For nearly 200 years, copper has been the go-to material for electrical applications due to its exceptional ability to conduct electricity. But what makes it so effective?

You might be surprised to learn that copper’s unique atomic structure allows it to conduct electricity with minimal resistance, making it the standard against which all other electrical conductors are measured.

As you explore the world of electrical connectors and manufacturing, understanding the science behind copper’s conductivity is crucial for making informed decisions about material selection.

The Science Behind Copper’s Conductivity

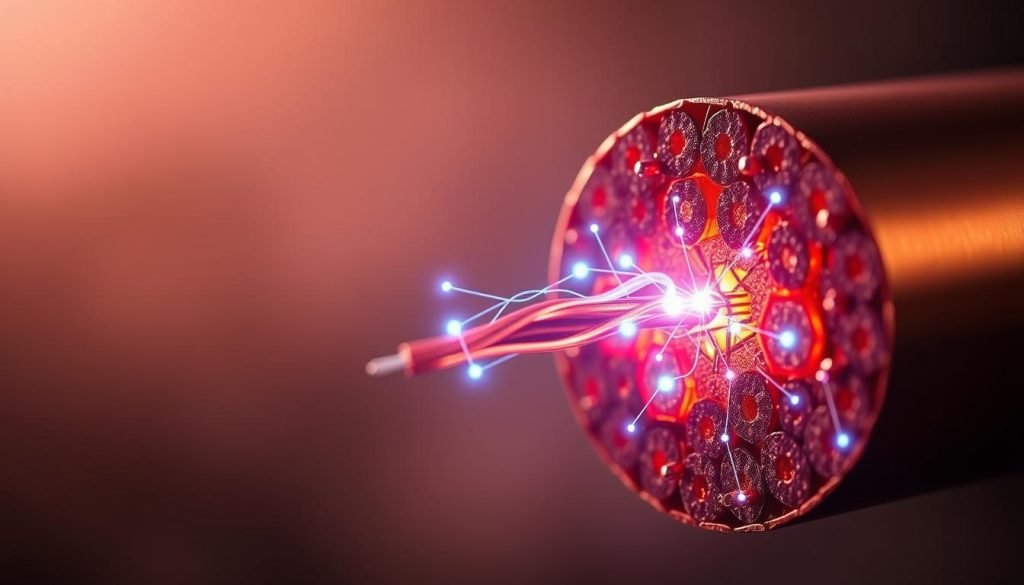

Copper is renowned for its exceptional ability to conduct electricity, but what makes it so effective? The answer lies in its atomic structure and how it facilitates the movement of electrons.

Atomic Structure and Electron Movement

Copper’s atomic structure is key to its conductivity. It has a single electron in its outermost shell, which is loosely bound, allowing it to move freely. This freedom of movement enables copper to efficiently conduct electrical energy. When an electrical potential difference is applied across a copper wire, the free electrons flow, creating an electric current.

International Annealed Copper Standard (IACS)

The International Annealed Copper Standard (IACS), established in 1913, is the benchmark for measuring electrical conductivity in metals. Copper with a 100% IACS rating has a conductivity of 58.0 MS/m at 20°C. Modern commercially pure copper often exceeds this standard, achieving 101% IACS or higher. The primary grade used in electrical applications is Electrolytic-Tough Pitch (ETP) copper, which is at least 99.90% pure.

The conductivity of copper decreases by approximately 0.393% per degree Celsius increase in temperature. Understanding the IACS rating system helps in comparing copper with other conductive materials and has maintained consistency in wire and cable manufacturing worldwide.

Is Copper a Conductor? Understanding Its Exceptional Properties

The versatility of copper as a conductor is unmatched, offering both electrical and thermal benefits. Copper is widely recognized for its high electrical conductivity, but its thermal conductivity properties are equally significant.

Electrical Conductivity Rating

Copper’s electrical conductivity rating is one of the highest among metals, making it an ideal material for electrical wiring and circuits. Its ability to efficiently conduct electricity is crucial for the reliable operation of electrical systems.

Thermal Conductivity Benefits

Copper also exhibits high thermal conductivity, which is essential for dissipating heat in electrical systems. With a thermal conductivity rating 60% higher than aluminum, copper is better able to reduce thermal hot spots in electrical wiring systems. This property is particularly valuable in high-current applications where heat management is critical. By efficiently dissipating heat, copper helps prevent the formation of dangerous hot spots in electrical connections and terminations, contributing to the safety, reliability, and longevity of electrical systems.

In electrical installations, copper’s thermal conductivity benefits translate to reduced maintenance requirements and lower failure rates. This dual conductivity (electrical and thermal) makes copper uniquely suited for applications where both properties are essential for optimal performance.

Factors Affecting Copper’s Electrical Conductivity

Understanding the factors that affect copper’s electrical conductivity is crucial for optimizing its use in electrical systems. Copper is widely used in wiring and electrical applications due to its high conductivity, but its performance can be influenced by several factors.

Purity Levels and Oxygen Content

The purity of copper significantly impacts its electrical conductivity. High-purity copper has fewer impurities, which can scatter electrons and reduce conductivity. Additionally, the oxygen content in copper can affect its conductivity; oxygen-free copper is preferred for high-performance applications.

Temperature Effects

Temperature is another critical factor that influences copper’s electrical conductivity. As the temperature increases, the resistance of copper also increases, leading to decreased conductivity. This is because higher temperatures cause the atoms in the copper to vibrate more, scattering electrons and reducing their flow.

Mechanical Stress and Deformation

Mechanical stress and deformation can alter the crystalline structure of copper, affecting its electrical conductivity. Work hardening through bending, stretching, or compressing copper wire can increase its resistance. Copper’s excellent resistance to creep helps maintain secure electrical connections over time, making it a reliable choice for electrical wiring.

Types of Copper Conductors in Modern Applications

Modern electrical systems rely heavily on different types of copper conductors, each with its unique characteristics. The choice of copper conductor depends on the specific application, considering factors such as conductivity, flexibility, and durability.

Electrolytic-Tough Pitch (ETP) Copper

Electrolytic-Tough Pitch (ETP) Copper is one of the most commonly used types of copper conductors. It offers a good balance between conductivity and cost, making it suitable for a wide range of electrical applications. ETP Copper contains a small amount of oxygen, which doesn’t significantly affect its conductivity but enhances its mechanical properties.

Oxygen-Free Copper

Oxygen-Free Copper is another type of copper conductor known for its high purity and conductivity. It is used in applications where high conductivity and low signal loss are critical, such as in audio equipment and high-end electrical wiring. Oxygen-Free Copper is more expensive than ETP Copper but offers superior performance in certain applications.

Solid vs. Stranded Copper Wire

The choice between solid and stranded copper wire depends on the specific requirements of the application. Solid copper wire consists of a single conductor and is typically used in permanent installations where flexibility is not a concern, such as in magnet wire for motors and transformers. On the other hand, stranded copper wire is made up of multiple smaller conductors twisted together, offering greater flexibility and resistance to fatigue. Stranded wire is ideal for applications that require frequent bending or are subject to vibration.

Understanding the differences between solid and stranded copper wire is crucial for selecting the right type for your specific needs. While solid wire provides maximum conductivity per cross-sectional area, stranded wire offers the flexibility and durability needed for dynamic applications. By choosing the appropriate type of copper conductor, you can ensure the reliability and efficiency of your electrical systems.

Copper vs. Other Conductive Metals

Copper’s dominance in the electrical industry can be attributed to its unique combination of conductivity, durability, and cost-effectiveness. For nearly 200 years, copper has been the material of choice for electrical connectors, and its widespread use continues today in power generation, distribution, and transmission systems.

Copper vs. Silver: Conductivity and Cost Comparison

While silver is the most conductive metal, copper offers a compelling balance between conductivity and cost. Silver is approximately 6% more conductive than electrical copper, but its higher cost makes copper the more economical choice for most applications. In fact, copper used in electrical wiring and connectors provides a cost-effective solution without significantly compromising on conductivity.

Copper vs. Aluminum: Performance Differences

Aluminum is another conductive metal often compared to copper. Although aluminum is lighter and less expensive, it has lower conductivity and is more prone to oxidation, which can lead to connection issues over time. In power transmission lines and other high-demand applications, copper‘s superior performance makes it the preferred material.

Why Copper Dominates the Electrical Industry

Copper remains the top choice for electrical applications due to its excellent conductivity, mechanical properties, and resistance to corrosion. Its versatility allows it to be used in a wide range of applications, from microelectronics to large-scale power transmission systems. As a result, copper continues to be the default material in the electrical industry today.

Practical Applications of Copper as a Conductor

Copper’s exceptional conductivity makes it a vital material in various electrical applications. You will find copper used in numerous ways, from electrical wiring to telecommunications.

Electrical Wiring and Power Distribution

Copper is extensively used in electrical wiring and power distribution systems due to its high electrical conductivity. This ensures efficient transmission of electricity with minimal loss of energy. The use of copper in this way supports the reliability of electrical grids and reduces the risk of power outages.

Telecommunications and Data Transmission

In telecommunications, copper plays a significant role in data transmission. Although fiber optics have become more prevalent, copper remains a crucial material for certain types of data transmission, particularly in local networks. Copper’s conductivity enables fast data transfer rates, making it suitable for various telecommunication applications.

CNC Machining and Manufacturing Considerations

When it comes to CNC machining, copper’s high electrical conductivity influences its machining characteristics. The process of machining copper requires careful consideration of tool selection, cutting parameters, and cooling strategies to achieve optimal results. Copper alloys are often preferred for their improved machinability, although they have slightly reduced conductivity compared to pure copper. This tradeoff is crucial in manufacturing components that require both electrical performance and mechanical precision.

Conclusion

As we’ve explored, copper’s exceptional conductivity makes it a vital component in modern electrical systems. Copper is the material of choice for electrical conductors due to its unmatched combination of properties. Today, as the world pushes toward electrification and renewable energy, copper’s importance is more pronounced than ever. Its superior conductivity contributes significantly to energy efficiency, particularly in applications such as electric vehicles and power distribution.

When designing electrical systems or selecting materials for manufacturing electrical components, make sure to consider copper’s conductive properties. Whether you’re working with copper wire or copper wires, understanding the factors that affect copper’s conductivity, such as purity levels and temperature, is crucial for optimal performance.