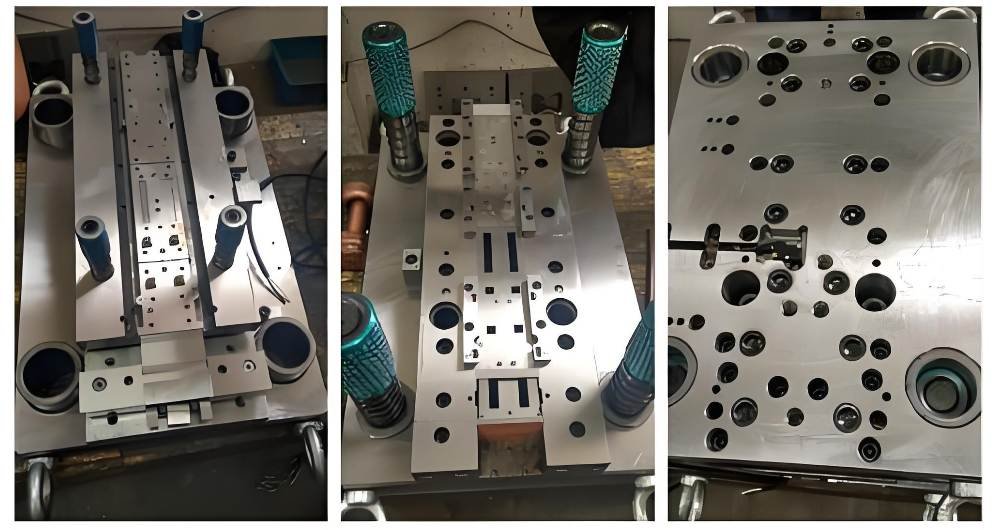

Stamping dies come in dramatic size variations—from fitting in your palm to spanning 20 square feet. These precision tools have come a long way since the Industrial Revolution and now form the foundations of modern manufacturing.

Production lines with stamping dies can produce up to 60 parts per minute. They make automotive components, medical equipment and household items. The technology has four main types: single punch, progressive, compound and transfer dies. Each type has a different production need.

This article will cover the different types of stamping dies, their applications, and how they contribute to the efficient manufacturing process.

What is Die Stamping?

Die stamping is a precise cold-forming operation that shapes and cuts sheet metal into desired profiles without heat. Manufacturers use specialized tools called stamping dies to create components from simple paper clips to intricate computer parts.

Stamping dies made from hardened tool steel or wear-resistant materials like carbide perform two basic operations: cutting and forming. A flat sheet metal piece called a blank sits between die sections where pressure changes it into the intended shape.

Today’s die stamping heavily relies on computer-aided design (CAD) software and analytical programs to create accurate designs. Skilled craftsmen, called diemakers, turn these digital blueprints into physical stamping dies. When mounted in presses, these dies process sheet metal at impressive speeds and can do up to 1,500 cycles per minute.

The stamping process covers several specialized techniques:

- Cutting Operations: Including blanking, piercing, and notching

- Forming Operations: Comprising bending, flanging, and drawing

- Surface Operations: Such as coining and embossing

Friction between the die and metal creates considerable heat, making stamped parts quite hot despite being a cold-forming process. Manufacturers apply specialized lubricants through drip, spray, or roller methods to create a protective layer that reduces die damage and minimizes defect rates.

Die stamping uses four main types of presses, each with distinct force-generating mechanisms:

- Mechanical Presses: Using stored energy from flywheels

- Hydraulic Presses: Employing pressurized incompressible fluid

- Servo Presses: Utilizing precise servomotors

- Pneumatic Presses: Operating through air pressure

Servo presses are revolutionary forces that allow programmable dwell time at the bottom of each stroke. This feature ensures a perfect workpiece settling before forming and enables advanced functions like pre-heating tough materials such as stainless steel.

The process follows a clear sequence: proper die positioning in the stamping press, precise metal strip feeding through the die, execution of necessary blanking and forming actions, and automated removal of excess material. Each operation either separates the material or shapes it through plastic deformation while maintaining strict control over metal flow and dimensional accuracy.

Die stamping’s versatility goes beyond simple parts production. Manufacturers can perform multiple operations simultaneously through various die configurations, which reduces production costs and lead times. The process works with both single-function operations and sequential series of functions performed in stages, offering flexible manufacturing approaches.

Basic Types of Stamping Die

Metal stamping dies are the lifeblood of industrial production. They shape 60% to 80% of micrometal parts used in electronics, automobiles, motors, and electrical appliances. These precision tools can be classified into four main categories based on how they combine processes and what they can do.

1) Single Stamping Dies

Single stamping dies are designed to perform one specific operation per press stroke. This means that each time the press moves, it punches, blanks, bends, or deep draws the metal. These dies are simple in design and cost-effective, perfect for small batch and large batch production.

A good example of their use is in the automobile industry, where they help create vehicle body panels. Since these dies require minimal setup, manufacturers prefer them for projects that involve different production runs with frequent changes.

2) Compound Dies

Compound dies also perform multiple operations in a single stroke, but unlike progressive dies, all the actions happen at the same position. This design ensures high precision between the inner and outer shapes of the stamped parts. Compound dies are commonly used in industries that require exact measurements and efficient material usage, such as the production of washers and metal gaskets.

These dies maximize material efficiency by reducing waste and using the available metal sheets best. Material usage reaches peak efficiency as these dies handle both short materials and leftover pieces well.

3) Transfer Dies

Transfer dies work like progressive dies but uses a mechanical transfer system to move parts between stations. This unique method gives precise control over component movement, making them perfect for complex assemblies that need strict quality standards.

One of the best examples of transfer die applications is in the aerospace industry, where high-precision metal components like aircraft brackets and turbine parts are manufactured. These dies ensure that each part meets strict quality standards while maintaining a smooth production flow.

4) Progressive Dies

Progressive dies shine in high-volume manufacturing. They process metal strips through multiple stations to create complex parts. Each station handles specific operations as the metal moves through the die. The metal strip travels with precision between stations and maintains equal distances, which is called progression. Pilots line up within thousandths of an inch to achieve optimal accuracy.

The process follows a systematic workflow, starting with metal strip feeding through a reel system and precise positioning via clamping mechanisms. As the strip moves through the die, sequential operations take place at each station, leading to continuous part production and ejection. Production rates reach more than 800 parts per minute with progressive dies. This makes them perfect for automotive components and electronics manufacturing.

5) Coining Dies

Coining dies showcase precision stamping technology. They use closed-die forging principles to create intricate details and superior surface finishes. These dies put extreme pressure on metal workpieces. This causes plastic deformation that matches die shapes exactly.

Key characteristics of coining operations include complete die closure during operation, high-tonnage press requirements, improved surface detail reproduction, and reduced material thickness in processed areas. Medical device manufacturers and the jewelry industry often use coining dies. These components need exceptional precision and detailed surface patterns.

6) Embossing Dies

Embossing dies create permanent patterns on metal surfaces. They use a two-component system: the male die (punch) has raised engravings, and the matching female die (cavity) features recessed patterns. These precision-engineered tools need 2 to 5 tons per square inch of pressure for the best pattern transfer.

Materials used for embossing dies depend on the application. Tool steels like D2, M2 and S7 are used for standard applications, and carbide inserts are used for high volume production due to durability. Custom engineering is often necessary for complex patterns, and precise relief angles help ensure smooth material flow. Embossing dies in many applications. They range from industrial part marking to consumer product labeling. Their versatility helps create anti-counterfeiting marks, tamper-evident seals, and decorative patterns on metal goods.

Conclusion

Stamping dies are essential tools in modern manufacturing. They offer different solutions for different production needs: single stamping dies for specific tasks, progressive dies for complex multi-step processes, compound dies for precision and material use, and transfer dies for detailed assemblies with mechanical systems. Under ideal conditions, stamping dies can process material at high speeds, up to 1,500 cycles per minute. Specialized dies like coining and embossing add to manufacturing capabilities and are useful in automotive, medical, and consumer goods industries.

Choosing the right die type depends on volume, part complexity, and material requirements. Though the cost varies, stamping dies are of great value as they give consistent quality, high production rates, and precise metal forming. Engineering and CAD advances keep improving these tools and keeping them at the heart of efficient manufacturing.

At Fecision, we specialize in the design and manufacturing of high-precision stamping dies, tailored to your materials, tolerances, and production requirements. With advanced machining capabilities and experienced tooling engineers, we deliver durable dies that ensure reliable performance throughout their service life.

If you’re looking for a trusted partner to manufacture custom stamping dies for your metal forming projects, contact Fecision today and let us support your production with precision-engineered tooling solutions.