In precision manufacturing, machining complex, high-hardness metals with intricate geometries presents a major challenge—traditional cutting tools often struggle with breakage, deformation, or require prohibitively expensive equipment. This is where electrical discharge machining comes in. In this guide, we’ll explore how wire EDM works, its key advantages, and its diverse industrial applications.

What is Wire EDM Cutting?

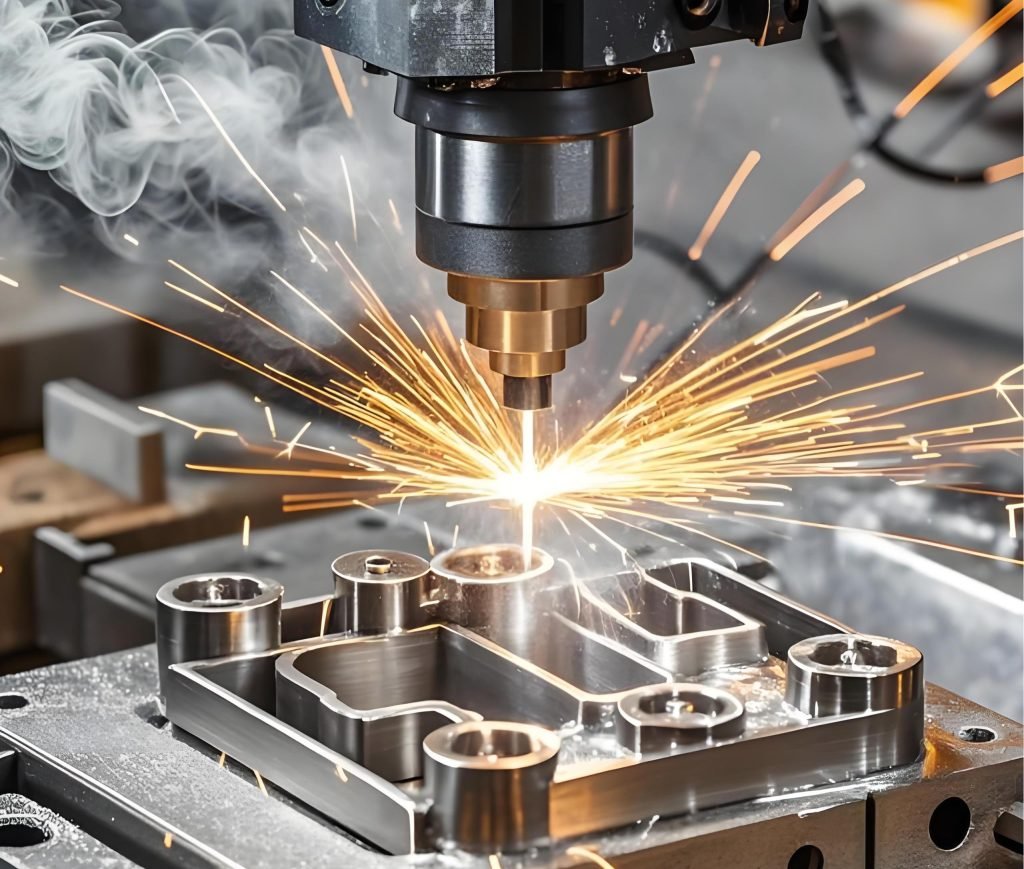

Wire EDM (electrical discharge machining) is a high-accuracy manufacturing process that uses a moving wire as an electrode to continuously cut conductive materials like metals, making it a key technique in EDM cutting. In most cases, this live wire made of brass or copper forms sparks, which cause the spark-melt disintegration of workpiece material. CNC-controlled machining allows the production of complex geometries, such as complicated molds and precision components, without physical contact. Therefore, the material remains resistant to deformation. This method successfully processes complex parts that are usually unsuited for traditional cutting techniques.

How Does Wire EDM Cutting Work

A thin, charged wire (typically brass or zinc-coated) moves along a programmed path near the workpiece, which is submerged in dielectric fluid (usually deionized water). When the wire and workpiece approach each other, high-voltage sparks generate intense heat, vaporizing microscopic particles of the material. The dielectric fluid serves three critical roles: it acts as an insulator until the voltage reaches the sparking threshold, cools the cutting zone, and flushes away eroded debris.

Because the wire never physically contacts the workpiece, there’s no mechanical force—just controlled thermal erosion. This allows for micron-level accuracy, intricate geometries, and exceptionally smooth finishes, even in ultra-hard or delicate materials.

Components of A Wire EDM Machine

A wire EDM machine is a sophisticated integration of several critical subsystems. Here are the key parts:

CNC Control

The brain of the operation. Using stepper motors and programmed instructions, it automates the cutting path and wire movement. Ideal CNC leads to fewer mistakes and quicker work.

Power Supply

This unit delivers 100–300 V electrical pulses to the wire and workpiece, controlling the frequency and intensity of charges. An advanced power supply is essential to provide the right charge type and quality, directly influencing cutting efficiency and accuracy in EDM wire cutting.

Dielectric Fluid

Wire-cut EDM requires a dielectric bath. This special fluid, called a dielectric, keeps tiny bits of the workpiece from sticking to the wire, clears away any mess, and eases the heat stress on the workpiece. The dielectric most often used is deionized water. It not only cools things down during the process but also helps create a smooth and clean finish on the surface.

Electrodes

The core electrical interaction involves the wire acting as the cathode and the workpiece as the anode. This arrangement is critical for generating the electrical discharges that shape the material. A servo motor plays a vital role here, constantly adjusting the wire’s position to ensure it never makes physical contact with the workpiece during cutting.

Wire Feeding System

This system controls the wire’s tension and feed speed, enabling its reciprocating movement and proper coiling on the drum without overlaps. By maintaining stable wire positioning, it supports consistent cutting performance.

Wire Electrode

The wire itself is the electrode that generates electrical discharges, with its diameter determined by the workpiece’s thickness and shape (typically 0.05–0.25 mm). Common types include:

- Brass (most popular, balancing cost, conductivity, and speed);

- Copper (good conductivity but slow cutting, low durability);

- Tungsten/molybdenum (Pricier, faster cutting, better wear resistance);

- Coated wires (e.g., zinc-coated, diffusion-annealed) for enhanced performance;

- Steel-core brass (improved straightness for precision tasks)

- Selection is based on factors such as tensile resistance, conductivity, and vaporization temperature.

Working Table

Holds the workpiece firmly. Separate stepper motors move it precisely relative to the wire. High-speed tables use ball screws and guides on X/Y axes for rigidity and control.

Recycling System

Cleans the dielectric fluid (deionized water). A pump pulls water from the tank, filters out impurities, sends it to nozzles near the cut, and returns it to the tank. If the cutting quality declines, change the filter or fluid.

Materials That A Wire EDM Machine Can Cut

The use of wire EDM has become widespread, enabling it to create intricate designs on workpieces, but its efficacy is restricted to materials with high conductivity, which is due to the nature of the electrical discharge process. Here’s a detailed summary of materials appropriate for wire EDM manufacturing, including their primary characteristics and critical factors to account for:

| Material Category | Key Properties for Wire EDM | Advantages of Wire EDM | Important Considerations |

| Aluminum & Alloys | Excellent conductivity, naturally soft | Capable of intricate cuts | Can form gummy residue; requires careful flushing |

| Titanium & Alloys | Excellent conductivity, sticky | Withstands stickiness, breaks long chips; minimal heat distortion | Requires deionized water dielectric for heat control |

| Steel – Pre-Hardened/Die Steel | Inherent hardness from heat treatment | Maintains shape integrity; minimizes wire deflection → smoother finish, longer tool life | Ideal; avoids post-machining heat treatment |

| Steel – Austenitic Stainless | High corrosion resistance, good thermal conductivity | Prevents thermal damage; keeps the cutting sharp | Performs well with appropriate settings |

| Steel – Carbon/Alloy/High Alloy | Very strong | Preferred over CNC for complex shapes in hard steel | Generates significant heat; precautions essential |

| Steel – Non-Hardened | Lower hardness | Can be cut | Suffers from tool wear; higher machining cost; less cost-effectiveness |

| Brass | High tensile strength, soft, lower melting point | Relatively easy to cut | Requires slow cutting speeds; less cost-effective than some alternatives |

| Bronze | Good machinability, lower melting point | Suitable for cutting | Less cost-effective; reduced tool life |

| Copper & Alloys (includes Pure Copper) | Good conductivity | Can be cut | Often more cost-effectively machined with other methods |

| Graphite | Conductive, brittle | Sharp wire prevents particle pull-out; avoids issues with conventional tools | Requires specific parameters |

| Tungsten & Molybdenum | Very high melting point | Withstands intense heat; minimal thermal distortion; efficient heat dissipation | Well-suited for the process |

| Other Metals (Inconel, Hastelloy, Kovar) | Tough, heat-resistant | Capable of precision machining | Requires robust parameters |

| Cemented Carbide (YG, YT series) | Extreme hardness | Can be cut effectively | Suitable for intricate shapes |

| Heat-Treated Materials (General) | Hardened state | Cuts without causing distortion | Particularly useful for post-hardening machining |

Materials NOT suitable for wire EDM:

- Non-conductive materials: Plastics, ceramics, glass, rubber, wood, paper, and other non-metallic materials, which lack the electrical conductivity essential for the EDM process.

EDM Wire Cutting vs Conventional EDM

EDM involves the use of controlled electrical sparks to modify the shape of conductive materials. Wire EDM and conventional EDM operate differently and have distinct applications that complement each other. Here are the key differences:

Electrode Type: The electrode of wire EDM is a thin wire that moves continuously, whereas conventional EDM employs solid electrodes with shaped components (usually graphite or copper) to match the desired cavity or feature.

Design Capabilities: Wire EDM is a superior option for designing intricate 2D shapes and thin wafers, whereas conventional EDM is more suitable for creating 3D cavities and blind features.

Speed and setup: Wire EDM requires little setup once the wire is in it, so it speeds up fast turnaround projects. However, the process of creating custom-made electrodes using conventional EDM takes time. This is a slow process.

Precision and Surface Finish: Typically, wire EDM produces higher precision and finer surface finishes, which results in a reduced requirement for finishing. Conventional EDM may have rougher surfaces and less precision for intricate 2D features.

Comparison Table for Easy Review:

| Feature | Wire EDM | Conventional EDM |

| Electrode | Thin, moving wire | Shaped solid (graphite/copper) |

| Best For Shapes | Intricate 2D profiles, thin sections | Complex 3D cavities, blind features |

| Setup Time | Quick (wire positioning only) | Slow (requires custom electrode creation) |

| Typical Precision | Higher precision, finer surface finishes | Lower, less precise for 2D features |

Here’s a breakdown of the pros and cons of wire EDM versus conventional EDM:

Pros and Cons of Wire EDM

Pros:

- Produces exceedingly precise results and tight tolerances.

- Produces smooth surfaces that may require minor surface enhancement.

- Good for intricate 2D shapes, thin segments, and precision parts.

- Minimal mechanical stress on the work surface during cutting.

- Extends the absence of burrs on the cut edges.

- The wire electrode doesn’t wear down, ensuring consistent cuts.

- Setup is generally faster than conventional EDM once the wire is positioned.

Cons:

- Cuts only 2D shapes and cannot form intricate 3D structures.

- Requires a starting hole or edge access; cannot create blind features.

- Cutting speed can be slower than some methods, especially for thicker materials.

- Can only machine electrically conductive materials.

- Materials like aluminum may develop an oxide layer on the cut surface, requiring cleaning.

- Initial machine investment and ongoing costs are typically high.

Pros and Cons of Conventional EDM

Pros:

- Capable of producing intricate 3D cavities and shapes within the material.

- Can start machining anywhere on the workpiece; doesn’t require edge access or holes.

- Efficient for creating multiple identical features using the same electrode.

- Can handle a broad range of conductive materials, including very hard or thick ones.

Cons:

- Generally, slower cutting speed compared to wire EDM for many jobs.

- The roughness of the surface finish is typically greater than that of wire EDM, which often requires additional finishing work.

- Adds time and expenses to the manufacturing of customized electrodes for each shape.

- The solid electrode wears down during use, impacting accuracy over time and requiring replacement.

- Achieving the finest detail possible with wire EDM can be harder.

- Overall process cost can be higher due to electrode creation, wear, and machining time.

Applications of Wire EDM Cutting

Wire EDM machines have become a pivotal part of the precision manufacturing industry, and their ability to work with complex shapes by holding tight tolerances makes them quite valuable across an array of industries.

Aerospace

You really can’t build modern aircraft without wire EDM. Safety and pinpoint accuracy are everything. Think landing gear, jet engines, turbine blades—these complex parts demand incredibly tight specs and flawless surfaces. Wire EDM chews through tough stuff like titanium and Inconel no sweat, even when other methods would warp or damage the part from heat or stress. Plus, it’s key for making the super-detailed molds used in cabin interiors, guaranteeing every little bit meets the strictest aerospace rules.

Medical Devices

Wire EDM is considered very important in the manufacture of medical devices due to its micron-level precision. Wire EDM builds detailed surgical instruments such as forceps, complex orthopedic implants, and dental devices that are biocompatible and demanding components. This ensures that tiny details can be added to components such as syringes without sacrificing the structure of the component, which is ideal for life-critical applications.

Automotive

Cars need parts that are both tough and precisely made, and wire EDM is up to the task. It makes key components like cylinder heads, valves and fuel injectors with exact measurements and also produces molds and dies for shaping parts like bumpers and dashboards. Since it doesn’t rely on brute force, it easily cuts hard materials like alloys and tool steels, customizing parts of all shapes and sizes.

Electronics

Wire EDM excels at producing miniature components in electronics, as well as high-precision components. It efficiently creates microelectrodes for circuitry and sensors, parts that need extremely tight tolerances to function properly. It also manufactures connector pins and lead frames for integrated circuit packaging, meeting the demands of small, intricate devices like IoT tools and wearables.

Tool and Die Manufacturing

Wire EDM is a go-to for crafting high-precision die tools. It quickly produces injection mold inserts that ensure accurate reproduction of plastic parts, along with stamping dies for sheet metal, extrusion dies, blanking dies, and cutting punches. Its ability to cut intricate shapes guarantees these tools perform reliably and last, making it essential for tool and die manufacturing.

Conclusion

Wire EDM cutting is the main technology in mold part processing. It can realize the high-precision cutting of mold parts with higher hardness and more complex shapes, ensuring that the dimensional accuracy and geometric tolerances of die components meet standards. For mold makers, this isn’t just progress—it’s a revolution in what’s possible.

Reliable Wire EDM Service Provider for Best Mold Components

Need precision-cut mold components? Fecision’s Wire EDM services deliver ±0.003mm accuracy on hardened steels and exotic alloys.

- Material Versatility: Reliably machines hardened steels (AISI H13, HRC 48–52) and tool steels (thermal conductivity: 24–30 W/m·K) without compromising structural integrity.

- Dimensional Accuracy: The spark erosion process ensures ±0.01 mm core/cavity linear tolerances and ≤0.005 mm ejector pin coaxiality—critical for mold alignment and longevity.

- Surface Finish: Achieves Ra ≤0.2 μm polished surfaces and preserves nitrided hardness (HV 800–1000 per DIN 50190) without post-machining degradation.

- Machining Precision: Supported by CNC positioning accuracy of ±0.005 mm (5-axis) and wire-cut precision (LS-WEDM) of ±0.003 mm.

- Quality Control: Achieve 3D CMM accuracy of ±0.002 mm; Mold bases comply with HASCO/DME standards.

Whether you’re producing automotive parts, medical devices, or consumer goods, Fecision’s EDM wire cutting services contributes to high-performance mold components, cycle after cycle. With partners like Fecision, you’re not just buying a service—you’re accessing the edge of subtractive manufacturing.

Ready to elevate your mold or component project? Contact Fecision for a wire EDM solution that merges speed, surface, and accuracy.