Did you know that nearly 90% of mechanical failures are due to material fracture, often caused by excessive tensile stress? When designing or selecting materials for your projects, understanding the maximum stress a material can withstand is crucial.

The tensile strength of a material is a critical property that quantifies its ability to resist breaking under tension. It’s the maximum stress a material can endure before failing. As an engineer, grasping this concept is vital for ensuring the integrity and performance of your products.

This article will guide you through the definition, calculation methods, and significance of ultimate tensile stress in materials science, helping you make informed decisions in your design and material selection processes.

Understanding Ultimate Tensile Stress

You need to grasp the concept of ultimate tensile stress to understand material failure. Ultimate tensile stress refers to the maximum stress a material can withstand while being stretched or pulled before failing. This measure is critical in materials science as it helps in determining the suitability of a material for a particular application.

Definition and Basic Concepts

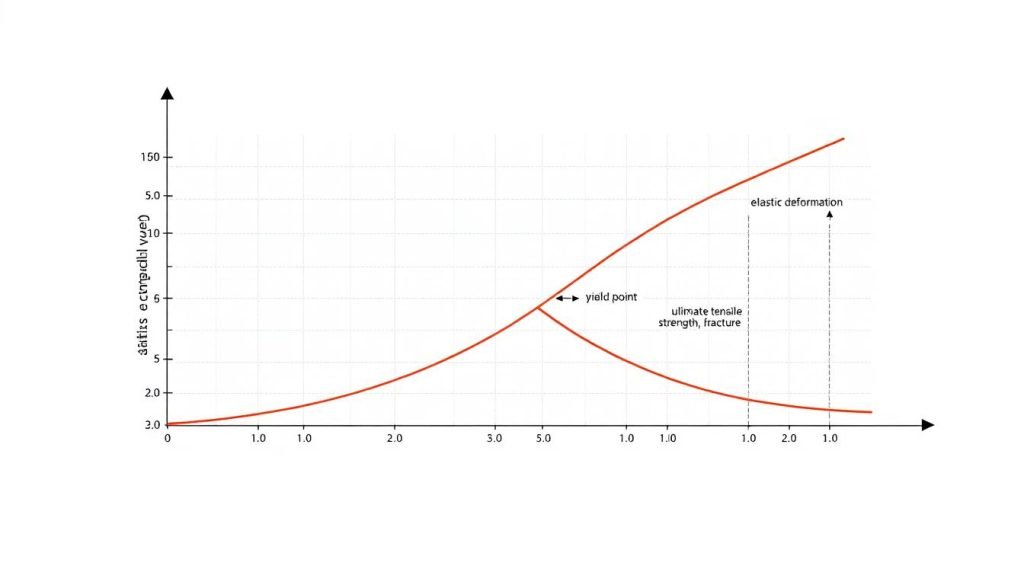

Ultimate tensile strength (UTS), also known as tensile strength (TS) or ultimate strength, is a measure of the maximum stress that a material can handle. It is typically determined through a tensile test, where the material is subjected to increasing stress until it breaks. The stress-strain curve obtained from this test is crucial in identifying the ultimate tensile strength as the highest point on the curve.

The fundamental concepts related to ultimate tensile stress include stress, strain, and material deformation. Stress refers to the force applied to a material, while strain is the resulting deformation. Understanding these concepts is essential to grasp how materials behave under different types of loading.

Ultimate Tensile Stress vs. Other Stress Measurements

Ultimate tensile stress is often compared with other stress measurements such as yield strength, compressive strength, and shear strength. Yield strength is the stress at which a material begins to deform plastically, whereas ultimate tensile stress is the maximum stress before failure. Compressive strength and shear strength refer to a material’s ability to withstand compressive and shear forces, respectively.

Understanding the differences between these stress measurements is vital for selecting the right material for a specific application. For instance, a material with high ultimate tensile stress may not necessarily have high compressive strength.

How Ultimate Tensile Stress Works

Understanding how ultimate tensile stress works is crucial for evaluating the strength and durability of materials. When you apply a force to a material, it undergoes deformation, which can be either temporary or permanent, depending on the material’s properties and the magnitude of the force applied.

The Stress-Strain Relationship

The stress-strain curve is a graphical representation of how a material responds to increasing force during tensile testing. Initially, many materials exhibit a linear elastic behavior, where they become deformed but return to their original shape once the force is removed. This elastic behavior continues until the yield point is reached.

Beyond the yield point, ductile materials like steel undergo plastic deformation, meaning they do not return to their original shape and size when the load is removed. As the force continues to increase, the material strain hardens until it reaches its ultimate tensile stress, representing the maximum load-bearing capacity.

Elastic and Plastic Deformation

The deformation process involves two main stages: elastic and plastic deformation. In the elastic stage, materials return to their original shape after the load is removed. However, once the yield point is exceeded, plastic deformation occurs, resulting in a permanent change in shape.

Ductile materials, such as metals, can undergo significant plastic deformation before fracture, whereas brittle materials, like ceramics, exhibit little plastic deformation and tend to fracture suddenly. Understanding these deformation processes is essential for predicting how materials will behave under different types of stress.

Calculating Ultimate Tensile Strength

To determine a material’s ultimate tensile strength, you need to understand the standard calculation methods. Ultimate tensile strength (UTS) is a measure of the maximum stress a material can withstand while being stretched or pulled before failing or breaking. This is a critical property in materials science, as it helps engineers and designers select appropriate materials for their projects.

Standard Calculation Methods

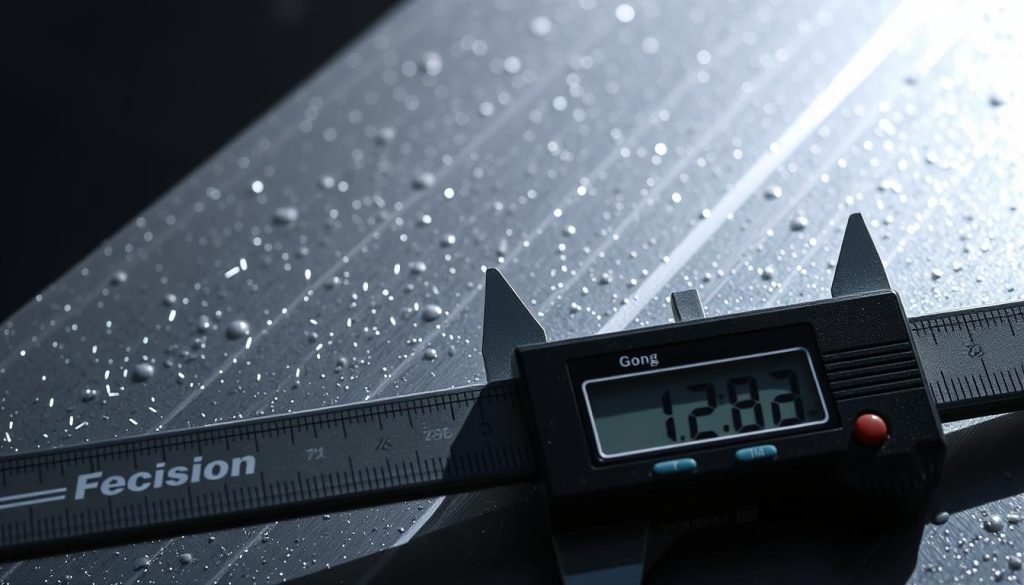

The standard formula for calculating ultimate tensile strength is: UTS = Maximum Load / Original Cross-sectional Area. To apply this formula, you first need to measure the cross-sectional area of the test specimen accurately. The maximum load is determined using a tensile testing machine, which pulls the specimen until it breaks.

Units of Measurement

Ultimate tensile strength is typically measured in units of force per unit area. The SI unit is Pascal (Pa), but it’s commonly expressed in megaPascals (MPa) due to the large values involved. In the United States, it’s often measured in pounds per square inch (psi). Understanding these units and their conversion factors is essential for comparing material properties across different systems.

Testing Procedures and Equipment

Tensile testing involves preparing a sample with a known cross-sectional area and then pulling it with a tensometer or universal testing machine at a constant strain rate until it breaks. The data collected during the test, including the maximum load and the stress-strain curve, are used to determine the ultimate tensile strength. Proper sample preparation and test setup are crucial for obtaining accurate and reliable results.

The Significance of Ultimate Tensile Stress in Materials Science

Understanding the significance of ultimate tensile stress is crucial in materials science. Ultimate tensile stress is a fundamental property that determines a material’s ability to withstand tensile forces without failing. This property is essential for engineers to consider when designing and selecting materials for various applications.

Role in Material Selection

When selecting materials, engineers rely heavily on ultimate tensile strength data to predict how materials will perform under load in real-world conditions. The ultimate tensile strength is particularly important for brittle materials, as they have no yield point. It is also used for quality control due to the ease of testing and helps in roughly determining material types for unknown samples.

Impact on Product Design and Performance

The ultimate tensile stress values significantly influence design decisions across various industries, including automotive, aerospace, construction, and consumer products. By understanding the tensile strength of materials, engineers can optimize designs for both performance and safety, creating products that are both lightweight and strong. Moreover, ultimate tensile stress testing ensures consistent material properties, which is vital for quality control in manufacturing processes.

Ultimately, the significance of ultimate tensile stress lies in its ability to help engineers make informed decisions about material selection and product design, ensuring that products meet the required safety and performance standards.

Ultimate Tensile Stress of Common Materials

The ultimate tensile stress of materials varies significantly and is a critical property to consider in material selection. Different materials exhibit a wide range of ultimate tensile strengths, which is vital information for engineers and designers.

Metals and Alloys

Metals and alloys are widely used in various applications due to their high ultimate tensile strength. For instance, structural ASTM A36 steel has an ultimate tensile strength of 400-550 MPa, while Aluminium alloy 6061-T6 has a value of 310 MPa. Copper, with 99.9% purity, exhibits an ultimate tensile strength of 220 MPa. The tensile strength of these materials makes them suitable for construction, aerospace, and other industries.

Polymers and Composites

Polymers and composites also display a range of ultimate tensile strengths. Thermoplastics, thermosets, and elastomers have unique stress-strain behaviors that affect their tensile strength. Composite materials like carbon fiber, with an ultimate tensile strength of 1600 MPa for laminates and 4137 MPa for fibers alone, offer exceptionally high strength-to-weight ratios, making them ideal for advanced applications.

Natural Materials

Natural materials such as wood, bone, spider silk, and plant fibers have evolved to exhibit remarkable tensile strength. For example, spider silk is known for its high tensile strength, which is comparable to some high-strength alloys. Understanding the ultimate tensile stress of these materials can provide insights into their potential applications and the development of new biomimetic materials.

Factors Affecting Ultimate Tensile Stress

Understanding the factors that influence ultimate tensile stress is crucial for selecting the right materials for your projects. The ultimate tensile strength of a material is an intensive property, meaning its value doesn’t depend on the size of the test specimen. However, other factors can significantly impact this property.

Temperature Effects

Temperature plays a significant role in determining the ultimate tensile stress a material can withstand. Most materials show decreased strength at elevated temperatures. For instance, extreme cold can make some materials more brittle, potentially increasing their ultimate tensile stress but reducing their ductility and toughness.

Material Composition and Structure

The composition of a material, including alloying elements, impurities, and microstructural features, can dramatically alter its tensile properties. You should consider how these factors affect the material’s ability to withstand stress.

Manufacturing Processes

Manufacturing processes like heat treatment, cold working, and annealing can be used to manipulate the ultimate tensile stress of metals. Additionally, factors such as specimen geometry, surface finish, and the presence of defects can affect test results and create discrepancies between laboratory values and real-world performance.

Other factors, including strain rate during testing and environmental factors like corrosion, radiation, and chemical exposure, can also influence a material’s ultimate tensile stress. Understanding these factors is essential for accurately predicting how a material will perform in real-world applications.

Conclusion

With a comprehensive understanding of ultimate tensile stress, you can optimize product performance, safety, and reliability. Ultimate tensile strength is a critical property that determines how materials will perform under load, making it a crucial consideration in engineering design, quality control, and material selection.

The key concepts related to ultimate tensile stress, including its definition as the maximum stress a material can withstand before failure under tension, are essential for engineers working with various materials. The importance of ultimate tensile strength in materials selection cannot be overstated, as it guides engineers in choosing appropriate materials for specific applications.

As advancements in materials science continue, new materials with exceptional tensile strength properties are enabling innovative designs and applications across various industries, from aerospace to consumer products. Understanding the factors that affect ultimate tensile stress and how to account for them in designs and material specifications is vital for optimizing product performance.