When electronics heat up, performance suffers, and sometimes, systems fail entirely. That’s where the unsung hero of thermal management steps in: the heat sink.

While it may look like just a piece of metal with fins, a heat sink plays a crucial role in keeping your devices safe, efficient, and long-lasting.

But exactly how do heat sinks work? Let’s find out in this article.

What is a Heat Sink?

A heat sink is a device that helps remove heat from electronic components like CPUs, GPUs, power transistors, and LEDs. Its main job is to keep these components cool by drawing the heat away and then releasing it into the surrounding air.

These are often designed with fins or ridges to increase surface area, which helps release heat faster.

Some common types of heat sinks include:

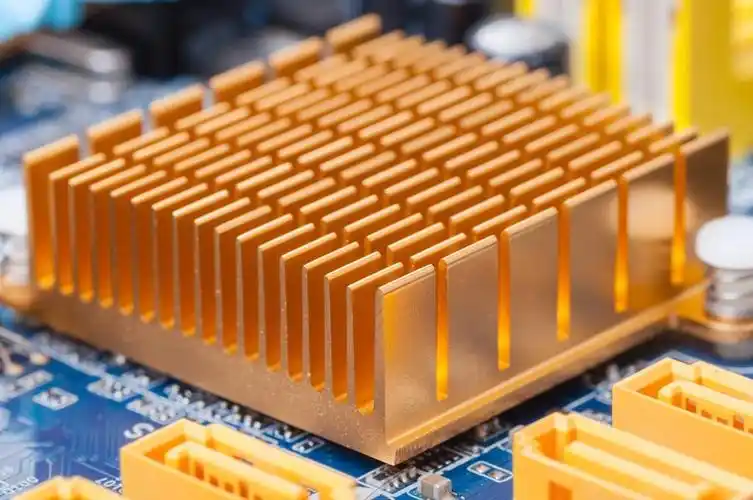

- Aluminum Heat Sinks: Lightweight, cost-effective, and good for general cooling needs. They’re commonly used in computers and consumer electronics.

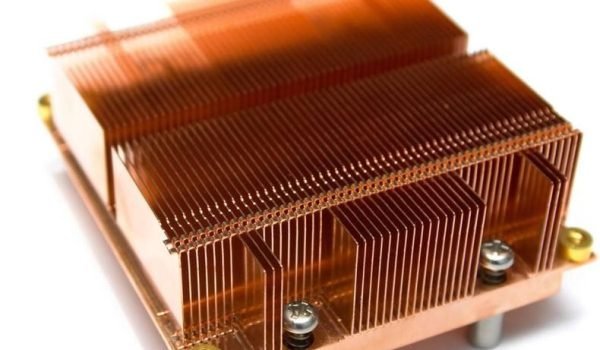

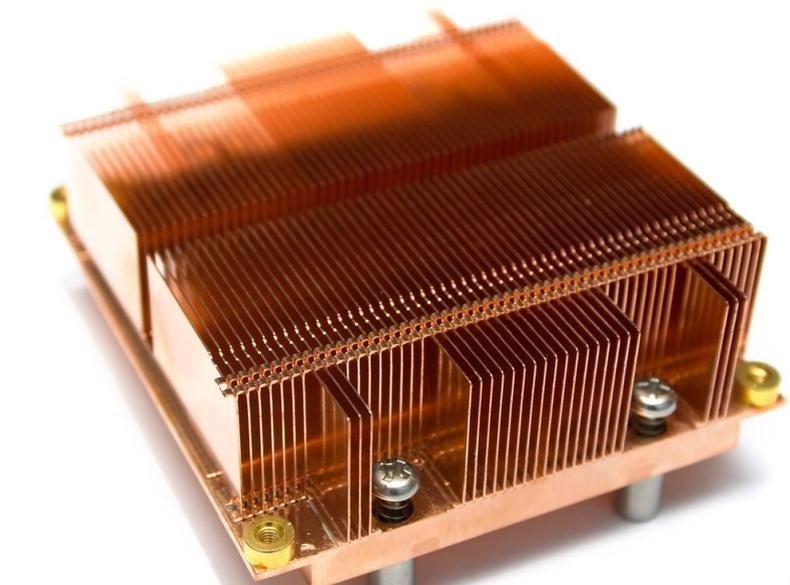

- Copper Heat Sinks: Copper Heat Sinks are better at conducting heat than aluminum, but are heavier and more expensive. Often used in high-performance systems that generate more heat.

How Do Heat Sinks Work?

Heat sinks work by absorbing heat from electronic components and dissipating it into the surrounding air, helping to maintain safe operating temperatures. Without them, devices like computers, power supplies, or LED lights would overheat and fail quickly.

The process relies on three key principles of heat transfer:

- Conduction: Heat moves from the hot component (like a processor) to the cooler heat sink material, usually an aluminum or copper heat sink.

- Convection: Once the heat reaches the surface of the heat sink, it is released into the surrounding air. This can happen naturally or with the help of a fan.

- Radiation: A small amount of heat is also emitted as infrared radiation, though this plays a lesser role.

The more surface area a heat sink has, the more efficiently it can release heat into the air.

Passive vs. Active Heat Sinks

There are two main types of heat sinks, and both serve the same purpose—cooling—but in different ways.

1. Passive Heat Sinks

Passive heat sinks rely on natural convection, airflow that occurs without any mechanical assistance.

They have no moving parts and are completely silent, making them ideal for quiet environments or small devices with low heat output. In consumer devices, aluminum heat sinks are mostly used as they are lightweight and affordable.

Key Traits

- No fans or motors.

- Longer lifespan (no moving parts to fail).

- Requires good natural airflow.

- Best for low-power or energy-efficient devices.

2. Active Heat Sinks

Active heat sinks use a fan or blower to push air over the surface of the sink, which speeds up heat removal. This forced airflow greatly increases cooling performance, which is why they’re commonly used in high-performance electronics.

Key Traits

- Includes a fan (or multiple fans).

- Better for high-heat environments.

- Needs power to operate.

- It can produce noise depending on fan speed.

Key Components That Rely on Heat Sinks

Here are some of the most common parts that rely on heat sinks to stay cool and functional:

1. CPUs and GPUs

CPUs and GPUs generate significant amounts of heat, especially when handling heavy tasks like gaming, video rendering, or data processing. Without a heat sink, these chips can overheat in seconds, which leads to crashes or permanent damage.

That’s why high-performance PCs often use large active heat sinks with multiple fans or even liquid cooling systems.

Fact: Modern high-end CPUs can consume over 300 watts of power while gaming—imagine that much heat being trapped inside a box.

2. LED Lighting

While LED lights are efficient, they still convert a portion of energy into heat, especially high-power LEDs used in automotive headlights, industrial lights, or spotlights.

Heat sinks in LED fixtures help manage this heat and prevent color shifts, flickering, or burnout. A good heat sink extends the lifespan of LEDs dramatically, often by several thousand hours.

Studies show that poor thermal management is one of the top reasons LED fixtures fail prematurely.

3. Power Transistors and Voltage Regulators

Transistors and voltage regulators handle high current and switching operations that generate intense heat in power supplies, amplifiers, and voltage regulation circuits.

If there is no heat sink, these components could quickly exceed safe temperature limits, leading to performance loss or short circuits.

In these systems, passive heat sinks or aluminum plates are often mounted directly to the devices to stabilize temperatures. This is especially true in industrial heat sink applications where reliability over time is critical.

Main Functions of a Heat Sink

Heat sinks play a critical role in almost every electronic device you use. The main functions of a heat sink include:

1. Prevents Overheating of Components

A heat sink draws the heat away from the component and spreads it out across its surface. It allows heat to dissipate into the surrounding air. This keeps the component from reaching dangerous temperatures that could cause immediate damage or shorten its lifespan.

2. Improves Device Performance and Lifespan

A good heat sink helps your devices run at their optimal speed and last longer by keeping things cool and stable. Over time, better temperature control means fewer failures, lower repair costs, and better overall reliability.

3. Maintains Safe Operational Temperature

By consistently managing heat output, heat sinks help maintain safe operating conditions across various environments. Whether it’s a desktop PC under load or an outdoor LED light facing direct sunlight, a well-designed heat sink ensures everything runs within a safe temperature zone.

Factors That Affect Heat Sink Performance

The functionality of a heat sink depends on a few critical factors that influence how well it pulls heat away. Let’s examine the three biggest performance drivers.

1. Surface Area

The more surface area a heat sink has, the better it can dissipate heat. That’s why you often see heat sinks with many thin fins; they dramatically increase the total surface in contact with air, boosting cooling.

Industrial heat sink manufacturers often focus on optimizing surface design to maximize airflow contact.

Pro Tip: The more fins and grooves your heat sink has—without restricting airflow—the better it performs.

2. Material Conductivity

The type of material used in the heat sink affects how fast heat can move away from the component. Thermal conductivity is the key measurement here—it tells you how quickly a material can transfer heat. For instance:

- Copper has a high thermal conductivity of ~400 W/mK.

- Aluminum is not as conductive (~235 W/mK) but is lighter and less expensive.

3. Ambient Temperature and Airflow

No matter how good the heat sink is, it won’t perform well if the surrounding air is hot or stagnant. That’s why ambient temperature and airflow are so important.

Active cooling (using a fan) increases airflow and helps maintain a temperature difference between the heat sink and the environment. On the other hand, poor airflow causes heat to linger and reduces the sink’s efficiency.

Partner with Fecision for High-Performance Thermal Solutions

The right heat sink can mean the difference between smooth operation and system failure. Whether you’re working with compact LED housings, high-power CPUs, or voltage regulators, the design and structure of your heat sink directly impact how well your system handles thermal stress.

However, for it to work, you also need the right partner to produce your thermal components. And Fecision is here to help out.

We provide precision-engineered heat sink solutions using advanced CNC machining, mold tooling, and custom molding.

Let’s talk about your next project and how Fecision can help you take control!