Did you know that nearly 70% of manufactured parts require some form of surface modification to enhance their functionality or aesthetic appeal? One such crucial process is knurling, which involves deforming a workpiece to create a rough pattern on its surface. This technique is particularly useful for improving grip and friction properties on various components.

As a manufacturer, understanding the process of knurling and its applications can help you make informed decisions about your products. By creating textured patterns on the surface of a workpiece, you can significantly enhance the handling characteristics and visual appearance of your components.

Precision will walk you through the basics of knurling and its role in manufacturing, exploring its various applications and the benefits it offers.

What Is Knurling?

Knurling is a precise manufacturing technique that creates textured patterns on the surface of a workpiece through controlled deformation rather than material removal. Unlike cutting processes, knurling displaces the surface material using specialized tools with patterned wheels that press against the workpiece while it rotates.

The Knurling Process in Manufacturing

Knurling, a fundamental process in manufacturing, involves creating patterns on metal surfaces using specialized tools. This process is crucial for enhancing the grip, friction, and aesthetic appeal of various products. The knurling process can be performed using two primary methods: hand knurling and machine knurling.

Hand Knurling Methods

Hand knurling involves using manually operated tools, such as knurling hammers and knurling wheels, to create a regular textured pattern on the metal surface. This traditional approach offers excellent flexibility for custom work but requires significant skill to maintain uniform patterns. Hand knurling is particularly useful for small-batch production or customized parts where precision and flexibility are paramount.

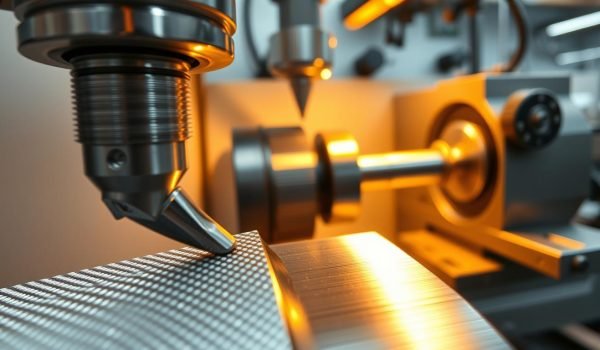

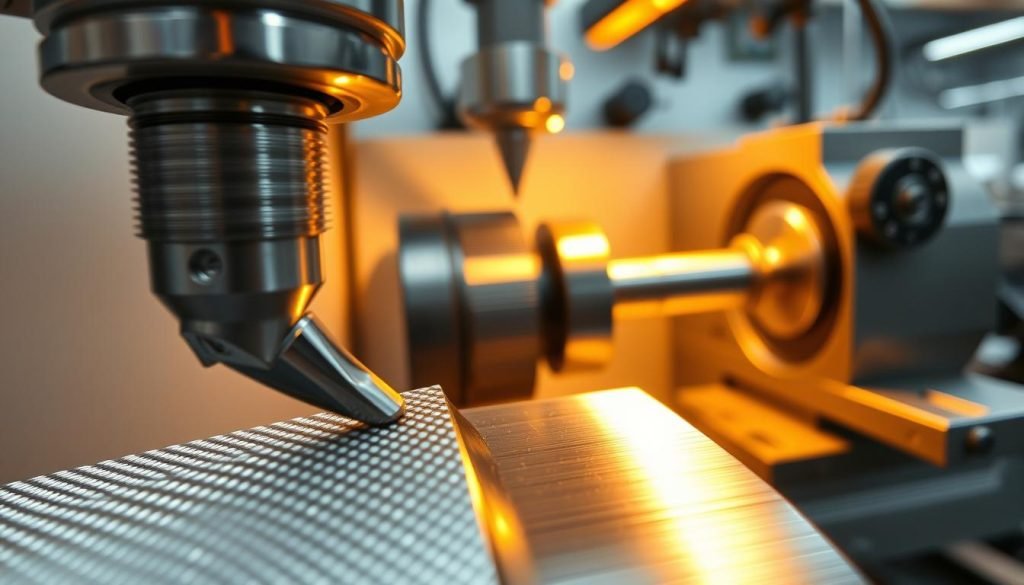

Machine Knurling Techniques

Machine knurling techniques utilize lathes or specialized knurling equipment where the workpiece rotates while knurling tools apply precise, controlled pressure to create uniform patterns. This method is highly efficient and well-suited for mass production, allowing for consistent quality across large production runs. During machine knurling, lubricants are often used to reduce friction and prevent material buildup on the tools, thus extending the life of both the knurling tool and the workpiece surface.

Understanding the differences between hand and machine knurling processes helps you select the appropriate method based on your production volume, precision requirements, and available equipment. Both processes require careful setup and monitoring to ensure the knurling pattern forms correctly without damaging the workpiece or creating uneven textures.

Types of Knurling Patterns

The type of knurling pattern used can significantly impact the performance and appearance of the workpiece. Knurling patterns vary widely depending on functional requirements and aesthetic preferences, with each pattern offering distinct advantages for specific applications.

Straight Knurling

Straight knurling creates parallel ridges that run either horizontally or vertically across the workpiece surface. This pattern provides moderate grip while maintaining a clean, simple appearance ideal for decorative applications and light-duty handling needs.

Diagonal Knurling

Diagonal knurling features angled lines, typically at 30° to 45°, that run in a single direction across the workpiece surface. It offers improved grip compared to straight patterns while maintaining a distinctive, dynamic appearance.

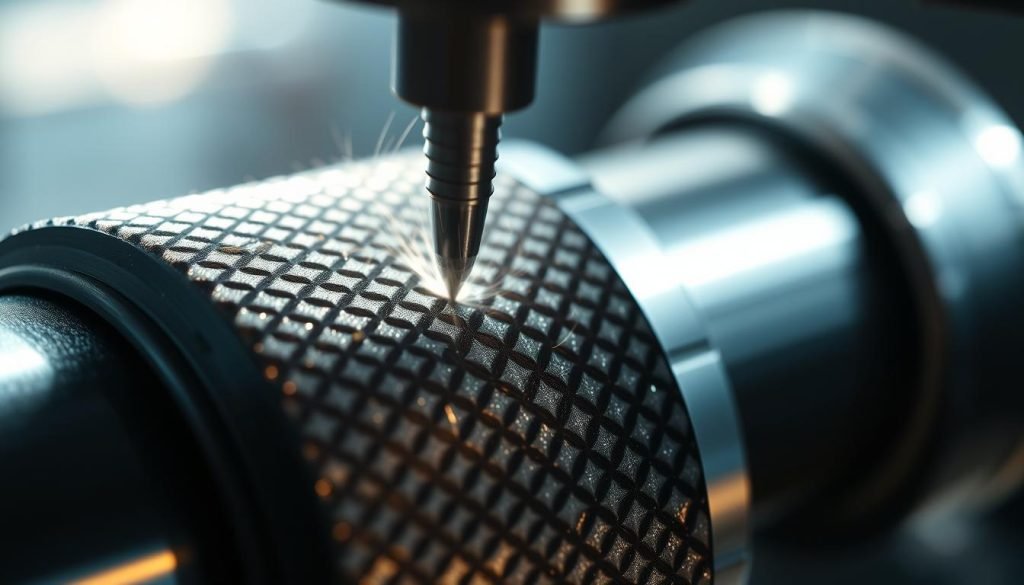

Diamond Knurling

Diamond knurling, the most common pattern, combines two sets of diagonal lines running in opposite directions to create a diamond-shaped texture that provides superior grip. It’s frequently used for tool handles, barbell bars, and other applications requiring maximum friction.

Other Specialized Patterns

Beyond these standard patterns, specialized variations include convex knurling with rounded ridges for comfortable grip, concave knurling with inward-curved depressions, and square knurling with grid-like patterns. The choice of knurling pattern significantly impacts both the functional performance of the knurled surface and its visual appeal, making pattern selection a critical decision in the manufacturing process.

Understanding the characteristics of different knurling patterns helps you select the most appropriate option for your specific application requirements, balancing grip performance with aesthetic considerations. Each pattern requires specific tool configurations and machine settings to produce correctly.

Knurling Tools and Equipment

To produce high-quality knurled surfaces, manufacturers must utilize the correct knurling tools and equipment. The variety in design and complexity of these tools, from simple hand-held devices to sophisticated machine-mounted systems, caters to different manufacturing needs.

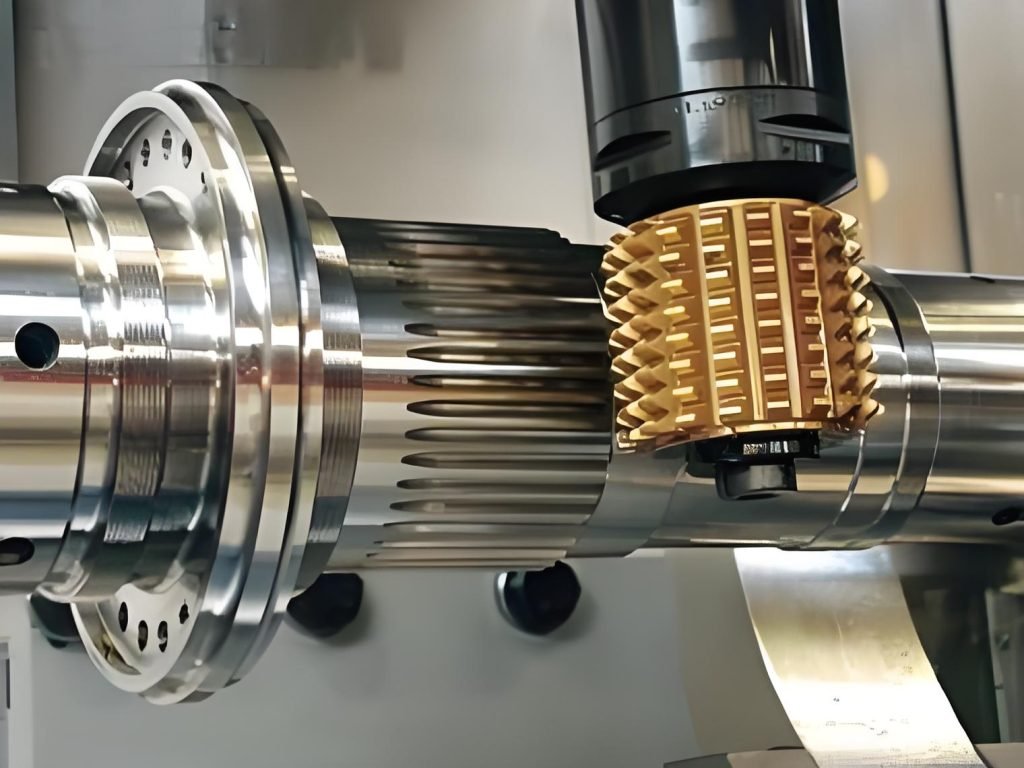

Knurling Wheels and Dies

Knurling wheels are the core components of most knurling tools, featuring hardened steel rollers with precisely machined teeth. These wheels come in various configurations to achieve different knurling patterns and pitches, allowing for specific texture requirements to be met.

Knurling dies, on the other hand, are used for specific applications, including internal and face knurling, thus expanding the versatility of the knurling process.

Lathe Knurling Tools

Lathe knurling tools are specially designed holders that mount on the tool post of a lathe. They position the knurling wheels correctly against the rotating workpiece to create uniform patterns. Modern knurling tools often feature adjustable pressure mechanisms, enabling operators to control the depth of the pattern and accommodate different material hardnesses.

The quality of knurling tools directly impacts the final appearance and functionality of the knurled surface. Understanding the capabilities and limitations of different knurling tools is crucial for selecting the appropriate equipment for specific manufacturing requirements and material types.

Materials Suitable for Knurling

The knurling process can be applied to various materials, each with its unique properties and applications. As you explore the possibilities of knurling, understanding the characteristics of different materials is crucial for achieving the desired outcome on your workpiece.

Metals

Metals are the most common materials for knurling, with mild steel, aluminum, brass, and stainless steel being particularly well-suited due to their ductility and ability to retain the impressed pattern on the surface. When knurling harder metals like stainless steel or tool steel, machine knurling is typically required to apply sufficient pressure. Special considerations for tool hardness and lubrication become essential to prevent excessive wear on knurling wheels.

Plastics and Other Materials

Plastics can also be knurled, though the process requires careful control of temperature and pressure to prevent melting or cracking. Thermoplastics are generally more suitable than thermosets due to their greater ductility. The knurling process for plastics often uses lower pressure and specially designed knurling wheels with less aggressive patterns to accommodate the material’s lower strength and heat resistance. Other materials like wood, particularly hardwoods, and certain composites can be knurled using specialized techniques, though the results typically differ from metal knurling.

Understanding the relationship between material properties and knurling performance helps you achieve optimal results across different workpiece materials while minimizing tool wear and material damage to the surface.

Key Parameters of Knurling in Manufacturing

When it comes to knurling in manufacturing, several key parameters must be carefully controlled to achieve high-quality results. The knurling process involves pressing a knurling tool against a rotating workpiece, displacing material to form the desired pattern. Understanding and managing these parameters is crucial for successful knurling operations.

Pitch and Angle

The pitch of a knurling pattern refers to the spacing between the ridges, typically measured in teeth per inch (TPI). Common pitches range from 14 to 33 TPI, with finer pitches creating more delicate patterns and coarser pitches producing more aggressive textures. The angle of knurling determines the orientation of the pattern lines relative to the workpiece axis. Straight knurling is achieved at 0° or 90°, while diagonal knurling is typically done at 30° or 45°. Diamond patterns are created by combining two diagonal angles.

Depth and Pressure

Depth and pressure are critical in controlling how deeply the pattern is impressed into the workpiece surface. Excessive pressure can cause material damage, while insufficient pressure results in poorly defined patterns. The appropriate depth varies based on the workpiece material properties; softer materials allow deeper impressions, while harder materials require more controlled, shallow patterns to prevent tool damage.

Speed and Feed Rate

Speed and feed rate must be carefully balanced during the knurling process. Excessive speed can generate harmful heat and vibration, while improper feed rates may cause pattern irregularities or tool wear. For optimal results, manufacturers typically use slower speeds for knurling compared to other machining operations, with feed rates adjusted based on material type, pattern complexity, and desired surface finish quality.

By understanding and controlling these key parameters, you can achieve consistent, high-quality knurled surfaces across different manufacturing applications and material types.

Types of Knurling Based on Location

The classification of knurling is heavily influenced by its location on the workpiece. Beyond pattern variations, knurling is also classified based on the location and extent of the pattern on the workpiece, with each type serving specific functional and aesthetic purposes.

Band Knurling

Band knurling applies the pattern to a limited section or band of the workpiece surface, creating a designated grip area while leaving the remainder smooth. This type is commonly used for tool handles and control knobs where grip is needed only in specific zones.

Full Knurling

Full knurling covers the entire external surface of the workpiece with a uniform pattern, maximizing grip area and creating a consistent appearance. It’s ideal for applications like barbell bars, complete tool handles, and decorative components.

Internal Knurling

Internal knurling creates patterns on the inside surfaces of hollow workpieces, typically used to improve the grip between assembled components or to enhance friction in bearing surfaces and bushings.

Face/Milling Knurling

Face/milling knurling applies patterns to flat surfaces rather than cylindrical ones, requiring specialized tools and techniques different from traditional lathe knurling. It’s commonly used for control surfaces on equipment panels and decorative elements.

Taper Knurling

Taper knurling creates patterns on conical or tapered sections of a workpiece, requiring specialized setup to maintain consistent pattern depth despite the changing diameter. It’s often used on tool handles and knobs with ergonomic tapered designs.

Each location-based knurling type requires specific tooling configurations and machine setups to achieve optimal results, with considerations for workpiece geometry significantly influencing the approach. Understanding these location-based variations helps you specify the most appropriate knurling type for your specific component design and functional requirements.

Benefits of Knurling in Manufacturing

Knurling offers numerous benefits that enhance both the functionality and appearance of components in manufacturing. By incorporating ridges or patterns onto the surface of materials, knurling improves the overall performance and usability of the final product.

Enhanced Grip and Friction

The primary advantage of knurling is the enhancement of grip and friction. The raised pattern on the surface significantly increases the coefficient of friction, allowing for secure handling even with oily or wet hands. This is particularly valuable for tool handles, control knobs, and other components that require precise manipulation.

Aesthetic Improvements

Knurling also transforms ordinary cylindrical surfaces into visually distinctive components with professional, finished appearances. These aesthetic improvements make knurled surfaces particularly desirable for consumer products where visual appeal contributes significantly to perceived value and brand identity.

Functional Advantages

Functionally, knurling provides advantages beyond grip, including improved heat dissipation through increased surface area, enhanced resistance to rotational slippage in assembled components, and better retention of lubricants in certain applications. For components like adjustment knobs and control wheels, knurling creates tactile feedback that allows for more precise operation.

Limitations and Challenges of Knurling

While knurling offers numerous benefits, it also presents certain challenges that manufacturers must consider when deciding whether to incorporate this process into their production. The limitations of knurling include increased manufacturing costs and processing time, potential effects on the strength and structural integrity of the component, and difficulties in cleaning and maintenance due to the textured surface.

Common Knurling Defects

Common knurling defects include double-tracking, where the pattern lines don’t align properly, partial knurling, which results from incomplete pattern formation, and excessive material displacement that can lead to cracking or distortion of the workpiece. These defects typically result from improper tool setup, incorrect pressure application, or using worn or damaged tools.

The quality of the knurled surface is heavily dependent on the condition of the tool and the material being processed. For instance, extremely hard materials may resist proper pattern formation, while very soft materials might experience excessive deformation under knurling pressure.

Troubleshooting Knurling Issues

Troubleshooting knurling issues requires a systematic analysis of multiple factors, including tool condition, machine setup, workpiece material properties, and process parameters like speed, pressure, and lubrication. Understanding these factors helps you make informed decisions about when knurling is appropriate for your manufacturing needs and how to mitigate potential issues through proper planning and process control.

By carefully considering the limitations and challenges associated with knurling, manufacturers can optimize their processes to achieve high-quality results while minimizing the potential drawbacks. This includes selecting the right materials, maintaining proper tool condition, and adjusting process parameters as needed.

Knurling vs. Engraving: Understanding the Differences

To choose the right surface modification method, you need to understand how knurling and engraving differ. Both processes create patterns on workpieces but have distinct approaches and outcomes.

Process Comparison

Knurling involves displacing material through pressure to create raised patterns on the workpiece surface, preserving most of the original material. In contrast, engraving removes material to create recessed designs, potentially reducing material thickness and creating stress points. The tools used also differ: knurling employs patterned wheels, while engraving uses cutting tools, lasers, or chemical processes.

Applications and Use Cases

Knurling is primarily used for functional purposes, such as creating grip surfaces and mechanical interfaces, with aesthetic benefits being secondary. Engraving, on the other hand, is mainly decorative, used for text, logos, and intricate designs. The choice between knurling and engraving depends on whether your primary requirement is functional performance or decorative detail.

Understanding these differences helps you select the appropriate surface modification method for your needs. By considering the process and application differences, you can make informed decisions for your manufacturing projects.

Applications of Knurling Across Industries

You can find knurling in numerous industries, where it serves both practical and decorative purposes. The technique’s versatility allows it to be applied in various contexts, from enhancing the functionality of industrial components to adding aesthetic value to consumer products.

Manufacturing and Tools

In manufacturing and industrial tools, knurling is used to create textured surfaces on handles, adjustment knobs, and control wheels. This enhances grip for operators, particularly when working with heavy machinery or precision equipment. Tool handles, for instance, benefit significantly from knurling, as the textured surfaces allow for secure gripping even in challenging conditions involving oils or lubricants.

Consumer Electronics

Consumer electronics often incorporate knurling on control dials, adjustment wheels, and battery compartments. The knurling pattern not only improves functionality through better grip but also adds a premium tactile quality to the user experience. This makes the devices more user-friendly and enhances their overall aesthetic appeal.

Jewelry and Decorative Uses

In the jewelry industry, knurling has evolved into a distinctive decorative technique. It is used to create textured patterns on rings, watch bezels, and other accessories, combining aesthetic appeal with practical benefits. The use of knurling in jewelry and decorative items showcases its versatility beyond functional applications.

Conclusion

With its unique combination of functional and aesthetic benefits, knurling remains essential in manufacturing. You’ve seen how this process transforms ordinary workpiece surfaces into functional components through strategic pattern application. The versatility of knurling is evident in its various pattern options and material compatibility, allowing for tailored solutions. As manufacturing technology advances, knurling techniques evolve, incorporating greater precision and efficiency. By understanding knurling’s tools, parameters, and benefits, you can make informed decisions about its application, enhancing both functionality and appearance of your products.