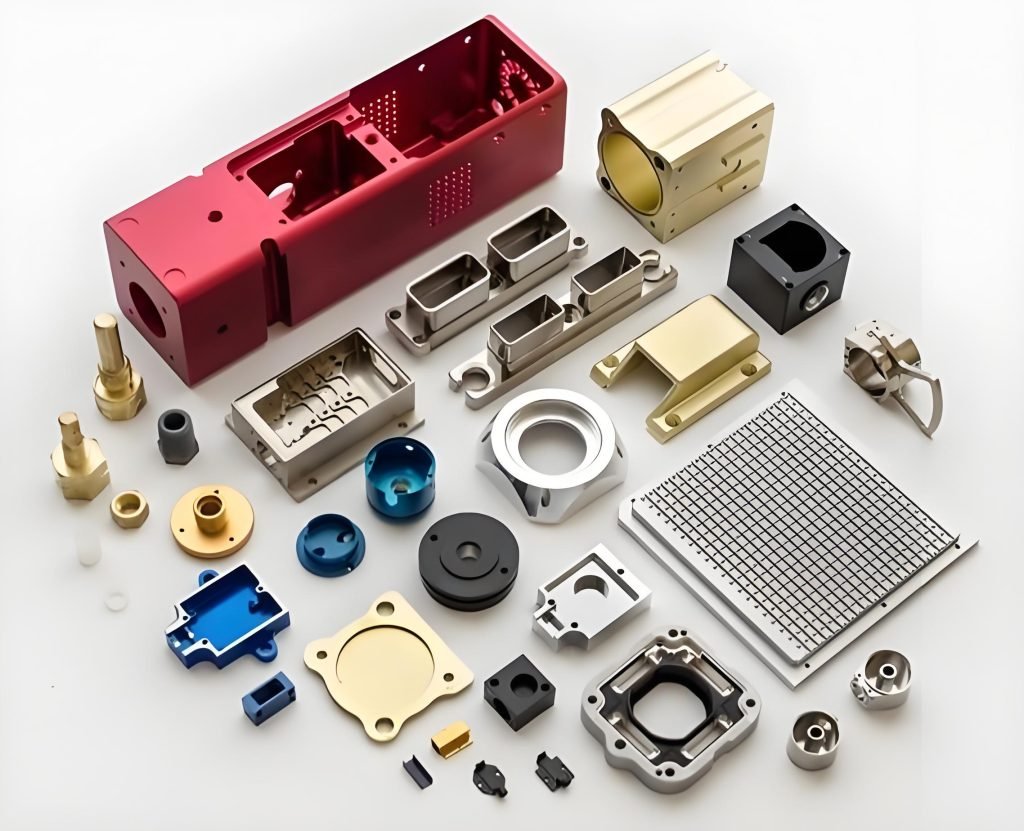

Welcome to the ultimate guide to surface finishing CNC machined parts! Whether you’re a seasoned engineer or a newcomer to engineering CNC machined parts, surface finishing is important when achieving perfect CNC machined parts. In this thorough and comprehensive guide, we will cover all the elements of surface finishing, including the basics, the types, and how to choose the surface finish. Let’s get started!

What is Surface Finish?

When referring to surface finish, we mean the surface characteristics of a machined part – the texture and smoothness of the exterior. This is a very critical aspect not only of how the part looks, but also of how it performs and its mechanical characteristics. Think of it like skin; a machined part cannot perform without an appropriate surface finish.

It should be noted that “surface finish” and “surface finishing” are different. The surface finish is the actual texture that a part has after machining. Surface finishing includes any processes or steps that will be taken to alter or improve those surface properties.

So, why is surface finish so important? There are a few primary reasons. First, it improves corrosion resistance, so your part will not rust or corrode as easily over time. Second, it significantly decreases friction, which is especially important functionally for moving parts. It also increases your part’s ability to seal, which ensures the part has a proper fit together with no leaks. Most importantly, it ensures you are meeting specifications for the intended purpose of your part, which makes sure it functions as it should.

Pre-Surface Finish Processes for CNC Machined Parts

Before your CNC machined parts receive their final surface finishes, they typically have gone through a few important precursory steps. This is done in order to prepare the surface for finishing in a clean and smooth state.

Degreasing

First up is degreasing. During the machining process, oils, coolants, and other lubricants are utilized to eliminate heat and friction. While they accomplish their goal for the machining process, they need to be completely removed before finishing can take place. There are different solvents or even ultrasound that can be used to degrease, depending on the material of your part and the level of finish required. The goal is to ensure that there are no contaminants waiting to affect your parts’ final finish.

Deburring

Next, we have deburring. Machining can leave tiny, sharp edges protruding on the workpiece called burrs, and deburring then removes them. This is vital not only for the part’s performance but for safety reasons – no one wants to handle a part with sharp edges!

Grinding

Grinding is another step in pre-finishing. Grinding uses an abrasive wheel to clean up the surface and take away any extra material. It improves the overall evenness of the surface, especially where machines generate a lot of accumulated contaminants on the surface. This step is much like giving the part a full scrub, wash, and polish.

Inspection

Lastly, there is a comprehensive inspection before any type of surface finishing is started. This is the final opportunity to inspect your part for any defects and to resolve any problems that might be present. It verifies that the part is completely ready for surface finishing and prevents any issues in the future.

Different Types of Surface Finishes for CNC Machining Projects

Now let’s review the different types of surface finish processes available for your CNC machined parts. Each has its own benefits and is suitable for particular applications.

Anodizing

Anodizing is one of the most common chemical processes used, especially for aluminum parts, as it creates a protective oxide layer on the surface that increases not only durability, but corrosion resistance and the visual aesthetics of the part. There are different types: Type II (thinner layer, lasts up to 25 microns) and Type III (thicker oxide layer, lasts from 25 to 150 microns), and lots of options, since anodizing can vary the thickness and properties of the oxide layer which allows the user the ability to choose the correct hardness and protection levels.

Alodine Coating

Alodine coating, or chromate conversion coating, applies a thin layer of chromate on aluminum substrates. The benefits of Alodine coating are mostly for corrosion resistance and providing optimal adhesion for paint or powder coatings that get applied afterwards. It does rely on environmentally hazardous chemicals and requires highly accurate application.

Black Oxide Coating

Black oxide coating on steel and iron parts is created by oxidation, in which a strong oxide layer is formed. This finish provides reasonable wear resistance and gives a distinctive, dark, and appealing machining surface finish. It looks good, but it’s not as durable or corrosion resistant as some of the other finishes, and can be easily worn from abrasion.

Electroplating

Electroplating is a process to deposit a thin layer of metal onto the workpiece. It is primarily used for the protection against corrosion and the cosmetic appearance of the part. It is a very flexible option and can be done on many conductive materials. The use of hazardous chemicals requires operators to have considerable know-how to do it correctly.

Passivation

Passivation is a post-processing application that is specifically for stainless steel. It removes surface contaminants and creates a natural oxide layer, which significantly enhances the stainless steel material’s resistance to corrosion and surface quality – ideal for applications where clean and rust-free is critical.

Bead Blasting

Bead blasting uses high-pressure air to blast small beads (glass or ceramic) onto the surface of your part. This process produces a uniform, textured surface that is often slightly rough. It is a great process to remove contaminants and prepare the surface for other secondary finishing processes. If bead blasting is not performed properly, the surface could become damaged.

Powder Coating

Powder coating is a dry finishing process in which a fine powder is electrostatically applied to the part, and after the curing process, it provides the part with a durable, long-lasting finish. Powder coatings provide an impact-resistant, solvent-chemicals resistant, and UV radiation resistant finish that can all make the coating extremely tough. Additionally, powder coating can be produced in extensive colors and finishes, giving many options for aesthetics.

Brushing

Brushing involves taking an abrasive pad or brush and applying a specific finish to a surface. It provides the best look for metal surfaces, especially when a brushed look is desired for stainless steel, and that allows you to create a linear or circular brushed pattern to greatly improve how a surface looks. Brushing is easy to accomplish, but if done poorly, the surface can be damaged.

Polishing

If you need an ultra-smooth, glossy look, polishing is your choice of finish for your part’s surface. A polishing operation will give you a high-shine finish by using abrasives or polishing chemicals. Polishing will enhance the visual properties of the part and perhaps reduce the chance of cracking or chipping by providing a very smooth surface. There are drawbacks; the time and costs of producing a polished finish can be excessive and challenging for complex geometry.

Painting

Painting is another surface treatment and provides corrosion protection as it applies a layer of paint to the part, covering all of the surface. Painting also provides an incredible range of colors and finishes that have a significant number of unique types. But it has environmental impact characteristics based on the type of paint, and the drying time can be extensive.

Summary of Surface Finishes

| Surface Finish | Best For | Pros | Cons |

| Anodizing | Aluminum parts | High corrosion resistance, durable, aesthetic | Limited to aluminum, higher cost for Type III |

| Alodine Coating | Aluminum (pre-paint prep) | Improves paint adhesion, thin layer | Uses hazardous chemicals, limited durability |

| Black Oxide | Steel/iron parts | Wear-resistant, sleek black finish | Low corrosion resistance, prone to abrasion |

| Electroplating | Conductive metals | Versatile (metals like nickel, chrome), shiny | Toxic chemicals, expertise required |

| Passivation | Stainless steel | Enhances rust resistance, clean surface | Only for stainless steel |

| Bead Blasting | All metals (pre-finish prep) | Uniform matte texture, removes contaminants | Risk of surface damage if overdone |

| Powder Coating | Metals (outdoor/color needs) | Extremely durable, UV/chemical resistant | Thick layer, not for fine details |

| Brushing | Stainless steel/aluminum | Decorative linear/circular patterns | Manual process, inconsistent if rushed |

| Polishing | High-gloss applications | Mirror-like finish, reduces micro-cracks | Time-consuming, expensive for complex shapes |

| Painting | Custom colors/branding | Wide color options, good protection | Long drying time, environmental concerns |

Factors to Consider When Choosing a CNC Machining Surface Finish

When it comes to choosing a machining surface finish, there is no standard finish for a CNC machined part. There are several principal factors to consider in order to obtain the best result for your project.

Functionality

The first thing you need to consider is functionality. What will the part be used for? Will the part see extreme wear and tear? Will it be in a corrosive atmosphere? Will it be functioning as a moving assembly with little tolerance for friction? The machining surface finish must meet the functional requirements in order for it to be successful. For example, if the part is going to constantly be with moisture, you’d better select a finish that is corrosion resistant.

Material

The material the part is made from is a major factor as well. Some surface finishes are only suited to certain materials. Anodizing is excellent for aluminum parts, while electroplating can be applied to various conductive metals. Likewise, you cannot anodize steel, and generally, you would not black oxide aluminum either. Beware, you must check the compatibility of the material and the finish.

Aesthetics

Surface aesthetics are also important, especially for visible parts. Do you want a high-gloss finish, or rather a matte textured finish? Different surface finishes produce different visual effects, so being clear on what you want is great to give you an idea of the aesthetics and how that aligns with your branding or product design.

Cost

Of course, cost matters. Some finishes can be many times more costly than other finishes depending on materials, process complexity, or time. It’s often about making a compromise between cost requirements and functional/aesthetic requirements of your part. You may also save costs in the long term by buying a slightly more expensive finish, which allows for a longer lifespan or better operation of the part.

Lead Time

Lead time relates to how long it takes to complete the finishing. Different processes have different time requirements. If your project is urgent, you will have to select finishing that can be applied with relatively faster methods. You will have to wrap finishing time into your full project timeline.

Environmental Impact

It is increasingly important to consider the environmental impact of the finishing process. Some processes involve hazardous chemicals or generate considerable waste. As much as possible, consider eco-friendly finish options or processes that create less of an impact. This is good for the environment and good for your company’s image.

Part Geometry

Lastly, part geometry may influence the choice of finish. Parts with very tight tolerances, detailed features, or complex internal passages may require a different finish than simpler parts with more generous designs. Some finishes may not be able to reach certain areas or may cause the process to distort or damage delicate features of your part. Always review your part geometry with your finishing provider.

Choose the Right Machining Surface Finish with Fecision

You’ve seen how crucial the right surface finish is for your CNC machined parts, affecting durability, looks, and performance. It’s not just an extra step; it’s vital for creating high-quality components. That’s where Fecision steps in. We understand that getting the perfect finish is just as important as the precise machining itself, especially for tough applications.

At Fecision, we’re experts in both CNC machining and a wide range of surface finishing services for precision parts. We offer robust options like anodizing for protection, various platings for enhanced conductivity or shine, and powder coating for durable color. We specialize in black oxide, passivation, brushing/polishing, painting, and more, upon inquiry for your project.

With our strict quality control practices, we ensure that every part has a consistent, high-quality finish. With fast turnaround times and competitive pricing, we deliver excellent value that you can trust with your precision CNC machined parts. From aerospace, automotive, medical, or industrial manufacturing, Fecision improves surface performance and increases product life with high-performance surface finishes.

Need the perfect finish for your CNC parts? Get a quote from Fecision today!