The injection molding process is key in today’s manufacturing. Knowing the different types of injection molding is vital for making top-quality products. Each type of injection mold affects the efficiency and success of the molding process.

Manufacturers can improve their production by understanding these molds. This knowledge helps in creating products that meet exact needs and standards.

The types of injection molding vary, from simple to complex designs. Each type has its own benefits and drawbacks. The molding process involves pouring molten material into a mold. The mold type greatly influences the product’s quality and look.

For manufacturers aiming to enhance their production and quality, knowing the types of injection molding is essential. These molds are made for specific needs and uses. Recognizing their unique features helps manufacturers make better choices for their production.

The injection molding process is complex. It requires careful thought about many factors, including the mold type. The type of injection molding used can greatly affect the product’s quality and appearance.

Overview of Injection Molding

Injection molding is a way to make many products, from simple parts to complex systems. It involves putting molten material, like plastic or metal, into a injection mold design. This creates the product’s shape. The choice of injection mold materials affects the product’s quality and how long it lasts.

This method is great for making lots of products quickly and at a low cost. It’s used in many fields, like cars, everyday items, and medical tools. Injection molding is key in making complex products on a large scale with great detail.

Definition of Injection Molding

Injection molding means putting molten material into a mold. Then, it cools and hardens, taking the mold’s shape. This method can make a variety of products, from simple to complex.

Importance in Manufacturing

Injection molding is vital because it makes high-quality products with precision. Using injection mold design and injection mold materials allows for detailed and complex products. It also has benefits like making lots of products fast and at a low cost, making it a cornerstone of modern manufacturing.

Types of Injection Molds

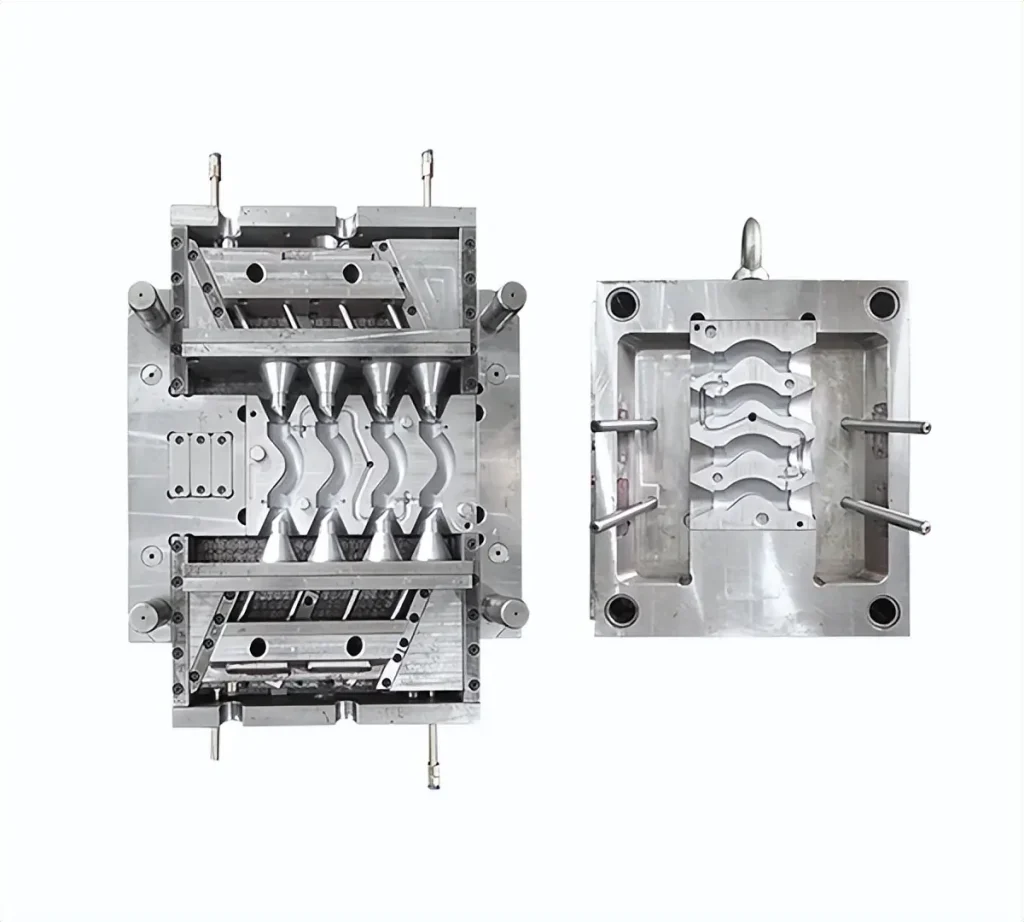

Injection molds are key in making products, and their design affects quality and efficiency. There are many types of injection molds, each with its own features and uses. Knowing about these types helps choose the best mold for a specific job.

The main types are single cavity molds, multi-cavity molds, and family molds. Single cavity molds make one part at a time. Multi-cavity molds make many parts at once, speeding up production. Family molds make different parts, adding flexibility.

These molds are used in many fields like cars, everyday items, and medical tools. The right mold depends on how many parts are needed, how complex they are, and what materials are used. Choosing wisely can make production better, cheaper, and more efficient.

| Type of Mold | Description | Applications |

|---|---|---|

| Single Cavity Molds | Produces one part per cycle | Low-volume production, prototype development |

| Multi-Cavity Molds | Produces multiple parts per cycle | High-volume production, mass production |

| Family Molds | Produces multiple parts of different sizes or shapes | Production of multiple related parts, flexible production |

It’s important for makers to know about different molds and their uses. This knowledge helps make production better and products of higher quality. By picking the right mold, makers can save money, work more efficiently, and create products that meet many needs.

Materials Used in Injection Molds

Choosing the right material for injection molds is key. The material’s properties impact the mold’s durability, resistance to corrosion, and how well it conducts heat. In mold design, picking the right material is essential for the mold’s performance.

Steel and aluminum are the top picks for injection molds. Steel molds are tough and resist corrosion well, making them great for big production runs. Aluminum molds are lighter and cheaper but not as durable.

Steel Molds

Steel molds are the go-to for injection molding. They’re hard, wear-resistant, and keep their shape well, perfect for precise parts. Steel molds also resist corrosion and handle high temperatures, fitting many uses.

Aluminum Molds

Aluminum molds are favored for small batches and prototypes. They’re cheaper and quicker to make than steel molds, ideal for fast prototyping. Aluminum molds are also lighter and easier to move, great for smaller parts.

Other Material Options

Other materials like copper, bronze, and beryllium copper are also used in molds. They have special properties like high heat conductivity and corrosion resistance. The right material depends on the mold’s design needs and the product’s requirements.

| Material | Properties | Applications |

|---|---|---|

| Steel | High durability, corrosion resistance, thermal conductivity | High-volume production, high-precision parts |

| Aluminum | Lightweight, less expensive, easy to handle | Low-volume production, prototype molding, small to medium-sized parts |

| Copper | High thermal conductivity, corrosion resistance | Electrical components, heat sinks, thermal management applications |

Processes Involved in Injection Molding

The injection molding process has several key steps to make high-quality products. It’s important to know these steps to understand the complexity and precision needed. The process starts with injecting molten plastic into a mold cavity.

There are different types of injection molding, like thermoplastic and thermoset. Each type has its own features and uses. The choice depends on the product’s material, size, and complexity.

Key Phases of Injection Molding

- Injection Phase: This is the initial phase where molten plastic is injected into the mold cavity.

- Cooling Phase: After the injection phase, the molten plastic is allowed to cool and solidify in the mold cavity.

- Ejection Phase: Once the plastic has cooled and solidified, it is ejected from the mold cavity, resulting in a finished product.

The quality of the final product relies on the careful execution of these phases. Temperature, pressure, and timing are key to success. Knowing the different types and phases helps manufacturers make high-quality products efficiently.

To optimize the injection molding process, understanding the types and phases is essential. By controlling the process well, manufacturers can make precise and accurate products.

Specialized Injection Molds

Specialized injection molds are made for specific needs in many fields. These include the automotive, consumer products, and medical devices sectors. They are used for making complex parts with several components. The molds used are stack molds, insert molds, and overmolding techniques.

These molds bring many benefits. They make production faster, cheaper, and better quality. For example, stack molds can make many parts at once. Insert molds help create parts with complex designs. Overmolding allows for parts with different materials and textures.

- Increased production efficiency

- Reduced production costs

- Improved product quality

- Ability to produce complex parts with multiple components

These advantages make specialized molds key in many industries. They help companies make top-quality products at lower costs and faster. As companies look to improve and save money, the use of these molds will likely grow.

Design Considerations for Injection Molds

Creating injection molds requires careful planning. We must consider the mold’s design to ensure high-quality parts. This means looking at the mold materials’ strength, durability, and how well they conduct heat.

The choice of mold materials is key. It affects the mold’s performance and lifespan. Steel molds are durable and handle high pressures well. Aluminum molds are lighter and better at conducting heat.

Mold Flow Analysis

Mold flow analysis is vital. It helps spot design issues and ensures the part fills correctly. We consider the mold’s shape, material properties, and plastic flow.

Part Design Compatibility

Part design must match the mold. We look at the part’s shape, size, and material. This ensures quality parts and proper mold filling.

By focusing on these design factors and choosing the right materials, we make high-quality parts. This is key in industries like automotive and consumer goods, where part quality matters a lot.

| Material | Properties | Advantages |

|---|---|---|

| Steel | High strength, durability, and thermal conductivity | Durable, can withstand high pressures |

| Aluminum | Lightweight, good thermal conductivity | Lighter, offers better thermal conductivity |

Applications of Injection Molding

Injection molding is used in many fields like the automotive, consumer products, and medical devices sectors. It’s great for making complex and precise parts. This makes it a key part of manufacturing. The molds used depend on what each product needs.

In the car world, injection molding makes parts like dashboards and bumpers. For everyday items, it’s used for plastic containers, toys, and appliances. Medical devices also benefit, with molds for syringes and implants.

Industry-Specific Applications

- Automotive: dashboards, bumpers, interior components

- Consumer Products: plastic containers, toys, household appliances

- Medical Devices: syringes, implantable devices, medical equipment components

Using injection molding brings many advantages. It allows for making lots of products quickly, saving on labor costs. It also makes sure products are the same every time. As technology gets better, injection molding will help make even more advanced products.

Maintenance and Lifecycle of Injection Molds

Keeping your injection mold in good shape is key to making high-quality products. Regular checks and upkeep can stop damage before it starts. This means less need for expensive fixes and a longer injection mold lifecycle.

Inspect the mold for damage, clean and oil the parts that move, and swap out old parts. A well-kept mold makes products consistently, cuts down on waste, and boosts efficiency.

Things like what material you use, the mold’s design, and how it’s used can change how long it lasts. Knowing these can help you plan better for upkeep and make your molds last longer.

- Regular cleaning and lubrication of moving parts

- Inspection for signs of wear and tear

- Replacement of worn-out components

- Optimization of operating conditions

By focusing on injection mold maintenance and knowing what affects its injection mold lifecycle, makers can cut downtime, save money, and make better products.

| Maintenance Task | Frequency |

|---|---|

| Clean and lubricate moving parts | Daily |

| Inspect for signs of wear and tear | Weekly |

| Replace worn-out components | As needed |

Conclusion

In conclusion, injection molds come in many types, showing how versatile and key this process is. From simple single-cavity molds to complex stack molds and overmolding, the field keeps growing. It offers efficient ways to make a wide variety of products.

Summary of Injection Mold Types and Uses

We’ve looked at different mold designs, like single-cavity, multi-cavity, and family molds. Each one meets different production needs. The choice of materials, such as steel and aluminum, affects the mold’s strength and how well it works.

Future Trends in Injection Molding

Looking ahead, we’ll see more improvements in mold design and materials. New tech, like additive manufacturing, will make molds more customizable and efficient. Also, focusing on green materials and methods will become more important. This will help the injection molding industry meet future needs.

FAQ

What are the different types of injection molds?

There are several types of injection molds. These include single cavity molds, multi-cavity molds, and family molds.

What materials are commonly used in injection molds?

Injection molds are usually made from steel or aluminum. But, materials like beryllium copper and nickel-based alloys are also used.

What are the key processes involved in injection molding?

Injection molding involves three main steps. These are the injection phase, cooling phase, and ejection phase.

What are some specialized types of injection molds?

Specialized molds include stack molds, insert molds, and overmolding techniques.

What design considerations are important for injection molds?

Important design considerations include mold flow analysis and part design. They ensure the mold is filled properly.

In what industries is injection molding commonly used?

Injection molding is used in many industries. These include the automotive, consumer products, and medical device sectors.

How can injection molds be maintained and what is their typical lifecycle?

Keeping injection molds in good condition is key. Regular checks and fixing wear and tear help extend their life.