Terms like Z-axis, X-axis, and Y-axis are typically used to represent depth, height, and horizontal positioning in a coordinate system. In a CNC machine, these axes define the movement of the tool.

The Z-axis specifically controls vertical movement, meaning the cutting tool moves upward and downward along the vertical axis relative to the workpiece. Let’s explore this concept further below to understand its role and importance in CNC machining.

Understanding CNC Machine Axes

Every CNC machine operates using a coordinate system to control movement and ensure precise cutting, drilling, or shaping of materials. These movements are defined by three primary axes:

- X-Axis: Moves the tool left and right (side to side).

- Y-Axis: Moves the tool forward and backward (front to back).

- Z-Axis: Controls up and down movement vertically (tool approaching or moving away from the workpiece).

What Direction is the CNC Machine Z Axis?

Unlike the X and Y axes, which control horizontal movement, the Z-axis determines how the cutting tool or workpiece moves vertically along the spindle’s length. However, this depends mostly on the CNC machine type.

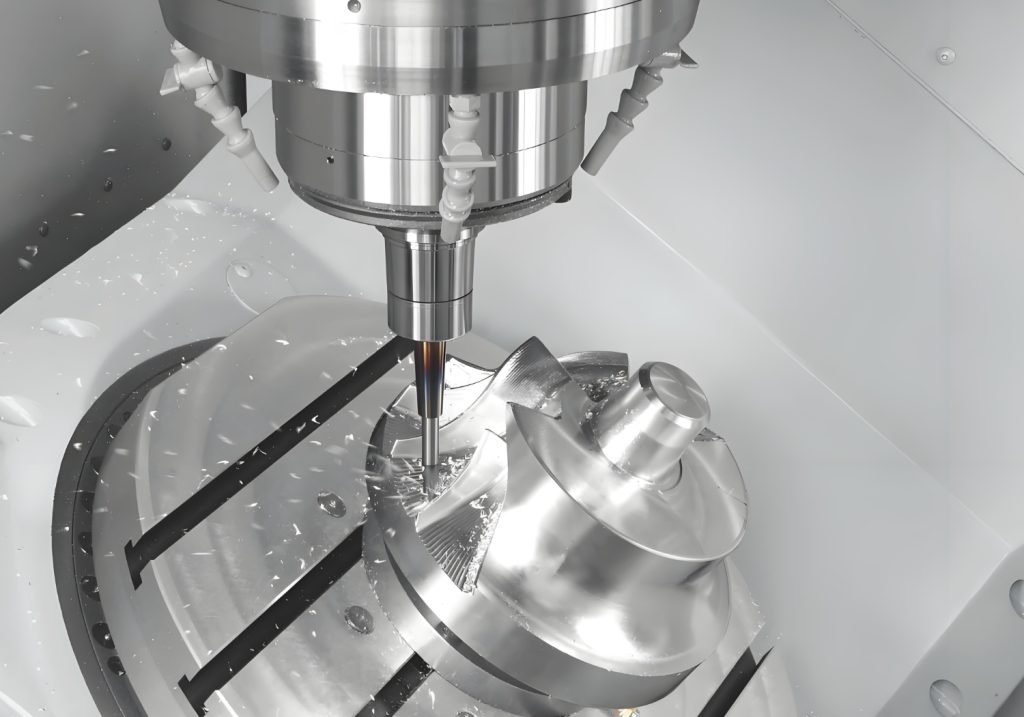

CNC Z-Axis Basics

In most CNC machines, the Z-axis controls depth. In simpler terms, it moves the cutting tool or spindle closer to or farther from the material. The positive (+Z) direction moves the tool away from the workpiece, while the negative (-Z) direction moves the tool toward the workpiece for cutting.

However, the specific orientation of the Z-axis varies depending on the machine type, particularly between CNC mills and CNC lathes.

1. Positive (+Z) Direction

- In CNC milling machines, the +Z direction moves the cutting tool upward, away from the workpiece.

- In contrast, the +Z direction in CNC lathes moves the cutting tool away from the spindle. This increases the distance between the tool and the rotating workpiece.

In simple terms, the positive Z direction retracts the tool or increases the gap between the cutting surface and the material.

2. Negative (-Z) Direction

- The -Z direction on a CNC milling machine moves the tool downward, which brings it closer to the workpiece for cutting or engraving.

- In CNC lathes, the -Z direction moves the cutting tool toward the spindle, reduces the distance, and engages the workpiece for material removal.

Negative Z is where the actual machining occurs, as the tool moves into the material to perform operations.

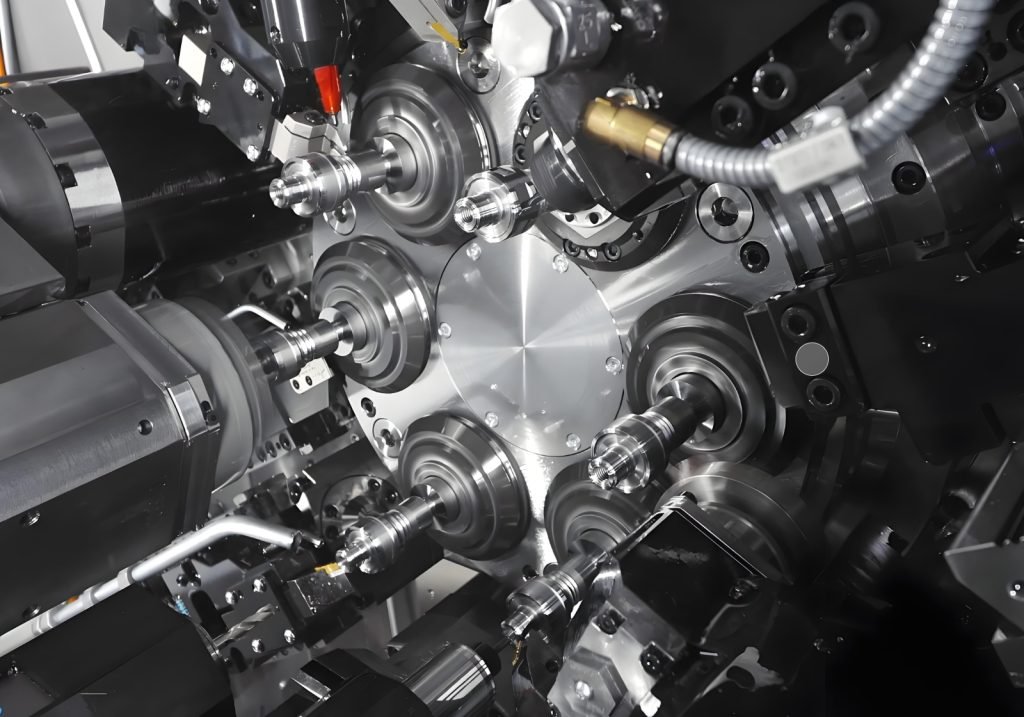

Z-Axis Orientation in 5-Axis CNC Machines

In 5-axis CNC machines, the Z-axis movement becomes even more complex, as the machine has additional rotational axes (A and B) that allow the tool to approach the workpiece from multiple angles.

The Z-axis controls the vertical movement but can also be dynamically adjusted based on tool orientation. Moreover, extra axes (A & B) allow for tilting and rotating, which reduces the need to reposition the workpiece manually. This makes 5-axis machines highly efficient for machining complex geometries, aerospace components, and intricate mold designs.

With multi-axis CNC machines, you need to understand Z-axis orientation with the rotational movements. It is essential for tool path programming, collision avoidance, and achieving precise angles.

Why Understanding the CNC Machine Z Axis is Important

The CNC machine Z-axis plays a crucial role in precision machining, tool movement, and overall manufacturing accuracy. Here’s why mastering the Z-axis direction is essential:

1. Preventing Costly Mistakes and Tools Crashes

Misunderstanding the Z-axis movement can result in serious machining errors, such as:

- Too much depth: The tool cuts too deep, which leads to excessive material removal or even tool breakage.

- Not enough depth: Parts come out unfinished or require manual adjustments, adding extra time to production.

- Collision with the workpiece: Incorrect Z-axis movement can cause tools to crash into the material, damaging both the tool and the machine.

Remember, precision in tool movements is measured in microns. So, even minor errors in Z-axis programming can lead to significant material wastage and costly repairs.

2. Ensuring Precision and Surface Quality

The Z-axis directly influences the depth, finish, and accuracy of the machined parts. For instance:

- Milling: Controls the cutting depth, which determines whether the final product meets the correct tolerances.

- Lathes: Affects the smoothness of the cut surface and how consistently the tool removes material from the workpiece.

- Multi-axis Machines: Allows for precise Z-axis movement for complex contours and smooth transitions between cutting surfaces.

By properly understanding and controlling Z-axis movement, you can achieve higher-quality parts with better surface finishes and tighter tolerances.

3. Achieving Consistent CNC Programming and Automation

In CNC programming, the Z-axis is critical for setting:

- Zero reference points: Defines the starting position for accurate tool paths.

- Depth of cut: Ensures repeatability in mass production.

- Safe retraction distances: Prevents unnecessary tool movements and reduces cycle time.

For automated manufacturing, precise Z-axis control is essential to maintain consistency across thousands of parts.

Common Z-Axis Mistakes and How to Avoid Them

Some common Z-axis mistakes that you might encounter include:

1. Setting the Wrong Z-Zero Position

This mistake happens due to misalignment during setup or failure to probe the workpiece surface properly. To avoid it, always zero the Z-axis using a reliable probing method (touch probe, feeler gauge, or automatic tool setter) and confirm before running a program.

2. Using Incorrect Z-Axis Feed Rates

It occurs because of poor calculation of material removal rates or incorrect CAM settings. The best way to avoid this is by referring to recommended feed and speed charts based on material type and tool diameters. This ensures optimal cutting efficiency.

3. Plunging Too Fast in the Z-Direction

If you move the tool into the workpiece too quickly, it can cause chatter, tool breakage, or excessive force on the spindle. For that reason, use an appropriate plunge rate based on material type, tool size, and depth of cut.

When dealing with harder materials, apply ramped or helical entries instead of direct plunges.

4. Skipping Routine Z-Axis Maintenance

Another mistake that machinists usually make is neglecting lubrication, calibration, or checking for CNC machine Z-axis wear. This leads to inaccurate movements and machine failure.

The only way to avoid this is by performing regular calibration checks, lubricating the ball screw, and inspecting for signs of backlash or wear in Z-axis components.

Mastering the Z-Axis for Perfect CNC Cuts

Understanding the CNC machine Z-axis is key to making accurate and efficient cuts. Whether you use a milling machine, lathe, or multi-axis CNC, knowing how the Z-axis moves helps you avoid mistakes and improve results.

So, avoid simple errors like setting the wrong Z-zero or using the wrong speed, as these can cause the tool to crash. In the end, always check your Z-axis settings, take your time setting up, and maintain your machine.

These small steps can save you time, money, and stress!