Machining is the backbone of modern manufacturing, a vital procedure that takes raw resources, and shapes them into the precise components needed for countless industries. Think of the intricate parts in an airplane, the sub-components in a medical device, or the necessary pieces in your car’s engine—all made possible through the process of machining. Machining is the process of converting raw materials into finished products with incredible accuracy.

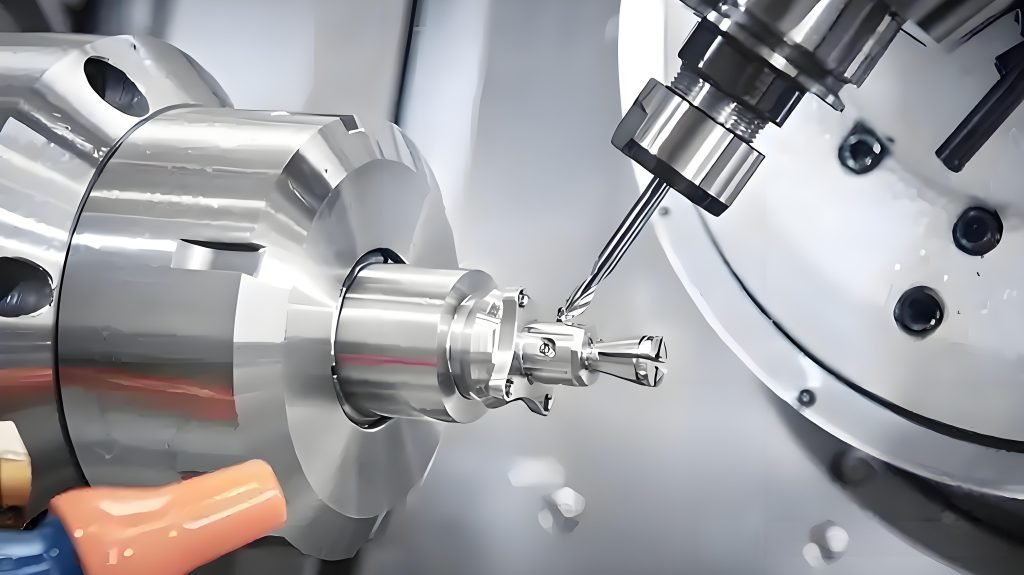

CNC (Computer Numerical Control) machining has not only opened the door to machining, but it has also brought about accuracy and efficiency. This technology has radically altered all machining processes, allowing manufacturers to formulate complex geometries and achieve consistent precision. In this article, we are going to look at the top 10 CNC machining types and how they shape the manufacturing environment.

What is Machining?

Machining is a subtractive manufacturing process that removes unwanted materials from a workpiece to achieve a useful shape, size, or surface finish. Unlike additive processes that add on material, machining is all about taking it away. Specialized tools are employed, namely cutting tools, abrasive wheels, and discs; these tools are controlled in such a manner that they shear, grind, or remove excess material. This process is a primary means of converting raw material, which can be metal, plastic, or composite, into parts that are installed in products that are used across diverse industries, from consumer goods to heavy equipment.

What is the Purpose of Machining?

Machining has multiple essential and critical functions during manufacturing, helping to create high-quality and functional parts.

Shaping & Sizing

Machining in manufacturing is used for the controlled removal of material in order to define a part’s geometry and dimensions. It optimally removes material to create various forms (e.g., perfectly flat surfaces, precisely cylindrical shafts, accurately sized holes, complex grooves and contours, etc). This ability is necessary when creating components that require precise shapes or tolerances, such as machining a round hole in a plate for a bearing or a flat surface for a sealing gasket.

Achieving Dimensional Accuracy

Machining is commonly known for its ability to create parts that have very tight tolerances. The final dimension of a part can be controlled within a few thousandths of an inch, or finer. This is necessary for applications where parts must fit perfectly together, function together, and collectively perform the same way each time. For example, if there is even a slight tolerance issue in an aerospace engine, it could cause a major failure of the assembly.

Surface Finishing

In addition to creating shapes, some machining operations —such as grinding— are utilized to improve a part’s surface finish. The surface finish of a part is important as it is not just a matter of appearance. A better surface finish has a direct influence on a part’s performance, function, and also durability. It can reduce friction, increase wear resistance, improve sealing capabilities, and increase fatigue life on components.

Excessive Material Removal

Raw materials often come in the form of standard shapes, like bars, plates, and castings. Machining in manufacturing is particularly important because it allows manufacturers to remove the wasteful raw material and reveal the desired final shape. Machining can efficiently facilitate the use of raw materials and also ensure that only the necessary material remains.

Customization and Flexibility

Machining will provide a high amount of flexibility in reference to manufacturing unique or custom parts. Processes that involve costly molds and dies apply restrictions on flexibility. Machining does not; it allows quick alterations of the original design without huge retooling costs. This fits prototyping and low-volume part production and is ideal for part production where they need special pieces for unique applications.

Cost-effectiveness

Because machining does not require the same hefty upfront investment in tooling or molds that many other manufacturing processes do, it can be surprisingly cost-effective, especially for small to medium production runs. This can lead to substantial savings, especially regarding design iterations or differences in parts.

Integration with Other Processes

Machining typically does not work alone. It is mostly in conjunction with other manufacturing processes such as casting, forging or sometimes even additive manufacturing (3D printing). For instance, a part could be cast very close to a final shape and then machined to get the precise dimensions and surface finishes. These different processes will enhance the properties of the finished part. Each process will have its strengths, which can be developed into an excellent product.

Top 10 Types of Machining Processes

Now, let’s look at the top 10 CNC machining types that are the bedrock of modern manufacturing.

Turning

Turning is a CNC machining process where a workpiece rotates quickly, while a single point cutting tool remains stationary and removes material. The tool travels along the length of the rotating workpiece to create cylindrical shapes. Turning is the most adaptable of all machining processes and has the highly regarded ability to routinely reproduce parts with equivalent high precision and exceptional finishes, from all types of material such as metal, plastics, and composites.

Applications:

- Shafts

- Bolts

- Engine parts

- Musical instruments (e.g., brass instruments)

Drilling

Drilling is defined as the creation of cylindrical-shaped holes in a workpiece using a multi-point drill bit. The drill bit rotates and advances into the material. Drilling is a fundamental operation and is typically used as a starting phase for tapping (producing internal threads) or creating holes to accommodate fasteners.

Applications:

- Fastener holes

- Preparation for tapping

- Construction (e.g., holes in structural beams)

- Medical equipment (e.g., holes in surgical instruments)

Milling

Milling uses rotating multi-point cutting tools to remove material while the workpiece is stationary. Unlike turning where the workpiece rotates as cutters cut into it, in milling, the cutter rotates, and the work is fed into the cutter. Milling can engrave many shapes including flat surfaces, slots, and pockets, but also complex three-dimensional shapes with ease. Modern CNC milling machines can make very high-detail and precise parts.

Applications:

- Gears

- Dies

- Molds

- Slots

- Pockets

- Grooves

Grinding

Grinding is a finishing process to remove very small amounts of material with an abrasive wheel to achieve precise dimensions and very smooth surfaces. The abrasive materials on the wheel function as tiny cutting tools. It is normally used after other machining processes to achieve the final required tolerance and finishing.

Applications:

- Surface finishing

- Precision machining of hardened materials

- Deburring (removing sharp edges)

Sawing

Sawing is a CNC machining process assisted by a saw blade with multiple teeth. It is used to cut material from longer material lengths down to shorter lengths or to specified shapes. Sawing is primarily a material preparation process; it is often used to prepare stock material down to manageable materials before further machining operations. Sawing is manual or automated, and the type of saw blade used will depend on the material being sawn.

Applications:

- Creating shorter lengths from extruded shapes

- Cutting bars and pipes

- Sectioning raw materials

Planing

Planing is a machining method for the removal of material from very large, generally flat surfaces with a single-point cutting tool. The workpiece will usually move back and forth in linear motion, while the fixed cutting tool takes multiple cuts from the surface.

This process is ideal for providing large, flat, and in many cases, precise dimensions on workpieces that are outside the capability of a milling machine. Planing is a common practice in preparing large castings or forgings for further machining, so that will be flat on the machined surface and consistent from casting to casting.

Applications:

- Machine tool components (e.g., machine beds)

- Jigs

- Fixtures

Broaching

Broaching is a highly specialized CNC machining process that uses a multi-tooth cutting tool called a broach. The broach has a series of cutting edges that are each progressively larger. The broach is drawn or pushed in a single pass past the workpiece and has the ability to create intricate internal or external shapes, with high precision and excellent surface finish. It can be used to create shapes such as keyways, splines and square holes.

Applications:

- Keyways

- Splines

- Square holes

- Internal gears

Electrical Discharge Machining (EDM)

EDM(Electrical Discharge Machining ), or spark machining, is defined as a non-conventional machining process that removes or erodes material through very controlled electrical discharges (sparks) between an electrode and the workpiece. EDM is extremely useful for machining anything that is hard, tough, or exotic materials which may be impossible to machine with traditional cutting tools. It permits the manufacture of some very ornate shapes and fine features.

Applications:

- Machining hardened steels and exotic alloys

- Creating complex die and mold cavities

- Producing small holes and intricate designs

Chemical Machining

Chemical machining, or photochemical machining, is a subtractive process that removes material by immersion of the workpiece in a chemical etchant solution. Portions of the workpiece that are not to be removed are protected by a masking agent. This process works very well for the production of intricate designs, thin parts, and machining of very hard, brittle, or very thin material without mechanical stresses being induced.

Applications:

- Machining hard, brittle materials (e.g., ceramics, glass)

- Creating intricate designs in thin sheet metals

- Manufacturing micro-components for electronics

Electrochemical Machining (ECM)

Electrochemical Machining (ECM) is another non-conventional machining process that removes material via electrochemical interactions. Unlike EDM, there is no sparking; through an electrolytic dissolution process, the part is effectively removed one atom at a time. The workpiece acts as the anode, and a shaped tool acts as the cathode with an electrolyte flowing between the two.

Applications:

- Machining hard metals (e.g., nickel alloys, titanium)

- Producing smooth surface finishes on complex geometries

- Creating turbine blades and medical implants

Machining Processes—Recap

Here’s a quick reference list of the top 10 machining processes we’ve discussed:

Overview

| Machining Process | Type & Key Characteristics | Applications & Industries | Example Products |

| Turning | Material Removal– Rotating workpiece, single-point cutting tool for cylindrical shapes | Automotive, Aerospace, Musical Instruments | Shafts, bolts, engine parts, brass instruments |

| Drilling | Material Removal – Multi-point drill bit creates cylindrical holes | Construction, Medical, Manufacturing | Fastener holes, surgical instrument holes |

| Milling | Material Removal – Rotating multi-point cutter removes material from a stationary workpiece | Automotive, Mold Making, Aerospace | Gears, dies, slots, 3D contours |

| Grinding | Material Finishing – Abrasive wheel achieves high precision & smooth surfaces | Precision Engineering, Tool Making | High-tolerance parts, deburred edges |

| Sawing | Material Cutting – Multi-tooth blade cuts stock material into shorter lengths | Metalworking, Construction | Cut bars, pipes, raw material sections |

| Planing | Material Removal – Single-point tool creates large, flat surfaces | Heavy Machinery, Shipbuilding | Machine beds, large flat surfaces |

| Broaching | Material Cutting – Multi-tooth broach forms complex shapes in one pass | Automotive (transmissions), Aerospace | Keyways, splines, internal gears |

| Electrical Discharge Machining (EDM) | Precision Machining – Spark erosion for hard materials, no direct contact | Die/Mold Making, Micro-Machining | Complex mold cavities, micro-holes |

| Chemical Machining | Material Removal – Chemical etching removes material without mechanical stress | Electronics, Aerospace (thin parts) | Circuit boards, precision foil components |

| Electrochemical Machining (ECM) | Precision Machining – Electrolytic dissolution, no tool wear, smooth finishes | Turbine Manufacturing, Medical Implants | Turbine blades, implant surfaces |

Fecision – Best CNC Machining Service Provider

Selecting the most appropriate machining process is mission-critical for the success of your project. It designs everything from costs and lead times to the final quality and function of your parts.

Here at Fecision, we can provide high-precision CNC machining services, carefully tuned to meet industry requirements. Our 3, 4, and 5-axis CNC mills and turning capabilities produce complex parts with very tight tolerances, with tolerances finer than ±0.005 mm.

Our customers are working in aerospace, medical, automotive, and electronics applications where precision is key. From single prototype to high-volume production, we have experience with materials ranging from aluminum and stainless steel to titanium, brass, and engineering plastics. We also offer secondary services such as surface finishing, heat treatment and assembly to ensure we can provide a full end-to-end solution.

Why Choose Fecision for CNC Machining?

- Precision Engineering: We are ISO-certified to hold tolerances, and every component is consistently of the highest quality.

- Advanced Technology: Our multi-axis CNC machines are the newest technologies available for complex designs, producing practically superior quality.

- Expert Knowledge of Material: We machine any material, from common metals to exotics, unique to all your application’s needs.

- Fast Turnaround: We have rapid prototypes delivered within 3 – 5 days, and if you’re planning to scale up, we produce any size or quantity with lead times that work for you.

- Custom Solutions: Our Design-for-Manufacturability (DFM) supports your designs in terms of cost savings and improved performance.

Get in touch with Fecision to collaborate on precise and high-quality CNC machining services. Ready to get started building your design with precision and efficiency? Contact us right away!