When it comes to selecting the appropriate fastener for your applications, understanding the different types available and their uses is essential. Fasteners are mechanical devices designed to join two or more components together, either permanently or temporarily, without causing damage to the materials.

Choosing the right fastener involves considering factors such as the materials being joined, the environmental conditions, and the required durability. By understanding fastener specifications, standards, and compatibility, you can ensure optimal performance and safety in your projects.

Understanding Fasteners

What is a Fastener?

A fastener is a hardware device that mechanically joins or affixes two or more objects together. Fasteners provide a secure assembly, enabling the creation of complex structures and machines. They come in various forms, each designed for specific applications and requirements.

The diversity among fastener types arises from the demanding forces they must withstand. Reliable fasteners are crucial for holding parts, machine assemblies, sheet metal, and construction components together.

Permanent vs. Non-Permanent Fasteners

Fasteners can be categorized into two main types: permanent and non-permanent. Permanent fasteners, such as rivets and welds, create irreversible joints that cannot be easily disassembled. They provide maximum strength and stability but limit the ability to dismantle the assembly for maintenance or modification.

On the other hand, non-permanent fasteners, like screws and bolts, allow for disassembly, repair, or maintenance of the joined components. They offer flexibility for future adjustments, repairs, or component replacement while still providing reliable connections.

Understanding the distinction between these two types is crucial for choosing the right fastener for your project, considering factors such as manufacturing processes, maintenance schedules, and product lifecycle management.

Common Types of Fasteners

Fasteners come in a variety of forms, each designed to serve a specific purpose in different applications. Understanding the different types of fasteners is crucial for selecting the right one for your project, ensuring strength, durability, and safety.

Threaded vs. Non-Threaded Fasteners

Fasteners can be broadly categorized into threaded and non-threaded types. Threaded fasteners, such as screws and bolts, have threads that provide a strong grip in materials, making them ideal for applications where high torque or tensile strength is required. Non-threaded fasteners, like rivets and pins, do not have threads and are often used in situations where a permanent or semi-permanent joint is needed.

The choice between threaded and non-threaded fasteners depends on the specific requirements of your project, including the type of material, the load-bearing capacity needed, and whether the joint needs to be disassembled in the future.

Mechanical vs. Chemical Fasteners

Another way to classify fasteners is into mechanical and chemical categories. Mechanical fasteners create physical connections between parts through interference, friction, or interlocking components. Examples include screws, bolts, and rivets, which provide immediate strength and can often be disassembled.

Chemical fasteners, on the other hand, form bonds through adhesion or chemical reactions. Adhesives and epoxies are common examples, offering benefits such as evenly distributed stress, resistance to environmental factors, and the ability to join dissimilar materials without causing galvanic corrosion.

Threaded Fasteners: Screws

When it comes to threaded fasteners, screws are among the most versatile and widely used options. Screws are designed to join two or more materials together by creating a threaded connection. They come in a variety of types, each suited to specific applications and materials.

Machine Screws

Machine screws are used with pre-tapped holes or with nuts to fasten metal parts together. They are available in various head types, such as flat, round, or pan heads, and are commonly used in machinery, electronics, and other precision applications.

Wood Screws

Wood screws are designed for fastening wood to wood or wood to other materials. They have a coarse thread and a tapered tip, making them ideal for woodworking projects. The thread pattern provides a strong grip in wood, ensuring a secure connection.

Sheet Metal Screws

Sheet metal screws are used to fasten sheet metal to other metal parts or to wood. They have a sharp, self-tapping thread that allows them to create their own hole in thin metal, making them a convenient choice for metal fabrication projects.

Self-Drilling Screws

Self-drilling screws are specialized fasteners that eliminate the need for pre-drilling. They feature an integrated drill point tip that allows them to cut and form their own mating threads as they penetrate metal, wood, or plastic. These screws are invaluable for steel framing, roofing, HVAC ductwork, and light-gauge metal fabrication. High-performance self-drilling screws are often made from hardened steel and coated for enhanced corrosion resistance, offering rapid installation and durable fastening in high-volume applications.

You can maximize the effectiveness of self-drilling screws by understanding their categorization by point type (numbered #1-#5), with each design optimized for specific material thicknesses and applications. Proper driving techniques and tool selection are also crucial for maximizing the lifespan of these screws in your projects.

Threaded Fasteners: Bolts

Bolts, a fundamental type of threaded fastener, are widely utilized in numerous industries for their strength and reliability. They are designed to be used with nuts or tapped holes to fasten parts together securely. The versatility of bolts makes them a crucial component in construction, engineering, and manufacturing projects.

Hex Head Bolts

Hex head bolts are one of the most common types of bolts, characterized by their hexagonal head. This design allows for easy tightening and loosening with a wrench or socket. They are used in a variety of applications, from construction to machinery assembly, due to their strength and the ease with which they can be secured.

Carriage Bolts

Carriage bolts, also known as coach bolts, have a rounded head and are used in wood or metal applications where a smooth finish is required on the surface. The bolt is inserted through a pre-drilled hole, and a nut is tightened on the other end to secure it in place. They are commonly used in deck building and other woodworking projects.

Eye Bolts

Eye bolts have a loop or “eye” at one end, which is used for attaching cables, ropes, or chains. They are designed for applications where a secure attachment point is needed, such as in rigging, lifting, and securing heavy loads. The threaded end of the eye bolt is screwed into a tapped hole or secured with a nut.

Anchor Bolts

Anchor bolts are specialized fasteners designed to secure structural elements or equipment to concrete or masonry foundations. They come in various configurations, including L-shaped, J-shaped, and sleeve anchor bolts, each tailored for optimal holding strength and load transfer. Proper selection and installation of anchor bolts are critical for construction safety and reliability, especially in steel construction where they embed into concrete.

Threaded Fasteners: Nuts

As a critical element in fastening systems, nuts are designed to work in tandem with bolts to provide secure connections. Nuts are available in various types, each with its own set of characteristics and applications.

Hex Nuts

Hex nuts are one of the most common types of nuts, characterized by their hexagonal shape. This design allows for easy tightening and loosening with a wrench. Hex nuts are widely used in construction, machinery, and automotive applications due to their versatility and reliability.

Lock Nuts

Lock nuts are designed to provide a secure connection by preventing the nut from loosening over time. They are often used in applications where vibration or movement could cause standard nuts to come loose. Lock nuts are available in various designs, including those with nylon inserts or distorted threads.

Wing Nuts and Cap Nuts

Wing nuts feature distinctive “wings” that allow for hand tightening without tools, making them ideal for applications requiring frequent adjustment. Cap nuts, also known as acorn or dome nuts, have a domed end that covers the bolt thread, enhancing safety, reducing corrosion, and improving appearance. Both types are used in applications where ease of use and aesthetics are important.

Types of Fastener Heads and Drives

Understanding the different types of fastener heads and drives is crucial for choosing the right fastener for your project. The type of driver used to install or remove a bolt or screw impacts torque, access, and efficiency of installation. Using the correct driver ensures optimal engagement, reduces stripping or cam-out, and increases productivity for professionals in construction, automotive, and manufacturing industries.

Common Head Types

Fastener heads come in various shapes and sizes, each designed for specific applications. While the details of each head type are unique, they all serve the purpose of providing a means to install or remove the fastener. The choice of head type depends on the specific requirements of the project, including the tooling available and the desired appearance.

Drive Types

Drive types refer to the pattern recessed into fastener heads that accepts matching driver tools for installation and removal. You’ll find various drive types, each with its advantages and typical applications. For instance, slotted drives are the oldest and simplest design, accepting flat-blade screwdrivers but offering limited torque capacity. In contrast, Phillips drives feature a cross-shaped recess that provides better centering and torque transfer.

Other drive types include Pozidriv, which improves upon the Phillips design by reducing cam-out and allowing higher torque application. Hex (Allen) drives provide excellent torque transfer through six-point contact in a hexagonal recess, making them popular in furniture assembly and machinery. Torx (star) drives offer superior torque transfer through six-lobed recesses that resist cam-out and stripping, even at high torque levels.

Additionally, square (Robertson) drives are known for their excellent driver engagement and torque transfer through a square recess, commonly used in woodworking and deck construction. Security drive types incorporate special features to prevent unauthorized removal, including tamper-resistant Torx, one-way heads, and pin-in-socket designs. By choosing the right drive type, you can ensure that your fasteners are installed efficiently and securely.

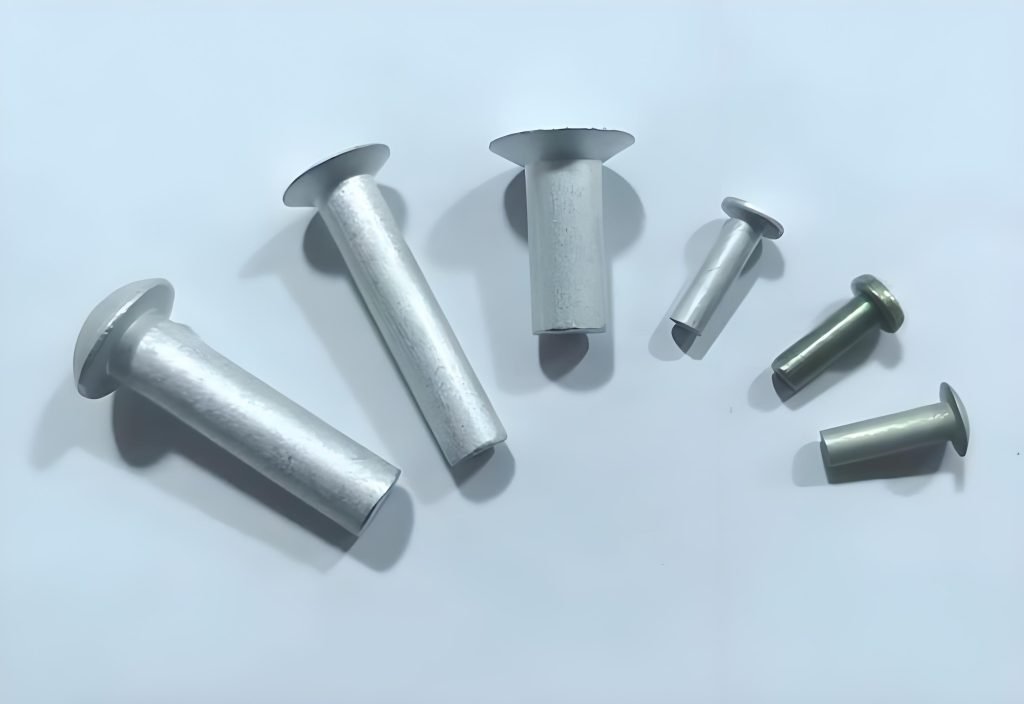

Non-Threaded Fasteners: Rivets

You might not always notice them, but rivets are essential in creating strong, lasting joints in various applications. Rivets are a type of non-threaded fastener that provides a permanent solution for joining materials. They are widely used in construction, manufacturing, and other industries where strong, reliable joints are crucial.

Solid Rivets

Solid rivets are one of the most common types of rivets used in various applications. They are made from a single piece of metal and are known for their strength and reliability. When installed, the rivet is deformed on the tail end to create a secure joint. Solid rivets are often used in structural applications where high strength is required.

Blind Rivets

Blind rivets, also known as pop rivets, are designed for situations where access to the tail end of the rivet is limited. They consist of a mandrel and a rivet body. When the mandrel is pulled, it causes the rivet to expand and secure the materials together. Blind rivets are commonly used in applications where only one side of the material is accessible.

Tubular Rivets

Tubular rivets are similar to solid rivets but feature a partial hole at the tail end. This design makes them easier to install, as less force is required to deform the hollow end. The rivet is rolled or flared outward, creating a secure connection. Tubular rivets are commonly used in electronics, HVAC ductwork, and lighting fixtures where a lighter fastening solution is sufficient. They are available in various materials, including aluminum, brass, copper, and steel, to suit different aesthetic and functional requirements.

Non-Threaded Fasteners: Pins and Retainers

Non-threaded fasteners, including pins and retainers, are essential components in various mechanical assemblies. They provide a reliable means of securing parts together without the need for threading.

These fasteners come in different forms, each designed for specific applications. Understanding their types and uses is crucial for selecting the right fastener for your project.

Dowel Pins

Dowel pins are used to align and secure components in place. They are typically made from hardened steel and are designed to fit snugly into corresponding holes in mating parts.

Cotter Pins

Cotter pins are used to secure bolts and other fasteners in place. They work by passing through a hole in the fastener and then being bent or spread to prevent it from coming loose.

Retaining Rings

Retaining rings, also known as snap rings or circlips, are specialized fasteners that fit into grooves to hold components in axial position on shafts or within bores. They are available in two main types: external rings that fit around shafts and internal rings that fit inside holes or housings.

Retaining rings provide quick, tool-accessible component retention while allowing for disassembly when needed. They are commonly used in transmissions, motors, pumps, and other mechanical assemblies to secure bearings, gears, and other components. The rings are available in various materials and finishes to suit different strength requirements and environmental conditions.

Washers and Their Functions

Washers are a crucial component in various fastening systems, playing a key role in distributing load and ensuring the stability of assemblies. They are used under the head of a bolt or screw to provide a smooth, even surface, and to help distribute the load evenly. This helps prevent damage to the surface of the material being fastened.

Flat Washers

Flat washers are used to distribute the load of a fastener, providing a larger bearing surface and helping to prevent damage to the material being fastened. They are commonly used in applications where the material is soft or prone to damage.

Lock Washers

Lock washers are designed to provide a secure fastening by preventing the nut or bolt from loosening due to vibration or other external forces. They work by applying a spring-like force against the nut or bolt head, keeping it in place.

Spring Washers

Spring washers are flexible, resilient fastener components designed to maintain tension and absorb shock in bolted assemblies. They come in various forms, including wave washers, curved washers, and Belleville washers. Spring washers provide constant tension even when materials compress or when thermal expansion/contraction occurs, making them ideal for applications subject to vibration or dynamic loads, such as electrical connections, automotive suspensions, and machinery.

By understanding the different types of washers and their functions, you can choose the right washer for your specific fastening needs, ensuring a secure and stable assembly.

Materials Used for Making Fasteners

The choice of material for fasteners can significantly impact their performance. Different materials offer varying levels of strength, corrosion resistance, and other properties that are crucial for specific applications.

Steel Fasteners

Steel is one of the most common materials used for fasteners due to its high strength and durability. Steel fasteners are suitable for a wide range of applications, from construction to automotive. They can be further categorized into different grades based on their composition and properties.

Stainless Steel Fasteners

Stainless steel fasteners offer excellent corrosion resistance, making them ideal for use in harsh environments. They are commonly used in marine, chemical processing, and food processing industries where exposure to corrosive substances is a concern.

Non-Ferrous Fastener Materials

Non-ferrous materials such as aluminum, brass, bronze, copper, and titanium are used for fasteners in specialized applications. Aluminum fasteners are lightweight and corrosion-resistant, making them suitable for aerospace and marine applications. Brass and bronze fasteners offer good corrosion resistance and electrical conductivity, while titanium fasteners provide an exceptional strength-to-weight ratio and outstanding corrosion resistance.

Fasteners may also be coated with materials like chrome or zinc for added functionality, such as enhanced corrosion resistance or electrical insulation. Understanding the properties and applications of these materials is crucial for selecting the right fastener for your project.

Fastener Standards and Specifications

Fastener standards and specifications are foundational elements in the production of high-quality fasteners. These standards ensure that fasteners meet specific requirements for material, design, and performance, facilitating compatibility and reliability across different applications and industries.

ASME Standards

The American Society of Mechanical Engineers (ASME) provides a range of standards for fasteners, covering various types and applications. ASME standards include specifications for rivets (B18.1.1 and B18.1.2), metric hex cap screws (B18.2.3.1M), socket cap and set screws (B18.3), wood screws (B18.6.1), and machine screws (B18.6.3). Additionally, ASME B18.18 addresses quality assurance for fasteners, ensuring that they meet stringent performance and safety criteria.

ISO and Metric Standards

ISO (International Organization for Standardization) standards provide globally recognized specifications for metric fasteners used worldwide. These standards ensure international compatibility and interchangeability, facilitating global trade and manufacturing. ISO 898 defines mechanical properties for steel fasteners, while ISO 4759 covers dimensional tolerances. Metric fasteners are designated by diameter, pitch, and length in millimeters (e.g., M10x1.5×25), making specifications clear and consistent. ISO property classes (such as 8.8, 10.9, and 12.9 for bolts) indicate strength characteristics. DIN standards, closely related to ISO standards, remain widely referenced in European manufacturing.

Specialized Fasteners for Specific Applications

When it comes to fastening solutions, different industries require specialized fasteners tailored to their unique needs. Understanding the distinctions among fastener types is essential for selecting the right fastening solution for application-specific requirements, ensuring structural integrity and serviceability.

Automotive Fasteners

Automotive fasteners are designed to withstand the harsh conditions of the automotive environment, including extreme temperatures, vibrations, and corrosive substances. These fasteners are used in various vehicle components, such as engines, transmissions, and chassis.

Construction Fasteners

Construction fasteners are engineered for building and construction applications, where they are subjected to heavy loads, weathering, and other environmental factors. Examples include fasteners used in framing, roofing, and decking.

Electronics and Precision Fasteners

Electronics and precision fasteners are miniaturized, highly specialized components designed for electronic devices, medical equipment, and precision instruments. You’ll find micro screws and fasteners with thread diameters as small as 0.5mm (M0.5) used in smartphones, wearable devices, and miniature electronics. These fasteners often feature specialized head designs, such as Torx or hex socket, to enable precise torque application in confined spaces. Electronics fasteners are frequently made from non-magnetic materials or feature specialized coatings to prevent interference with sensitive components.

Precision fasteners often have extremely tight tolerances and specialized thread forms to ensure reliable assembly in critical applications. These specialized fasteners may incorporate features like thread-locking patches, captive designs, or self-retaining mechanisms to simplify assembly processes.

How to Choose the Right Fastener for Your Project

Selecting the right fastener for your project is crucial for its success and longevity. With numerous types of fasteners available, each designed for specific applications and materials, making an informed decision can be challenging.

To ensure you choose the most suitable fastener, several factors need to be considered. These include the load requirements of your project, environmental conditions, material compatibility, and installation and maintenance needs.

Considering Load Requirements

Understanding the load requirements is critical. Different fasteners are designed to handle various types of loads, such as tensile, shear, or a combination of both. For instance, if your project involves heavy machinery or structural components, you’ll need fasteners that can withstand significant forces.

Environmental Factors

Environmental conditions, including exposure to moisture, extreme temperatures, or corrosive substances, play a significant role in fastener selection. For example, stainless steel or coated fasteners might be necessary for projects exposed to harsh environments to prevent corrosion.

Material Compatibility

The material of the fastener must be compatible with the materials it will be fastening. For instance, using wood screws for wood or anchor bolts for concrete ensures a secure hold. Material incompatibility can lead to failures or damage.

Installation and Maintenance Needs

Practical considerations, such as the ease of installation and future maintenance, should also influence your choice. Selecting fasteners that are appropriate for the tools available and the required torque can save time and labor costs. Additionally, considering whether removable or permanent fasteners are needed can impact the long-term performance and serviceability of your project.

By carefully evaluating these factors, you can select the right fastener for your project, ensuring its efficiency, longevity, and overall success.

Conclusion

Now that you’re familiar with the different types of fasteners, you can make informed decisions for your project. You’ve learned about the various fasteners available, their specific applications, and the factors to consider when choosing the right fastener. This knowledge enables you to ensure the safety, durability, and functionality of your projects. Remember, selecting the correct fastener is crucial, and consulting with specialists can provide additional expertise for critical applications. By understanding the different types of fasteners and their use, you can optimize the performance and longevity of your projects.