Have you ever wondered how small devices deliver strong, reliable power without bulky connectors? Or why some charging systems fail after just a few uses, while others work perfectly for years? The answer is high-current pogo pins.

These tiny components may not look important, but they solve some of the biggest problems in electronics: limited space, weak connections, and short lifespans.

So, are you ready to learn what high-current pogo pins are and how they can revolutionize power connections in your design? Let’s get into it.

What are High Current Pogo Pins?

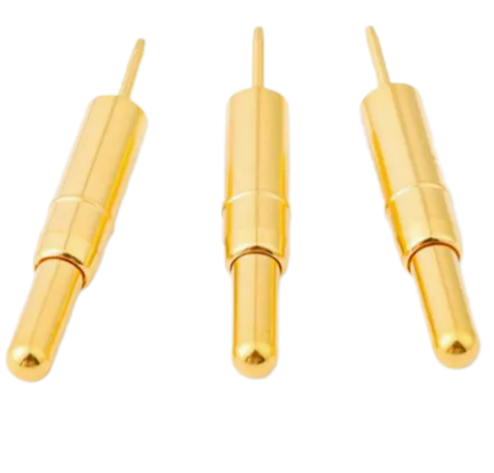

High-current pogo pins are specialized spring-loaded connectors designed to handle larger electrical currents while maintaining a stable connection. They typically range from 5A to over 20A. Unlike standard pogo pins used for signal transfer, these are optimized for power delivery in compact sizes.

They consist of:

- A plunger that moves with pressure.

- Spring provides a consistent contact force.

- The barrel that holds the internal structure.

Despite being smaller in size, pogo pins have a longer life cycle (often over 100,000 mating cycles) and provide exceptional electrical performance. This makes them ideal for battery charging docks, electric vehicle testing, medical devices, and more.

Importance of High-Current Pogo Pins

In the latest electronics, space is tight, and performance demands are remarkably high. High-current pogo pins solve this problem.

- Stable Power Transfer: They maintain a stable electrical connection, even under vibration or motion.

- Compact Design: Offers high current capacity (5 to 20+ amps) without bulky connectors or cables.

- Durability: They can withstand repeated connections without losing conductivity or mechanical fatigue (up to 100,000+ mating cycles).

- Safe and Efficient: Lower contact resistance means less heat generation and better safety.

Without these pins, designers risk overheating, unreliable charging, and premature product failure.

What Makes a Pogo Pin “High Current”?

Depending on the design, a pogo pin is considered high-current when it can safely carry more electrical current than a standard pin, usually five amps or more.

What makes it so effective?

- Thicker internal spring and plunger that increases the surface area for current flow.

- Low-resistance materials such as gold or nickel plating help reduce heat and power loss.

- Strong spring force to ensure tight, stable contact with the mating surface.

- Optimized design of shorter paths and longer contact points, which improves conductivity.

Core Components of High Current Pogo Pins

High current pogo pins are small but have three main parts, each playing a key role in delivering power reliably and safely. These include:

1. Barrel

The barrel is the outer shell of the pogo pin. It holds the internal components (plunger and spring) in place and provides structural stability. The barrel is usually made from brass or copper alloys and plated with nickel or gold to prevent corrosion.

It acts as a part of the current path, so it needs to be highly conductive. Moreover, it protects the inner parts from dust, moisture, and physical damage.

2. Plunger

The plunger is the moving pin that makes contact with the mating surface (pad or connector). It slides in and out of the barrel under pressure and is designed with a dome, crown, or flat tip, depending on the application.

The plunger is often thicker and highly polished in high-current pins to maximize surface contact and reduce resistance.

3. Spring

The spring provides the pressure that keeps the plunger pushed outward, which is what gives pogo pins their “spring-loaded” name. This part is made from stainless steel or beryllium copper for strength and elasticity.

Spring strength is carefully tuned in high-current pogo pins to ensure solid contact without wearing out too fast.

Material and Plating

Here’s a quick overview of which materials and plating are used in pogo pins:

| Material / Plating | Benefits | Common Uses |

| Beryllium Copper | High conductivity, strong, and flexible. | Ideal for high-performance and durable pins |

| Phosphor Bronze | Good strength, corrosion resistance, and cost-effectiveness. | Used in standard or budget-friendly designs |

| Gold Plating | Excellent conductivity, low contact resistance | Ensures stable current flow and prevents oxidation |

| Nickel Plating | Corrosion resistance and wear protection | Often used beneath gold or for less critical pins |

Applications of High Current Pogo Pins

Here are some of the most common applications:

1. Battery Charging and Docking Stations

With global smartphone shipments expected to reach 1.26 billion units in 2025, pogo pins offer clean, efficient charging for phones, tablets, wearables, and even drones. They allow thousands of mating cycles without wear, which makes them ideal for repeated use.

2. Electric Vehicles (EVs) and Automotive

In EV manufacturing, pogo pins are used in battery module testing, sensor connections, and charging interfaces. They perform reliably even in harsh conditions with vibration, heat, and movement.

In fact, with the EV market projected to hit $2,453 billion by 2034, demand for durable, high-current connectors is rapidly rising.

3. Medical Devices

Portable medical devices like heart monitors and insulin pumps rely on high current pogo pins for safe and stable power delivery. The smooth contact design also reduces wear, something that is important for hygienic and long-term usage.

4. Consumer Electronics

In wearables like smartwatches and earbuds, pogo pins allow sleek, cable-free charging. They’re small, durable, and can withstand daily use. With the global wearable tech market valued at over $80 billion, pogo pins are an essential part of delivering slim, reliable designs.

Challenges and Limitations of High Current Pogo Pins

While high current pogo pins offer many benefits, they also come with a few challenges and limitations to keep in mind during design and application.

1. Heat Management

Handling high currents in a small pin can generate heat. Without proper material selection or heat dissipation design, this can lead to overheating or reduce the lifespan of the pogo pin.

2. Contact Resistance

If not properly maintained or designed, a pogo pin may develop increased contact resistance over time. This can lower efficiency and affect the overall performance in power-sensitive applications.

3. Sensitivity to Contamination

Dirt, dust, or corrosion on the mating surface can interfere with the connection quality. These pins require clean environments or regular maintenance to bring out the best in this little tool.

Let Fecision Help Power Up Your Product

Although high-current pogo pins may be small, they play a big role in delivering reliable, efficient power to today’s most advanced devices.

However, to get the most out of these pogo pins, you need precise engineering, proper materials, and flawless integration—and that starts with choosing the right manufacturing partner.

At Fecision, we specialize in mold tooling, CNC machining, and molding services that ensure every part of your product works perfectly.

Contact Fecision today to get started!