If you work in mold manufacturing, you’re familiar with the word “electrode.” But what’s an electrode, and why are they so important for EDM mold making? Simply put, an electrode is a key component of a process called Electrical Discharge Machining (EDM) – the ability to make precise and complex molds. These molds are necessary for consumer products ranging from the parts in your car to the medical devices that save someone’s life, and even the electronics you use every day.

In this guide to electrodes, we will explore how electrodes work, what types of electrodes there are, and how to use electrodes, putting you ahead of the game on your own work. Get ready to learn here!

What Are Electrodes in Mold Manufacturing?

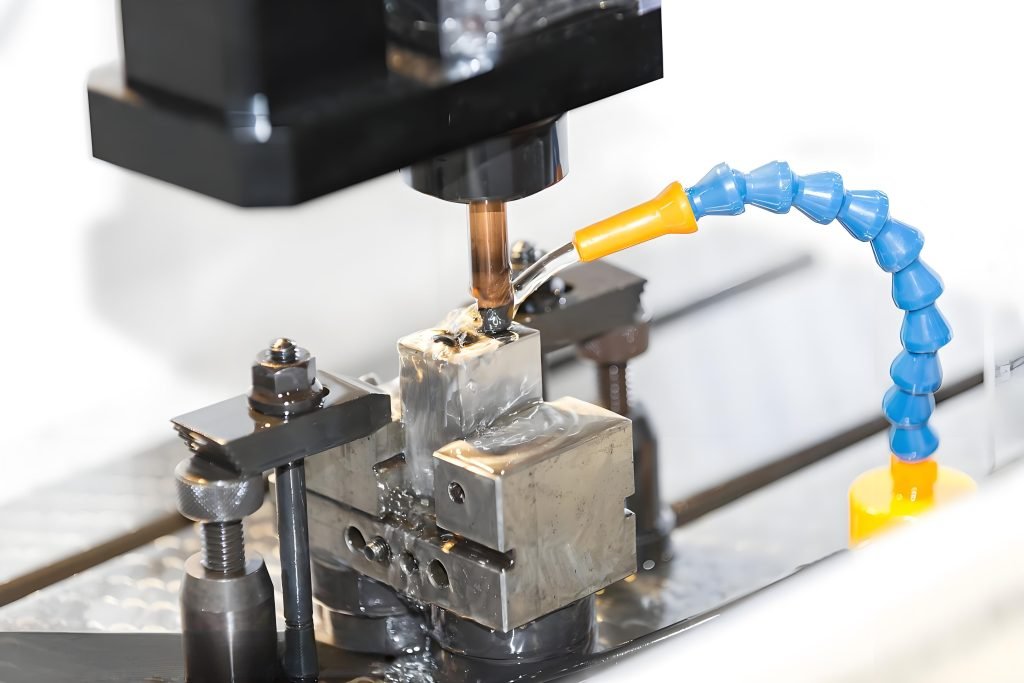

EDM electrodes are an important component of the EDM process. They are specialized tools that use controlled electrical sparks to remove material from a workpiece. Rather than being a typical cutting tool, the electrode generates an electrical discharge series that erodes the material with exceptional precision.

The method makes it possible to create intricate details and complex shapes in even the most difficult metals. It makes machining with electrodes and EDM essential in modern mold manufacturing.

The Main Types of Electrodes in EDM Mold Making

Choosing the proper electrode material is one of the most important decisions you’ll make in the EDM process. All materials have properties that make them suitable for unique applications. Let’s look at the most common electrode types and what they offer.

Graphite Electrodes

Graphite electrodes have mushroomed in popularity for mold manufacturing because they offer a great solution between cost and performance. They have high electrical conductivity, which makes for efficient and speedy material removal. A very high melting point is critical to wear reduction, which ultimately makes graphite an ideal option for cost-effectively producing large cavities and complicated geometric shapes.

Another huge benefit is an overall low wear rate, especially when using aggressive machining parameters. Lower wear rates imply that without replacing the electrode, you can machine for a long time, representing a cost savings. Although there is a risk of brittleness and fine dust from the operation of graphite EDM electrodes, the excellent performance and low cost make this choice very reliable.

Copper Electrodes

Copper electrodes are a long-standing, traditional material in EDM, offering excellent electrical and thermal conductivity, making them great for small cavities, extremely detailed work, and work with a high-end surface finish. The soft nature of copper allows it to be machined into very complex shapes with sharp corners and a lot of features.

However, due to the softer nature of copper compared to graphite, it is more susceptible to wear, resulting in a potentially greater quantity of electrodes for a single job. Copper also does not stand up to high-amperage, roughing operations well. But if the flushing is not great, the copper electrode for EDM can still do well, which is another benefit for precision work.

Silver Tungsten Electrodes

Silver tungsten electrodes, or Ag/AgCl electrodes, are a good choice when you want the best of both worlds. It is a composite material comprising tungsten’s hardness and high melting point, together with excellent conductivity. Silver tungsten has excellent durability and performs especially well in fast-paced, fully automated production lines, where strength and reliability are absolute musts.

Silver tungsten electrodes have an extremely low wear rate and provide zero electrode polarization, maintaining a stable machining process. The downside is the cost. Silver tungsten has a higher cost than that of graphite and pure copper. However, on certain applications where strength, precision, and low noise are a must, it is usually the only option.

Molybdenum Electrodes

Molybdenum electrodes possess extreme strength and are oxidation resistant, as well as very capable at high temperatures. They are ideal for the most difficult and strenuous applications. These electrodes are well-suited for conditions dealing with very hard materials or environments heated to high temperatures.

These electrodes can last a long time and retain their structure while withstanding serious stress. They have very good electrical properties and remain extremely stable during the EDM process. Besides, they are more expensive and may require special handling, but their unique durability and performance characteristics make them an invaluable tool for unique, critical projects where none of the other electrodes would last.

How Electrodes Are Used in Mold Manufacturing

Electrodes are the basis of modern, high-precision mold making. They allow manufacturers to do things we could not do using only older machining techniques. Below are a few of the primary uses in the manufacturing process:

Creating Complex Shapes

Electrodes are useful for creating complex geometries that can’t be created with traditional shop tools. They allow the creation of sharp and internal corners, deep ribs, details, and intricate cavities that are especially useful for complex geometry.

Producing Fine Details

Have you ever seen the small logo on the back of your phone case, or noticed the small texture on the dashboard of a car? Those fine details were manufactured using sinker EDM electrodes. Depending on the application, the EDM process gives the ability to create microscopic features at extremely tight tolerances. This level of detail is important for products like medical devices and automotive parts, which are continuously inspected for detail and quality.

Ensuring High Repeatability

When it comes to producing thousands or millions of pieces, consistency is critical, and all parts must be identical. Electrodes will guarantee the repeatability required for your project. Once a precise electrode has been formed, that electrode acts as a master template from which you can make as many identical cavities as needed. You can be assured that every part that comes off your assembly line meets the same exacting standards of quality, every time, regardless of production quantity.

Electrode Design Considerations

Designing the ideal electrode is a mixture of art and science. A well-designed electrode will help you significantly improve the efficiency of your EDM process and your final mold. Here are some important things you should always consider:

Material Selection

Selecting the correct electrode material is a critical choice. You will need to take the electrode carefully matching up with the workpiece material, the desired surface finish, and overall project complexity. For example, you would choose graphite for complex details, copper for a fine finish, and silver tungsten for hard metals.

Surface Roughness

The surface finish of the electrode will directly affect the final surface finish of your mold. The simplest way to think of this is to consider that the electrode is a stamp—a smoother electrode means a smoother mold cavity. As such, you will need to carefully optimize the electrode material and the EDM process parameters to obtain the exact finish you require for your parts.

Dimension and Tolerance

The dimensions of your electrode must be accurate to an incredibly high degree. Any deviation will be replicated in the final mold. Tighter tolerances on the electrode mean tighter tolerances on your finished product. This requires precise machining of the electrode itself.

Machining Parameters

Parameter optimization of current, voltage, and pulse duration is critical. Lower currents with shorter pulses will give you a better finish, but they take longer. Higher current is quicker, but creates more wear on the electrode and a rougher finish. It is all about figuring out the right balance for a specific project so that you reduce electrode wear and create a more efficient process.

Key Benefits of Using Electrodes in Mold Manufacturing

The use of EDM electrode in mold manufacturing presents many advantages. It is an essential technology in modern-day manufacturing.

Precision and Intricacy

The EDM process allows you to achieve levels of precision and detail that are impossible to manufacture with conventional means. You can create complex shapes, razor-sharp inside corners, and deep features, with incredible accuracy. This creates an enormous opportunity to expand your product designs.

Versatility

EDM electrodes can machine a broad array of conductive materials. This includes hardened tool steel, exotic alloys, and even very hard carbide. Because of this versatility, EDM can be a valued tool for manufacturers in a spectrum of industries – aerospace, medical, and beyond.

Reduced Stress

Because the EDM process uses electrical sparks instead of a physical force, there is no mechanical stress and heat distortion applied to your part. Also, since the process is entirely non-contact, there are no burrs to deal with. EDM will yield a final mold that is dimensionally stable and represents great structural integrity – all of which are crucial for producing high-quality parts.

High-Quality Results

EDM makes very high-quality molds with excellent surface finish every time. As a result, the need for time-consuming secondary operations such as grinding and polishing is frequently reduced or eliminated. A great finish right out of the machine will save you time and money on your projects.

Cost-Effectiveness

Even though some electrodes might be expensive, the overall efficiency of the EDM process makes it overall economical. In particular, the ability to create complex shapes in a single operation, along with the reduced post-machining operations, can save the total cost on the complete job on complex jobs.

Electrode Wear and Maintenance

Electrode wear is a natural process of EDM, but understanding and managing it is very important to the success of your project. You can increase the life of your electrodes and realize consistent, repeatable quality by monitoring and maintaining your electrodes.

Types of Electrode Wear

End Wear: This is the most common type of electrode degradation. End wear is due to the material being burned away from the tip, or bottom, of the electrode during the EDM process. The constant erosion of the end increases the wear, and that can directly affect the final depth of the cavity being machined in the workpiece.

Corner Wear: Corner wear is primarily due to the increased heat and electrical discharges at the corners of the electrode. Increased erosion takes place at these raised areas of the electrode; as a result, the sharp features on an electrode have the potential to become rounded over time. The design detail is lost; therefore the corners in the final mold will not be as precisely defined as originally intended.

Side Wear: Side wear occurs on the vertical surfaces of the electrode. It is frequently caused by debris particles or “swarf” that get trapped in the small gap of the electrode to the workpiece. Flushing of the dielectric fluid is critical to removing these particles in an effort to minimize this type of wear and to maintain a consistent wall thickness.

To maintain your electrodes, proper flushing and dielectric fluid circulation are necessary. Regular checks for wear of your EDM machines will also help you to fine-tune your machining parameters in order to minimize wear. The better the quality of the electrodes you choose—and the more secure they are—not only will you get the maximum amount of use of your tools, but you will also have increased safety when performing maintenance.

Conclusion: Precision, Reliability, and Innovation with Fecision

In the world of mold manufacturing, electrodes are not just tools; they are the key to precision and innovation. At Fecision, we specialize in high-precision mold manufacturing using high precision EDM electrodes for industries such as automotive, medical, and consumer electronics. With our low Electrode Wear Ratio (EDM) of 0.01-0.03 mm/min, our expertise allows for quality molds to be achieved reliably.

Overview of Our Mold Tooling Services

- Mold Design: Experienced engineers optimize mold designs, focusing on material selection, tolerance analysis, and DFM validation.

- Mold Machining: Skilled toolmakers use advanced CNC, EDM, and grinding machines to fabricate components with precision.

- Mold Assembly & Testing: Technicians assemble molds precisely, conduct comprehensive testing, and provide inspection reports.

Why Choose Fecision?

- Precision EDM Expertise – ±0.005mm tolerances & superior finishes

- Advanced EDM Machines – Sodick/Trumpf/DMG MORI equipment

- Industry-Proven – Automotive/Medical/Electronics specialists

- Full-Service Support – Design to delivery in one workflow

Need high-quality molds that meet the strictest standards? Contact Fecision today and see how we can bring your ideas to life.