Swiss Machining: Precision Engineering for Complex Components

Swiss machining excels at producing intricate, high-tolerance components with exceptional surface finishes and dimensional accuracy, extending across medical, aerospace, automotive, and electronics sectors where precision is paramount.

Discover how Fecision’s Swiss machining services can transform your complex component challenges into manufacturing success.

----Who We Are

Your Trusted Partner for Tailored Swiss-Type Machining Parts

At Fecision, we’ve established ourselves as leaders in precision Swiss machining through our commitment to quality, innovation, and customer satisfaction. Our comprehensive capabilities ensure your complex components are manufactured to the highest standards.

Advanced Equipment

The latest multi-axis Swiss machines from industry-leading manufacturers are capable of producing complex geometries with exceptional precision.

Expert Team

With over 20 years of specialized experience in Swiss machining, our engineers and machinists bring unparalleled expertise to every project.

Quality Assurance

Our AS9100 and ISO 9001 certifications demonstrate our commitment to quality. Every part undergoes rigorous inspection to ensure accuracy.

Reliable Delivery

Our proven project management system ensures on-time delivery without compromising quality, giving you the confidence to plan project schedule with certainty.

Speciliazed CNC Machining

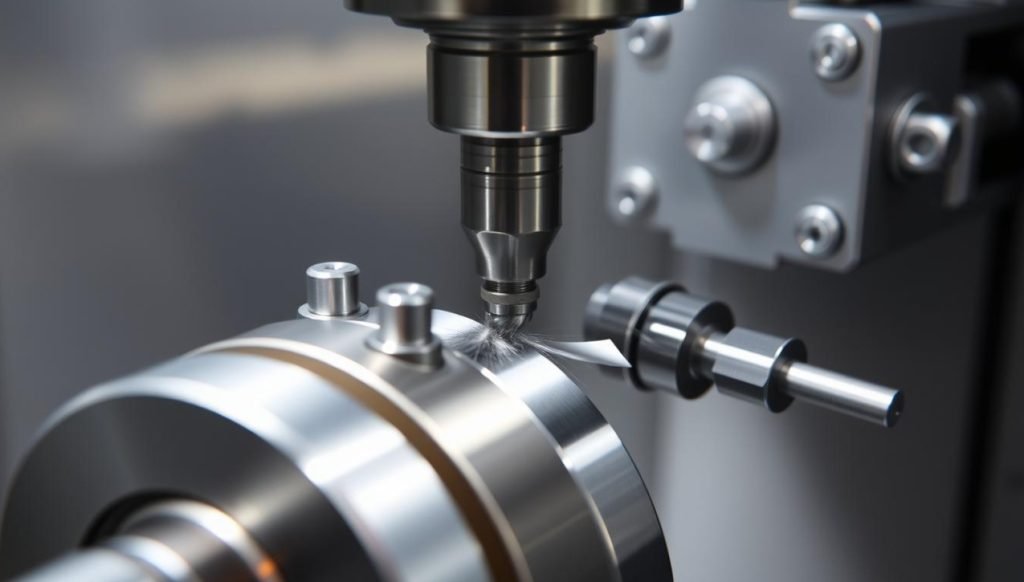

Precision Swiss Machining

Swiss machining is a specialized CNC turning process that uses a sliding headstock and guide bushing system to produce small, complex parts with exceptional precision. Unlike conventional turning where the workpiece is held stationary in a chuck, Swiss machining feeds the bar stock through a guide bushing that provides support extremely close to the cutting tool. This unique approach virtually eliminates deflection and vibration, allowing for tighter tolerances and superior surface finishes.

Swiss machining specializes in producing small, complex, long and slender parts with tight tolerances, typically ranging from 0.1 mm to 32 mm in diameter. The process is defined by its unique setup: A sliding headstock holds the workpiece and feeds it axially through a guide bushing. Cutting tools are stationary or move radially, while the workpiece rotates and advances, minimizing deflection—critical for machining slender part.

High Precision

Strict dimensional accuracy

Tolerances as tight as ±0.001 mm

Multitasking Capability

Integrates multiple processing methods in a single setup

High Production Rates

Designed for high-volume manufacturing with fast cycle times

Materials Used in Swiss Precision Machining

Swiss machining accommodates a wide range of materials, making it versatile for various applications.

The process excels with both common and exotic materials that require tight tolerances and superior surface finishes.

| Material Category | Common Examples | Typical Applications |

| Stainless Steel | 303, 304, 316L, 17-4 PH | Medical implants, surgical instruments, food processing components |

| Aluminum | 6061, 7075, 2024 | Aerospace fittings, electronic housings, lightweight components |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | Medical implants, aerospace fasteners, chemical processing parts |

| Brass & Copper | C360, C260, C110 | Electrical connectors, plumbing fittings, decorative components |

| Engineering Plastics | PEEK, Delrin, Nylon, PTFE | Medical devices, electrical insulators, bearing components |

| Exotic Alloys | Inconel, Hastelloy, Kovar | High-temperature applications, corrosive environments |

The material selection for Swiss machining typically requires high-quality bar stock with consistent diameter and straightness to ensure optimal performance through the guide bushing. At Fecision, we maintain an extensive inventory of certified materials to meet your specific application requirements.

How the Swiss Machining Process Works

The Swiss machining process differs fundamentally from conventional turning in how the workpiece is supported and manipulated.

Understanding this unique approach helps explain why Swiss machining excels at producing small, precise components.

Material Feeding

The process begins with high-quality bar stock loaded into the machine's feeder. The material advances through the collet and into the guide bushing, which provides rigid support just millimeters from where cutting occurs.

Simultaneous Machining

Multiple tools work on the workpiece simultaneously, with the sliding headstock advancing the material through the guide bushing. This synchronized movement maintains support extremely close to the cutting area.

Part Completion & Ejection

Once primary operations are complete, a sub-spindle can grab the part for back-working operations before the finished component is cut off and ejected, allowing continuous production.

Key Components of a Swiss-Type Machine

The true magic of Swiss machining lies in how the guide bushing supports the workpiece just millimeters from where cutting occurs. This minimizes deflection and vibration, allowing for deeper cuts, tighter tolerances, and superior surface finishes compared to conventional turning methods.

- Sliding Headstock: Advances the bar stock through the guide bushing along the Z-axis

- Guide Bushing: Provides rigid support extremely close to the cutting area

- Main Spindle: Rotates the bar stock at precise speeds

- Sub-Spindle: Allows back-working operations on the opposite end of the part

- Tool Stations: Multiple fixed and live tooling positions for turning, milling, drilling, and threading

- CNC Control: Coordinates all movements with extreme precision

Benefits of Swiss Machining Services

Swiss machining offers numerous advantages over conventional machining methods, particularly for small, complex parts with tight tolerances.

These benefits make it the preferred choice for industries where precision is non-negotiable.

Limitations of Swiss-Type Machining

While Swiss machining excels at producing small, precise components, it's important to understand its limitations to determine if it's the right process for your application.

Size Constraints

Swiss machines are typically limited to working with bar stock diameters between 2mm and 38mm. While some specialized machines can accommodate slightly larger diameters, Swiss machining is fundamentally designed for smaller components.

Economic Considerations

The rigid support and minimal vibration during machining result in superior surface finishes, often eliminating the need for secondary finishing operations. This saves time and reduces overall production costs.

Material Requirements

Swiss machining requires high-quality bar stock with consistent diameter and straightness to function properly through the guide bushing. Lower-quality materials may cause issues with the guide bushing fit, leading to reduced precision or machine stoppages.

Swiss CNC Machining vs Traditional CNC Machining

Understanding the differences between Swiss and traditional CNC machining helps in selecting the optimal process for your specific application requirements.

| Feature | Swiss CNC Machining | Traditional CNC Machining |

| Workpiece Support | Guide bushing supports material very close to cutting tool | Chuck or collet holds workpiece, often with significant overhang |

| Material Movement | Material moves through sliding headstock | Material remains fixed while tools move |

| Typical Tolerances | ±0.0001″ (2.5 microns) | ±0.001″ (25 microns) |

| Ideal Part Size | Small diameter (≤38mm) | Wide range, including large diameters |

| Length-to-Diameter Ratio | Excels at high ratios (up to 20:1) | Limited to lower ratios (typically ≤4:1) |

| Simultaneous Operations | Multiple tools can work simultaneously | Typically one tool active at a time |

| Setup Complexity | More complex initial setup | Generally simpler setup |

| Production Volume Sweet Spot | Medium to high volumes | Low to medium volumes |

★ While both processes have their place in modern manufacturing, Swiss machining offers distinct advantages for small, complex parts with tight tolerances and high length-to-diameter ratios. Traditional CNC machining remains more economical for larger parts, simpler geometries, or very low production volumes.

At Fecision, we offer both Swiss and traditional CNC machining capabilities, allowing us to recommend and implement the optimal process for your specific requirements. Learn more about our CNC milling services for complementary manufacturing solutions.

Swiss Machining Applications

Industries We Serve

Swiss machining's exceptional precision and ability to produce complex geometries make it ideal for numerous industries where quality and reliability are paramount.

Medical Devices

Surgical instruments

Dental components

Drug delivery devices

Diagnostic equipment parts

Automotive

Transmission parts

ABS system elements

Sensor housings

Precision valves

Electronics

Precision pins and sockets

Sensor components

Miniature housings

Test equipment parts

Aerospace

Hydraulic fittings

Fuel system components

Sensor housings

Control system elements

Customized Swiss Machining Parts

Your Strategic Partner for Tailored Swiss-Type Machining Parts

Why Choose Fecision?

At Fecision, we've established ourselves as leaders in precision Swiss machining through our commitment to quality, innovation, and customer satisfaction.

Our comprehensive capabilities ensure your complex components are manufactured to the highest standards.

Validated Performance, Guaranteed Quality

Commitment to Quality & Validation

We employ rigorous validation protocols, including in-process and final CMM inspection, steel certifications, heat treat certifications, and comprehensive mold trials (T1, T2...) to ensure your mold performs flawlessly and meets all specifications from the first shot. Trust our ISO-certified quality system.

Ready to Experience Superior Swiss Machining?

Request a Quote

From prototyping to production, our Swiss machining capabilities deliver the precision, quality, and reliability your project demands.