A heat sink is a vital part of thermal management. It’s designed to pull heat away from electronic devices to maintain optimal performance and longevity. Studies show that too much heat can shorten component life and cause system failures.

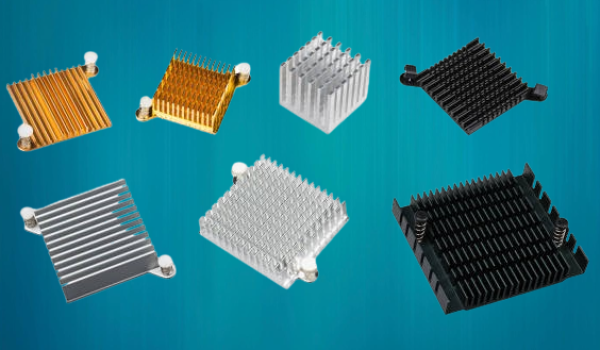

Heat sinks are categorized based on material, design and cooling mechanism. Aluminum and copper are the most common materials because of their high thermal conductivity. Choosing the right heat sink depends on application requirements, airflow, material properties and manufacturing process. This article will break down different types of heat sinks based on these criteria.

1. Heat Sinks by Airflow

a. Passive Heat Sink

A passive heat sink relies on natural convection to transfer heat from the device to the surrounding air. Since it has no moving parts, it’s more reliable and doesn’t require external power. Passive heat sinks are used in low power applications and often serve as a dual purpose device enclosure. An example is a metal casing that’s both the structural housing and heat dissipating component.

b. Active Heat Sink

An active heat sink has additional cooling mechanisms like fans, blowers, or liquid cooling systems. These heat sinks increase heat dissipation efficiency by forcing air or liquid over the heat exchanger. While they perform better, they require external power, making them less reliable than passive solutions. Active heat sinks are used in high performance computing, industrial equipment and applications that require high cooling capacity.

2. Heat Sinks by Material

a. Aluminum Heat Sink

Aluminum is the most widely used material for heat sinks because it’s lightweight, affordable and easy to manufacture. Common aluminum alloys for heat sinks production can be machined through different grades of aluminum. are:

- 6061 and 6063 – Balances strength and thermal conductivity.

- 1050 and 1100 – Higher purity and better thermal performance. Although aluminum has moderate thermal conductivity, it may not be suitable for applications that require high heat transfer rates.

b. Copper Heat Sink

Copper is a better heat conductor with thermal conductivity of around 400 W/m-K making it ideal for high performance cooling applications. However, copper is heavier and more expensive than aluminum, limiting its use in applications where weight and cost are a concern. Copper heat sinks are used in data centers, industrial machinery and critical cooling systems.

c. Hybrid (Copper-Aluminum) Heat Sink

A hybrid heat sink has a copper base with aluminum fins to balance performance, weight and cost. The copper base extracts heat from the source while the aluminum fins dissipate heat. This design is used in electronics cooling where moderate cost and high performance are required.

3. Heat Sinks by Use of Water

a. Solid Metal Heat Sink

Solid metal heat sinks are the most common type, consisting of a solid metal base and an array of fins that dissipate heat into the air. These heat sinks are made from aluminum or copper and are a cost effective cooling solution for various electronics. Its simplicity and durability make it the most widely used heat sink type in consumer electronics and industrial applications.

b. Pumped Liquid Heat Sink

Pumped liquid heat sinks use a coolant circulated through a cold plate attached to the heat source. The liquid absorbs heat and carries it away to a separate heat exchanger where it’s dissipated. While highly effective, this method introduces additional components like pumps and tubing, reducing overall reliability. Pumped liquid cooling is used in high performance computing, medical devices, and industrial applications where extreme heat loads need to be managed.

c. Two-Phase Heat Sink

Two-phase heat sinks have vapor chambers or heat pipes to enhance heat transfer. These devices use phase-change technology to move heat efficiently across a surface. Heat pipes transfer heat through a working fluid that evaporates and condenses cyclically, while vapor chambers spread heat uniformly across a large surface area. Two-phase heat sinks are as reliable as solid metal designs but provide better cooling performance at a slightly higher cost.

4. Heat Sinks by Manufacturing Process

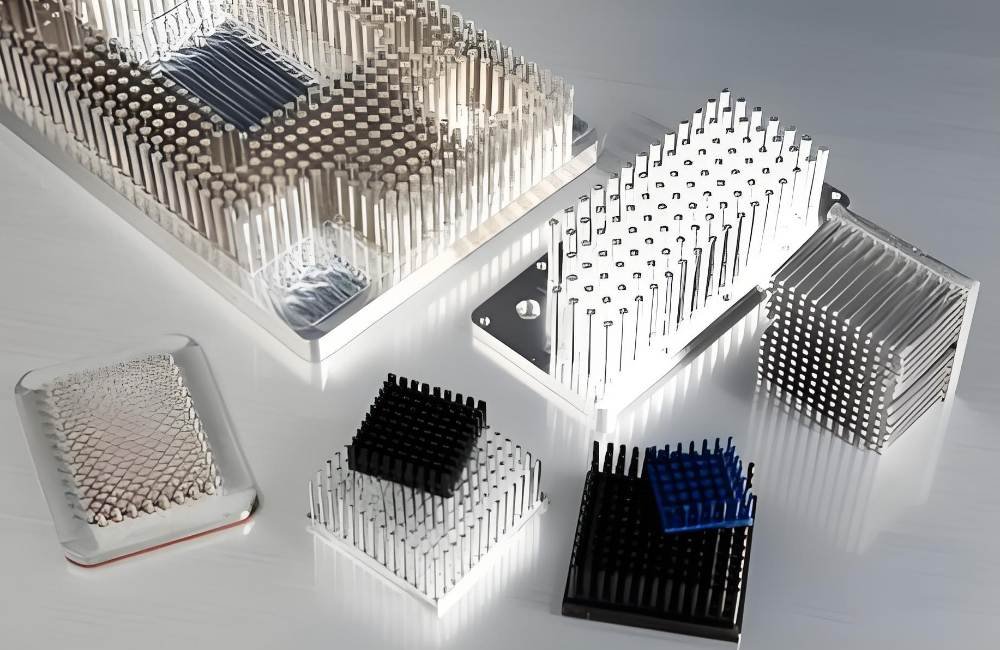

a. CNC Machined Heat Sink

CNC machined heat sinks allow for complex, high-precision designs with excellent thermal properties. However, this manufacturing process is expensive and time-consuming, making it unsuitable for mass production. CNC machined heat sinks are used in custom applications where performance and precision outweigh cost considerations.

b. Forged & Die Cast Heat Sink

Forged and die-cast heat sinks are cost effective solutions for high volume production. Forging allows intricate heat sink designs, while die-casting is ideal for thick fins used in natural convection applications. However, both require significant upfront tooling cost, making it more suitable for large scale manufacturing.

c. Zipper Fin Heat Sink.

Zipper fin heat sinks have thin, densely packed fins for high performance. They are often used with heat pipes or vapor chambers to maximize heat dissipation. A good balance of performance and cost makes them suitable for mid-to-high performance applications.

d. Skived Fin Heat Sink

Skived fin heat sinks have thin, high-aspect-ratio fins carved directly from a solid metal block for high performance. This method allows for tight fin packing without additional bonding or assembly. While skived heat sinks are efficient, the fins can be fragile and prone to bending.

e. Bonded Fin Heat Sink

Bonded fin heat sinks are for large cooling applications where maximum heat dissipation is required. This method allows for different materials for base and fins, offering design flexibility. Bonded fin heat sinks are used in power electronics and industrial cooling systems.

f. Extruded Heat Sink

Extruded heat sinks are the most cost-effective option. They are produced by forcing aluminum through a die to create a continuous shape which is then cut to size. While extrusion limits design flexibility, secondary machining can enhance performance. Extruded heat sinks are used in consumer electronics and moderate performance applications.

Conclusion

Choosing a heat sink involves considering performance, material, cost and application requirements. Passive and active heat sinks cater to different airflow needs, while aluminum and copper heat sinks have different advantages based on cost and performance. Two-phase heat sinks improve performance in high performance applications.

At Fecision, we provide precision machining services for custom heat sinks, delivering tight tolerances, excellent thermal performance, and material options tailored to your specific application. Whether you need prototypes or large-scale production, our advanced manufacturing capabilities ensure heat sinks that meet your exact thermal and mechanical requirements.

Partner with Fecision today to create high-performance, custom-machined heat sinks designed for superior cooling efficiency.