A boat impeller significantly stops catastrophic engine damage, which can lead to cracked blocks and baked gaskets. This small component creates pressure differences to keep engines running smoothly and forces fluid where needed.

Aggressive usage, debris exposure, and sandy water can significantly affect a boat impeller’s lifespan. This guide will explain a boat impeller, how it works, signs of failure, and maintenance tips to ensure your boat runs smoothly.

What Is A Boat Impeller?

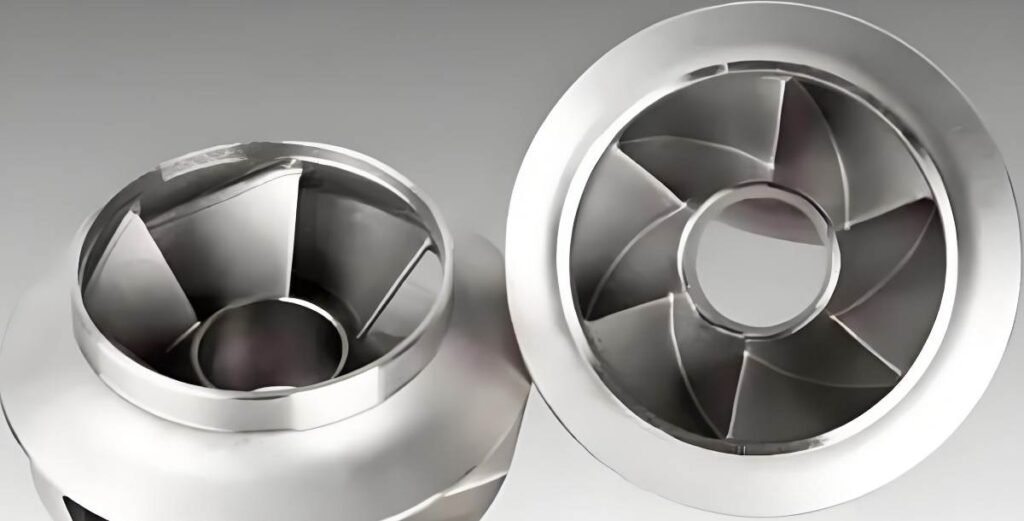

A boat impeller works like the heart of a marine engine’s water pump system. This small but powerful rotating part sits inside the engine’s water pump, creating a cooling system that keeps boats running smoothly. The design features flexible vanes connected to a central hub that spins inside a stainless-steel liner.

The impeller moves water through the engine’s cooling system to prevent overheating. Its blades create suction that pulls water into the pump when it rotates. The fins then push water around the engine block, creating a high-pressure, high-velocity stream that keeps the engine at the right temperature.

You’ll find impellers in two main spots on a vessel. Outboard engines and stern drives have the impeller just above the lower unit, near the cavitation plate. Sea water pumps, on the other hand, mount these parts on the engine’s front. They pull water from either the lower unit intake or hull intake.

Most boats use one or more flexible impeller pumps that need regular maintenance. These parts work in several systems:

- Engine belt-driven water pumps

- Engine raw water pumps

- Outboard motor water pumps

- Ballast pumps for wakeboard boats

The impeller’s makers use rubber or nitrile materials to build it, and it works like a fan. It spins inside a circular housing where the vanes open to pull water in before pushing it out. This process transfers energy from the motor to the pumped fluid, which moves water through specific engine channels.

A broken impeller means the water pump can’t pull in water, which could wreck your engine. Boat owners must understand this part well because a failed impeller could leave them far from shore. The impeller’s condition affects your engine’s life, making it a key part of boat maintenance.

How Does a Boat Impeller Work?

A boat impeller’s mechanical operation follows a precise sequence that starts when the engine’s driveshaft begins to rotate. The rotating motion powers the impeller and creates a centrifugal force that pulls water outside the vessel through dedicated channels.

The impeller’s flexible rubber vanes work seamlessly with the stainless-steel liner inside the pump housing. These rotating vanes create varying pressure zones that effectively move water through the system. The design maintains consistent pressure throughout the cooling process to ensure optimal water circulation.

The impeller works much like the original Archimedes screw in its operation. The central hub’s rotation makes the vanes flex, creating chambers between the blades. Water fills these chambers at the inlet point as the impeller’s continuous rotation moves it through the pump.

Modern boat engines with combustion systems use impellers as vital components in their dual-cooling setup. These boats typically run on a mixture of 50% distilled fresh water and 50% traditional antifreeze inside the engine block. External water flows through specialized corrosion-resistant tubes within a heat exchanger, thanks to the impeller’s pumping action. This setup cools the internal mixture without direct contact.

Proper lubrication is crucial for an impeller’s performance. Mechanics apply waterproof grease or manufacturer-approved lubricants to the shaft during installation or service. This prevents the impeller from sticking to the shaft and reduces friction when starting up.

The impeller can fail in two distinct ways:

- Gradual deterioration: The impeller and housing wear down, causing a slow performance decline

- Sudden failure: The impeller wheel breaks apart, usually from running dry or blockages

The impeller needs consistent water flow to work properly. Running without an adequate water supply can cause the pump to heat up faster, which might lead to complete failure. The seal between the impeller and its casing is a vital component, and wear rings or plates serve as warning signs of deterioration.

Signs of a Failing Boat Impeller

Detecting symptoms of a failing boat impeller can save your engine from serious damage. Your boat will show several warning signs that point to potential impeller problems that need quick attention.

- Overheating Engine – Poor water circulation causes rising temperatures. If the engine reaches 240°F, inspect the impeller immediately.

- Reduced Water Flow – Weakened suction reduces discharge pressure. Debris buildup or wear can block water flow.

- Cracked or Missing Blades – Check for cracks, worn peaks, or missing blades. Broken pieces can clog hoses and cause overheating.

- Difficulty Starting—Long periods of inactivity can cause impellers to stick to their housing. Blocked inlets also accelerate wear.

Impellers degrade over time due to heat, sand, and inactivity. Leaking seals indicate the need for replacement. Regular checks help avoid sudden failure.

When Should You Replace a Boat Impeller?

Boat manufacturers recommend replacing impellers based on operating hours or calendar time. The standard guideline suggests replacement every 100 hours of operation. Most outboards and sterndrives need new impellers every other year, even with limited use. MerCruiser systems are different – they need replacement every three years due to their unique design.

Smart boat owners replace impellers yearly instead of waiting until they fail. This preventive approach costs less than fixing engine damage from failed impellers. Many mechanics suggest checking the impeller’s condition during spring commissioning.

Factors Affecting Lifespan

The impeller’s durability depends on several environmental and operational conditions:

- Water conditions: Sandy or silty water wears down impellers faster through abrasion. Boats operating in these conditions need more frequent replacements.

- Extended inactivity: Impellers can go bad even when not used. The rubber might become brittle or deformed after sitting unused for a year or more.

- Dry running: Running without water lubrication damages impellers quickly. The impeller tips can melt and break apart within moments.

Flexible impeller pumps work best with regular use. An idle impeller might stick to its housing or become permanently deformed. Chemical exposure and debris can also substantially reduce its service life.

Saltwater creates extra challenges for impeller longevity. Its corrosive nature speeds up wear and tear, which means more frequent maintenance might be needed. Boat owners should inspect their impellers regularly, especially after harsh operating conditions.

Essential Maintenance Tips

With the right maintenance routines, your boat impeller will last longer than usual. By following the manufacturers’ recommendations, you’ll get reliable performance throughout the boating season.

Regular Inspection Schedule

A monthly visual check will show early signs of impeller wear. You just need to get into the vanes at the start of each season to spot cracks, brittleness, or distortion. Boats running less than 200 hours yearly can align these checks with regular maintenance.

Most marine operators overlook preventive maintenance’s true value. Quick, proactive checks will help you avoid mechanical breakdowns and enjoy more time on the water. A full inspection is essential after winter storage.

Cleaning Procedures

A thorough system cleaning prevents future issues once you’ve removed damaged impellers. Here are the essential cleaning steps:

- Get into transmission coolers to remove trapped debris

- Look at thermostat housings for lodged fragments

- Check valves along water flow paths

- Clean pump housing with clean rags

Glycerin serves two purposes during reassembly: it helps install the impeller and lubricates until water starts flowing. Clean gaskets seal properly and prevent leaks that could reduce pump efficiency.

Storage Best Practices

Your spare impellers need specific storage conditions to stay flexible. Many experienced boaters keep their spares in glycerin or oil. The right storage methods stop rubber parts from getting brittle or deformed.

You should remove impellers from pumps during seasonal storage to prevent vanes from sticking to housing walls. Long-term boat storage requires extra attention to impeller conditions. Rubber parts will become brittle from dry rot if left unused too long.

Good service records will help track when replacements are needed. Writing down what you find during inspections helps identify wear patterns and predict failures. Boat owners who maintain their impellers consistently get the longest operational life and fewer unexpected breakdowns.

Conclusion

A boat impeller may be small, but its role in keeping your engine cool and running efficiently is absolutely essential. Understanding how it works, recognizing signs of wear, and following proper maintenance routines can dramatically extend the life of your marine engine—and save you from costly repairs or breakdowns on the water. Whether you’re a boat owner, repair technician, or marine equipment manufacturer, choosing high-quality impellers is just as important as routine maintenance.

If you need custom boat impellers engineered with precision and durability, Fecision is here to help. Our advanced CNC machining services allow us to produce impellers with tight tolerances, superior surface finishes, and materials suited for marine environments. Whether you’re developing new designs or replacing legacy components, Fecision delivers reliable, high-performance impeller solutions tailored to your needs.

Ready to create custom marine-grade impellers? Contact Fecision today and bring your design to life with world-class CNC machining.