CNC drilling is a highly efficient and precise machining process used to create holes in various materials through computer-controlled automation. It ensures accuracy, speed, and consistency, making it a crucial method in industries like aerospace, automotive, and electronics. Unlike manual drilling, CNC drilling minimizes human error and enhances productivity by automating hole-making operations.

This article explores the fundamentals of CNC drilling, its advantages, applications, and how it compares to CNC milling and boring. Understanding CNC drilling helps manufacturers optimize production processes, reduce costs, and achieve superior quality in their products, making it an essential technique in modern manufacturing.

Understanding CNC Drilling

CNC (Computer Numerical Control) drilling is a machining process where a computer controls a drilling machine to create holes with high precision. CNC drilling machines use programmed instructions to operate automatically. They feature a high-speed rotating drill bit that can drill holes in metals, plastics, ceramics, and other materials with minimal human effort. These machines ensure uniform drilling and can handle complex designs, making them an essential part of CNC machining in modern manufacturing.

Key Functions in Precision Manufacturing

CNC drilling plays a crucial role in modern manufacturing by ensuring accuracy, efficiency, and consistency. Here’s how it contributes to precision manufacturing:

- Produces Highly Accurate Holes: CNC drilling machines use programmed instructions to create holes with exact dimensions and placement. This precision is essential for industries like aerospace and electronics, where even minor deviations can affect performance.

- Works on Different Materials: CNC drilling can handle a wide range of materials, including metals (steel, aluminum, titanium), plastics (PVC, acrylic, nylon), and ceramics. This versatility makes it ideal for various industries, from automotive to medical device manufacturing.

- Reduces Human Error: Since the drilling process is automated, there is minimal manual intervention, reducing the risk of human mistakes. This leads to greater consistency in production, ensuring that every drilled hole matches exact specifications.

- Speeds Up the Manufacturing Process: Compared to manual drilling, CNC drilling significantly reduces production time. Machines can operate continuously with minimal downtime, and multi-spindle drilling machines can create multiple holes simultaneously, further enhancing productivity.

By integrating CNC drilling into manufacturing, companies can achieve higher precision, lower error rates, and faster production times, ultimately improving product quality and efficiency.

Advantages and Disadvantages of CNC Drilling

Advantages

- High Speed: CNC drilling operates at much higher speeds than manual drilling, allowing manufacturers to produce large quantities of drilled components in a shorter time.

- Automation: Since CNC drilling is computer-controlled, it requires minimal human intervention, reducing labor costs and improving efficiency.

- Consistency: Every hole drilled using CNC machines maintains the same size, depth, and precision, ensuring uniformity across all parts.

- Efficiency: CNC drilling machines can handle multiple drilling operations simultaneously, reducing downtime and increasing overall productivity.

Disadvantages

- Limited to Hole-Creation: Unlike CNC milling or turning, CNC drilling is specialized for hole-making and cannot be used for shaping or cutting complex geometries.

- High Initial Cost: CNC drilling machines and their setup can be expensive, making them a significant investment for small businesses.

- Requires Skilled Operators: Even though CNC machines reduce manual effort, programming and operating them require skilled professionals who understand machine settings, tool selection, and material properties.

Applications of CNC Drilling

Aerospace and Automotive Manufacturing: CNC drilling plays a critical role in the aerospace and automotive industries, where precision is essential. It is used to drill holes in structural components, engine parts, and mounting brackets. The accuracy of CNC drilling ensures that parts fit perfectly during assembly, reducing errors and improving overall product quality.

PCB and Electronic Component Fabrication: In the electronics industry, CNC drilling is used to create precise holes in printed circuit boards (PCBs). These tiny, accurately placed holes allow the installation of electronic components such as resistors, capacitors, and microchips. The ability to drill multiple small holes with high precision ensures the reliability and functionality of modern electronic devices.

CNC Drilling Process and Techniques

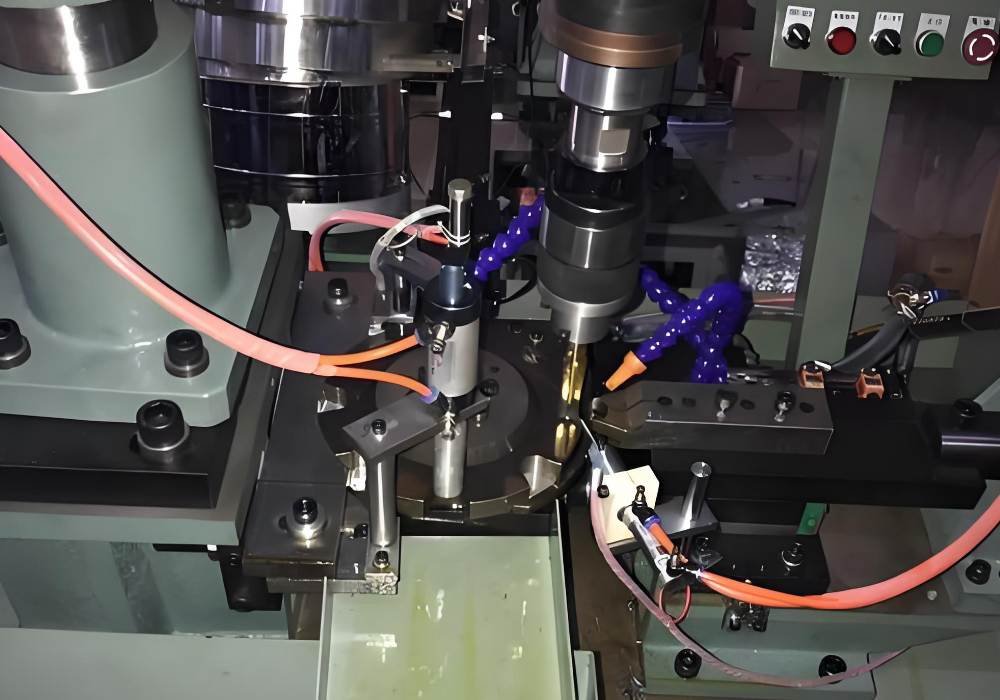

CNC (Computer Numerical Control) drilling is an automated machining process used to create precise, consistent holes in a workpiece. This process is widely used in industries like aerospace, automotive, electronics, and construction, where accuracy and efficiency are critical.

How CNC Drilling Works

- Design & Programming: The drilling pattern is created using CAD (Computer-Aided Design) software and then converted into machine-readable G-code.

- Material Setup: The workpiece is securely clamped to prevent movement during drilling.

- Drilling Operation: The CNC machine controls the drill bit’s movement along the Z-axis to create holes at precise depths and locations. Multi-axis machines can drill at different angles.

- Coolant & Chip Removal: Coolants help prevent overheating, while chip evacuation systems remove debris for smooth operation.

Key Techniques in CNC Drilling

- Peck Drilling: Involves incremental drilling to remove chips and prevent bit breakage.

- Spot Drilling: Used to mark hole positions before full drilling for improved accuracy.

- Deep Hole Drilling: Specialized techniques, like gun drilling, are used for deep, narrow holes.

- High-Speed Drilling: Utilizes advanced CNC systems to maximize efficiency and reduce cycle time.

CNC drilling enhances productivity, minimizes human error, and ensures uniformity, making it a crucial process in modern manufacturing.

Types of CNC Drilling Machines

CNC drilling machines come in different types, each designed for specific drilling needs. The choice of machine depends on the type of material, hole depth, and production volume.

Bench Drilling Machines: Bench drilling machines are small, stationary machines used for light-duty drilling. They are ideal for small workshops and precision work where high-speed drilling is not required. These machines are commonly used for drilling holes in soft metals, plastics, and wood.

Multi-Spindle Drilling Machines: Multi-spindle drilling machines have multiple drill heads that can drill several holes at once. They are designed to increase productivity by reducing drilling time in mass production environments. These machines are widely used in automotive, aerospace, and electronics manufacturing, where multiple identical holes are required in a single component.

Deep Hole Drilling Machines: Deep hole drilling machines are designed to drill holes with a depth-to-diameter ratio greater than 10:1. These machines use special cooling and lubrication techniques to ensure precision while preventing tool wear. They are commonly used in industries that require deep holes, such as oil and gas, aerospace, and hydraulic cylinder manufacturing.

Drilling Operations and Tools

Drilling is not just about creating holes, it involves different techniques that enhance accuracy, efficiency, and functionality. The right method and tool selection depend on the type of hole required and the material being drilled.

Spot Drilling: Spot drilling is the first step in precision drilling. It creates a small indentation at the exact location where the main drill bit will start cutting. This prevents the drill bit from slipping or wandering off, ensuring accuracy in hole placement. Spot drilling is crucial for high-precision industries such as aerospace and electronics, where even a minor misalignment can cause defects in the final product.

Counterboring and Countersinking

These two operations improve the fit and appearance of drilled holes:

- Counterboring: enlarges the top part of a hole, creating a flat-bottomed recess. This allows bolts, screws, or fasteners to sit flush with the surface, improving stability and reducing protrusions.

- Countersinking: creates a conical opening at the top of the hole, allowing flathead screws to sit flush with the material. This is commonly used in applications requiring a smooth, snag-free finish, such as in furniture making and aircraft assembly.

Tapping and Reaming

These operations refine and enhance drilled holes:

- Tapping is the process of cutting internal threads inside a hole, allowing screws and bolts to fasten securely. CNC tapping ensures consistent thread depth and pitch, which is crucial for mechanical assemblies that require strong connections.

- Reaming enlarges and smoothens an existing hole, ensuring precise dimensions and a high-quality finish. This process is commonly used in metalworking and automotive manufacturing, where precise hole diameters are essential for component fitting.

Materials Used in CNC Drilling

The choice of material in CNC drilling depends on the intended application, strength requirements, and environmental conditions.

Metals

- Steel: A strong and durable material used in automotive, aerospace, and construction industries.

- Aluminum: Lightweight and corrosion-resistant, making it ideal for aircraft parts and consumer electronics.

- Titanium: Highly resistant to heat and wear, often used in aerospace and medical applications.

Plastics

- Acrylic: Transparent and impact-resistant, commonly used in display cases and medical devices.

- PVC: A cost-effective and durable plastic used in construction and piping systems.

- Nylon: Strong and flexible, used in gears, bearings, and automotive components.

Ceramics

Ceramics are used in high-precision industries due to their hardness and heat resistance. They are commonly found in:

- Electronics: Used in circuit boards, insulators, and semiconductors.

- Medical Applications: Utilized in dental implants, prosthetics, and surgical tools due to their biocompatibility and strength.

Manufacturing Costs of CNC Drilling

Several factors affect the overall cost of CNC drilling:

Tooling Costs: CNC drilling requires high-quality drill bits that can withstand high-speed operations. Over time, drill bits wear out and need replacement. Maintenance of cutting tools also adds to the overall cost.

Setup Costs: Programming the machine, setting up the workpiece, and calibrating the drill bit take time and expertise. Skilled labor is required to ensure the machine operates correctly, contributing to the cost.

Material Costs: The type of material being drilled affects the cost. Harder materials, like titanium or stainless steel, require specialized drill bits and longer machining times, increasing expenses.

Comparison with Manual and Other CNC Processes

CNC drilling is more expensive than manual drilling but offers better accuracy. Compared to other CNC processes like milling, it is cost-effective for hole-making but limited in functionality.

CNC Drilling vs. Other Machining Methods

CNC drilling is just one of many CNC machining methods, and it differs significantly from other techniques such as CNC milling and CNC boring. Understanding these differences helps manufacturers choose the best process for their needs.

CNC Drilling vs. CNC Milling

| Feature | CNC Drilling | CNC Milling |

| Function | Hole-making | Material removal |

| Tool Movement | Vertical (Z-axis) | Multi-axis (X, Y, Z) |

| Material Removal | Limited | Extensive |

| Tools Used | Drill bits | End mills, cutters |

| Precision | High (holes) | High (shapes, surfaces) |

| Applications | Holes, fasteners | Slots, pockets, engraving |

| Complexity | Simple | Complex |

| Materials | Metal, plastic, wood | Metal, plastic, ceramic |

| Cost | Lower | Higher |

CNC drilling is specifically designed for creating holes with precision and speed, using a straight, vertical movement. In contrast, CNC milling is a more versatile process that uses rotary cutting tools to cut, shape, and remove material in multiple directions. While CNC drilling excels at high-speed, repetitive hole-making, CNC milling is better suited for complex geometries and custom shapes.

CNC Drilling vs. CNC Boring

| Feature | CNC Drilling | CNC Boring |

| Function | Creates new holes | Enlarges existing holes |

| Tool Movement | Vertical (Z-axis) | Multi-axis (X, Y, Z) |

| Material Removal | Initial hole-making | Precise hole expansion |

| Tools Used | Drill bits | Boring bars, cutters |

| Precision | Moderate | High (tight tolerances) |

| Applications | Fasteners, threading | Precision hole finishing |

| Complexity | Simple | complex |

| Materials | Metal, plastic, wood | Metal, plastic, ceramic |

| Cost | Lower | Higher |

CNC boring is used to enlarge an already existing hole for greater precision and smoothness, while CNC drilling creates a hole from scratch. Boring is preferred when extreme accuracy in diameter and surface finish is required, whereas drilling is ideal for initial hole creation in various materials.

Cost and Speed Comparisons

CNC drilling is faster and more cost-effective for high-volume hole-making, while CNC milling offers greater versatility but at a higher cost and slower speed.

Speed Considerations: CNC drilling is much faster than manual drilling and many other machining processes for hole-making. Automated CNC drilling machines work continuously with minimal downtime, increasing production efficiency. Multi-spindle drilling machines further enhance speed by drilling multiple holes at once, reducing cycle times. In contrast, CNC milling and boring involve more complex tool movements, making them slower for hole-making tasks. In industries like automotive and aerospace, CNC drilling is preferred for its ability to produce precise holes quickly, helping meet high-volume production demands while maintaining quality standards.

Cost Considerations: The cost of CNC drilling varies based on several factors, including machine type, tooling, setup, and material costs. Generally, CNC drilling is more cost-effective than CNC milling or boring for simple hole-making tasks because it requires less time and tool movement.

- Tooling Costs: CNC drilling uses drill bits that are relatively inexpensive compared to milling cutters or boring tools. However, specialized drill bits for deep hole drilling or high-precision applications may increase costs.

- Setup Costs: The initial setup involves programming the machine, calibrating tools, and selecting materials. While CNC drilling has a lower setup cost than milling and boring, businesses investing in high-end CNC drilling systems must consider programming expertise and maintenance expenses.

- Material Costs: The cost of drilling also depends on the material being worked on. Harder materials, such as titanium or hardened steel, require high-performance drill bits and advanced cooling systems, which increase operational costs.

While CNC milling and boring are more expensive per operation, they offer greater flexibility in shaping, cutting, and refining materials. Businesses must consider whether they need only hole-making (where CNC drilling is more cost-effective) or additional machining processes, which might justify the higher costs of CNC milling or boring.

Efficiency and Cost-Effectiveness

CNC drilling is the most efficient and cost-effective option for large-scale hole production. It minimizes material waste, reduces human error, and speeds up the manufacturing process. However, for applications requiring precise shaping, hole enlargement, or complex geometries, CNC milling and boring may be better suited despite their higher costs. Manufacturers should evaluate their production needs to select the most economical and time-efficient machining method.

Conclusion

CNC drilling is an essential machining process for creating precise, consistent, and repeatable holes in components across countless industries—from electronics and automotive to aerospace, energy, and medical devices. Its ability to deliver tight tolerances, smooth finishes, and reliable alignment makes it a cornerstone of modern manufacturing. Understanding CNC drilling capabilities helps engineers design stronger, more efficient parts while ensuring compatibility with downstream assembly and production requirements.

At Fecision, we offer high-precision CNC drilling services tailored to your exact needs, supported by advanced equipment and skilled engineering expertise. Contact us today to produce custom parts with exceptional accuracy, quality, and performance.