Punch and die systems power high speed production lines that run over 100 strokes per minute, they are an essential part of modern metal fabrication. These precision tools work together to create features in metal sheets, holes, louvers, cutouts and custom shapes without any additional finishing work. In industries like automotive, aerospace and consumer electronics punch and die tooling delivers the accuracy and consistency required for quality manufacturing.

The process requires very precise specifications, for example a 1mm thick stainless steel sheet needs a clearance of 0.1mm to 0.15mm between the punch and die components. Plus the versatility of these tools allows manufacturers to work with materials up to 1 inch thick, mild steel, aluminum and stainless steel. This article covers everything you need to know about punch and die systems, their applications, materials and selection criteria for top metal fabrication results.

What is a Punch and Die?

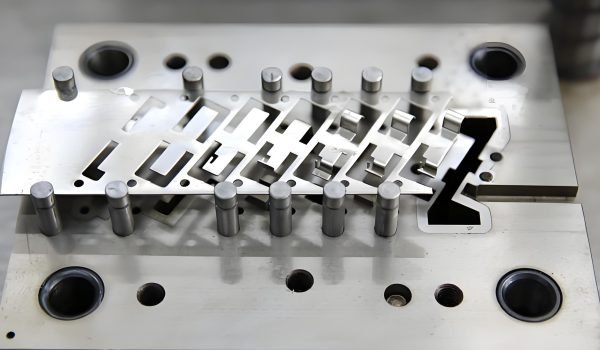

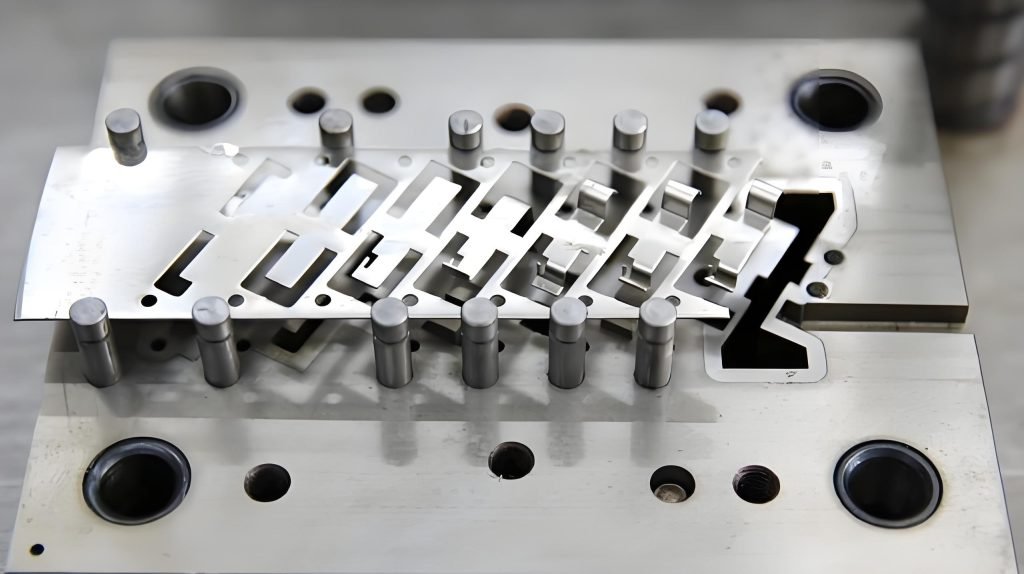

A punch and die set is a fundamental tooling system where two complementary components work together to modify metal through controlled force application. The punch is the male component that penetrates the material, the die is the female component that supports the workpiece and provides the cutting edge.

How they work together to shear, form or cut material.

The punch and die work together through a precisely engineered relationship. Positioned on opposite sides of the workpiece, the punch travels down with force into the die. This creates highly localized shear stresses between the punch and die that exceeds the material’s shear strength. The material fails when the punch has moved about 15-60% through the material thickness.

The process occurs in three stages: deformation (initial pressing of the punch against the material), penetration (the punch starts to enter the material) and fracture (complete separation occurs). During this sequence proper clearance between the punch and die is critical, typically 5-40% of the material thickness depending on the material. This clearance helps make clean cuts and reduces burrs, which are unwanted raised edges left on the cut surface.

Where punch and die tooling is used.

Punch and die tooling is widely used in various industries. In automotive manufacturing they create components for body parts through stretching, bending and blanking operations. Aerospace, industrial engineering, electronics, manufacturing and textile sectors rely heavily on this technology.

The versatility of punch and die systems allows manufacturers to work with almost all metals, stainless steel, aluminum, brass, copper, iron and specialty alloys. Modern punch presses, especially CNC controlled machines can deliver around 600 punches per minute with high precision. Some advanced systems have turrets holding up to 100 different punches that rotate into position as needed.

Beyond simple hole making punch and die tooling enables blanking, coining, broaching, bulging and complex compound operations where multiple functions occur at the same time. This flexibility makes punch and die systems essential for fabricators that require high volume production of precision metal components.

Types of Punch and Die Sets

Across industries from automotive to electronics manufacturers use various types of punch and die sets for specific applications and materials. The diversity in design allows fabricators to get precise cuts and shapes while maximizing efficiency and tool life.

Metal Punches and Die

Metal punch and die sets come in many standard and custom configurations to meet different manufacturing needs. These tools come in various shapes such as round, oblong, square, rectangular, teardrop, triangle, and octagon. When standard shapes aren’t suitable, manufacturers can also design custom punches and dies for specific applications. The versatility extends to special designs like:

- Cross shaped, double oblong and trapezoid punches for specific applications

- Corner rounds and key radius ends for precision work

- Flatted rounds and curved oblongs for specialized cutting requirements

The shape selection depends entirely on the outcome of the punched material. Custom options are available by submitting sketches or samples to tooling providers.

Sheet Metal Punches and Die

Sheet metal punching uses specific punch and die sets for piercing, blanking, notching, lancing, embossing and coining. Piercing creates holes in metal sheets using a punch that penetrates into a die, blanking cuts out shapes from larger sheets. Notching cuts away sections along the sheet edge, lancing makes partial cuts to create tabs or flanges.

Embossing creates raised or recessed designs and coining produces detailed shapes under high force. These operations can be done with single punch dies for simple jobs or more complex progressive, compound or transfer dies for multi stage operations.

Steel Punches and Dies

Steel is the most common material for punch and die sets, with varying levels of hardness and durability depending on the application. High-quality steel punches are ground at precise angles with accurately centered tips. Overall, steel punches and dies offer an excellent balance of cost and performance for most uses.

High quality steel components have proper chamfers, razor sharp cutting edges and surface hardness between 58-60 Rockwell. These tools undergo heat treatment that hardens the tips for durability, while keeping the other end softer to avoid shattering when hit with a hammer. For high volume production manufacturers sometimes use carbide punches and dies which offer better durability but at a higher cost.

Punch and Die Tooling Applications

Beyond simple hole punching punch and die tooling enables various manufacturing processes that form the backbone of modern metal fabrication. These versatile tools transform flat metal into complex components through specialized operations that each serve specific production needs.

Discuss how they’re used

Bending operations use punch and die sets to create precise angles in sheet metal. In bottom bending the punch presses the workpiece completely into the die creating a form lock that virtually eliminates springback. Although this method requires 3-5 times more tonnage than air bending it delivers accuracy of ±0.25° under optimal conditions.

Embossing produces raised or recessed designs on metal surfaces through controlled stretching. This process creates shallow depressions with little inward metal flow. Manufacturers use embossing tools to mark parts with numbers, logos or create standoffs and spacers. The success of embossing depends largely on die geometry, specifically the punch radius—larger radii allow metal to stretch over a greater surface area, reducing the risk of fracture.

Perforating uses cluster tooling with 2 to 120+ tips per punch to create multiple holes with a single stroke. This increases efficiency and combats sheet distortion and oil canning that occurs during perforation. For high-volume production, wide punch presses with multiple punching rams can strike entire rows of holes simultaneously.

Notching, a type of shearing process, cuts away material from the edges or outer sections of a workpiece. This process creates specific shapes along metal edges to facilitate assembly or joining. Through notching manufacturers can create complex configurations so metals fit together seamlessly. There are various techniques, tube notching, end notching and side notching—each for specific joining requirements.

Integration into CNC punch presses and manual punch tools.

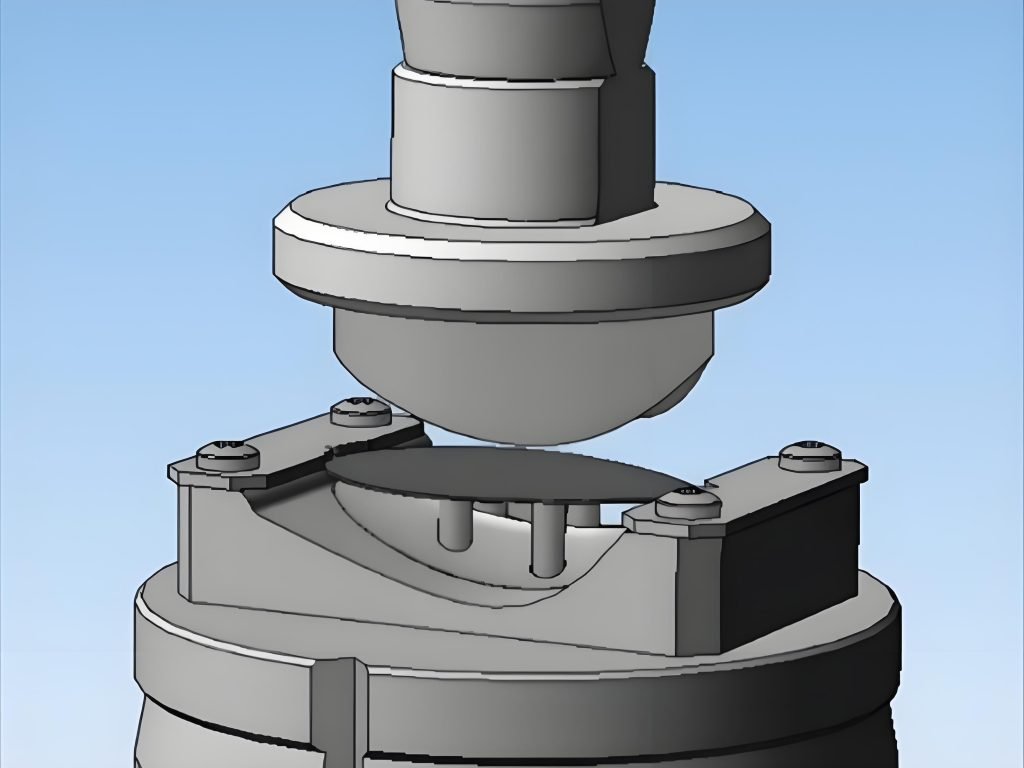

Modern CNC punch press systems use multi-axis linkage control technology to perform complex stamping operations. These machines have thick sleeve turret structures that increase tool durability while maintaining guiding accuracy during high speed operations. Advanced models can deliver 1000 hits per minute with sheet positioning speed of 150 meters per minute.

Manual punch tools are for smaller operations or specialized tasks. Though less automated, quality hand punches can produce accurate results with proper technique and safety considerations.

Common Punch and Die Materials

The material used for punch and die components affects tool life, production quality and overall cost. Steel is the most common material for punch and die tooling, the best balance of durability, machinability and cost.

High-carbon tool steels like D2 and A2 are popular because of their excellent wear resistance and dimensional stability during heat treatment. D2 tool steel with 1.5% carbon and 12% chromium has great hardness (58-62 HRC) and abrasion resistance for high volume production. A2 tool steel has slightly better toughness at the expense of some wear resistance and is good for complex shaped punches that might chip.

High-speed steels (HSS) like M2 and M4 are used in applications that require heat resistance. These materials retain their hardness even at high temperatures and work well in high-speed punching operations where friction generates a lot of heat. The tungsten and molybdenum in high-speed steels make them perform well under thermally demanding conditions.

For extreme wear applications tungsten carbide is unbeatable for hardness and longevity although more expensive. Carbide-tipped or solid carbide punches can last 10 to 20 times longer than steel punches when working with abrasive materials such as fiberglass or carbon-fiber composites. So they are often more economical in the long run for high volume production.

Beyond the base material, surface treatments make a big difference in punch and die performance. Titanium nitride (TiN) coatings reduce friction and extend tool life by up to 300% compared to uncoated tools. Chromium nitride (CrN) coatings are good for corrosion protection when working with reactive materials.

The final material selection depends on workpiece material, production volume, punch geometry and budget constraints.

How Punch and Die Sets Are Made

The making of precision punch and die sets involves complex engineering processes that transform raw materials into accurate tooling components. Modern manufacturing combines traditional craftsmanship and technology to meet exacting standards.

Computer Numerical Control (CNC) machining is the backbone of modern punch and die manufacturing. This method uses computer controlled machines to produce components with high precision, to create complex geometries and intricate shapes required for special punches and dies. So manufacturers can have consistent quality across production runs.

Robotic systems are also part of the process. These automated systems handle repetitive tasks like loading materials, drilling operations and component assembly. In many facilities robots do tapping holes and other precision work, making the process more efficient and cost effective.

Additive manufacturing, or 3D printing, is a newer method used in the production of tooling. This technology creates components by layering materials, to produce geometries that are impossible with traditional methods.

Before production tool and die engineers design detailed blueprints using Computer-Aided Design (CAD) software. These digital models are the basis for the manufacturing process, engineers work close to production areas for effective collaboration.

Quality control is paramount throughout production. High quality punch and die manufacturers quarantine and test their steel before processing. Then the materials go through computerized vacuum internal quench heat-treating systems to ensure batch-to-batch consistency.

The process itself involves multiple precision operations where clearance between die steel and punches must be controlled. Punch and die sets for specific applications often require custom clearances based on material type and thickness. After production trials help identify defects before full production starts.

With this combination of technology and quality control manufacturers produce punch and die tooling that delivers maximum efficiency, durability and performance in metal fabrication applications.

What to Consider When Choosing Punch and Die Tooling

Choosing the right punch and die tooling requires evaluating multiple technical factors that impact production quality, tool life and overall efficiency. First and foremost matching the material type and thickness with the right tooling prevents premature wear and ensures accuracy in the finished product.

Clearance between punch and die components is critical. Under-clearance raises tool load and burr height, while too much clearance causes ragged edges and reduces hole quality. A starting point: clearance = material thickness × material factor (0.06 for aluminum, 0.08 for mild steel, 0.10 for stainless).

The workpiece material itself is a major consideration. Mild steel up to 3 mm thick can be processed using standard tool steel, while abrasive stainless steel or high-strength alloys require high-speed steel (HSS) or carbide punches. Also make sure your press brake has enough tonnage to handle the punching force—never exceed 80% of your press’s rated capacity.

For production efficiency consider:

- Punch geometry must match the finished part requirements—tight corner radii or miniature holes need smaller punch tips and tighter die clearances

- Surface coatings like TiN, TiCN or AlCrN reduce galling when punching sticky aluminum or stainless

- Tool material durability affects maintenance intervals—high quality tool steel is ground at proper angles with accurately centered tips

- Supplier expertise ensures you get the right technical guidance for your application

Specialized tools should be designed to reduce setup time and be versatile across different press types. Tools should have safety features like self-retaining installation and front-loading to protect operators and simplify the setup process.

In summary, evaluating these factors helps manufacturers balance initial investment against long term productivity gains and get the right punch and die for their fabrication requirements.

Conclusion

Punch and die systems are the backbone of modern metal fabrication, turning raw sheet metal into complex parts through operations like bending, embossing, perforating, and notching. These precision tools rely on exact specifications, clearance, material, and geometry to deliver clean, accurate results.

Choosing the right material is critical; high-carbon tool steels balance cost and durability, while tungsten carbide suits high-volume work. Surface treatments like TiN coatings significantly extend tool life. Advances in CNC machining, robotics, and additive manufacturing now allow for tighter tolerances and complex designs. When selecting tooling, fabricators must consider material thickness, production volume, and press capacity. Ultimately, punch and die systems remain essential to efficient, high-speed production across automotive, aerospace, electronics, and consumer industries.