In manufacturing, doing things right the first time can save a lot of time, money and headaches. One crucial measure designed to help ensure that products come out perfect is a mold trial. It’s a test run for molds – tools that turn materials like plastic, metal, or rubber into parts for things like cars, gadgets or even toys. With mold trials, you test whether the mold is functioning properly before producing thousands of parts. They assist in catching mistakes early, getting the highest quality out of your render, and making production run smoother.

In this guide, we’ll explain exactly what mold trials are and why they are important, the types of mold trials, the process, and how they help to reduce errors. Written in clear language, this post is for those who are curious about manufacturing or want to learn how to make the most of their manufacturing process. We’ll take that time and keep it clean, practical and full of useful info for you to learn how to do mold trials.

What is a Mold Trial?

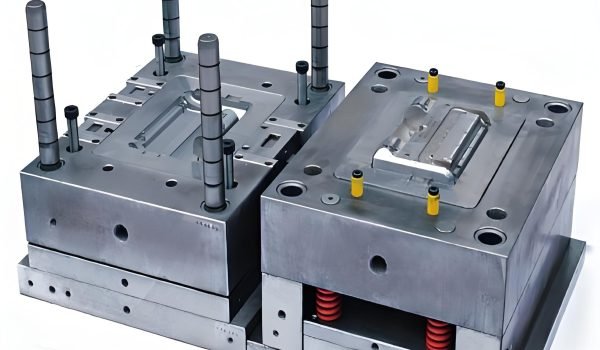

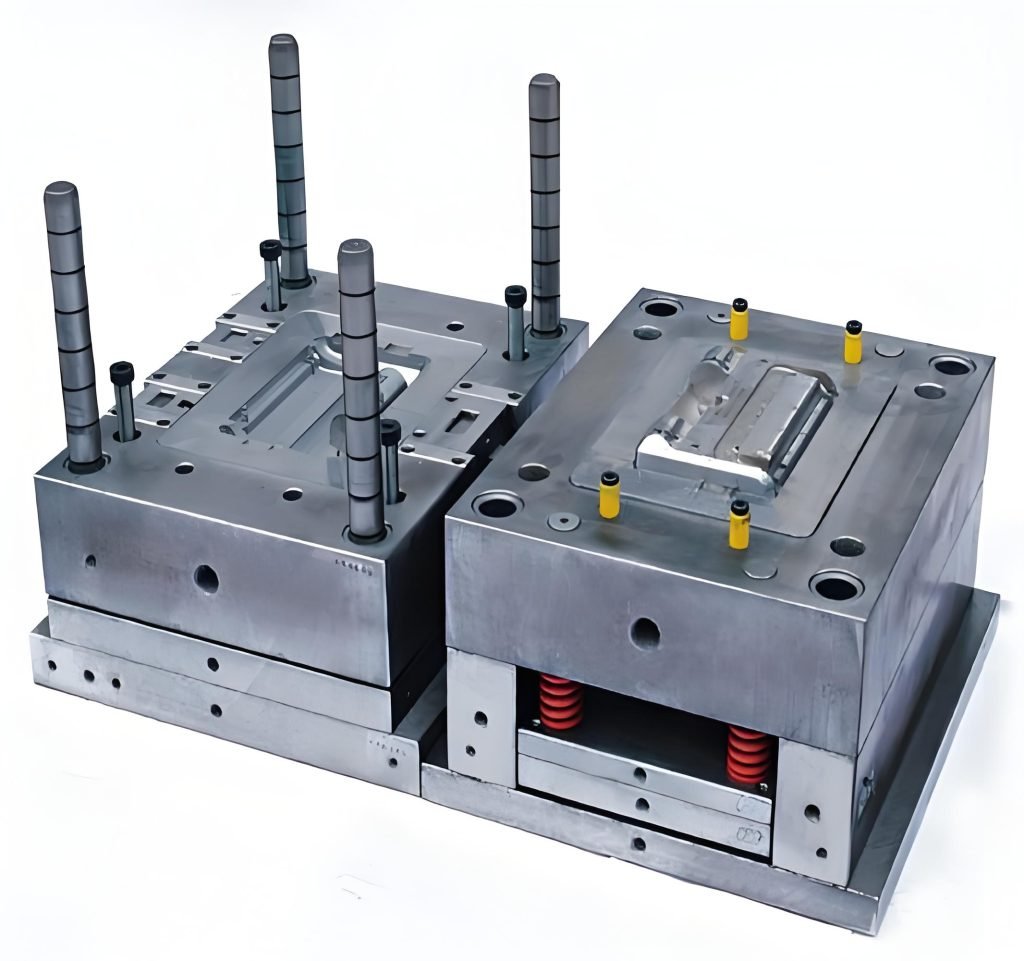

A trial is a kind of practice run for a mold right before it’s put to use churning out a bunch of parts. Think of a mold as a special tool that makes melted plastic or metal take the form of phone cases, car parts or bottle caps. The trial is putting the mold in a machine and making a few parts and seeing if they come out properly. It’s a method to see if the mould does its work without, say, any weird shapes, broken edges or weak spots.

The ultimate goal of a mold trial is to ensure that the mold produces parts that are identical to the design – the same size, the same shape, and the same quality. By performing this test, manufacturers save materials or time spent on faulty parts. In the automotive, electronics and medical device industries, mold trials are super common, and even tiny missteps can spell big problems. The earlier you catch problems, the better the product and the happier the customers.

Types of Mold Trials

There are three types of mold testings, with a specific role to play in the effort.

First Trial

This is the mould’s test after it’s constructed. It’s like test-driving a new car to see how it handles. The first check makes sure the mold can actually make parts, and searches for large problems, like parts that don’t form correctly or a mold that gets stuck. It’s a matter of catching big fat flaws at the beginning.

Check Trial

The check trial digs deeper. It checks if the mold produces parts in full accordance with the rules, like needed dimensions or strength. This trial is run against the mold in near real production conditions to make sure everything is on point. It’s like proofreading your work before you hand it in.

Production Trial

This is a trial that is the real thing. It’s a way to test the mold as if it were producing parts for a full production run, with many parts made over a longer time. The idea is to demonstrate that the mold can handle the stress of actual production without breaking or producing bad parts. It’s the last green light before mass production.

Steps to Run a Mold Trial

A mold trail can take a lot of planning and a lot of step-by-step. Here’s how it usually goes:

Get Everything Ready

First the mould is inspected for any damage or debris and then prepared in the molding machine. Workers ensure all the tools, materials and settings – whether temperature or pressure – are okay. It’s as if you were prepping a kitchen for cooking.

Choose and Load Material

The appropriate material – plastic pellets, metal – is selected based on what the part requires. Carefully, they load it into the machine to keep it clean and ready.

Run a Test Batch

The mold produces a limited number of parts to test how it works. Workers keep an eye out for things that are not filling in, rough edges or weird shapes.

Tweak the Settings

If the parts are not perfect, these parameters are tweaked – sometimes it’s a question of pressure, sometimes it’s the speed of the cooling, and sometimes it’s the amount of time the water can cool the parts. This phase is all about the sweet spot of where the mold works.

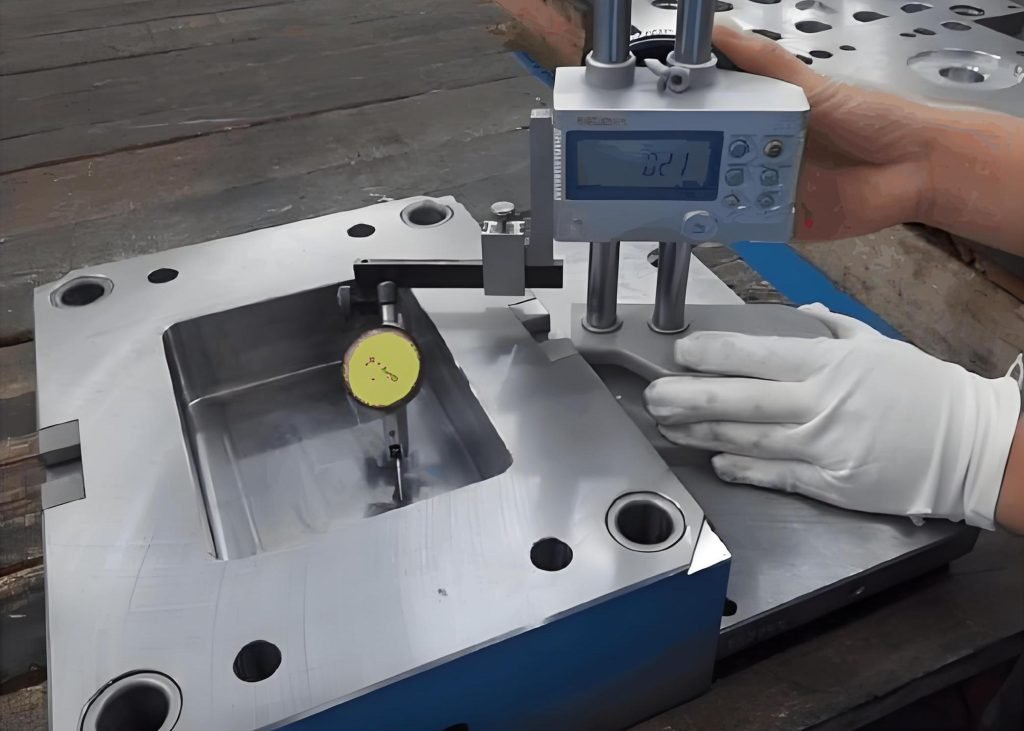

Inspect the Parts

The test parts are inspected closely – measured for size, looked at for smoothness, and tested for strength. Rulers and high-tech machines are tools that help make sure everything is right.

Fix Any Issues

If something is wrong – if there’s a part that doesn’t look right – that’s written down. ‘The real need for some cosmetic machinery: So when dancers need to fix or adjust things. They not only have to up a machine but even repair a mold.

Write a Report

What worked, what didn’t work and what was modified gets written down, everything that was in the trial. This report is useful for future trials or at the start of production.

Give the Green Light

If the mold is producing parts that meet your standards, it’s time to run production. If not, other trials follow until everything’s just right.

What Gets Checked in a Mold Trial?

There’s a bunch of stuff we check for on a mold trial to make sure that the mold and parts are good:

- Size and Shape: Parts are dimensionally measured to verify they are the correct size and shape.

- Surface Quality: The pieces are examined for smoothness, scratches or any dents.

- Cycle Time: It tests how long it takes to produce each part in order to ensure fast but good enough.

- Pressure and Velocity: The pressure and the velocity with which the material is forced into the mold are modified to circumvent problems.

- Cooling: Time and temperatures are verified to ensure parts don’t warp or crack.

- Material Behavior: They test how the material flows or shrinks to verify that it behaves correctly.

- Mold Parts: Items such as pins, gates or cooling channels in the mold are examined to make sure they’re doing their jobs.

These checks strike problems at an early stage and ensure the mold is good to go.

Common Problems and Fixes

Mold trials often find issues that need fixing before production. Here are some typical problems and how they’re handled:

- Incomplete Parts (Short Shots)

Issue: The mold doesn’t fill all the way, leaving half-formed parts.

Fix: Turn up the pressure, heat the material more, or clear any clogs in the mold.

- Extra Material (Flash)

Issue: Extra material leaks out, making messy edges.

Fix: Lower the pressure or fix the mold’s seal to keep it tight.

- Warped or Shrunk Parts

Issue: Parts twist or shrink because of uneven cooling.

Fix: Adjust cooling time or switch to a material that shrinks less.

- Dents (Sink Marks)

Issue: Small dents show up where the material didn’t set properly.

Fix: Add more pressure or let the part cool longer.

- Worn-Out Mold

Issue: The mold gets damaged from use or poor care.

Fix: Repair or replace parts and set up regular maintenance.

- Air Bubbles or Burns

Issue: Air gets trapped, or parts burn from moving too fast.

Fix: Add vents to let air out or slow down the material flow.

Fixing these during trials stops bigger problems later and saves a ton of hassle.

Why Mold Trials Are a Big Deal

Mold trials are a critical step used to ensure a high quality level in production. They identify mistakes before defective parts are made, which saves money and keeps customers happy. In the absence of trials, you could wind up with thousands of defective parts, which translate into expensive rework or, worse, product recalls.

Trials also can help production run more smoothly. By testing and adjusting the mold, manufacturers determine the ideal settings to produce parts as quickly as possible without sacrificing quality. This reduces waste materials, saves energy and accelerates the overall process. And the information from trials continues to improve future molds, so production becomes better and better over time.

How Mold Trials Cut Errors and Speed Things Up

Mold trials are a kind of safety net; they catch mistakes before they screw up production. If the mold is a known factor, do you know early in the process whether you have to fix a mold?” For instance, if a trial reveals that parts are coming out warped, the mold can be addressed at the start, saving loads of bad parts. This cuts down waste and keeps those machines humming.

Trials also speed things up, testing molds so they run smoothly. A good mold equals less downtime for repairs or off parts, and you have production without hiccups. Trials help adhere to strict quality standards, establishing trust with customers and making your goods sell.

A Final Word

Mold trials are a must for any manufacturer who wants high quality products without expensive mistakes. First, check and production trials may help companies spot problems, fine-tune, and ensure that every part is just right. With careful steps, thorough checks and quick fixes, mold trials result in better products, less waste and faster production. They Are an intelligent approach to future-proofing manufacturing, whether it involves car parts, medical tools or everyday products.