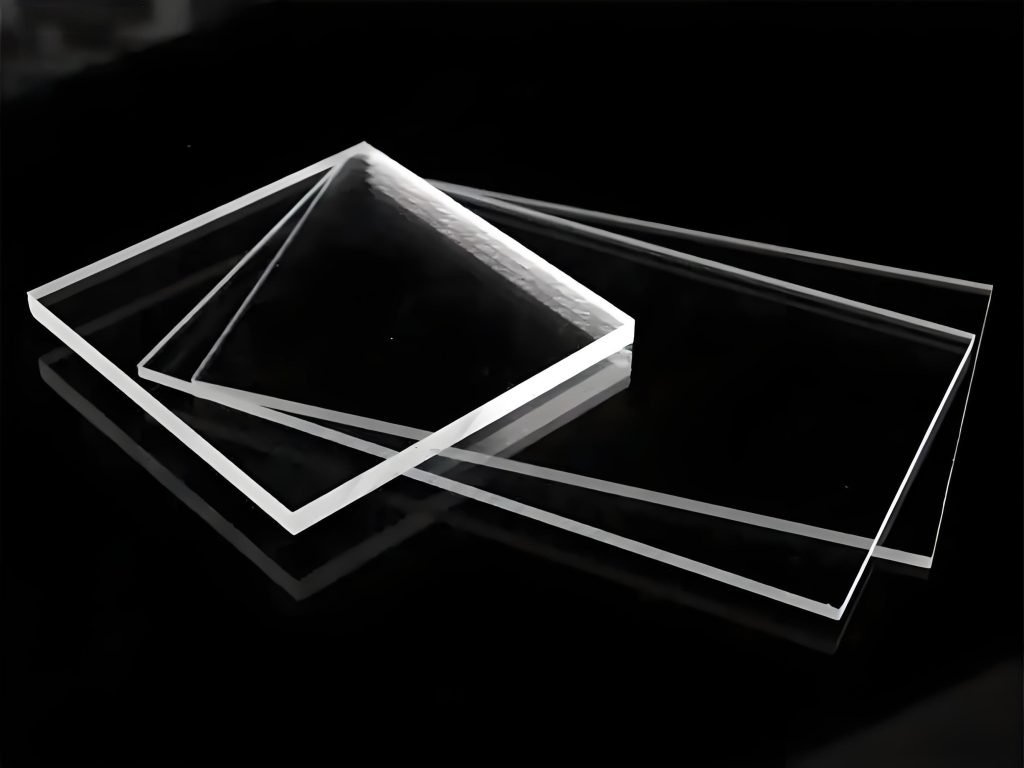

Have you ever wondered if acrylic and plexiglass are actually the same material? You’re not alone. Many people use these terms interchangeably, but is there a difference?

Both acrylic and plexiglass are made from polymethyl methacrylate (PMMA), a versatile and impact-resistant glass alternative. The confusion arises from the fact that “Plexiglas” was originally a brand name that became a generic term for acrylic sheets, much like “Band-Aid” is used for adhesive bandages.

This article will explore the nuances between these terms, their manufacturing processes, and their various applications, helping you make informed decisions for your projects.

Are Plexiglass and Acrylic the Same Thing?

To determine if Plexiglass and Acrylic are the same, we need to examine their composition and branding. While often used interchangeably, these terms have distinct origins that clarify their relationship.

Brand Names vs. Generic Terms

Plexiglass is a term that originated from the trademarked name Plexiglas®, which refers specifically to a type of cell-cast acrylic produced by Rohm and Haas (now Arkema). Over time, “plexiglass” has become a generic term for any acrylic sheet, regardless of the manufacturing process. Other brand names like Lucite®, Perspex®, and Acrylite® also refer to essentially the same material, polymethyl methacrylate (PMMA).

Chemical Composition

The chemical composition of both Plexiglass and Acrylic is polymethyl methacrylate (PMMA), a synthetic polymer derived from acrylic acid. This means that, fundamentally, Plexiglass and Acrylic are the same material. However, the difference lies in the manufacturing process and branding. While Plexiglas® is made only via cell casting, acrylic can be produced by either cell casting or extrusion.

Manufacturing Process of Plexiglass vs Acrylic

Understanding how acrylic and Plexiglass are manufactured can reveal their distinct characteristics. The production of these materials involves complex processes that result in different properties and applications.

Cell Casting Method

The cell casting method is a significant process in acrylic sheet manufacturing. It begins with creating a “syrup,” a mixture of methyl methacrylate (MMA) monomer and other additives. This syrup is then poured between two parallel, tempered glass plates separated by rubber gaskets to form a cell. The cell undergoes a carefully controlled heat treatment in water baths, a process known as polymerization, which transforms the liquid syrup into a solid, glass-like sheet. Cell-cast acrylic, often branded as Plexiglas, typically offers superior optical clarity, better chemical resistance, and higher impact strength than extruded acrylic.

Extrusion Method

In contrast, the extrusion method involves melting acrylic resin and forcing it through a die to create continuous sheets of uniform thickness. This process is more economical, making extruded acrylic less expensive. However, it may have lower optical quality and more internal stress than cell-cast acrylic. The extrusion process allows for the production of larger sheets and can be more efficient for high-volume production.

Both manufacturing processes have quality control measures to ensure consistency in thickness, clarity, and structural integrity. Understanding these processes helps in selecting the appropriate type of acrylic or Plexiglass for specific applications.

Key Differences Between Plexiglass and Acrylic

When it comes to choosing between Plexiglass and Acrylic, understanding their differences is crucial for your project’s success. Both materials are popular alternatives to glass, offering high transparency and clarity. However, there are key differences in their properties that can affect the outcome of your project.

Optical Clarity and Transparency

Plexiglass, which is essentially cast acrylic, offers superior optical clarity compared to extruded acrylic. This is because the cell casting process results in fewer impurities and less internal stress, allowing for up to 92% light transmission. In contrast, extruded acrylic typically transmits around 90% of visible light.

Impact and Weather Resistance

Both Plexiglass and Acrylic are known for their impact resistance, being approximately 10-17 times more resistant than glass of equal thickness. They also resist UV degradation, but Plexiglass tends to offer superior long-term outdoor performance due to its manufacturing process.

Thermal Properties

In terms of thermal conductivity, both materials are good insulators, but Plexiglass has a slightly lower thermal conductivity (0.19 W/mK) compared to extruded acrylic (0.2 W/mK). This makes Plexiglass a marginally better insulator, and it generally has better dimensional stability and higher heat deflection temperatures.

Understanding these differences will help you make an informed decision when choosing between Plexiglass and Acrylic for your specific application.

Physical Characteristics and Properties

Understanding the physical characteristics of plexiglass and acrylic is crucial for determining their suitability for various applications. Both materials exhibit a range of properties that make them valuable in different contexts.

Strength and Durability

Plexiglass and acrylic are known for their remarkable strength and durability. They are approximately 17 times more impact-resistant than glass of equal thickness, making them a safer alternative in many applications. This durability allows them to withstand everyday wear and tear while maintaining their visual appeal.

Weight and Flexibility

Acrylic sheets are about half the weight of glass with equivalent dimensions, making them easier to transport, install, and support. When heated, plexiglass and acrylic become flexible, allowing for thermoforming into curved shapes and custom designs that would be difficult or impossible with glass.

UV Resistance and Weatherability

Properly formulated acrylic exhibits excellent UV resistance, not yellowing or degrading significantly when exposed to sunlight over extended periods. The weatherability of cell-cast acrylic typically offers superior outdoor performance in challenging environmental conditions compared to extruded acrylic.

These physical properties make acrylic an ideal material for applications ranging from architectural elements to retail displays and protective barriers.

Applications and Uses of Plexiglass and Acrylic

Plexiglass and acrylic are versatile materials used in a wide range of applications, from construction to medical devices. Their unique properties make them ideal for various industries, offering a durable and adaptable alternative to traditional materials like glass.

Construction and Architecture

In construction and architecture, acrylic’s strength, clarity, and weatherability make it a preferred alternative to glass. It is used in window glazing, soundproofing panels, greenhouses, and even in structural elements like staircases and bridges. Plexiglass’s flexibility enables architects to create complex, curved structures that would be challenging with traditional glass.

Retail Displays and Signage

Acrylic is the material of choice for signage and displays due to its superior clarity and durability. It is used in retail display cases to protect valuable items while maintaining an unobstructed view. From small nameplates to large outdoor signs, plexiglass provides a sleek, polished look that’s hard to beat.

Automotive and Aerospace Industries

In the automotive and aerospace industries, acrylic’s impact resistance and optical clarity make it valuable for various applications. It is used in headlight lenses, interior components, aircraft windows, and cockpit canopies, where its lightweight nature and strength-to-weight ratio offer critical performance benefits.

Medical and Scientific Applications

The non-toxic nature of acrylic makes it a safe choice for medical applications. It is used in the manufacturing of dentures, lens implants for cataract surgery, and even in the production of prosthetics. The clarity of acrylic also makes it ideal for use in vision-related medical equipment, such as microscopes and medical visors.

Conclusion

In summary, understanding the nuances between Plexiglass and acrylic is crucial for selecting the right material for your project. While both are forms of polymethyl methacrylate (PMMA), differences in branding, manufacturing processes, and properties set them apart.

Plexiglass, a brand of acrylic, and other acrylic products offer superior optical clarity, impact resistance, and weatherability compared to traditional glass. When choosing between cell-cast acrylic (often branded as Plexiglas) and extruded acrylic, consider factors like required optical clarity, impact resistance, and budget constraints.