Understanding a material’s ability to conduct heat is crucial in various manufacturing processes. Thermal conductivity is a measure of this ability, denoted by k, λ, or κ, and is measured in W·m−1·K−1.

In manufacturing, heat transfer plays a significant role, and materials with low conductivity transfer heat at a lower rate compared to those with high conductivity. Fourier’s law for heat conduction defines this relationship as q = -k∇T, where q is the heat flux, k is the thermal conductivity, and ∇T is the temperature gradient.

As a manufacturing professional, understanding material properties like conductivity is essential for optimizing production processes and ensuring energy efficiency. Proper material selection can significantly impact manufacturing operations, from injection molding to electronic component production.

Understanding Thermal Conductivity in Manufacturing

In the manufacturing industry, thermal conductivity is a key property that influences the performance of materials and processes. As you delve into the world of manufacturing, it’s essential to grasp the concept of thermal conductivity and its far-reaching implications.

Definition and Basic Concepts

Thermal conductivity refers to the ability of a material to conduct heat. It is a measure of how easily heat can flow through a material. Materials with high thermal conductivity, such as metals, can efficiently transfer heat, while those with low thermal conductivity, like insulators, resist heat flow. Understanding this property is crucial for selecting the right materials for specific manufacturing applications.

The basic concept of thermal conductivity is rooted in the way materials respond to temperature differences. When there’s a temperature gradient, heat flows from the hotter region to the cooler one. The rate at which this heat transfer occurs is directly related to the material’s thermal conductivity.

Why Thermal Conductivity Matters in Industry

Thermal conductivity plays a vital role in various manufacturing sectors, including automotive, electronics, and consumer goods production. Its impact is multifaceted, influencing production efficiency, product quality, and overall cost-effectiveness. By understanding and managing thermal conductivity, manufacturers can optimize their processes, reduce energy consumption, and improve product performance.

For instance, in injection molding, thermal conductivity affects the cooling rate of molten plastic, which in turn influences cycle times and product quality. In electronics manufacturing, materials with high thermal conductivity are used to dissipate heat from sensitive components, ensuring reliable operation. By carefully selecting materials based on their thermal conductivity, manufacturers can minimize heat-related defects and improve overall product reliability.

Moreover, optimizing thermal conductivity can lead to significant cost savings. By reducing cycle times and energy consumption, manufacturers can lower their operational costs while maintaining or improving product quality. As the manufacturing industry continues to evolve, understanding and leveraging thermal conductivity will remain crucial for achieving sustainability and energy efficiency goals.

The Science Behind Thermal Conductivity

The science behind thermal conductivity involves complex mechanisms that enable efficient heat transfer in various materials. You need to understand these mechanisms to appreciate how different materials respond to temperature changes, which is crucial in manufacturing processes.

Heat Transfer Mechanisms

Thermal conduction occurs through different mechanisms depending on the state of matter. In solids, it primarily happens through two mechanisms: the migration of free electrons and lattice vibrations, also known as phonons. The first mechanism is dominant in pure metals, where delocalized electron movement within metallic bonding facilitates high thermal conductivity. In contrast, non-metallic solids rely more on lattice vibrations for heat transfer.

In a gas, thermal conduction is mediated by discrete molecular collisions. Understanding these mechanisms is essential for selecting materials in manufacturing processes where heat management is critical.

Molecular Basis of Thermal Conduction

At the molecular level, thermal conduction is influenced by the arrangement and interaction of atoms within a material’s structure. In metals, the presence of free electrons allows for efficient energy transfer, making them good conductors of heat. In non-metallic materials like polymers and ceramics, lattice vibrations play a more significant role in thermal conduction.

The molecular structure and arrangement significantly affect a material’s thermal conductivity. Crystalline materials, with their ordered structure, typically conduct heat better than amorphous materials. This understanding helps in selecting and designing materials for specific manufacturing applications where thermal properties are crucial.

Thermal Conductivity Formula and Units

Understanding thermal conductivity is crucial for optimizing manufacturing processes, and it starts with grasping the fundamental formula and units involved. Thermal conductivity is a measure of a material’s ability to conduct heat, and quantifying this property is essential for various industrial applications.

Fourier’s Law of Heat Conduction

Fourier’s Law of Heat Conduction is the foundation for understanding thermal conductivity. It states that the heat flux through a material is proportional to the negative gradient of temperature and the area through which the heat flows. Mathematically, this is expressed as q = -kA(dT/dx), where q is the heat flux, k is the thermal conductivity, A is the cross-sectional area, and dT/dx is the temperature gradient. This law forms the basis for measuring thermal conductivity.

SI Units and Conversion Factors

In the International System of Units (SI), thermal conductivity is measured in watts per meter-kelvin (W/(m⋅K)). This unit represents the amount of heat that flows through a unit area of a material with a given thickness when there is a temperature difference between the two sides. Other units like watts per centimeter-kelvin [W/(cm⋅K)] and imperial units such as BTU/(h⋅ft⋅°F) are also used in different contexts. To facilitate conversions between these units, specific conversion factors are applied. For instance, to convert from W/(m⋅K) to BTU/(h⋅ft⋅°F), you can use the conversion factor: 1 W/(m⋅K) = 0.5778 BTU/(h⋅ft⋅°F).

Understanding these units and being able to convert between them is crucial for manufacturing professionals working with international specifications or legacy data. The dimensional analysis of thermal conductivity (MLTΘ) relates to other thermal properties relevant to manufacturing, such as thermal resistance, thermal diffusivity, and heat capacity.

Thermal Conductivity Measurement Techniques

Understanding how to measure thermal conductivity is essential for optimizing manufacturing processes. Thermal conductivity measurement techniques are vital for determining the thermal properties of materials, which directly influence their performance in various applications.

Steady-State Methods

Steady-state methods involve establishing a constant temperature gradient across a sample. These techniques require careful control of the experimental conditions to ensure accuracy. The guarded hot plate method is a common steady-state technique used for measuring thermal conductivity.

Steady-state methods provide reliable data on a material’s thermal conductivity but can be time-consuming and require larger sample sizes.

Transient Methods

Transient methods, on the other hand, determine a sample’s thermal properties by observing its response to temperature changes over time. Techniques such as the Transient Hot-Wire (THW) method, the Transient Line Source (TLS) method, and the Transient Plane Source (TPS) method are commonly used.

These methods offer several advantages, including faster measurement times and the ability to test smaller samples, making them particularly useful for production quality control in manufacturing.

Factors Affecting Thermal Conductivity

The ability of a material to conduct heat is determined by various factors, making it essential to understand these influences. Thermal conductivity is not an intrinsic property that remains constant under all conditions; rather, it is affected by several variables that can significantly alter its value.

Temperature Effects

Temperature is a significant factor that affects thermal conductivity. As temperature increases, the thermal conductivity of materials can change due to alterations in their molecular structure. For instance, some materials may exhibit increased thermal conductivity at higher temperatures, while others may experience a decrease.

Material Composition and Structure

The composition and structure of a material play a crucial role in determining its thermal conductivity. Materials with a more ordered crystal structure tend to have higher thermal conductivity due to the efficient transfer of phonons. In contrast, materials with a disordered or amorphous structure typically exhibit lower thermal conductivity.

Phase and State of Matter

The phase and state of matter significantly influence thermal conductivity. For example, materials in a solid state generally have higher thermal conductivity than their liquid or gaseous counterparts. The change in state from solid to liquid or gas can lead to a substantial difference in thermal conductivity.

Environmental Conditions

Environmental conditions, including pressure, humidity, and exposure to chemicals or radiation, can also impact thermal conductivity. For instance, porous materials with trapped gases can see their thermal conductivity affected by changes in atmospheric pressure. Similarly, moisture can alter the thermal conductivity of materials, with wet materials often conducting heat differently than dry ones.

Understanding these factors is crucial for designing manufacturing processes and selecting materials for specific operating conditions. By accounting for environmental variables and material properties, manufacturers can ensure consistent thermal performance and optimize their processes.

High Thermal Conductivity Materials in Manufacturing

Materials with high thermal conductivity are essential for efficient heat management in manufacturing. As you explore the latest advancements in this field, you’ll discover a range of materials that are transforming the industry.Metals and Alloys

Metals and alloys have been the traditional choice for high thermal conductivity applications. Copper and aluminum are widely used due to their excellent thermal conductivity and relatively low cost. You can leverage these materials to enhance the efficiency of your manufacturing processes.

Diamond and Carbon-Based Materials

Diamond and carbon-based materials are emerging as superior alternatives for high thermal conductivity applications. Diamond, in particular, offers exceptional thermal conductivity, making it ideal for demanding applications. You can explore the use of diamond and carbon-based materials for advanced thermal management.

Emerging High-Conductivity Materials

The development of emerging high-conductivity materials is opening new avenues for manufacturing. Materials like graphene and carbon nanotubes are being researched for their potential to revolutionize thermal management. You can stay ahead of the curve by investigating these cutting-edge materials for your manufacturing needs.

Low Thermal Conductivity Materials in Manufacturing

Manufacturing processes often rely on materials with low thermal conductivity to achieve optimal thermal insulation and performance. You can benefit from understanding the properties and applications of these materials to enhance your manufacturing efficienc Polymers and Plastics

Polymers and plastics are widely used in manufacturing due to their low thermal conductivity, which makes them excellent insulators. These materials are lightweight, durable, and can be engineered to have specific thermal properties. For instance, certain polymers have thermal conductivity values as low as 0.1 W/m·K, making them suitable for applications requiring minimal heat transfer.

Ceramics and Glasses

Ceramics and glasses are another class of materials with low thermal conductivity, often used in high-temperature applications. Their thermal conductivity can be as low as 0.5 W/m·K, although this varies depending on their composition and structure. These materials are prized for their ability to maintain their properties under extreme conditions, making them ideal for use in manufacturing processes involving high temperatures.

Composite Insulating Materials

Composite insulating materials, such as aerogels and syntactic foams, represent the cutting edge of low thermal conductivity technology. Aerogels, for example, have the lowest known thermal conductivity of any solid material, with values as low as 0.023 W/m·K. These materials are engineered to have specific properties, combining low thermal conductivity with other necessary characteristics like strength and durability.

Thermal Conductivity in Injection Molding Processes

The thermal conductivity of materials used in injection molding significantly affects the heat transfer during the molding process, influencing both part quality and production speed. Thermal conductivity directly impacts both part quality and production efficiency in injection molding. Higher thermal conductivity in mold materials allows for faster heat removal from the polymer, potentially reducing cycle times.

Heat Transfer During Mold Filling

During the mold filling stage, heat transfer plays a critical role in determining the flow characteristics of the polymer melt. The rate of heat transfer affects the melt viscosity, influencing how easily the material fills the mold cavity. Efficient heat transfer during this stage is crucial for preventing defects and ensuring uniform part quality.

Cooling Phase Optimization

The cooling phase is where thermal conductivity has its most significant impact. Materials with high thermal conductivity can efficiently dissipate heat, reducing the cooling time and thereby decreasing the overall cycle time. Optimizing the cooling phase based on the thermal conductivity of the mold material can lead to significant productivity gains.

Impact on Part Quality and Cycle Time

Thermal conductivity affects not only the cycle time but also the quality of the molded parts. Proper thermal management ensures dimensional stability, reduces the risk of defects like sink marks and warpage, and minimizes internal stresses. By controlling the cooling rate through the selection of appropriate mold materials, manufacturers can achieve the desired balance between productivity and part quality.

Thermal Management in Electronic Manufacturing

Thermal management in electronic manufacturing is a critical aspect that affects the overall performance and lifespan of electronic devices. Effective thermal design requires a comprehensive understanding of heat generation, transfer paths, and dissipation methods.

Understanding the thermal conductivity of materials in the thermal path is essential for predicting and managing component temperatures. You can achieve effective thermal design by creating preferential heat conduction paths using high-conductivity materials while isolating sensitive components with low-conductivity barriers.

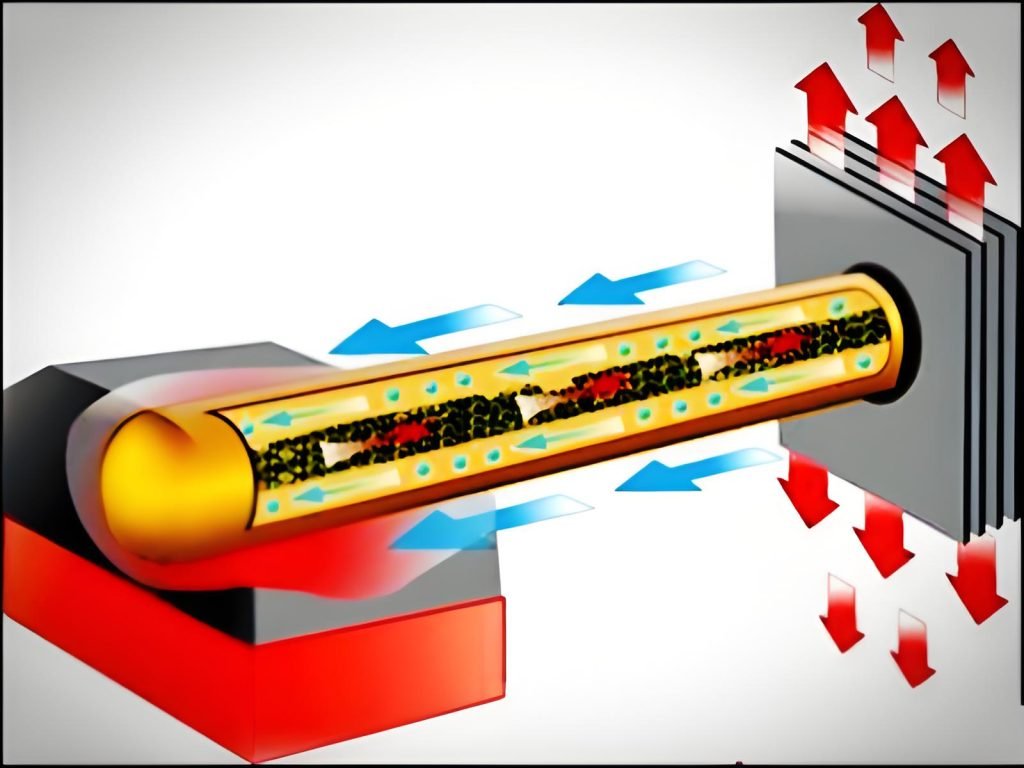

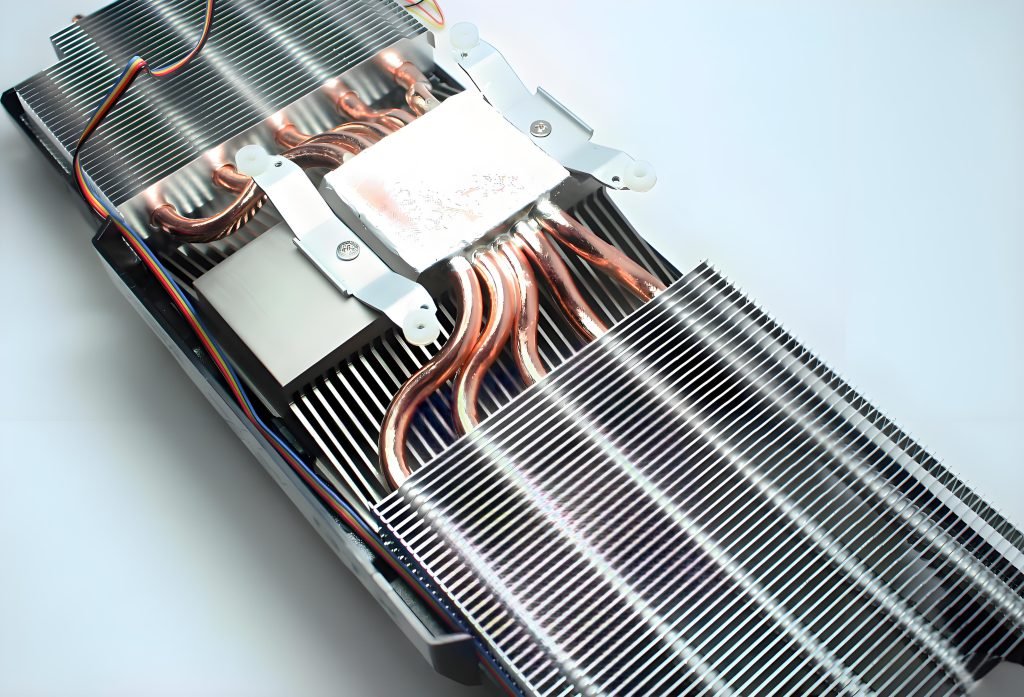

Heat Sinks and Thermal Interface Materials

Heat sinks and thermal interface materials play a crucial role in thermal management. Heat sinks are designed to dissipate heat away from critical components, while thermal interface materials enhance the thermal conductivity between the component and the heat sink.

Thermal Design Considerations

When designing electronic assemblies, you must consider thermal conductivity from the earliest concept stages through final production. This includes thermal modeling and simulation techniques that incorporate material thermal conductivity data to predict heat flow and temperature distributions.

Thermal conductivity influences PCB design decisions, including copper layer thickness, thermal vias placement, and component arrangement to optimize heat dissipation. Advanced thermal management strategies leverage thermal conductivity principles, such as heat pipes and liquid cooling systems.

Thermal Conductivity Testing in Quality Control

In the realm of manufacturing, thermal conductivity testing plays a vital role in quality assurance. Ensuring that materials meet specific thermal conductivity standards is crucial for the performance and reliability of the final product. This is particularly important in industries where heat management is critical, such as electronics and aerospace.

Testing Methods for Production Environments

When it comes to testing thermal conductivity in production environments, manufacturers have several methods at their disposal. The choice of method depends on the material type, the required accuracy, and the production speed. Common techniques include the guarded hot plate method and the laser flash method, each with its own advantages and limitations.

You should consider the specific requirements of your production line when selecting a testing method. For instance, some methods may be more suitable for high-volume production, while others may offer higher precision for critical applications.

Interpreting Thermal Conductivity Data

Interpreting thermal conductivity data requires a comprehensive understanding of the measurement method used, the temperature conditions during testing, and the material’s structure. For anisotropic materials, thermal conductivity can vary significantly with direction, making interpretation more complex.

When analyzing thermal conductivity data, you must consider how the values will translate to real-world performance in the specific application environment. This involves understanding the common sources of variation and error in thermal conductivity measurements and being able to distinguish between significant deviations and normal test variability.

Optimizing Manufacturing Processes Through Thermal Conductivity

Optimizing manufacturing processes through thermal conductivity is crucial for improving product quality and reducing energy consumption. By understanding how thermal conductivity affects various manufacturing processes, you can make informed decisions to enhance your operations.

Energy Efficiency Improvements

Improving energy efficiency is a significant benefit of optimizing thermal conductivity in manufacturing processes. By adjusting process parameters based on the thermal conductivity of materials, you can reduce energy waste and lower production costs. For instance, in injection molding, understanding the thermal conductivity of the polymer allows you to optimize melt temperature, injection speed, and cooling time, leading to more efficient energy use.

Process Parameter Adjustments

Adjusting process parameters based on thermal conductivity is essential for optimizing manufacturing processes. This involves examining how thermal conductivity affects optimal temperature settings, processing speeds, and cycle times. By making these adjustments, you can improve product quality, reduce cycle times, and enhance overall process efficiency. For example, in processes like heat treatment and annealing, understanding thermal conductivity helps in setting optimal temperature settings, ensuring consistent product quality.

Conclusion: The Future of Thermal Conductivity in Manufacturing

Advancements in thermal conductivity are revolutionizing manufacturing processes across industries. As you look to the future, it’s clear that this property will continue to play a crucial role in product quality, process efficiency, and energy consumption. Emerging trends in research and development, such as novel materials and advanced measurement techniques, will significantly impact manufacturing practices.

The increasing demand for energy efficiency and sustainability is driving innovation in materials and processes, with thermal conductivity optimization at the forefront. As electronics continue to miniaturize, new thermal conductivity challenges will arise, requiring creative solutions from manufacturers. Meanwhile, advances in additive manufacturing are opening up new possibilities for creating structures with precisely engineered thermal properties.

To stay ahead, manufacturers should prioritize investments in research and development, focus on skill development, and forge strategic partnerships. By leveraging knowledge of thermal conductivity, you can gain a competitive advantage in thermal-critical applications and position your company for success in a rapidly evolving manufacturing landscape.