The mold cavity is the core part of the injection molding process. It defines the outer shape and surface finish of the final product. While the cavity may look like a negative space in the mold, it actually determines almost every external characteristic of the plastic parts.

In fact, a cavity in injection molding is the hollow portion where the molten plastic is injected to form the desired shape. The design of a cavity injection mold must consider several critical factors such as cooling channels, ejector pins and gates to optimize the production. The choice between single cavity and multi cavity molds greatly affects the production efficiency and cost; multi cavity molds produce multiple identical parts in a single cycle. This article will cover everything you need to know about mold cavities and their importance in injection molding.

Understanding the Basics: What is Mold Cavity?

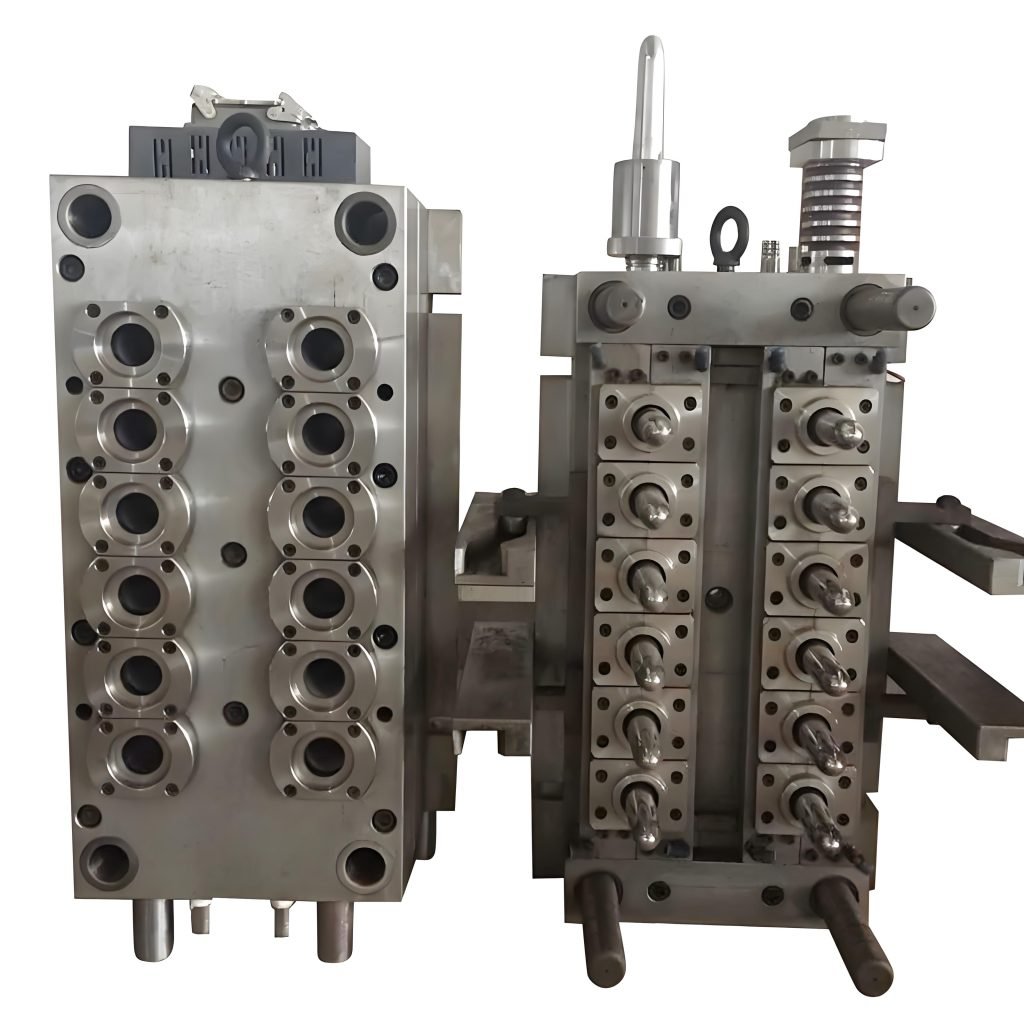

A mold cavity is the precisely machined hollow section inside an injection mold where the molten plastic is injected to form a part. It is the negative or female shape of the finished product, means it determines the outer dimensions, surface details and texture of the molded item. The cavity, typically located on the fixed (A-side) of the mold, pairs with the core on the moving (B-side) to form the complete three-dimensional shape of the part when the mold is closed.

In short, the mold cavity is where the raw material takes shape. It must be designed with absolute accuracy to ensure every part produced meets the required specifications in terms of size, appearance and function.

Importance of cavities in shaping the final product

The mold cavity plays a key role in shaping many features of the finished part. Primarily, it defines the shape, dimensions and esthetics of the final product. When designed properly the cavity ensures precise replication of the intended part geometry with excellent dimensional accuracy.

Also the cavity size affects the production quality. If designed too small it may result in incomplete filling and defects like voids or sink marks. If designed too big it will result in excessive material usage and longer cooling time.

The cavity design also affects the material flow patterns, cooling rates and overall molding efficiency. You can double or even multiply your output by having multiple chambers in a single mold. For example molds for mineral water bottle caps often have dozens or hundreds of cavities, increasing the productivity while reducing the cost of production.

Difference between mold cavity and mold core

Understanding the distinction between the mold cavity and the mold core is crucial in the injection molding process.

| Feature | Mold Cavity (A-Side) | Mold Core (B-Side) |

| Function | Form the external features of the part | Forms internal features (holes, threads) |

| Location | Fixed half of the mold (stationary) | Moving half of the mold (ejector side) |

| Shape | Female/Negative mold | Male/Positive mold |

| Durability Needs | Often made of hardened steel for longevity | Can be softer (e.g., aluminum), depending on design |

| Ejection Role | Plastic shrinks away from the cavity | Plastic clings to the core; ejection happens here |

In short, the cavity defines the part’s appearance from the outside, while the core shapes its internal details. Together, they form a complete mold system to produce complex, high quality plastic parts.

What is Cavity in Injection Molding?

Injection molding cavities are precise negative spaces where molten plastic turns into finished products. Unlike the general concept of a hollow area, a cavity in this context means the female portion of the mold that creates the outer geometry and surface finish of the manufactured part.

Explanation of What is a Cavity in Injection Molding, Specifically

The cavity in injection molding means the carefully engineered space into which molten plastic material is forced under pressure. Located typically on the fixed (A-side) of the mold, this component forms the exterior geometry and surface details of the final product. Throughout the molding cycle the cavity is in direct contact with the molten polymer as it fills, packs and solidifies.

Unlike the core (which creates inner features), the cavity shapes outer contours, textures and appearance characteristics. After the heating cylinder melts the raw polymer, the material flows through delivery systems into this negative space where it assumes the cavity’s precise dimensions before cooling and solidification.

Role of the cavity in determining part size, shape and quality

The mold cavity influences several key factors that determine part quality.

- Dimensional accuracy: The cavity size determines the exact measurements of the final product—too small causes incomplete filling, while oversized cavities waste material and extend cooling times

- Surface finish: The cavity’s texture and polish transfers to the part’s exterior

- Strength: Proper cavity design prevents warpage, sink marks and voids

- Tolerance control: Cavity pressure is vital in maintaining accurate dimensions and tight tolerances.

Also, cavity pressure during filling has a big impact on part quality. Proper control of this pressure is crucial for parts with specifications.

Material flow and how the cavity affects it

The cavity design controls how the molten plastic flows through the mold. Properly designed cavities ensure uniform flow patterns and prevent defects that occur when material solidifies unevenly. The cavity also has venting systems to release air during injection to avoid burn marks or incomplete filling.

Cavity shape also affects cooling rates which affects production efficiency and part quality. Cooling is a big portion of the overall cycle time so cavity design is critical for productivity. Uniform cooling through proper cavity design reduces thermal stress and warpage in the final product.

Types of Mold Cavities in Injection Molding

Manufacturers choose different types of mold cavities based on production requirements, volume needs and budget constraints. The number of cavities directly affects productivity, part consistency and overall cost.

1) Single-Cavity Molds: One Part per Cycle

A single-cavity mold makes one part each time the injection cycle runs. This type of mold is used for Low to medium volume, High precision requirements and Simple to moderately complex parts.

Since only one part is produced per cycle, production rate is slower but the simplicity of the mold means easier maintenance, lower tooling cost and higher dimensional accuracy. Single-cavity molds are best for early product testing and prototyping stages.

Benefits:

- Lower tooling and maintenance cost

- Simpler mold design and shorter lead time

- Greater control over part quality and consistency

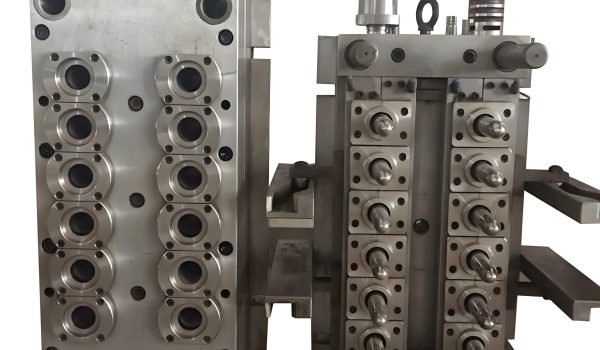

2) Multi-Cavity Molds: Multiple Parts per Cycle

Multi-cavity molds have multiple identical cavities in one mold base and produce multiple identical parts per cycle. This type of mold is used for High volume production, Mass production of uniform parts and reducing cost per unit over time.

While multi-cavity molds increase output and efficiency, it requires careful design to ensure balanced filling and cooling across all cavities. Uneven filling can lead to differences in part quality.

Benefits:

- Higher productivity and shorter cycle time

- Lower cost per part in long run production* Better use of machine time and energy

3) Family-Cavity Molds: Different Parts per Cycle

A family mold is a kind of multi-cavity mold that produces different components in one molding cycle. Each cavity within the mold is uniquely designed for a specific part. This is useful for molding a complete product with multiple components molded together.

However, balancing the flow of molten plastic into differently shaped cavities is complex as parts may vary in size, wall thickness or geometry. Uneven filling can cause dimensional errors or defects, making family molds more challenging to design and operate.

Benefits:

- Ideal for molding sets of related parts together

- Reduces tooling and handling cost

- Enhances assembly-line efficiency

Injection Mold Cavity Types – Quick Comparison Table

| Feature | Single-Cavity | Multi-Cavity | Family-Cavity |

| Production Volume | Low to medium | High | Small to medium |

| Efficiency | One part per cycle | Multiple identical parts per cycle | Different related parts per cycle |

| Part Complexity | Highly complex parts supported | Simpler, standardized parts preferred | Moderate complexity across varied components |

| Design Flexibility | High | Low | Medium |

| Tooling Cost | Lower | Higher | Higher than single-cavity |

| Cost per Part | Higher | Lower | Medium |

| Lead Time | Shorter | Longer | Longer than single-cavity |

| Best Use Case | Prototyping, custom low-volume production | Mass production of identical parts | Product sets or assembly components |

2 Cavity Injection Mold: When and Why It’s Used

A 2-cavity injection mold is a type of tooling used in the plastic injection molding process that produces two identical parts during each molding cycle. Instead of one part per cycle, this mold has two cavities, mirror or identical impressions, allowing for parallel production. It’s a middle ground between low-volume single-cavity molds and more complex multi-cavity molds, offering higher throughput with manageable costs.

Here are the benefits:

- Ideal for moderate volume production (typically over 10,000 units annually).

- Balanced cost-efficiency, lower cost per part with manageable initial investment.

- Shorter lead times due to dual-part output.

- Allows for scalable growth without a major upfront commitment.

- Suitable for companies transitioning from prototyping to manufacturing.

4 Cavity Injection Mold: Boosting Production Efficiency

A 4-cavity injection mold contains four cavities, allowing it to produce four parts in each cycle. This is for high-volume production where speed and efficiency are key. By quadrupling the output of a single-cavity mold, it’s for larger scale and lower cost per part.

Key advantages include:

- For high-volume production (over 50,000 units annually).

- Higher efficiency with minimal added cycle time (e.g., 22s vs. 20s for 2-cavity).

- Lower cost per part due to higher output and optimized energy/material use.

- Faster production and better ROI for long runs.

Comparison Between 2-Cavity and 4-Cavity Molds

| Feature | 2-Cavity Mold | 4-Cavity Mold |

| Initial Investment | Moderate | Higher |

| Cycle Time (typical) | ~20 seconds | ~22 seconds |

| Output per Cycle | 2 parts | 4 parts |

| Cost Per Part | Higher (for high-volume runs) | Lower (ideal for 50,000+ annual units) |

| Time to ROI | ≈2.2 months | ≈10 months |

| Best Use Case | Medium-volume production | High-volume, cost-sensitive production |

A business with steady or growing high demand will benefit from the cost efficiency and speed of a 4-cavity mold. A company in early production stages will prefer the affordability and flexibility of a 2-cavity system.

Things to Consider When Choosing the Number of Cavities

Choosing the right number of cavities for an injection mold requires careful evaluation of several key factors. The decision impacts production efficiency, part quality and overall project economics.

- Production Volume Requirements: The number of parts needed significantly impacts cavity count. High-volume production (e.g., over 500,000 parts/year) justifies higher cavity molds to reduce cost per part, while low-volume jobs (e.g., ~15,000 parts/year) are best with 1- to 2-cavity molds to keep tooling cost reasonable.

- Part Complexity and Size: Complex parts with features like slide cores reduce the number of cavities possible due to space constraints in the mold. Large parts with more surface area require more machine tonnage per cavity, limiting how many can be in one mold.

- Machine and Tooling Cost: The total material volume from all cavities must be within the machine’s capacity—ideally under 80% of its limit. Higher cavity molds require bigger, more expensive machines and higher tooling cost, but lower cost per part over time. Balancing these upfront and operational costs is key.

Conclusion

Understanding a mold cavity and how it works in the injection molding process is crucial for efficient and cost-effective production. The mold cavity is the foundation of injection molding, shaping the final product and determining its size, shape and quality.

Choosing between single, 2-cavity, 4-cavity or higher multi-cavity molds depends on production volume, part complexity and machine capability. A well thought-out cavity design can greatly improve productivity, reduce waste and product variability. Whether you’re designing a prototype or preparing for production, understanding mold cavity concepts will help you make better decisions that align with your manufacturing goals.