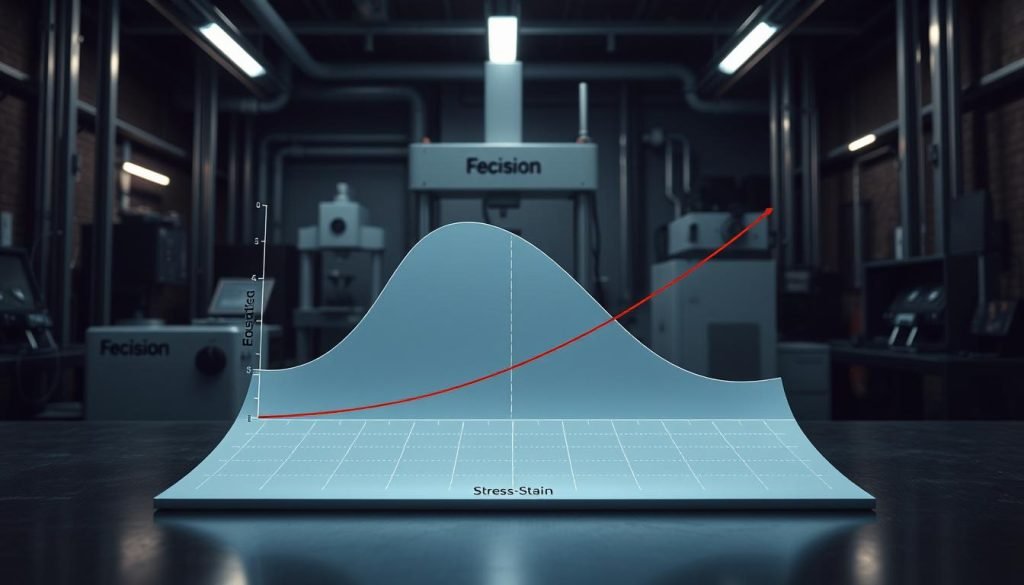

The Stress-Strain Curve Explained

The stress-strain curve is a graphical representation that helps in understanding the mechanical properties of materials. It illustrates how materials respond to applied forces, providing critical information about their behavior under stress. By analyzing this curve, engineers can determine key material properties.

What is Stress and Strain?

Stress refers to the force applied per unit area of a material, causing it to deform. Strain, on the other hand, measures the resulting deformation relative to the material’s original dimensions. Understanding these concepts is fundamental to interpreting the stress-strain curve.

Interpreting the Stress-Strain Curve

The stress-strain curve can be broken down into several regions, including the elastic region, yield point, plastic region, and ultimate tensile strength point. Each region provides insights into the material’s behavior under different levels of stress. By analyzing these regions, engineers can determine a material’s elastic modulus, yield strength, and tensile strength.

Different materials exhibit unique stress-strain curves, with ductile materials like metals showing a distinct yield point and plastic region, whereas brittle materials like ceramics fracture without significant plastic deformation. The shape of the curve provides valuable information about a material’s toughness, ductility, and resilience.

What is Yield Strength?

The concept of yield strength is essential in material science, as it indicates the maximum stress a material can withstand without undergoing permanent deformation. Yield strength is a critical property that engineers consider when designing components to ensure they can handle the stresses they will encounter during service.

Definition and Measurement

Yield strength is defined as the stress at which a material begins to deform plastically, transitioning from elastic to permanent deformation. It is measured through standardized testing procedures, including tensile testing, where the yield point is determined on the stress-strain curve. This measurement is crucial for understanding a material’s behavior under different loads.

Elastic vs. Plastic Deformation

When a material is subjected to stress below its yield point, it undergoes elastic deformation, returning to its original shape once the stress is removed. However, if the stress exceeds the yield point, the material experiences plastic deformation, resulting in permanent changes to its shape or form. Understanding this distinction is vital for selecting materials that meet specific application requirements.

What is Tensile Strength?

Understanding tensile strength is essential for selecting materials that can resist pulling forces without failing. Tensile strength is a measure of a material’s ability to withstand tensile loads until it fractures or breaks.

Definition and Measurement

Tensile strength is defined as the maximum stress a material can withstand while being stretched or pulled before failing or breaking. It is measured through standardized testing procedures, where specimens are subjected to increasing tensile loads until failure occurs. This testing helps determine a material’s resistance to fracture.

Ultimate Tensile Strength vs. Breaking Point

The ultimate tensile strength is the maximum stress on the stress-strain curve, representing the highest point of tensile load a material can handle. The breaking point, on the other hand, is where complete separation occurs. Different materials exhibit different failure modes when their tensile strength is exceeded, including ductile failure with significant deformation and brittle failure with minimal warning.

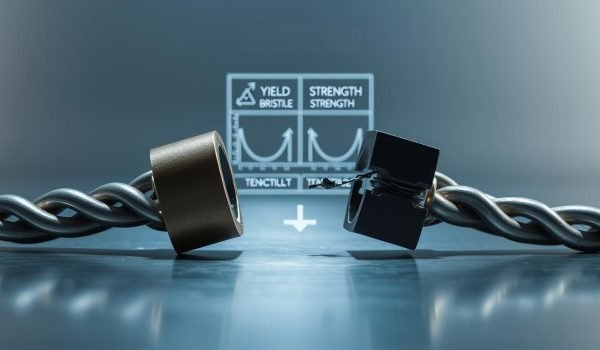

Yield Strength Vs Tensile Strength: Key Differences

The comparison between yield strength and tensile strength provides valuable insights into a material’s behavior under stress. Yield strength is measured at the point of plastic deformation, whereas tensile strength is measured at the point of fracture.

Comparative Analysis

Yield strength occurs at the onset of permanent deformation, while tensile strength represents the maximum stress before fracture. Yield strength is always lower than tensile strength, regardless of the material type. The difference between these values relates to a material’s ductility.

| Property | Yield Strength | Tensile Strength |

|---|---|---|

| Definition | Stress at plastic deformation | Maximum stress before fracture |

| Material Behavior | Onset of permanent deformation | Maximum stress before failure |

| Design Consideration | Preventing permanent deformation | Preventing catastrophic failure |

Practical Implications of the Differences

Engineers use yield strength for preventing permanent deformation and tensile strength for preventing catastrophic failure. The ratio between yield and tensile strength provides insights into a material’s behavior, with higher ratios indicating more brittle behavior. Understanding these differences is crucial for material selection and design considerations.

Factors Influencing Yield and Tensile Strength

Several factors play a critical role in determining the yield and tensile strength of materials used in engineering applications. Understanding these factors is essential for optimizing material performance.

Material Composition and Microstructure

Material composition significantly influences both yield and tensile strength. The proportions of different elements and their interactions can enhance or reduce these mechanical properties. For instance, increasing the carbon content in certain steel alloys can enhance tensile strength. The microstructure, including grain size and phase distribution, also plays a vital role in determining a material’s strength properties.

Environmental and Processing Factors

Environmental factors, such as temperature, and processing methods also impact yield and tensile strength. Elevated temperatures typically decrease yield strength by facilitating dislocation movement. Processes like heat treatment and cold working can be used to manipulate and optimize these properties for specific applications.

| Factor | Effect on Yield Strength | Effect on Tensile Strength |

|---|---|---|

| Material Composition | Increases with certain alloying elements | Can be enhanced by specific elements |

| Temperature Increase | Decreases due to reduced intermolecular forces | Generally decreases |

| Cold Working | Increases due to strain hardening | Increases |

Yield and Tensile Strengths of Common Materials

When it comes to material selection, knowing the yield and tensile strengths of common materials can make a significant difference. These properties are crucial in determining the suitability of a material for a specific application.

Metals and Alloys

Metals and alloys are widely used in various industries due to their excellent mechanical properties. Here, we discuss some common types:

Aluminum Alloys

Aluminum alloys like 6061, 7075, and 2024 are known for their high strength-to-weight ratios, making them ideal for aerospace and automotive applications.

Steel Alloys

Steel alloys, including carbon steel and high-strength low-alloy (HSLA) steels, exhibit varying tensile strengths. For example, carbon steel typically ranges from 400 to 700 MPa.

Stainless Steel Alloys

Stainless steel alloys offer a combination of corrosion resistance and strength, making them suitable for harsh environments.

Titanium Alloys

Titanium alloys are renowned for their exceptional strength-to-weight ratios, corrosion resistance, and biocompatibility, making them valuable for aerospace and medical applications.

Copper and Brass Alloys

Copper and brass alloys are used for their excellent electrical conductivity and moderate strength properties.

| Material | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| Aluminum 6061 | 240 | 290 |

| Carbon Steel | 250 | 400-700 |

| Stainless Steel 304 | 215 | 505 |

Non-Metallic Materials

Non-metallic materials, such as plastics, polymers, and composites, offer unique combinations of properties that make them suitable for various applications.

Plastics and Polymers

Plastics and polymers are used in a wide range of applications due to their versatility and ease of processing.

Composites

Composites, such as carbon fiber reinforced polymers (CFRP), offer high strength-to-weight ratios and are used in high-performance applications.

| Material | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| Polyethylene | 20-30 | 20-40 |

| CFRP | – | 1000-2000 |

Selecting Materials Based on Strength Requirements

To ensure the longevity and performance of a component, it’s essential to select a material that meets the specific strength requirements of the application. This involves a comprehensive understanding of the material properties and how they relate to the component’s intended use.

Application-Specific Considerations

Different industries have unique requirements for material strength. For instance, aerospace components often prioritize weight reduction while maintaining strength, whereas structural components focus on long-term durability under varying environmental conditions. You must consider these application-specific factors when selecting materials.

Safety Factors and Design Limitations

In engineering design, safety factors are crucial to account for uncertainties and variations in material properties and loading conditions. Typically, materials are specified with strength properties several times greater than the maximum expected stress. Understanding these safety factors and potential design limitations is vital for optimal material selection.

When evaluating materials based on strength requirements, consider the following table that compares the yield and tensile strengths of common materials used in engineering applications:

| Material | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| Aluminum 6061-T6 | 240 | 290 |

| Stainless Steel 304 | 215 | 505 |

| Carbon Steel A36 | 250 | 400-550 |

By carefully evaluating the strength requirements of your project and considering application-specific factors, safety factors, and design limitations, you can select the most appropriate material to ensure your component withstands the expected stresses and loads.

Conclusion

Understanding the distinction between yield strength and tensile strength is crucial for material selection in engineering applications. Yield strength represents the stress at which a material begins to deform permanently, while tensile strength indicates the maximum stress before fracture.

You should consider both properties for ductile and brittle materials to ensure the chosen material returns to its original shape under stress below the yield strength. Consulting with materials engineers can provide precise knowledge for critical applications.