CNC milling is a highly precise and automated machining process that removes material from a workpiece using computer-controlled cutting tools. Unlike CNC drilling, which is limited to hole-making, CNC milling allows for multi-directional cutting, making it ideal for complex designs and high-precision manufacturing. T

his process is widely used in industries such as aerospace, automotive, and medical due to its accuracy and efficiency. However, factors like material selection, labor, and machine type impact its cost. Understanding CNC milling’s advantages, applications, and cost considerations helps optimize production efficiency and choose the best machining process for your needs.

Basics of CNC Milling

CNC milling is a machining process that uses rotating cutting tools to remove material from a workpiece, creating complex shapes and designs. Unlike CNC drilling, which focuses on hole-making, CNC milling can cut in multiple directions, making it ideal for intricate parts and high-precision manufacturing.

CNC Milling Definition

CNC milling (Computer Numerical Control milling) is an advanced machining process that uses automated, computer-controlled cutting tools to remove material from a workpiece. This process is widely used in industries such as aerospace, automotive, and manufacturing to create precise and complex parts.Unlike manual milling, CNC milling operates through programmed instructions, ensuring greater accuracy, efficiency, and consistency in production. It allows manufacturers to produce custom-designed components with minimal human intervention, making it a highly reliable and cost-effective machining method.

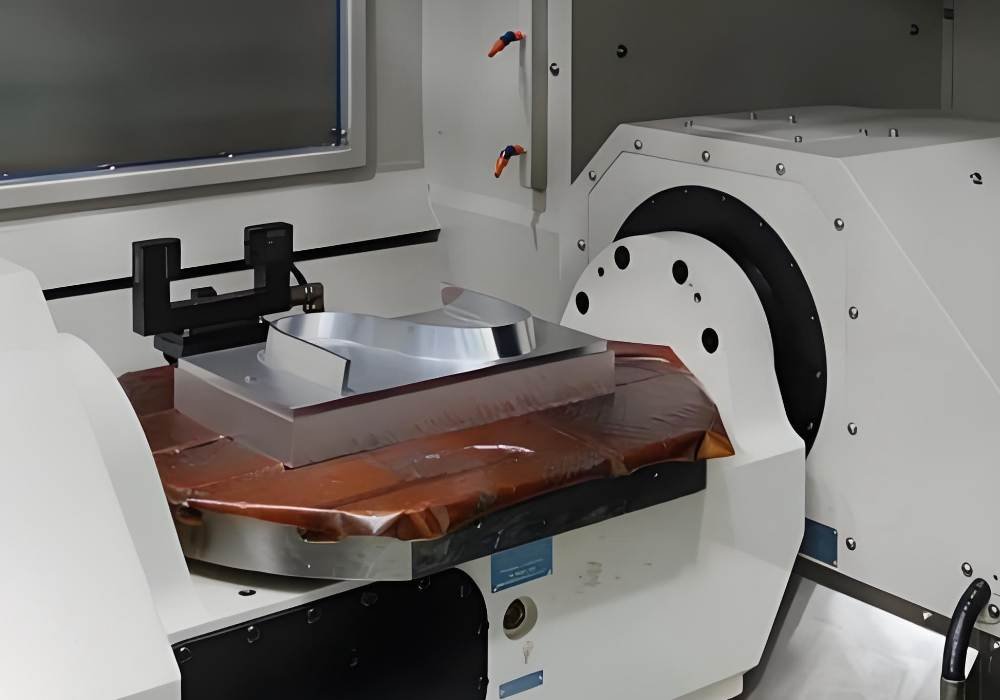

How CNC Milling Works

CNC milling works by using a computer-controlled machine to cut and shape materials. The process starts with a digital design, which is converted into G-code to guide the machine. The cutting tool moves in multiple directions and spins at high speeds to remove material layer by layer. This automated process ensures precision and consistency, making it ideal for creating complex parts.

Advantages and Disadvantages of CNC Milling

High Precision and Repeatability: One of the biggest advantages of CNC milling is its ability to produce parts with exceptional precision and consistency. These machines operate with tight tolerances, ensuring that each part meets exact specifications. Whether producing a single component or a large batch, CNC milling guarantees repeatability, making it ideal for industries like aerospace, medical, and automotive manufacturing where accuracy is critical.

High Initial Setup Costs: Despite its many benefits, CNC milling comes with a high initial investment. Purchasing a CNC machine can be expensive, and additional costs include maintenance, programming software, and operator training. This makes CNC technology less accessible for small-scale manufacturers or startups. However, the long-term benefits, such as reduced labor costs and improved production efficiency, often outweigh the initial expenses.

Applications of CNC Milling

With its precision, efficiency, and ability to handle various materials, CNC milling is widely used across multiple industries. From manufacturing aircraft components to producing intricate medical devices, this technology plays a vital role in modern production.

Aerospace and Automotive Industries: CNC milling plays a crucial role in the aerospace and automotive industries, where precision and durability are essential. In aerospace, CNC machines are used to manufacture complex aircraft components such as engine parts, turbine blades, and structural components, ensuring they meet strict safety and performance standards.

In the automotive sector, CNC milling is widely used to create engine blocks, transmission components, and customized car parts with high accuracy. The ability to machine lightweight materials like aluminum and titanium makes CNC milling essential for improving fuel efficiency and vehicle performance.

Medical and Electronic Components: The medical industry relies on CNC milling to produce high-precision components such as surgical instruments, prosthetics, dental implants, and orthopedic devices. These parts require tight tolerances and biocompatible materials like stainless steel and titanium, which CNC milling can efficiently handle.

In the electronics industry, CNC milling is used to manufacture printed circuit boards (PCBs), heat sinks, and casings for electronic devices. The ability to machine delicate and intricate parts makes CNC technology essential for producing high-performance electronic components.

CNC Milling Process and Techniques

CNC milling involves a variety of machines and techniques designed to achieve high-precision machining for different applications. Depending on the complexity of the design and material requirements, different types of CNC milling machines are used to optimize efficiency and accuracy.

Types of CNC Milling Machines

Vertical Milling Machines: Vertical milling machines feature a vertically oriented spindle, meaning the cutting tool moves up and down while the workpiece remains fixed on the table. These machines are commonly used for drilling, slot cutting, and face milling. They are widely preferred for their ease of operation, cost-effectiveness, and versatility in handling different materials.

Horizontal Milling Machines: Unlike vertical mills, horizontal milling machines have a horizontally oriented spindle, allowing for deeper and more robust cuts. These machines are ideal for heavy-duty applications, such as machining large or tough materials like steel. They also support multiple cutting tools, improving productivity and efficiency in mass production.

5-Axis CNC Milling: 5-axis CNC milling machines offer advanced multi-directional machining, allowing the cutting tool to move along five different axes simultaneously. This capability makes them perfect for creating highly complex and intricate parts, such as aerospace components, prosthetics, and automotive engine parts. While more expensive, 5-axis milling reduces the need for multiple setups, significantly improving precision and efficiency.

Key Milling Operations

CNC milling involves various cutting techniques, each designed for specific machining requirements. These operations determine how the cutting tool interacts with the workpiece to achieve the desired shape, surface finish, and precision. Below are three key CNC milling operations commonly used in manufacturing.

Face Milling: Face milling is used to create a smooth and flat surface on the workpiece. In this process, the cutting tool rotates perpendicular to the material, removing material from the surface to achieve a high-quality finish. Face milling is ideal for leveling rough surfaces, refining edges, and preparing materials for further machining.

Peripheral Milling: Peripheral milling, also known as contour milling, involves cutting along the edges of the workpiece. Unlike face milling, where the cutting tool moves across the surface, peripheral milling removes material from the sides. This technique is widely used for creating slots, grooves, and external profiles with high precision.

Pocket Milling: Pocket milling is a technique used to remove material from the interior of a workpiece, creating cavities, recesses, or pockets. This operation is essential for machining molds, dies, and components that require internal cutouts. CNC pocket milling allows for deep and intricate material removal while maintaining accuracy.

Materials Used in CNC Milling

CNC milling supports a variety of materials, each chosen based on strength, durability, and application needs. The most common materials include metals, plastics, and composites.

Metals (Aluminum, Steel, Titanium)

- Aluminum: Lightweight, corrosion-resistant, and easy to machine, making it ideal for aerospace, automotive, and electronics.

- Steel: Offers high strength and durability, widely used in industrial machinery, automotive parts, and structural components.

- Titanium: Known for exceptional strength, heat, and corrosion resistance, making it perfect for aerospace and medical implants.

Plastics and Composites

- Plastics: Materials like ABS, polycarbonate, and PEEK are used for medical devices, electronics, and consumer products due to their lightweight and chemical resistance.

- Composites: Carbon fiber and fiberglass offer high strength-to-weight ratios, commonly used in aerospace, sports equipment, and high-performance vehicles.

Manufacturing Costs of CNC Milling

Understanding the key cost factors in CNC milling helps businesses optimize expenses while maintaining precision and efficiency.

Factors Affecting CNC Milling Costs

Material Selection: The choice of material has a significant impact on overall costs. Metals like titanium and stainless steel are expensive to machine due to their high hardness and tool wear, requiring longer machining times and more durable cutting tools. In contrast, aluminum and plastics are easier and faster to machine, reducing both tool wear and production costs.

Labor Costs: While CNC milling is highly automated, it still requires skilled operators for setup, programming, tool changes, and quality control. The more complex the part, the higher the programming time and operator involvement, leading to increased labor costs.

Machine Type: The type of CNC machine used directly affects cost. 3-axis CNC machines are cheaper to operate and are suitable for simpler parts. However, 5-axis CNC machines offer greater precision and can handle complex geometries in fewer setups, but their higher operational costs and maintenance requirements make them more expensive.

Cost Comparison with Other CNC Processes

When compared to other CNC machining processes, CNC milling is often more cost-effective for low to medium production runs, especially for custom or intricate designs that require multi-axis cutting. However, for high-volume production, CNC turning or injection molding may be more economical due to their faster cycle times and lower material waste.

- CNC Turning is cheaper for cylindrical parts as it involves a continuous cutting process, reducing machining time and material waste.

- CNC Drilling is the most cost-effective for hole-making operations, as it is faster and requires less complex programming.

- Injection Molding becomes more cost-efficient for mass production since tooling costs are high upfront, but per-unit costs drop significantly with large quantities.

Ultimately, choosing the right process depends on the design complexity, production volume, and budget constraints. CNC milling is ideal for custom, precision parts, while turning and drilling are better suited for faster, high-volume production

CNC Milling vs. Other Machining Processes

CNC milling is often compared with CNC turning and CNC drilling as they are widely used machining processes. Each method differs in technique, efficiency, and cost-effectiveness. Understanding these differences helps manufacturers choose the best option based on design complexity, production speed, and budget.

CNC Milling vs. CNC Turning

| Factor | CNC Milling | CNC Turning |

| Function | Shapes complex parts | Produces cylindrical parts |

| Workpiece Movement | Stationary | Rotates |

| Tool Movement | Multi-axis cutting | Single-point cutting |

| Precision | High | High |

| Production Speed | Moderate | Faster |

| Cost | Higher | Lower |

| Best For | Complex geometries | Shafts, rods, pipes |

CNC turning involves rotating the workpiece itself, while a stationary cutting tool removes material. This process is significantly faster than CNC milling when producing cylindrical parts such as shafts, rods, and bushings. It is the preferred choice for high-volume production of round components due to its efficiency and lower cost per part. However, CNC turning is limited to symmetrical parts, whereas CNC milling can handle complex geometries and intricate designs.

CNC Milling vs. CNC Drilling

| Factor | CNC Milling | CNC Drilling |

| Function | Shapes entire part | Creates holes only |

| Tool Movement | Multi-axis cutting | Vertical drilling |

| Precision | High | Moderate |

| Production Speed | Moderate | Fast |

| Cost | Higher | Lower |

| Best For | Complex geometries | Fast hole-making |

CNC drilling is specifically designed for creating holes using a rotating drill bit. While CNC milling can also drill holes, CNC drilling is much faster and more cost-effective for this task. It is widely used in manufacturing, construction, and metal fabrication, where precision hole-making is required. However, CNC drilling lacks the versatility of milling and turning, as it is limited to simple hole-drilling operations and cannot shape complex parts.

Cost and Production Efficiency Differences

The cost and production efficiency of CNC milling, CNC turning, and CNC drilling vary depending on material, design complexity, production speed, and setup requirements. Each process has its advantages in terms of cost-effectiveness and efficiency.

CNC Milling: CNC milling is one of the most versatile machining methods, capable of handling complex designs and multi-axis operations. However, this versatility comes at a higher cost due to the longer machining time, tool wear, and energy consumption. It is best suited for low to medium production runs where precision and detail are essential.

CNC Turning: CNC turning is significantly faster and more efficient for cylindrical parts, reducing machining time and cost per unit. Since the workpiece rotates while the tool remains stationary, material removal is quicker, making it an ideal choice for high-volume production. The setup time is also lower compared to CNC milling, leading to improved efficiency for batch production.

CNC Drilling: CNC drilling is the most cost-effective process for hole-making operations. It requires minimal setup time, and drilling operations are rapid, making it the best choice for mass production. However, it lacks the flexibility of CNC milling and turning, as it is limited to creating holes rather than shaping entire parts.

Conclusion

CNC milling is a highly versatile and precise manufacturing process that enables the creation of complex geometries, tight tolerances, and high-quality surface finishes across a wide range of materials. Its ability to produce both prototypes and high-volume production parts makes it essential in industries such as aerospace, automotive, electronics, medical devices, and industrial equipment. Understanding how CNC milling works—and the capabilities it offers—helps engineers and designers make smarter decisions that elevate product performance and manufacturing efficiency.

At Fecision, we specialize in custom CNC milling services, combining advanced multi-axis machines with expert engineering to deliver precision-machined components tailored to your exact specifications. Contact us today to bring your designs to life with accuracy, consistency, and unmatched craftsmanship.