The injection molding cycle depends heavily on cooling time, which takes up 70-80% of the entire process. This makes the cooling system the most crucial and time-intensive phase of production. Heat dissipation happens mostly through conduction from melt to mold at 95%, and quick cooling affects both production speed and product quality directly.

Manufacturing outcomes rely heavily on how cooling systems are designed and built in injection molding. A well-laid-out cooling system cuts down cycle times and stops common problems like warping, sink marks, and blisters. Manufacturers now use groundbreaking methods like conformal cooling and thermal pins. These modern solutions improve heat transfer efficiency ten times more than traditional copper tubes.

This article covers everything in injection mold cooling systems. Readers will learn simple principles and advanced techniques to streamline their molding operations.

What is an Injection Mold Cooling System?

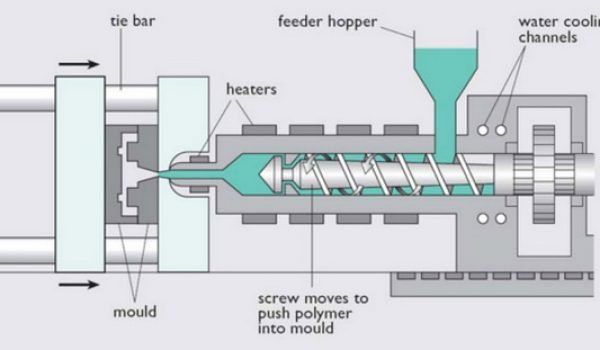

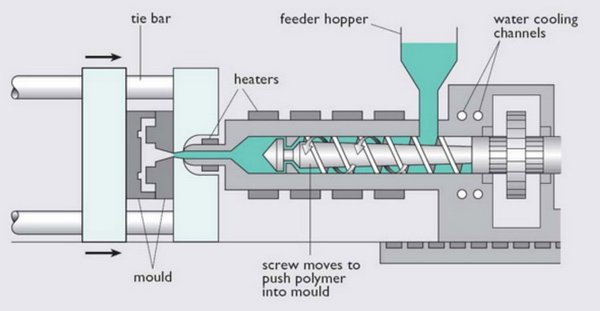

The injection mold cooling system works like an intricate network of channels and components. It pulls heat from molten plastic after injection and helps the material solidify into its final form. This system acts as the backbone of an efficient injection molding process and affects both production speed and product quality.

Definition and function

An injection mold cooling system features strategically placed cooling channels that connect to an external coolant source. These channels create one or more cooling circuits throughout the mold structure. The system’s core elements include cooling channels that guide the cooling medium, pumps that control pressure and flow rates, and heat exchangers that maintain consistent temperatures.

This system’s main goal is to pull excess heat from the mold cavity and injected material quickly. Water works best as the cooling medium because it conducts heat well. Companies also use air, oil, and cryogenic fluids based on specific needs.

The coolant flows through specially designed or drilled channels within the mold. They continuously draw heat away from the mold’s surfaces and the solidifying plastic inside. This heat transfer process turns molten material into solid, precisely shaped parts with minimal defects.

The role it plays in the overall injection molding cycle

The cooling phase takes up most time in injection molding – about 60-70% of the whole process. A well-designed cooling system makes production more economical. It cuts down cycle times and boosts output.

Even cooling prevents common defects. Plastic that cools unevenly develops internal stresses. These stresses can lead to warping, sink marks, and parts that don’t measure up correctly. So the cooling system’s performance determines both production speed and finished part quality.

The cooling channels’ position next to the mold cavity plays a huge role in cooling efficiency. Channel walls usually sit 12-15mm from cavity surfaces. Placing them closer risks uneven cavity surface temperatures, while greater distances make cooling less effective.

The cooling system determines cycle time, product quality, and how long the mold lasts. A well-designed system balances these factors through consistent temperature control during molding. It bridges the gap between raw material and finished product.

Why is the Cooling System So Important?

A manufacturer’s bottom line depends directly on how well they design and implement their injection mold cooling system. Cooling systems are vital to mold productivity. They shape both production economics and part quality.

The economic side of this is very important. Cooling can take up to 75% of the total cycle time, making it the longest step in the production process. Any improvements in cooling efficiency immediately boost production throughput. A good cooling system design cuts molding time significantly. It also helps increase productivity and lower running costs.

The quality of the product mostly depends on how well the cooling is done. Bad cooling almost always leads to defects. These parts need rework or complete rejection. Common defects include:

- Warpage and dimensional inaccuracies

- Sink marks from uneven solidification

- Thermal residual stress buildup

- Differential shrinkage across the part

Cooling and cycle time don’t follow a simple linear relationship – it’s geometric. To cite an instance, if you double a part’s wall thickness, the cycle time quadruples. This shows why optimizing your cooling system is your best chance to reduce cycle time.

Several interconnected factors determine cooling efficiency. Heat transfer rates change based on the plastic resin type, part geometry, mold material, and where you place cooling channels. A well-designed cooling channel system needs turbulent flow to maximize heat transfer efficiency.

Complex parts make uniform cooling harder to achieve. Standard straight-drilled channels might not work for complex geometries. These cases need different approaches like conformal cooling. Cores are especially tricky – they handle about 80% of the cooling load when parts shrink onto them during solidification.

Manufacturers who understand that mold cooling is the life-blood of injection molding stability can prioritize this vital element in their production. When you invest in cooling system optimization, you see improvements across your entire manufacturing operation.

Key Components of an Injection Mold Cooling System

Three primary components work together in an injection mold cooling system to achieve optimal temperature control and efficient heat transfer. Manufacturers can streamline processes and reduce cycle times by understanding these elements.

Cooling channels

Cooling channels act like a circulatory system in an injection mold and guide the cooling medium throughout the tool. These channels need strategic design and positioning to prevent product defects and reduce cycle time. The channel placement is a vital factor, and they should sit close to the mold’s thickest parts where heat builds up the most.

Good channel design follows key principles. Larger channels should maintain a consistent diameter throughout the mold. Multiple smaller channels work better than a single large one. The channels must create turbulent flow to maximize heat transfer efficiency by making sure all fluid touches the channel walls.

Baffles and bubblers

Baffles and bubblers are used to cool parts of a mold that are hard to reach. A baffle works by using a blade to divide the cooling flow, creating two semi-circular paths within a channel that is drilled perpendicular to the main cooling line. This design lets coolant reach more surface area and gives economical solutions for temperature control in tricky spots.

Bubblers work like baffles but use a small tube inside cooling channels. The coolant descends to the bottom of the tube, then shoots upward in a fountain-like motion at the top before flowing back into the main line. This bubbling creates turbulence in coolant flow and improves cooling in areas without direct channel access.

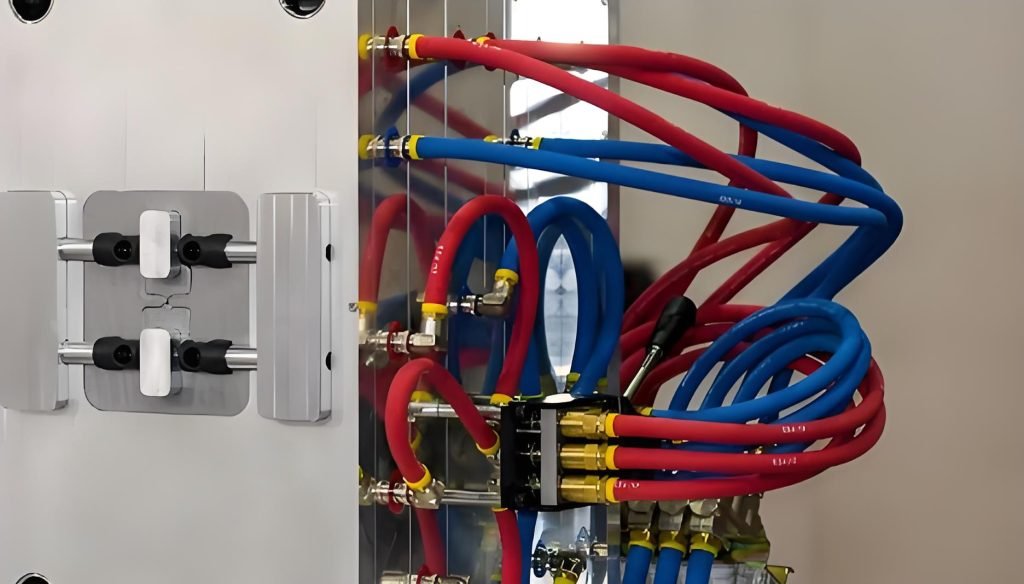

Temperature control units

Temperature control units (TCUs) regulate the heart of an injection mold cooling system. These compact units combine pumps, heaters, cooling systems, and electronic controls to keep precise mold temperatures. TCUs can heat with internal heaters and cool through direct water exchange or heat exchangers.

High-precision TCUs keep temperature points within strict limits and offer water or oil coolant options based on molding needs. They improve cycle times, boost product quality, reduce waste, and lower maintenance costs. The right TCU selection makes sure fluid moves through cooling channels fast enough to create the turbulent flow needed for the best heat transfer.

Cooling System Design Principles

The main goal of injection mold cooling system design is to achieve uniform cooling throughout plastic parts. Temperature control directly affects production costs and finished product quality.

Uniform cooling for balanced shrinkage

Parts cool unevenly when differential shrinkage occurs. This creates warping, sink marks, and dimensional problems. Carefully placed cooling channels help maintain even temperatures across the mold cavity. Materials like PE that shrink substantially need cooling channels aligned with the shrinkage direction to prevent deformation.

A cooling system that works must:

- Balance cooling between cavity and core

- Cool more intensely near gates where temperatures peak

- Keep cooling channels away from weld lines, which are naturally cooler

Channel placement and diameter considerations

The space between cooling channels and the cavity surface plays a big role in cooling efficiency. This distance should be more than 10mm, though 12-15mm works best. Parts with varying wall thickness need cooling channels closer to their thicker sections.

Channel size matters – more channels with larger diameters make cooling work better. Several narrow channels usually work better than one big channel. Cooling channels bigger than 10mm need consistent sizing throughout the mold.

Conformal cooling vs. traditional straight-drilled channels

Standard cooling uses straight-drilled channels to create cooling circuits around the mold. This works fine for simple shapes but falls short with complex geometries and creates hot spots.

Conformal cooling channels follow the mold cavity’s shape and provide better cooling. They can cut cycle times by up to 70% and make better parts. Though they cost more upfront, these channels are worth it for complex shapes.

Modern manufacturing methods like 3D printing (DMLS) let manufacturers place these complex channels exactly where needed. The choice between regular and conformal cooling comes down to part complexity, heat transfer needs, and production costs.

Types of Cooling Techniques

The injection molding industry uses several cooling methods, each serving unique purposes and offering distinct advantages. The right cooling technique can make a huge difference in how efficiently you produce parts and their final quality.

Direct water cooling

Water cooling stands out as the most popular method in injection mold cooling systems. This technique makes up about 60-70% of the total cooling cycle time. Cold water circulates through channels within the mold, absorbing heat via conduction. The water flow follows two main patterns:

- Laminar flow – water moves straight ahead while center water stays away from channel walls

- Turbulent flow – creates better cooling because more water touches the heated mold cavity

The cooling system doesn’t use pure water. The water contains additives like biocides that stop microbes from growing in cooling towers. Ethylene glycol helps protect cooling lines near the mold from rust. These systems need external cooling sources such as towers or evaporative condensers.

Oil-based systems

Oil cooling works great as an alternative for injection molding machines that use hydraulic systems. These specialized cooling systems maintain hydraulic or lubricating oil at optimal temperatures. Oil-based systems come with several benefits:

These systems were designed to maintain thermal stability and prevent overheating while keeping machine performance steady. They also help your critical components like pumps, valves, and seals last longer by reducing wear.

Oil-based systems cost more than water or air cooling but deliver the best cooling performance for specific applications. They prove especially valuable when you have hydraulic systems where temperature changes could throw off injection precision.

Advanced conformal cooling with 3D printing

Conformal cooling marks a major step forward from traditional cooling methods. Unlike regular straight-drilled channels, these cooling channels match your molded part’s exact contours.

Metal additive manufacturing, specifically Direct Metal Laser Sintering (DMLS), has changed how we design cooling systems. This technology lets us create complex cooling channels in the best possible positions. You can now make cooling channels that follow complex, curved shapes – something traditional manufacturing couldn’t achieve.

The results speak for themselves. Cycle times drop by up to 70%, parts warp less, quality improves, and production becomes more efficient. While conformal cooling channels cost more upfront, they quickly pay for themselves through better production rates.

Maintenance Tips for Cooling Systems

Regular upkeep of injection mold cooling systems affects production quality and speed. Systems that don’t get proper care often lead to expensive downtime, defects in production, and shorter equipment life.

Preventing scale buildup

Scale buildup acts as a hidden enemy of cooling performance in injection mold cooling systems. Calcium deposits inside cooling channels create an insulating barrier that slows down heat transfer by a lot. A thin 1/16-inch layer of scale can slow down machine cycles by about 15%.

Manufacturers should record baseline performance data for coolant flow and temperature change (ΔT) with clean molds. This helps them spot scaling issues before they cause major production problems.

You can prevent scale in several ways, including scheduled acid cleanings. Biodegradable descaling products made for injection mold metals can dissolve heat transfer scale. These products also protect equipment from corrosion. Clean passages restore proper heat transfer and reduce manufacturing defects.

Checking for leaks

Water leaks cause about 45% of all maintenance-related downtime in injection molding. About 80% of these failures happen because of missing or badly installed O-rings during bench work or mold setup.

Portable pressure testers are the quickest way to find water leaks in cooling circuits. These testers work with pressures from 0 to 870 psi without needing power. You can find leaks better by checking the mold’s history first. Then dry out the mold and test each circuit one by one.

Regular flushing and inspections

Simple maintenance steps help keep cooling working at its best. Here are the main tasks:

- Clean cooling channels often to clear debris and scale that block heat transfer

- Check cooling system parts like pumps, filters, and valves for rust or mechanical problems

- Flush systems with clean water or special cleaning solutions to remove contaminants

- Use filtration systems to stop blockages before they happen

Well-maintained cooling systems can boost flow rates by about 10% just through regular cleaning with good descaling solutions. This improved efficiency saves money and time while keeping the system from overheating.

Conclusion

Cooling systems are the life-blood of successful injection molding operations. Their design and maintenance directly impact production speed and part quality. These elements are vital to manufacturing success.

Manufacturers can achieve optimal cooling performance through advanced solutions like conformal cooling channels and proper maintenance protocols. These improvements result in shorter cycle times, fewer defects, and boosted overall productivity.

Companies that focus on their cooling system’s design and upkeep gain important advantages through faster cycle times and better part quality. The strategic placement of cooling channels, proper cooling method selection, and consistent maintenance are the foundations of efficient injection molding operations. A solid grasp of these fundamentals helps manufacturers improve their processes and stay competitive in today’s manufacturing landscape.