CNC turning delivers exceptional precision within ±0.001 inches, making it one of the most accurate production methods in manufacturing today. This computer controlled process can produce complex cylindrical parts in 3 days and meets critical requirements in automotive, aerospace and medical industries.

This manufacturing method’s versatility allows it to work with materials of all types—from metals and plastics to glass and ceramics. Parts with rotational symmetry, like shafts, gears, and pulleys, take shape as the process removes material from a solid workpiece until it matches the design.

This article covers everything about CNC, from basic principles and machine components to operations and real-world uses. You’ll learn how this technology turns raw materials into parts, its strengths and weaknesses and why it’s the lifeblood of modern manufacturing.

What is CNC Turning?

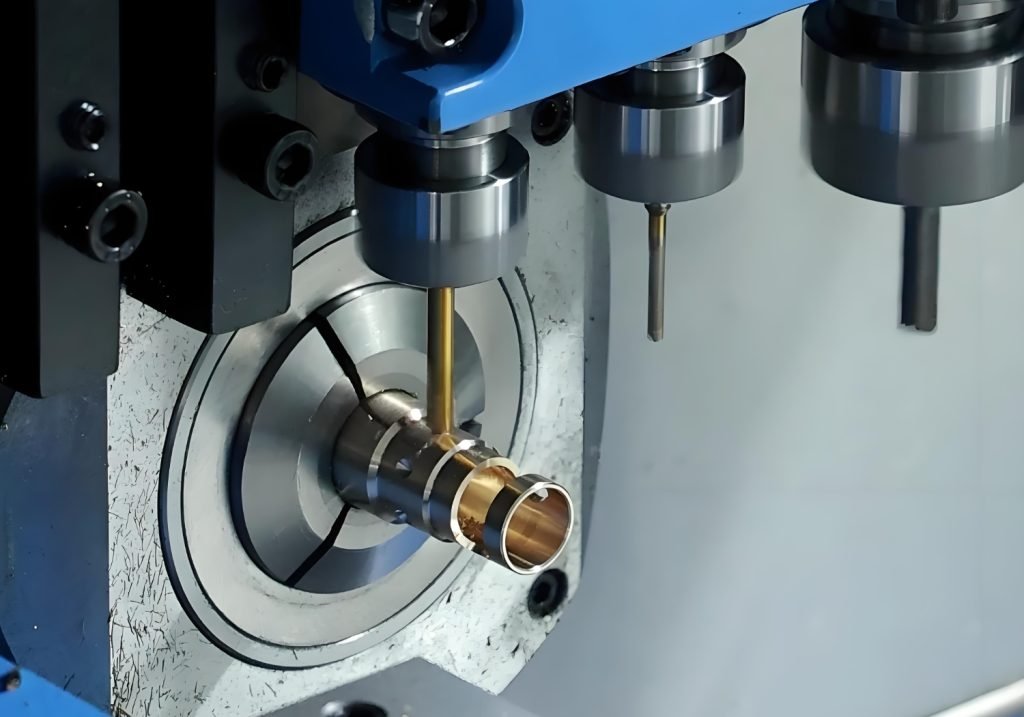

CNC turning has transformed manufacturing by a lot since its introduction. This machining method removes material from a rotating workpiece while a stationary cutting tool shapes the desired geometry. The process creates cylindrical components and can also produce conical, helical, and circular shapes.

Basic concept and definition

The workpiece rotates around a hypothetical Z-axis while secured in a lathe chuck during CNC turning. A cutting tool moves along multiple axes and performs precise cuts based on computer-programmed instructions. The desired shape emerges as the cutting tool contacts the workpiece surface through continuous cutting action.

Two main motions power this process: the workpiece’s major rotational motion and the cutting tool’s secondary linear motion (feed rate). Research shows that CNC lathes handle about 40% of all metal cutting operations.

How is CNC turning different from manual turning?

The main difference between CNC and manual turning comes down to their control mechanisms and capabilities. Manual turning needs constant human intervention, while CNC turning works through computer-controlled programming that reduces human error by a lot.

The key differences include:

- Precision and Speed: CNC turning produces more accurate results faster than manual methods. Computer control gives consistent quality across large production runs.

- Operational Complexity: CNC turning adjusts cutting depth and speed on its own to match various machining needs. The providing changes without equipment modification, which lets you quickly adapt for different parts.

- Production Efficiency: One skilled machinist can run production tasks on CNC machines, but manual turning needs more experienced operators. The automated process will give consistent quality and dimensional tolerances throughout production runs.

CNC turning has become the life-blood of modern manufacturing over the last 50 years, especially when you have components that need high accuracy and complex geometries.

Main Parts of a CNC Turning Machine

Modern CNC turning machines combine several key components that work together to produce precise machining results. Machine operators can get better performance by understanding how these components function.

The control system

The Machine Control Unit (MCU) acts as the brain behind CNC turning operations. This advanced system converts G-code instructions into exact machine movements. Operators can input commands, check machine status, and modify parameters through a user-friendly control panel. The control system uses high-end software to coordinate every movement of the lathe, from tool paths to operational changes.

Moving components

The driving system has several key elements that allow precise material removal. A spindle mounted on specialized bearings spins the workpiece at specific speeds. The worktable moves along multiple axes so the cutting tool can reach the material from different angles. Servo motors and ball screws power the axis system that delivers smooth and accurate movement.

The chuck holds the workpiece securely during machining and comes in different types:

- Three-jaw universal chucks work best with round workpieces

- Four-jaw independent chucks handle irregular shapes

- Collet chucks suit smaller components

Cutting tools

The tool turret serves as a central hub for multiple cutting tools. Tools change automatically without manual input, which streamlines the operation. Today’s CNC machines use various cutting tools:

- Turning tools remove exterior material

- Boring bars make internal holes larger

- Facing tools create perpendicular surfaces

- Chamfering tools bevel edges

The material composition determines how well cutting tools work. High-speed steel tools have exceptional hardness and thermal strength that make them perfect for rough machining. Carbide tools last longer and resist wear better, especially when cutting tough materials like stainless steel or cast iron.

How CNC Turning Works?

CNC turning creates precision components through a step-by-step process that delivers accuracy and quality. Each step connects to the next to build a complete manufacturing process.

Step 1: Design and programming

The trip starts when CAD designs transform into machine-readable instructions. Engineers use CAM software to convert 3D models into G-code – the programming language that tells CNC machines how to move. This code tells the machine about tool paths, cutting speeds, and feed rates. Programmers test the code with simulation software to catch any errors before production begins.

Step 2: Machine setup

Good machine prep is the foundation of successful turning operations. Operators first check oil and coolant levels. They load cutting tools into the carousel based on the program’s tool list. After the workpiece sits secure in the chuck, they adjust tool offsets and set reference points for exact machining.

Step 3: The turning process

The actual turning starts after setup finishes. The machine runs the program and rotates the workpiece against stationary cutting tools. The control system watches several key factors such as Cutting speed and feed rates, Tool positions and movements and Material removal rates.

Step 4: Quality checks

Quality control plays a crucial role in CNC turning operations. Teams check dimensional accuracy and tolerances to meet specifications. Surface finish tests show smoothness and find unwanted ridges or marks. Machine tool probing systems provide live quality checks that quickly spot potential problems. Operators watch these results and make adjustments to keep quality consistent across production runs.

Automated inspection systems work with human checks to create a detailed quality control system. This combined approach spots and fixes any issues before they affect later production stages.

What are Different Types of CNC Turning Machines?

CNC turning machines are available in different configurations, each one designed for specific machining requirements. Workpiece characteristics and production needs determine the choice between these variants.

1) Horizontal CNC Lathes

Manufacturing industries commonly use horizontal CNC lathes as their primary machine tools. These machines perform turning and boring operations exceptionally well. Their spindle orientations spin workpieces horizontally while static tools shape the part. Horizontal lathes feature an efficient chip management system where gravity pulls chips away from the workpiece straight into collection bins. The machines provide more flexibility because they have longer bed lengths compared to their spindle size.

2) Vertical CNC Lathes

Vertical turret lathes (VTLs) use a vertical main spindle position, making them perfect for large, heavy workpieces. These machines utilize gravity to improve workpiece stability. The workpiece’s weight helps secure it, which reduces the need for hard clamping. These machines can handle components up to 60,000 kg with diameters reaching 5 meters.

3) Horizontal Turning Centers

Horizontal turning centers go beyond simple lathes by adding more capabilities. These enclosed systems combine traditional turning operations with milling and drilling functions. Modern horizontal turning centers often feature multiple axis configurations, live tooling capabilities, automated tool-changing systems, and bar feeding interfaces that allow for continuous production.

4) Vertical Turning Centers

Vertical turning centers combine the benefits of vertical lathes with advanced machining functions. They are designed with infinitely adjustable cross rails that can handle different part sizes. These machines also provide full contouring functionality with C-axis integration and can include an optional live spindle for grinding, milling, and tapping operations. Their rigid cast iron bases ensure better stability, making them ideal for handling heavy loads.

Workpiece size, weight, shape, and required machining operations play crucial roles in choosing between these configurations. Large diameter, short components work best with vertical configurations, while horizontal setups work better for longer workpieces that need tailstock support.

Common CNC Turning Operations

CNC turning success depends on understanding its core operations. Simple cuts to complex threading each need specific tools and techniques to get optimal results.

Simple turning and facing

Straight turning is the life-blood of CNC operations. The process reduces workpiece diameter through controlled material removal. Single-point turning tools move along the workpiece side to create features like tapers, chamfers, and steps. Machinists perform multiple passes at small radial depths to improve precision.

Facing operations make workpiece ends smooth and flat by removing thin material layers. This vital step will give a proper part length and perpendicularity to the rotating axis. The cutting tool moves radially across the material’s end and completes the operation in a single pass due to minimal cutting depths.

Threading and grooving

Threading operations use specialized 60-degree pointed nose tools that move axially along the workpiece. This precise process creates uniform helical grooves with specific lengths and pitch measurements. Deep threads need multiple cutting passes to meet desired specifications.

Grooving creates narrow channels in the workpiece surface. The process includes two distinct types:

- External grooving – cutting tools move radially into the workpiece side

- Face grooving – tools machine grooves directly into the face surface

Advanced operations

Modern CNC turning centers shine at sophisticated machining techniques. Hard turning machines hardened steel through specialized cutting tools and high-pressure coolant systems. High-speed machining uses elevated spindle speeds and feed rates, making it perfect for high-volume production.

Multi-tasking capabilities let machines run various operations at once. Live tooling helps machines perform milling, drilling, and tapping without moving the workpiece. This integration makes production efficient by removing the need for secondary machining operations.

Live monitoring systems track cutting parameters and adjust speeds and feeds based on material response. This adaptive control maintains consistent quality in production runs while optimizing tool life and surface finish.

Which Materials Are Best for CNC Turning?

Choosing a material is important in CNC turning as material selection directly affects machining performance, tool life, surface finish, and overall cost.

- Aluminum alloys are preferred for their machinability and versatility. 6061 is generally good for use in most purposes, and 7075 is stronger and harder and therefore more suited for high-performance applications but more difficult to machine.

- Stainless steel has different advantages depending on the grade. Grade 304 is most commonly utilized since it is easy to machine and corrosion-resistant.

- Brass is an excellent material for precise components. It is easily machinable and resistant to saltwater corrosion, making it a best choice for plumbing and electronic components. C36000 is typically used in mechanical and architectural applications.

- Titanium alloys are lightweight, strong, and biocompatible. They are used in medical implants and aircraft parts. While costly and hard to machine, titanium alloys perform satisfactorily in extreme environments.

- Copper is the best choice for electrical components due to its high conductivity. It is second only to silver in conducting electricity. However, it is soft and requires careful machining.

- Engineering plastics provide unique advantages. ABS is strong and resistant to impact, PEEK is durable and does not absorb moisture, and Acetal is known for its mechanical strength and stability.

When selecting a material, consider factors such as environmental exposure, required strength, temperature resistance, cost, and production volume. The best material choice balances performance with practicality to ensure efficiency and quality.

What Are the Advantages and Disadvantages of CNC Turning?

CNC turning offers many benefits but also has some limitations. Understanding both helps manufacturers make better decisions.

Advantages of CNC Turning

- Precision and Consistency: CNC parts are highly precise, with tolerances as low as 0.0002 inches. An automated process delivers identical parts in every run.

- Efficiency: They work around the clock, lowering labor costs. One operator can control several machines, enhancing productivity.

- Minimized waste: Proper programming minimizes material waste and is cost-effective in production.

Disadvantages of CNC Turning

- High initial cost is a characteristic of CNC machines, but in mass production, they are cost-effective.

- Waste Material: Since it is a subtractive process, CNC turning generates scrap material.

- Size Limits: While small and mid-sized parts are well-suited to CNC turning, very large objects are too large for most equipment.

- Technical Skills: Programmers, tools setup personnel, maintenance and quality control personnel are needed.

Despite all constraints, CNC turning is still required in industries requiring accuracy. Technological innovations and integration with IoT are making it more efficient.

What Industries Depend on CNC Turning?

CNC turning is essential to producing highly accurate parts in most sectors.

- Aerospace: Used to manufacture landing gear, turbine shafts, and hydraulic system components, ensuring durability and accuracy.

- Automotive: CNC turning creates axles, gearbox shafts, and engine parts. CNC turning remains a key technology as the automotive industry shifts toward electric vehicles.

- Medical Devices: It produces surgical instruments, implants, and screws with high precision, ensuring patient safety.

- Defense: CNC turning makes firearm barrels, triggers, and military-grade components that meet strict reliability standards.

- Oil and Gas: Parts such as fittings, connectors, and flow control devices are made with CNC turning to withstand extreme conditions.

- Maritime: The industry relies on CNC-turned parts for shafts, propellers, and corrosion-resistant fittings.

- Construction: CNC turning produces locks, hinges, valves, and custom fasteners.

- Electronics: Small, detailed parts like casings, connectors, and knobs are machined with high accuracy for electronic devices.

CNC turning continues to develop and improve to meet the demands of such industries.

What are the Common Problems with CNC Turning?

Despite possessing a highly developed technology, CNC turning has certain disadvantages that can affect production efficiency and quality.

- Programming Errors: Errors in data or setup can lead to erroneous operations.

- Cutting conditions: Improper cutting rates and tool settings can wear out tools prematurely or decrease production rates.

- Worn or improper tools: Worn or improper tools can result in rough edges, burn marks, and low surface finishes.

- Mechanical Problems: Mechanical issues like overheating, vibration, and dimensional inaccuracy can influence accuracy.

- Incorrect machine setup: Errors in tool offsets, cutter radius, and work coordinates can result in incorrect part dimensions.

- Power Instability: Unstable power can cause machine malfunctions or display malfunctions.

Regular maintenance, constant surveillance, and proper training are needed to avert such problems. Early detection and repair prevent production disruptions and ensure smooth operations.

Conclusion

CNC turning is the backbone of modern-day production. It can be accurate to ±0.001 inches and can machine all materials, from metals to plastic engineering. Its benefits easily outweigh any disadvantages, although there are limitations, specifically when tool maintenance and programming accuracy are involved.

Machine operators who have learned basic elements, selected proper materials, and are familiar with standard troubleshooting achieve the best results in all application sizes. The process creates highly precise cylindrical components ideally suited for stringent markets like aerospace, medical, and automotive production, which have their own set of standards.

Quality output results from machine setup, material properties, and maintenance processes. Trained operators and stringent quality control processes position businesses to succeed consistently. Manufacturing technologies improve, and CNC turning adapts to sophisticated production requirements while still being crucial to precise part manufacture.