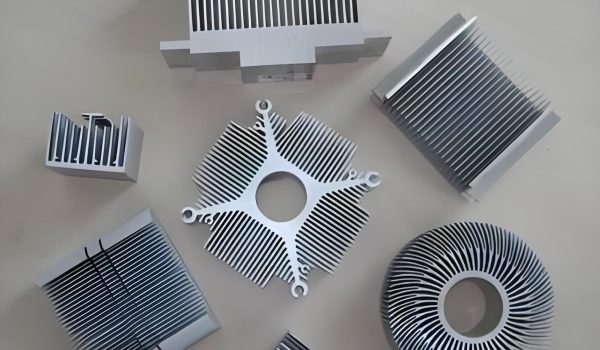

Heat sinks are important components of modern electronics. It plays an important role in cooling devices and maintaining optimal operating temperatures. Whether it’s a computer processor, an LED bulb or an electric vehicle battery system, heat sinks prevent overheating and ensure long term performance and reliability.

The effectiveness of a heat sink mostly depends on the material used. The right material must combine high thermal conductivity with durability and cost effectiveness. The most common materials are aluminum, copper and hybrid compositions, each with its own advantages for the application.

This article explains what heat sinks are made of, how they are made and how different materials affect thermal performance and cost. It also helps readers to choose the right solution for their cooling needs.

What Are Heat Sinks?

A heat sink is a critical component in thermal management systems, designed to absorb and disperse excess heat generated by electronic devices. These thermal conductors act as heat exchangers that transfer thermal energy from the device to the surrounding environment. When electronic components operate, heat dissipation is an unavoidable byproduct that needs to be managed to prevent performance degradation and damage.

The main purpose of a heat sink is to dissipate heat from the device into the surrounding environment. This path typically goes from the component to the printed circuit board, through the heat sink and finally to the ambient air. Heat sinks keep devices at optimal operating temperatures by absorbing heat from electronic components, ensuring both performance and longevity.

Common Applications of Heat Sinks

- Computers: Cooling CPUs, GPUs, RAM and chipsets.

- LED Lighting: Managing operating temperature to prevent degradation.

- Automotive Systems: Cooling ECUs, battery systems and LED headlights.

- Power Electronics: Used in inverters, amplifiers and voltage regulators.

- Telecommunications: Keeping modems and routers cool.

Common Materials Used in Heat Sinks

Material selection greatly impacts heat sink performance, striking a critical balance between thermal efficiency, weight and cost. The four most common materials each have their own advantages for the application.

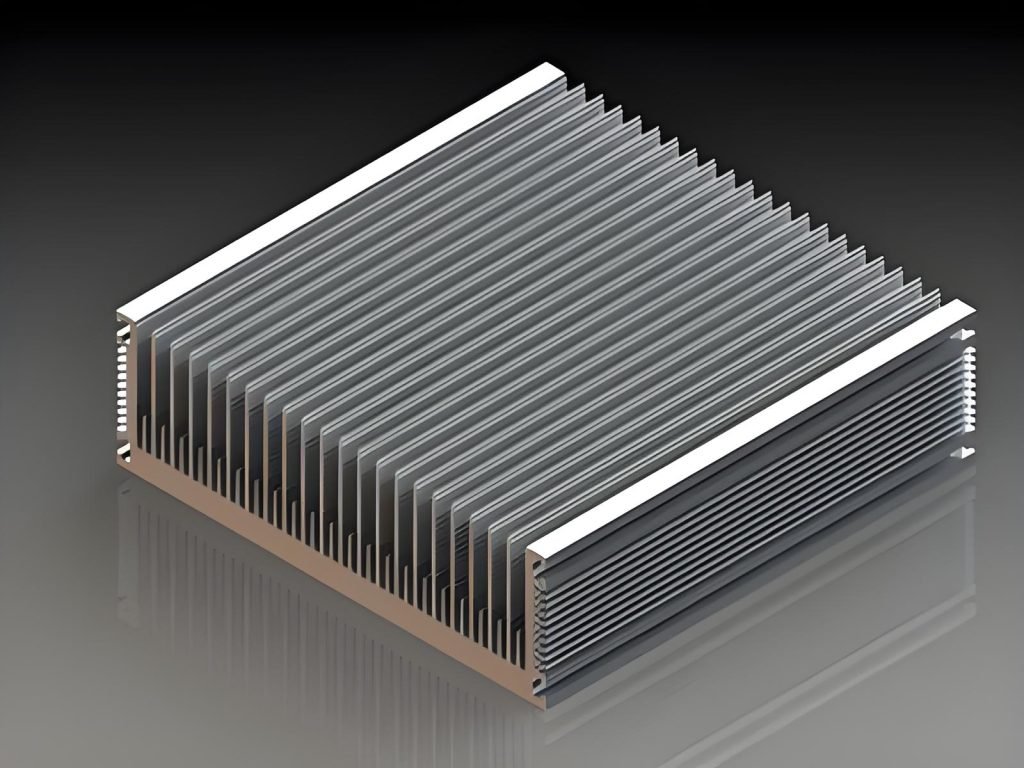

1) Aluminum Heat Sink: Lightweight and cost effective

Aluminum is the most common heat sink material due to its exceptional cost to performance ratio. With a thermal conductivity of 205 W/mK and 2.7 g/cm³ density, aluminum provides good heat dissipation while minimizing weight. Aluminum heat sinks cost around $1800 per metric ton making them economically viable for mass production.

Most commercial aluminum heat sinks use specific alloys like 6060, 6061 and 6063 each with slightly different thermal properties. The 6063 alloy has a thermal conductivity of 201 W/mK making it suitable for electronic cooling applications.

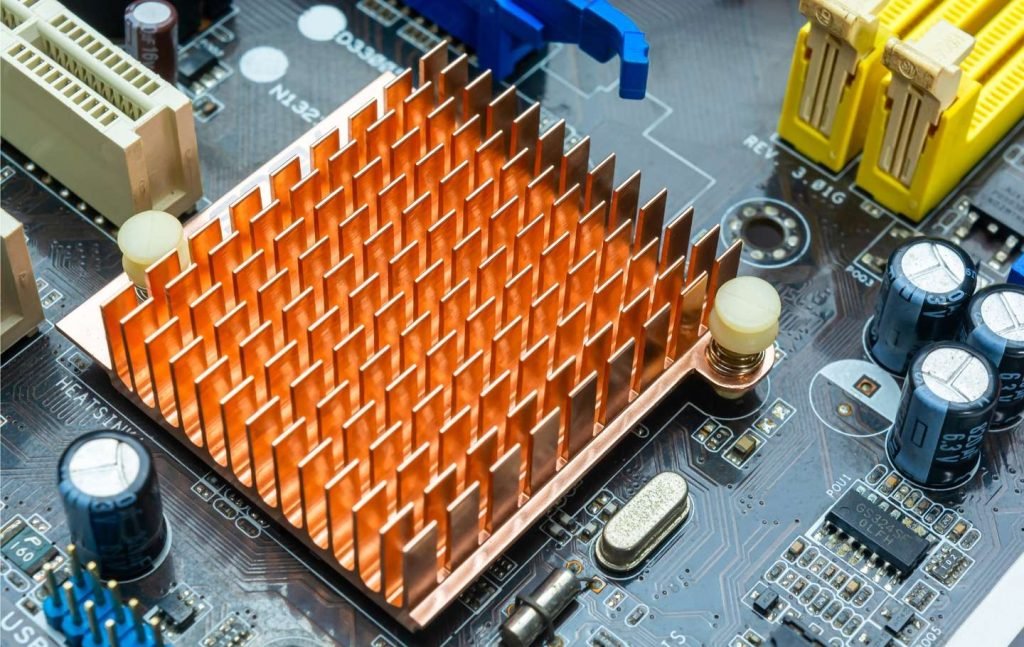

2) Copper Heat Sink: High thermal conductivity

Copper stands out with its high thermal conductivity of 400 W/mK, almost twice that of aluminum. This high heat transfer capability makes copper ideal for high performance computing applications. However copper’s higher density of 8.96 g/cm 3 and much higher cost – around $6939 per metric ton – limits its use to applications where thermal performance outweighs other considerations.

3) Graphite Heat Sink: Lightweight with high performance

Engineered graphite foam is an innovative heat sink material with thermal conductivity values similar to aluminum and 80% lighter. The thermal conductivity of graphite foam ligaments can reach 1900 W/mK. Graphite also has excellent chemical stability and corrosion resistance.

Despite these advantages, graphite heat sinks are fragile and require special handling. This fragility and higher manufacturing cost has limited their mainstream adoption.

4) Hybrid Heat Sink

Hybrid heat sinks use copper’s excellent heat conductivity and aluminum’s lightweight nature. Typically, the base that contacts the heat source is copper, while the fins are made from aluminum.

This design achieves almost the same thermal performance as all-copper (thermal resistance of 0.36 K/W compared to copper’s 0.33 K/W) while being much lighter. One comparative study showed that an 8.0-inch × 8.0-inch × 1.0-inch hybrid heat sink weighed 4.6 lbs compared to 9.5 lbs of its all-copper counterpart – a 51% weight reduction.

How Heat Sink Materials Affect Performance

Heat sink performance is determined by its material properties, each with its own advantages and limitations.

1) Thermal conductivity and heat dissipation

Thermal conductivity is crucial in a heat sink’s efficiency at dissipating heat from electronic components. Copper is better at this, with about 400 W/mK, nearly twice as much as aluminum, which has 205–230 W/mK. This difference becomes critical when managing high density heat sources. Note that thermal conductivity affects more than just heat transfer – it also affects spreading resistance which occurs when heat moves from a small area to a larger one.

Emissivity also plays an important role in heat transfer. Unfinished aluminum surfaces have an emissivity of around 0.05 while anodized aluminum surfaces have an emissivity of 0.85 making radiation heat transfer more effective especially in smaller passive heat sinks.

2) Weight and structural durability

Weight is a major consideration in material selection. Copper has a density of 8.96 g/cm³, nearly three times higher than aluminum’s 2.7 g/cm³, which adds a lot of weight to cooling systems. Because of this, aluminum’s high strength-to-weight ratio makes it a better choice for weight-sensitive uses like mobile devices.

Interestingly the same factors that make metals stronger also reduce their thermal conductivity. Crystal defects that make metal stronger by preventing atomic layers from sliding also create scattering centers that lower thermal conductivity.

3) Corrosion resistance and longevity

Aluminum forms a protective oxide layer that shields it from corrosion ensuring long term performance even in harsh environments. Copper despite its superior thermal properties has less corrosion resistance than aluminum.

4) Cost and manufacturing feasibility

Cost is also an important factor when choosing materials for heat sinks. Copper is 4-6 times more expensive than aluminum making aluminum the default choice for most applications. Manufacturing techniques also impact cost – aluminum can be extruded while copper must be machined or skived.

For applications that require exceptional performance, new materials like CarbAl (20% aluminum, 80% carbon materials) have thermal conductivity of 425 W/mK exceeding both aluminum and copper while being lighter.

Manufacturing Methods for Heat Sinks

Manufacturing precision shapes heat sink efficiency just as much as material selection. Various fabrication techniques create different thermal profiles each suited to specific cooling challenges.

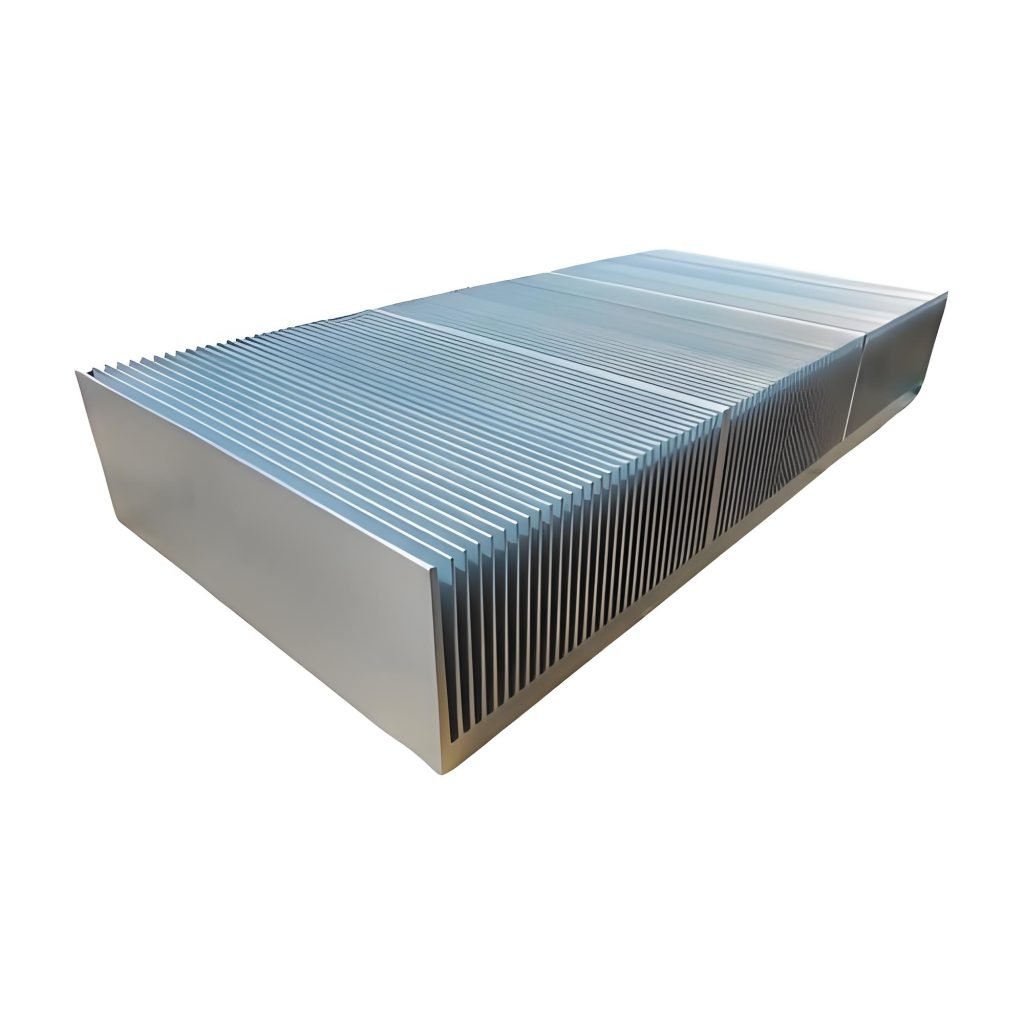

1) Extruded heat sinks

Extrusion pushes heated aluminum through a custom die to create continuous profiles with identical cross-sections. This method is cost effective with low tooling and unit costs making it economical for mass production. Ideal for low to medium power applications, extruded heat sinks are one piece construction with low thermal resistance. Although highly scalable, extrusion has dimension limitations – widths cannot exceed approximately 23 inches.

2) Bonded-fin heat sinks

Two-piece assemblies comprise a grooved base with fins individually attached using thermally conductive bonding agents. The base and fins can use different materials, effectively combining aluminum with copper for better performance. Bonded fin heat sinks can accommodate larger sizes and tighter fin spacing than extrusion allows, hence more surface area for heat transfer. One drawback is reduced performance in high vibration environments.

3) Skived heat sinks

Skiving creates heat sinks from solid metal blocks using precision engineered blade tools that shave thin layers, lift them and bend them vertically into fins. This method produces ultra thin fins with high aspect ratios up to 50:1, ideal for space constrained applications. Since fins form integrally with the base plate, there is no thermal interface to impede heat flow.

4) Stamped heat sinks

Progressive die stamping feeds continuous metal strips through automated machines that cut, bend and form the material. Stamped heat sinks, mainly used in low-power applications under 5W, are highly cost-effective due to automated manufacturing. They frequently incorporate “zipper fins” that interlock with each other during the stamping process.

5) Forged heat sinks

Cold forging shapes workpieces at room temperature under extreme pressure, typically takes 15-20 seconds per heat sink. This process eliminates air bubbles and impurities, resulting in high quality. Cold forged heat sinks can achieve pin aspect ratios up to 35:1, offering better thermal performance as the pins extrude directly from the base plate.

6) CNC Machined heat sinks

Computer numerical control machining excels at producing heat sinks with complex geometries and precise dimensions. CNC requires no tooling unlike mass production methods, making it perfect for prototyping and small batch production. This versatile method can handle various materials with high quality surface finish crucial for thermal performance.

Choosing the Right Heat Sink for Your Application

Choosing the right heat sink is all about balancing thermal needs with practical constraints. This decision making process often determines whether electronic components will work or fail.

1) Passive vs active cooling needs

Passive heat sinks rely only on natural convection and radiation to dissipate heat without external mechanisms. These are ideal when noise reduction and reliability is paramount. No moving parts means no points of failure, making passive heat sinks extremely reliable over long periods.

In contrast, active cooling uses fans or blowers to generate forced airflow. This approach can improve cooling efficiency by a factor of 2-3. Active solutions are best for high performance components that generate a lot of heat but require power consumption and maintenance.

2) Volume and airflow considerations

The available space constraints heat sink selection. Larger heat sinks dissipate more heat but spatial limitations often require design compromises. Airflow through the fins is critical – smaller spacing increases surface area but may restrict airflow and increase pressure drop.

3) Material vs cost trade-offs

Choosing the right material involves balancing thermal performance with cost considerations. Aluminum costs 9-12 times less than copper for equivalent size heat sinks so it’s the default choice for cost sensitive applications. But copper may be worth the premium when thermal requirements exceed aluminum’s capabilities.

4) Application specific recommendations

Active cooling solutions are required for computing applications with TDP ratings above 65W. LED lighting applications require thermal assessment as performance and longevity depend on operating temperature.

Hybrid heat sinks balance weight reduction with thermal performance which is beneficial for automotive applications. These are particularly valuable in vehicles where every gram counts. The ideal heat sink matches each unique application’s thermal requirements, available space, environmental conditions and budget constraints.

Conclusion

Heat sinks are more than just metal slabs. They are carefully designed thermal management tools shaped by material science and manufacturing innovation. From aluminum’s affordability to copper’s conductivity each material has a unique performance profile for specific cooling needs. Manufacturing methods, especially CNC machining provide unmatched precision and customization allowing designers to create heat sinks that balance thermal performance, cost and form factor.

Hybrid and next generation materials like CarbAl push the boundaries even further with higher performance and lower weight. Choosing the right heat sink is all about understanding your application’s unique requirements like thermal load, space constraints, airflow and budget. By using the information in this guide you can make informed decisions that ensure efficiency and reliability in your thermal management strategy.