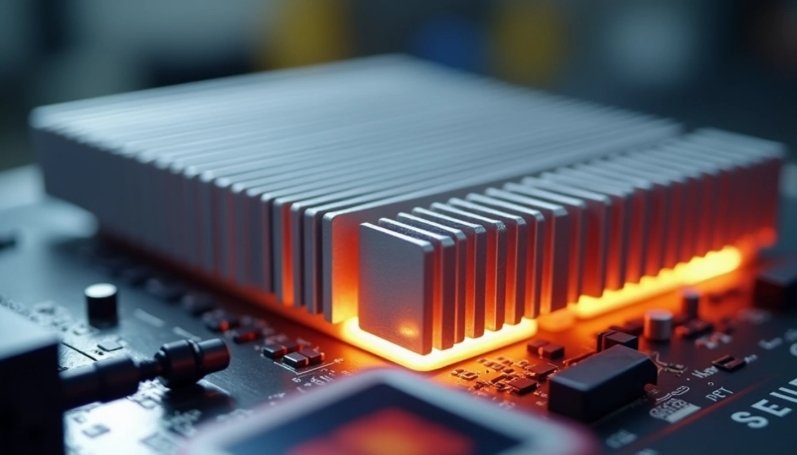

Thermal management is the backbone of modern electronics and industrial equipment. Without proper heat control, electronic devices can suffer from reduced performance, instability and ultimately system failure. That’s where heat sinks come in. A heat sink is a passive device designed to disperse heat from electronic components by expanding the surface area exposed to the surrounding air. It plays a crucial role in keeping safe operating temperatures.

Passive heat sinks are heat dissipation devices that operate without relying on fans, pumps, or other active cooling mechanisms. They work solely based on thermal conductivity and natural convection. Passive systems are more reliable, quieter and energy efficient than active cooling solutions. This article will explore the challenges of passive cooling systems and how advancements in materials, design and CNC Machining are helping to overcome them.

What are Passive Heat Sinks

A passive heat sink is a device that absorbs and dissipates heat away from an object without using any mechanical assistance, such as fans or pumps. These heat sinks rely solely on natural air movement and thermal radiation for heat transfer.

They are made of metals with high thermal conductivity, usually aluminum or copper and have finned structures that increase surface area. This design enables the transfer of heat from the hot component to the surrounding air.

How do Passive Heat Sinks work

The basic mechanism involves three types of heat transfer: conduction, convection and radiation. First heat is conducted from the component to the heat sink’s base. From there, heat travels through the fins and is dispersed into the air via natural convection and radiated away. The effectiveness of this system is influenced by factors such as airflow, fin shape, and the surrounding temperature.

While active cooling systems can force air over the fins, passive heat sinks depend entirely on natural convection, where warmer air rises and cooler air replaces it. This process is inherently slower and less efficient for high thermal loads.

Common Applications

Passive heat sinks are used in scenarios where silent operation, low maintenance and energy efficiency are key. Common applications are:

- LED lighting fixtures

- Set-top boxes and digital TV receivers

- Power supplies and converters

- Automotive electronics

- Passive cooling of CPUs in low-power computing systems

- Solar inverters and telecom base stations

Benefits of Passive Heat Sinks

Passive heat sinks are highly preferred because of their mechanical simplicity and reliability. These effective thermal management devices possess some useful benefits that render them suitable for use in various applications.

1. No Moving Parts = More Reliable

Passive heat sinks don’t have fans or motors, so less can go wrong. They are more reliable and longer lasting than active cooling systems that have moving parts that can wear out over time. Technologies like heat pipes can transfer heat efficiently without a fan. Because of this, passive heat sinks are perfect for critical systems where failure is not an option.

2. Completely Silent Operation

Since passive heat sinks have no moving parts, they make no noise. This is a big plus in quiet environments like hospitals, sound studios and homes. You won’t even hear a fan whirring or buzzing—just silent, efficient cooling. That’s why they’re commonly employed in gear where silence is paramount.

3. Low Maintenance and Energy Efficient

Another major advantage is that they need minimal maintenance. You won’t have to clean or replace fans, which saves time and money. And they don’t use electricity to run, so they’re extremely energy efficient. This combination of low upkeep and energy savings adds up to long term value.

4. Custom Designs with CNC Machining

With advanced equipment such as CNC machining, passive heat sinks can now be tailored according to individual requirements. This provides designers with an opportunity to make shapes that will enhance surface area for improved dissipation of heat while taking up minimal space. Heat pipes can be designed to channel heat away from essential components. This flexibility helps achieve the best cooling results for any setup.

The Main Obstacle: Limited Heat Dissipation

The fundamental challenge with passive heat sinks is their thermal dissipation capacity. Despite the benefits, they face significant limitations when heat loads exceed certain thresholds.

Why do passive heat sinks struggle with higher heat loads?

The core issue with passive heat sinks is their reliance on natural heat transfer methods when faced with high thermal output. Without active components to force airflow, these systems reach their dissipation limits quickly under higher heat loads. This creates a bottleneck as component temperatures rise faster than passive cooling can manage. When a component’s power draw exceeds the natural convection capacity, temperatures can rise to damaging levels.

Passive cooling relies entirely on natural processes, convection and radiation, to transfer heat away from electronic components. This natural approach, while elegant in its simplicity, can’t match active systems when dealing with high processing loads. The heat dissipation ceiling can’t be exceeded regardless of how the plate surfaces are arranged within a given volume.

Natural Convection and Ambient Temperature

Natural convection works through an effortless yet limited mechanism. As air near the heat sink warms it becomes less dense and rises creating a subtle chimney effect that draws cooler air from below. However this process generates very slow air velocities – centimeters per second compared to meters per second in forced convection systems.

Ambient temperature plays a big role in passive cooling efficiency. As room temperature increases the temperature differential between the heat sink and the surrounding air decreases dramatically reducing heat transfer rates. This temperature sensitivity means passive solutions perform inconsistently across different environments. At higher ambient temperatures passive cooling becomes less effective as the driving force for convection – the density difference – decreases.

Size and Material Limitations

The physical dimensions required for effective passive cooling often conflict with modern design requirements. In the absence of forced airflow, enhancing cooling capacity requires either larger heat sink dimensions or an increase in surface area. This scaling challenge creates fundamental tension in product development especially for compact electronics with space constraints.

Material selection is another constraint. While copper has better thermal conductivity than aluminum its greater weight and cost often forces compromise. Even with optimal materials passive systems eventually reach physical limits that can’t be overcome without transitioning to active cooling methods.

Improving passive cooling means increasing size which may not be compatible with product specifications especially in consumer electronics where slim profiles are required.

Factors That Affect Passive Heat Sink Performance

Several factors affect passive heat sink performance and understanding these is key to improving them.

1) Material Properties

Copper and aluminum are the two most common materials used for heat sinks. Copper has higher thermal conductivity (~400 W/mK) than aluminum (~200 W/mK) so it can transfer heat more efficiently. However, due to its lower weight and cost, aluminum is more commonly used for general applications than copper. Hybrid designs often use a copper base with aluminum fins to balance cost and performance.

2) Surface Area and Fin Design

Heat sinks work best when they have more surface area. Increasing the number and length of fins allows more heat to transfer from the metal to the surrounding air. The design and spacing of these fins directly impact heat dissipation rate. CNC Machining allows for intricate fin shapes that maximize surface area without compromising structural integrity. Tapered, pin-fin and folded-fin designs are examples of geometries that improve passive airflow dynamics.

3) CNC Machining

Advanced CNC Machining techniques allow for tight tolerances and complex geometries that were once impossible or impractical with traditional manufacturing. CNC processes can carve out custom features like thermal vias, airflow channels or honeycomb patterns to increase effectiveness. Multi-axis CNC machines can produce 3D structures that enhance the heat sink’s conduction and convection properties turning a simple metal block into a highly efficient passive cooling solution.

4) Environmental Conditions

Environmental variables like airflow patterns, ambient air temperature and device orientation impact passive heat sink performance. For example heat sinks with metal foam designs showed nearly 36% better temperature drop when tailored to specific conditions. This proves that where and how a heat sink is used can be just as important as how it’s built。

Solutions to Overcome Limitations

Overcoming the primary obstacle of limited heat dissipation requires a combination of material science, engineering design and manufacturing innovation.

CNC Machining Advancements

Recent advancements in CNC Machining allow for thinner fins, tighter spacing and more complex layouts. This means more efficient passive heat sinks without increasing size or weight. Technologies such as 5-axis machining, wire EDM, and laser-aided cutting enable new designs in high-precision cooling components.

Some CNC techniques even allow for the integration of heat pipes or vapor chambers into passive heat sinks blurring the lines between traditional passive and hybrid systems.

Innovative Materials and Coatings

Material innovation plays a big role. Graphene-infused composites, metal foams and carbon-based thermal interfaces are being developed for next-gen heat sinks. These materials offer higher thermal conductivity and lower weight for demanding applications.

In addition surface coatings like anodizing (for aluminum) can improve heat emissivity for radiative cooling. Nano-coatings can also enhance wettability and air-flow adherence for better heat exchange.

Hybrid Cooling Systems

Hybrid cooling systems are the middle ground when pure passive solutions aren’t enough. These systems combine passive heat sinks with minimal active components like low-RPM fans or thermoelectric coolers. The passive sink provides baseline cooling and the active part only kicks in under peak load conditions so it’s silent and energy efficient most of the time.

Some designs incorporate phase-change materials (PCMs) or heat spreaders to manage thermal spikes and further improve passive cooling reliability.

Conclusion

Passive heat sinks are the foundation of silent and energy efficient thermal management. They have no moving parts, low maintenance and can be customized through CNC Machining making them valuable for many industries. But their main limitation is the limited heat dissipation capacity which restricts their use in high power applications. This limitation is due to natural convection inefficiencies, size constraints and material limitations.

But the future of passive cooling looks bright. Advances in materials science, surface treatments and especially CNC Machining techniques are opening up more efficient, compact and capable passive heat sinks. As devices shrink and grow in power innovative thermal solutions that emphasize passive efficiency will be key.

Engineers, designers and manufacturers must work together to optimize passive heat sinks, leveraging the latest fabrication techniques and material science. By doing so they can overcome today’s thermal challenges and unlock tomorrow’s devices.