In the world of injection molding, a staggering 70% of production issues stem from improper clamping. This critical parameter ensures that your mold remains closed during the injection and cooling phases, directly impacting product quality and production efficiency.

clamping force is generated by a hydraulic press and is crucial for maintaining the integrity of your parts. Understanding the nuances of this force, including its hydraulic and mechanical aspects, is vital for any engineering professional involved in plastic product design and production.

As you delve into the world of injection molding, grasping the concept of clamping force and its role in your production process will be essential. This article will guide you through the fundamentals, calculation methods, and practical applications of clamping force, empowering you to optimize your injection molding operations.

The Fundamentals of Clamping Force in Injection Molding

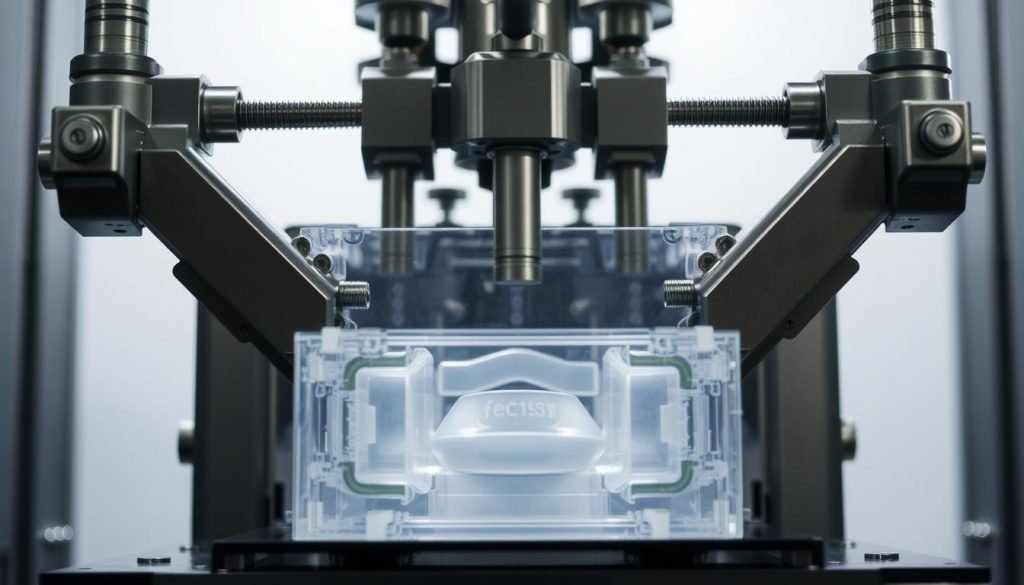

Understanding clamping force is essential for successful injection molding operations. Clamping force is the pressure applied to keep the mold halves closed against the force of injected material, preventing flashing and ensuring proper part formation. It’s a critical counterbalance to injection pressure, maintaining mold integrity during the filling phase.

Definition and Basic Principles

The clamping force is determined based on the mold design and material properties. When a mold factory delivers a mold, it typically includes an instruction manual specifying the optimal clamping force for that particular mold. This information is crucial for ensuring the proper operation and longevity of the mold. During production, confirming and setting the optimal clamping force according to the mold manual is vital.

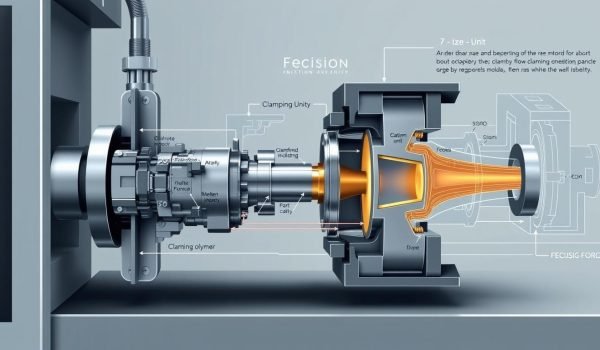

Types of Clamping Systems: Hydraulic vs. Mechanical

There are primarily two types of clamping systems used in injection molding: hydraulic and mechanical. Hydraulic clamping systems utilize hydraulic cylinders to generate the necessary force, offering precise control over the clamping pressure. Mechanical clamping systems, on the other hand, employ toggle mechanisms to amplify the applied force. The choice between these systems depends on factors such as machine size, clamping force capacity, and the specific requirements of the parts being produced.

Why Proper Clamping Force Matters

The significance of clamping force cannot be overstated in achieving quality injection molded parts. Proper clamping force is essential for maintaining the integrity of the mold and ensuring the production of high-quality parts.

Product Quality and Defect Prevention

Proper clamping force directly impacts the quality of the final product. Insufficient clamping force can lead to flashing, where material escapes between the mold halves, creating defects that require costly trimming or part rejection. On the other hand, excessive clamping force can cause mold damage and premature wear. By maintaining the correct cavity pressure during injection and cooling, proper clamping force ensures dimensional accuracy, surface finish, and overall part quality.

Mold Protection and Longevity

Optimized clamping force protects your valuable mold investment by preventing damage from flash, reducing wear on parting lines, and extending the service life of your tooling. This not only saves on maintenance costs but also ensures consistent production of high-quality parts over time.

Production Efficiency and Cost Implications

Correct clamping force settings lead to production efficiency gains, including reduced cycle times, lower energy consumption, and minimized downtime for mold maintenance. Conversely, improper clamping force can result in increased scrap rates, quality control issues, higher maintenance expenses, and shortened mold life, emphasizing the value of getting this parameter right.

Key Factors Influencing Clamping Force Requirements

Several key factors determine the clamping force required for injection molding processes. Understanding these factors is crucial for achieving optimal molding results and preventing defects.

Part Geometry and Projected Area

The projected area of your part, which is the area as viewed from the parting line direction, is the most significant factor in determining clamping force requirements. A larger projected area means a greater surface area where injection pressure acts to separate the mold, thus requiring more clamping force. The size and complexity of the part also play a role in this calculation.

Material Properties and Flow Characteristics

Different materials have varying properties that affect clamping force needs. High-viscosity materials, for instance, require greater clamping force than low-viscosity materials due to the higher injection pressures needed. Understanding the flow characteristics of your material is essential for accurate clamping force calculation.

Wall Thickness Considerations

Wall thickness is another critical factor influencing clamping force. Thinner walls generally require higher injection pressures to fill properly, thus necessitating greater clamping force to prevent flashing. Conversely, thicker walls may require less clamping force but can lead to other issues like sink marks or longer cycle times.

Injection Pressure and Mold Temperature

Injection pressure directly correlates with required clamping force. Higher injection pressures necessitate greater clamping force to keep the mold closed. Additionally, mold temperature affects the pressure distribution within the mold. Proper control of mold temperature, along with other process parameters like injection speed and packing pressure, is vital for optimal clamping force.

By considering these factors—part geometry, material properties, wall thickness, and injection pressure—you can accurately determine the clamping force required for your specific injection molding application. This not only ensures product quality but also helps in maintaining the longevity of your mold.

The Science Behind Clamping Force

The effectiveness of clamping force in injection molding depends on a complex interplay of scientific principles. To understand how clamping force works, you need to delve into the mechanics of force distribution within the mold and its relationship with injection pressure.

Understanding Force Distribution in the Mold

Clamping force isn’t uniformly distributed across the mold surface; instead, it concentrates at specific points, particularly around the parting line and support pillars. This creates a complex force distribution pattern that must be properly managed to ensure mold integrity. Advanced mold flow analysis can predict pressure distribution within the cavity, helping to determine the minimum required clamping force for specific part geometries and materials. The coefficient of friction between mold surfaces also affects the effective clamping force, highlighting the importance of proper mold maintenance.

Relationship Between Injection Pressure and Clamping Force

Injection pressure creates an opening force that acts against the clamping force. The relationship between these forces determines whether the mold remains securely closed during injection. Understanding this dynamic is crucial for setting the optimal clamping force. By analyzing the force distribution and the impact of injection pressure, you can make informed decisions about mold design, including the placement of support structures, ejector pins, and cooling channels to maintain mold integrity under pressure.

How to Calculate Clamping Force in Injection Molding

To achieve optimal results in injection molding, understanding how to calculate clamping force is essential. The clamping force is a critical parameter that ensures the mold remains closed during the injection process, preventing defects and maintaining product quality.

The Basic Formula: F = P × S

The fundamental formula for calculating clamping force is given by F = P × S, where F is the clamping force, P is the cavity pressure, and S is the projected area of the part and runner system. This formula establishes that the required clamping force equals the cavity pressure multiplied by the projected area.

Determining Cavity Pressure (P)

To determine the cavity pressure (P), several factors come into play, including the viscosity of the polymer material, the size and location of the runner and gate, the size and thickness of the product, injection speed, mold temperature, barrel temperature, and mold venting. Using material-specific flow coefficients and considering factors like flow path length and wall thickness ratio, you can accurately determine the cavity pressure.

Calculating Projected Area (S)

Calculating the projected area (S) of your part and runner system involves considering the geometry of the part and the runner layout. For complex geometries with varying wall thicknesses and multiple cavities, specific techniques can be applied to accurately determine the projected area. This step is crucial for ensuring that the clamping force calculation is accurate.

By understanding and applying the formula F = P × S, and accurately determining cavity pressure and projected area, you can ensure reliable production without excessive force. Incorporating safety factors into your calculations will further account for variations in material properties and machine performance.

Step-by-Step Guide to Determining Optimal Clamping Force

The key to efficient injection molding lies in accurately determining the optimal clamping force. This involves a combination of theoretical calculations and practical testing to ensure that your process is both reliable and efficient.

Using Flow Coefficients for Different Materials

To determine the optimal clamping force, you first need to understand the flow characteristics of your material. Different thermoplastic materials have varying flow coefficients, which are used to adjust your calculations. For instance, easy-flowing materials like PP and PE have lower coefficients compared to more challenging materials like PC and PEI. By using flow coefficient tables, you can accurately adjust your clamping force calculations based on the material properties.

Accounting for Flow Path to Wall Thickness Ratio

The flow path to wall thickness ratio significantly impacts the pressure required to fill thin-walled sections, consequently affecting the clamping force needed. For example, a thin wall of 1.5 mm and a flow path to thickness ratio of 177 would require a specific cavity pressure calculation. By understanding this ratio and its impact, you can make more accurate clamping force determinations.

Applying Safety Factors

Applying appropriate safety factors to your clamping force calculations is crucial. This balances the need for reliable production against the risks of excessive clamping force that can damage molds or machines. A well-calculated safety factor ensures that your process is robust without being overly cautious.

Practical Testing Methods

Practical testing is essential for validating your theoretical clamping force calculations. One effective method involves sequentially reducing the clamping force until flashing occurs, establishing the minimum effective force for your specific part and process. Start by setting the clamping force to 90% of the maximum pressure, then decrease it by 10 tons sequentially while recording the weight and checking for appearance defects. This method can be quickly tested on any machine and mold using a kilo electronic scale and adjusting the clamping force settings.

Common Clamping Force Issues and Solutions

Clamping force plays a vital role in determining the quality and consistency of injection-molded products. Achieving the optimal clamping force is crucial for preventing defects, ensuring mold longevity, and maintaining production efficiency.

Insufficient Clamping Force: Signs and Remedies

Insufficient clamping force can lead to flashing, increased part weight, and dimensional inconsistencies. To identify these issues early, monitor your production for signs such as material escaping at the parting line. Adjusting the clamping force to the recommended 70%~80% of the machine’s maximum capacity can help resolve these problems.

Excessive Clamping Force: Risks and Corrections

Excessive clamping force can result in premature mold wear, platen deflection, and increased energy consumption. To mitigate these risks, it’s essential to determine the optimal clamping force required for your specific product and machine. Based on data, a clamping force between 80 tons and 90 tons is considered optimal for certain products.

Troubleshooting Uneven Force Distribution

Uneven force distribution can cause localized flashing even when the overall clamping force appears adequate. To address this issue, analyze the force distribution across the mold and adjust the clamping system as necessary. This might involve mold modifications or adjustments to the hydraulic system to ensure even movement and distribution of force.

By understanding and addressing common clamping force issues, you can optimize your injection molding process for better product quality and production efficiency.

Practical Applications and Case Studies

To achieve optimal results in injection molding, understanding and applying the correct clamping force is essential. This section delves into practical applications and case studies that highlight the importance of clamping force optimization.

Real-World Testing Protocol for Optimal Clamping Force

Implementing a standardized testing protocol is crucial for determining the optimal clamping force for any part, regardless of material or geometry. You can start by calculating the projected area of your product and estimating the required clamping force based on the material’s properties. For instance, consider a product made of ABS material with a main runner length of 50mm, a square gate measuring 1.5mm, and a wall thickness of 2.0mm. By analyzing the flow path to wall thickness ratio, you can determine the necessary clamping force.

This method allows you to validate your theoretical calculations through systematic testing in your specific production environment, ensuring that your clamping force is optimized for the best results.

Case Study: Optimizing Clamping Force for ABS Products

In a real-world case study, optimizing clamping force for ABS products resulted in significant improvements in production efficiency and product quality. By applying the testing protocol outlined above, manufacturers were able to adjust their clamping force to the optimal level, reducing cycle time and energy consumption while improving part quality. The case study demonstrated that a clamping force of 234 tons was required for a specific ABS product, based on calculations involving the material’s flow coefficient and cavity pressure.

By adjusting the clamping force to this optimal level, the production team was able to minimize defects and maximize efficiency, showcasing the practical benefits of clamping force optimization in real-world injection molding applications.

Conclusion: Mastering Clamping Force for Superior Injection Molding

To achieve superior results in injection molding, it’s essential to grasp the concept of clamping force and its applications. Mastering clamping force is vital for balancing the need for sufficient force to prevent defects and avoiding excessive force that can damage equipment. By understanding the fundamental principles, calculation methods, and optimization techniques, you can improve your injection molding operations. The optimal clamping force varies based on part geometry, material properties, and processing conditions. Properly calculating and documenting this force for each mold will improve part quality, reduce scrap, and extend mold life.